9

2.1- Safety adhesive labels

Read the instruction manual before

turning on the machine. Pay close

attention to all the operating and safety

recommendations, in order to avoid any

unexpected accidents that may occur

while operating the machine.

Turn off the tractor and remove the key

from the ignition before performing any

maintenance, adjustment, lubrication,

cleaning jobs etc., on the machine.

Thereby you will avoid any accidental

actuation and avoid dangerous

situations that may cause serious

accidents.

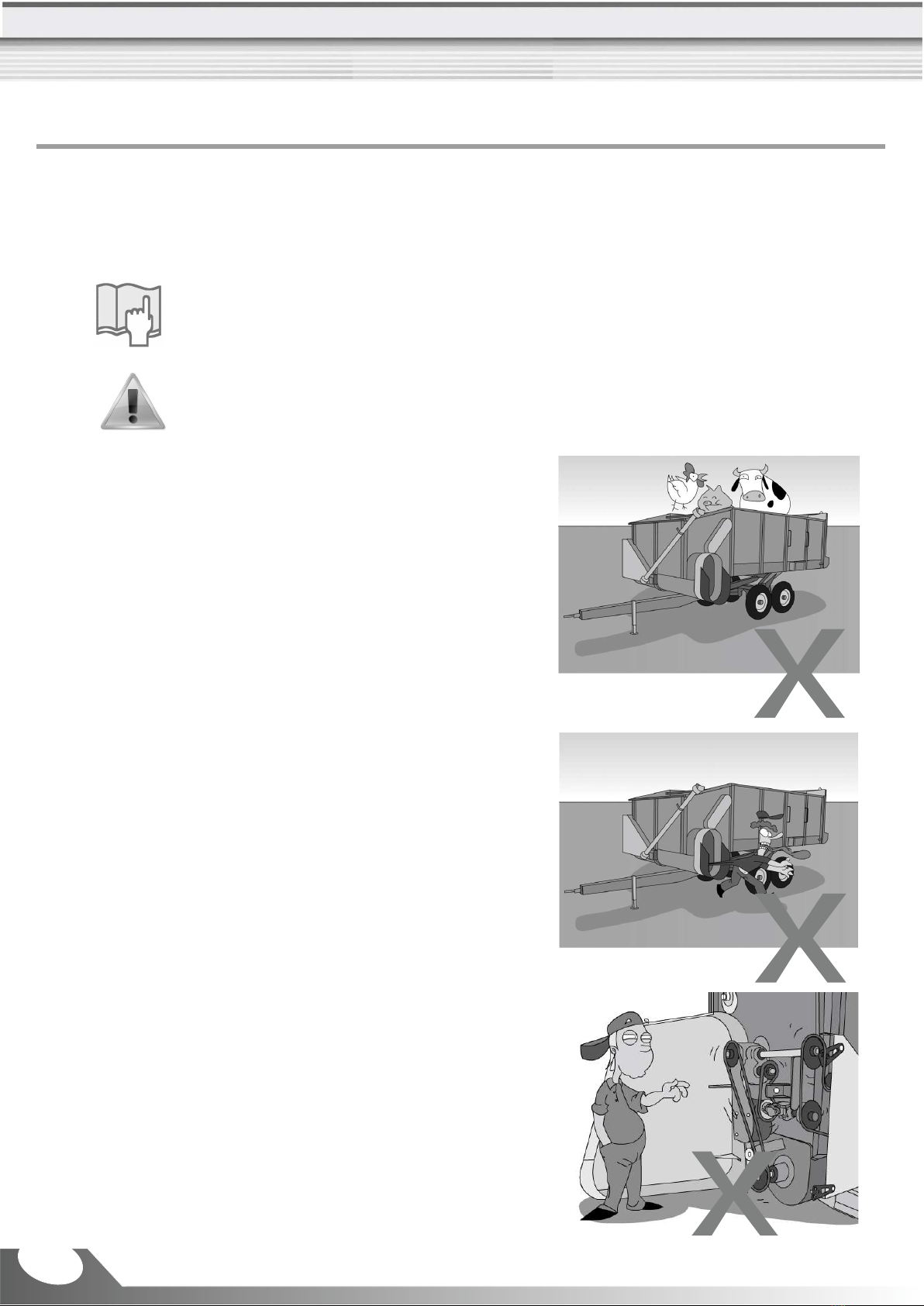

Do not stay on the machine while it is

operating or carrying loads. Sudden jolts,

starting, or stopping can cause falling,

causing an accident. Avoid all dangerous

situations.

Keep your distance and never place your

hands near the moving helix transporter,

as contact can cause a serious accident.

Do not get close to the machine until it is

completely motionless. Remember

rotating parts do not stop moving

immediately after turning the machine

off. Some parts continue moving also

unnoticeably, but you cannot see them.

Keep your hands away

from chains and other

moving parts, grabbing

t h e m a n d c a u s e

injuries.

Do not open or remove

covers or safety shields

from the machine when

it is operating.