Nohken VL13 CE Series User manual

TS02-100039

INSTRUCTION MANUAL

FOR

VIBRATING LEVEL SENSOR

MODEL: VL13□□-CE

VL23□□-CE

VL33F-CE

Issued 2019-11-28

- ADD 1 -

Read this manual carefully for safe usage.

・This manual applies to general purpose equipment. For equipment intended for

use in potentially explosive atmospheres, see applicable manuals.

・This manual contains important information on handling, inspection and

operation of the equipment indicated on the cover page. Before handling the

equipment, read this manual carefully.

・Instructions in documents submitted by Nohken or its representative have

higher priority than those in this manual.

・Keep this manual within easy access.

・Depending on environment, the equipment may not satisfy specifications

shown in this manual. Check the application conditions carefully beforehand.

・Please contact our sales office for any questions or comments about the

equipment or this manual. Sales offices are shown on the back of the manual.

Safety Symbols:

WARNING Means a potentially hazardous situation which,

if necessary precautions are not observed, can result

in death, serious injury and/or considerable material

damage.

CAUTION Means a hazardous situation which, if necessary

precautions are not observed, can result in minor or

moderate injury or damage to the device.

Means prohibited actions.

Means mandatory actions.

- ADD 2 -

WARNING

All work described in this manual must be carried out by qualified

personnel or those who have been trained and authorized for the

task.

This equipment is NOT intended for use in potentially hazardous

atmospheres. Never use it where flammable gas or vapor may be

present. Failure to observe this may result in ignition of flammable

gas or vapor, causing disaster.

Do not alter or disassemble the equipment, unless you have been

instructed to do so by Nohken or its representative.

Failure to observe this may result in:

- malfunction of or damage to the equipment or connected devices;

- ignition;

- electric shock or user injury.

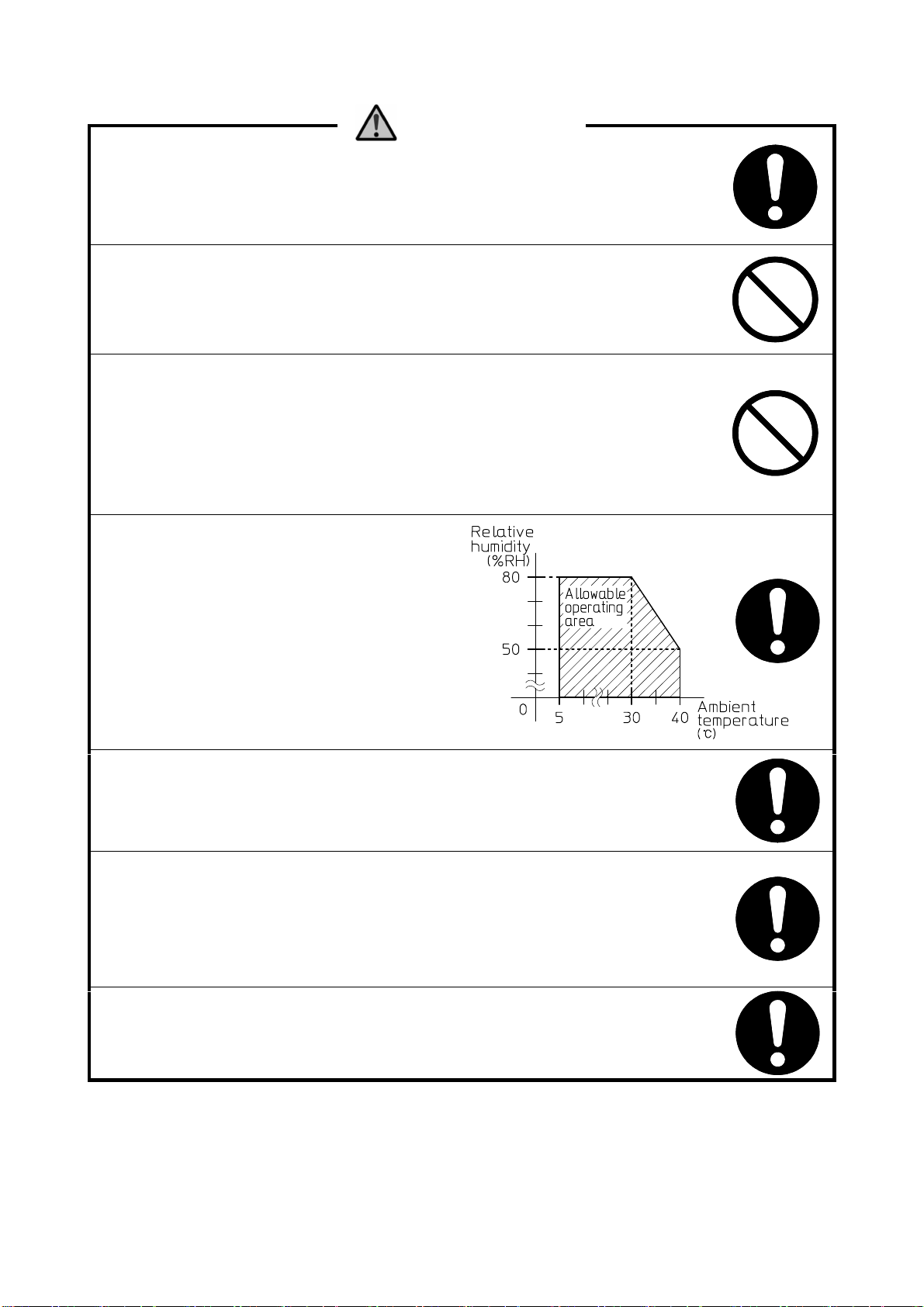

Mount, wire, adjust and service

the product under conditions shown in

the chart on the right.

Not observing this may result in product

damage.

Turn off the equipment before wiring or inspection. Otherwise

leakage or short circuit may cause ignition or electric shock.

After wiring is complete, always check for its correctness. Wrong

wiring may cause:

- damage to or malfunction of the equipment or connected devices;

- ignition;

- electric shock or user injury.

Turn off the equipment immediately in case smoke, unusual smells

or sounds are noticed. Do not supply power until problems are

solved.

- ADD 3 -

CAUTION

Handle the equipment with care. Do not drop, throw, or give

a strong shock to avoid damage.

Observe operation conditions specified in the manual. Use outside

the specified conditions may result in malfunction of or damage to

the equipment or connected devices, ignition, user injury, or

electric shock.

Perform operation tests before actual application to ensure

performance. Install back-up instruments based on different

technologies if failure of this equipment is expected to result in

a serious incident.

Check carefully for chemical compatibility of materials of

construction before installation.

Use the flange, thread or somewhere close to the process

connection to handle the equipment. Do not use the housing to

avoid dropping the equipment, and resultant damage to the

equipment or user injury.

Equipment 50cm or longer:

Lay the equipment when not in use. Otherwise it may fall and

damage itself or things around it, and cause user injury.

Always ground the equipment. (Grounding resistance: 100Ωmax.)

Without grounding, electric shock may occur in case excessive

voltage is applied to the housing.

When connecting to inductive or lamp loads:

Ensure the maximum voltage/current ratings will not be exceeded

to avoid damage to the relay contacts.

Use lightening arrestors or surge absorbers to prevent:

- malfunction, damage, or ignition of the equipment and connected

instruments;

- electric shock or injury.

- ADD 4 -

INTRODUCTION

A) This manual applies to standard models. Please note that information in

this manual may not be applied to customized versions.

B) We are willing to help customers select a suitable model or provide

information about chemical compatibility of materials used, but the

customer is responsible for the decisions made.

C) We always welcome suggestions and comments about this manual.

Please contact our sales office when you have questions or comments.

D) Component replacement:

The equipment design is regularly reviewed and improved. The same

components therefore may not be available when replacement is required.

In such cases, different components or products may be supplied. Please

contact our sales office for detail.

E) The contents of this manual are subject to change without prior notice as

a result of improvement of the equipment.

WARRANTY & DISCLAIMER

A) Nohken warrants the equipment against defect in design or material, and

workmanship for a period of one (1) year from the date of original

shipment from Nohken’s factory.

B) Nohken will not assume liability for loss nor damage resulting from the

use of the equipment.

C) Nohken will not assume liability for damage resulting from:

C-a) not observing instructions in this manual;

C-b) installation, wiring, operation, maintenance, inspection, or storing in

a manner not outlined in this manual;

C-c) unauthorized alterations and repairs;

C-d) the use of or replacement with components not provided by Nohken;

C-e) devices or instrument other than those manufactured by Nohken;

C-f) the use not described in Chapter 1 Purpose of Use of the manual;

C-g) force majeure including, but not limited to, fire, earthquake, tsunami,

lightning strike, riot, commotion, war, armed conflict or terrorist

attack, radioactive pollution, act of God, governmental decisions or

actions, and compliance with laws and regulations.

THE PROVISIONS OF THIS SECTION DO NO LIMIT YOUR LEGAL RIGHTS.

Table of Contents

1.PURPOSE OF USE

…………………………………………… 1

2.DESCRIPTION

…………………………………………… 1

2.1 Description …………………………………………… 1

2.2 Principle of Operation …………………………………………… 1

3.SPECIFICATIONS

…………………………………………… 1

3.1 Model Code …………………………………………… 1

3.2 Specifications …………………………………………… 2

3.3 Outline Drawing …………………………………………… 3

4.HANDLING NOTES

…………………………………………… 4

5.INSTALLATION

…………………………………………… 5

5.1 Unpacking …………………………………………… 5

5.2 Mounting …………………………………………… 6

6.WIRING

…………………………………………… 10

6.1 Before Wiring …………………………………………… 10

6.2 Wiring …………………………………………… 11

6.3 Cable Inlet …………………………………………… 12

6.4 Operation Check …………………………………………… 12

6.5 Placing the Cover …………………………………………… 12

7.PART NAME AND FUNCTION

…………………………………… 13

8.OPERATION

…………………………………………… 14

8.1 Tools Used for Sensitivity Adjustment/Check ………………………………… 14

8.2 Notes on Sensitivity Adjustment/Check ………………………………………… 14

8.3 Adjusting Sensitivity …………………………………………… 15

9.MAINTENANCE AND INSPECTION

……………………… 17

9.1 Removing from Process …………………………………………… 17

9.2 Maintenance …………………………………………… 18

9.3 Mounting …………………………………………… 18

9.4 Wiring …………………………………………… 18

9.5 Component Replacement …………………………………………… 18

9.6 When to Replace …………………………………………… 18

10.STORING

…………………………………………… 19

11.TROUBLESHOOTING

…………………………………………… 20

12.GLOSSARY

…………………………………………… 21

-1-

1. PURPOSE OF USE

This product is designed to detect fine powders, solids, granular materials, bulk solids or sludge

blanket at a desired level, and send signals. The signals are used to trigger alarms or control

electromagnetic switches. Do not use the product for any other purpose.

2. DESCRIPTION

2.1 Description

The product is mounted on a hopper using the threaded or flanged connection. When the material

reaches the detecting pipe*, the relay inside the housing makes or breaks contact.

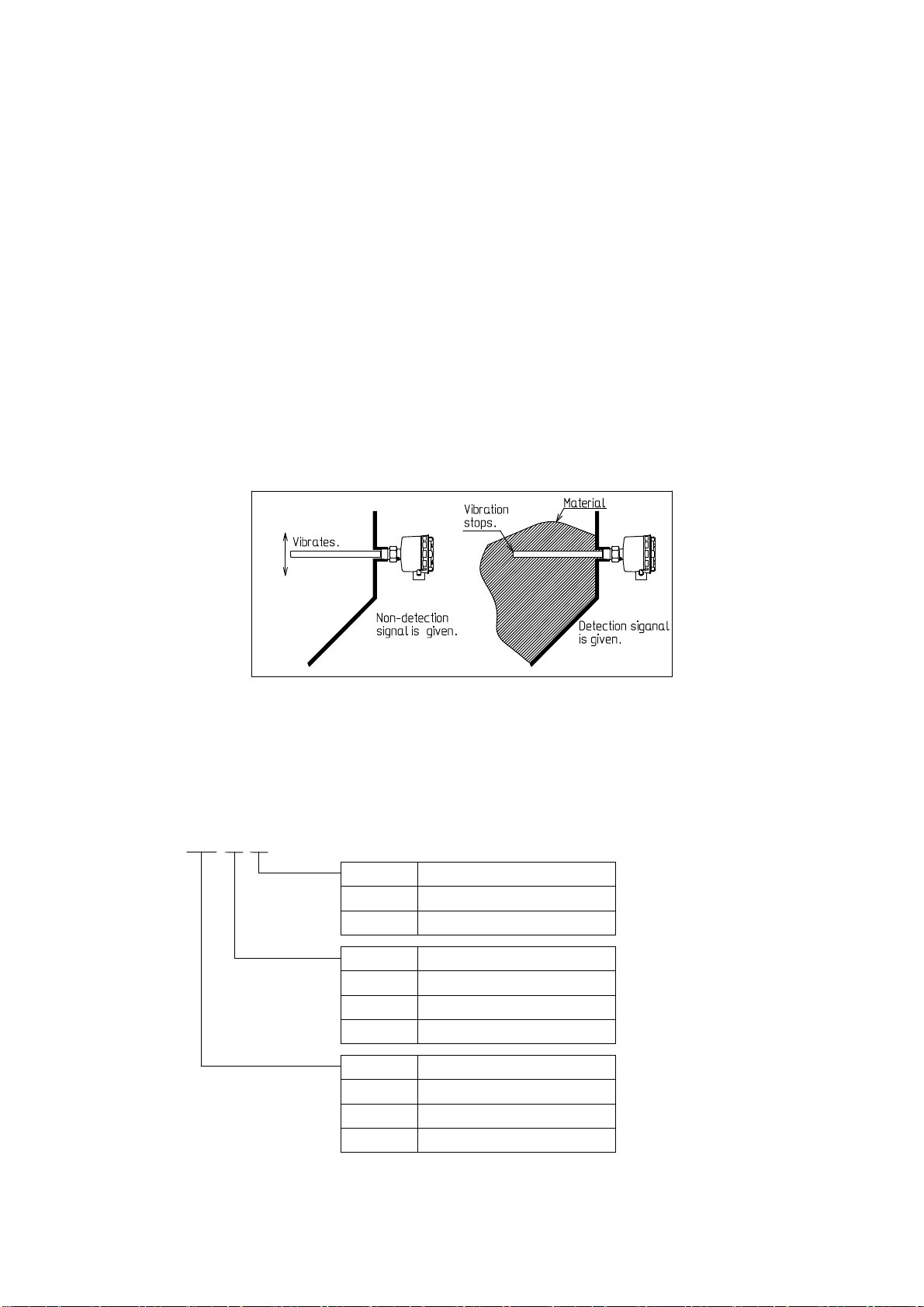

2.2 Principle of Operation

The product has a detecting pipe that incorporates a magnet and an electromagnet. The pipe

is vibrated by means of these magnets. Current that flows on the electromagnet decreases

when the pipe is covered by the material. The product detects this difference in current

value on the electromagnet, and sends electric signals.

Fig. 2-1

3. SPECIFICATIONS

3.1 Model Code

① ② ③

VL □□ □ □-CE

③ Temperature

(blank) standard

T high temperature

② Mounting

N threaded

F flanged

G guard flanged

① Detecting pipe

13 standard

23 long

33 flexible

* See chapter 12 GLOSSARY.

-2-

3.2 Specifications

Table 3-1

Product Vibrating Level Sensor

Model VL13N, F, G (T) VL23N, F, G (T) VL33F

Measured Material solids, granular materials, bulk solids,

sludge blanket (excluding VL33)

Operating Characteristics

Sensitivity Bulk density ≧ 0.2 (excluding sludge blanket applications)

Operation indicator Power: green LED, Energized relay: red LED

Startup behavior Relay de-energized for approx. 15 seconds after power-up

Vibration Approx. 300 to 500Hz

Electric Characteristics

Power supply 100 to 240V AC±10%, 50/60Hz

24V DC ±10%

Power consumption Approx. 2VA at 100V AC (excluding startup)

Approx. 5VA at 240V AC (excluding startup)

Approx. 1W at 24V DC

Relay output Dry contact (SPDT)

Relay energized/de-energized at detection (switchable)

Delay time: 3 to 5 seconds when set

3 to 5 seconds when reset

Contact ratings Maximum: 250V, 3A AC / 30V, 3A DC (resistive load)

Minimum: 5V, 10mA DC (resistive load)

Insulation resistance 100MΩ Min. at 500V DC, between each terminal and housing

(excluding protective earth)

Withstand voltage 2200V AC for 5 seconds, between each terminal and housing

(excluding protective earth)

Overvoltage protection Overvoltage category Ⅲ

Pollution degree 4

Mechanical Characteristics

Withstand pressure

(static) 2MPa Max. (excluding process connection) 1kPa Max. (excluding

process connection)

Lateral load 0.55kN Max.(static) -

Tensile strength -1kN Max.

(extension tube)

Environmental

Working temperature

Wetted parts -20 to +150℃ (standard)

-20 to +180℃ (high temperature) -20 to +70℃

Housing -20 to +60℃ (no dew condensation)

Humidity 95% RH Max.

Altitude 2000m Max.

Protection class

Wetted parts IP68 or equivalent IP65 or equivalent

Housing IP65 or equivalent

Material

Wetted parts

304 stainless steel 304 stainless

steel, silicone

304 stainless steel,

PVC(with steel core),

NBR, POM, silicone

Housing Aluminum die casting (acrylic coated)

Cable inlet G 3/4 or equivalent

-3-

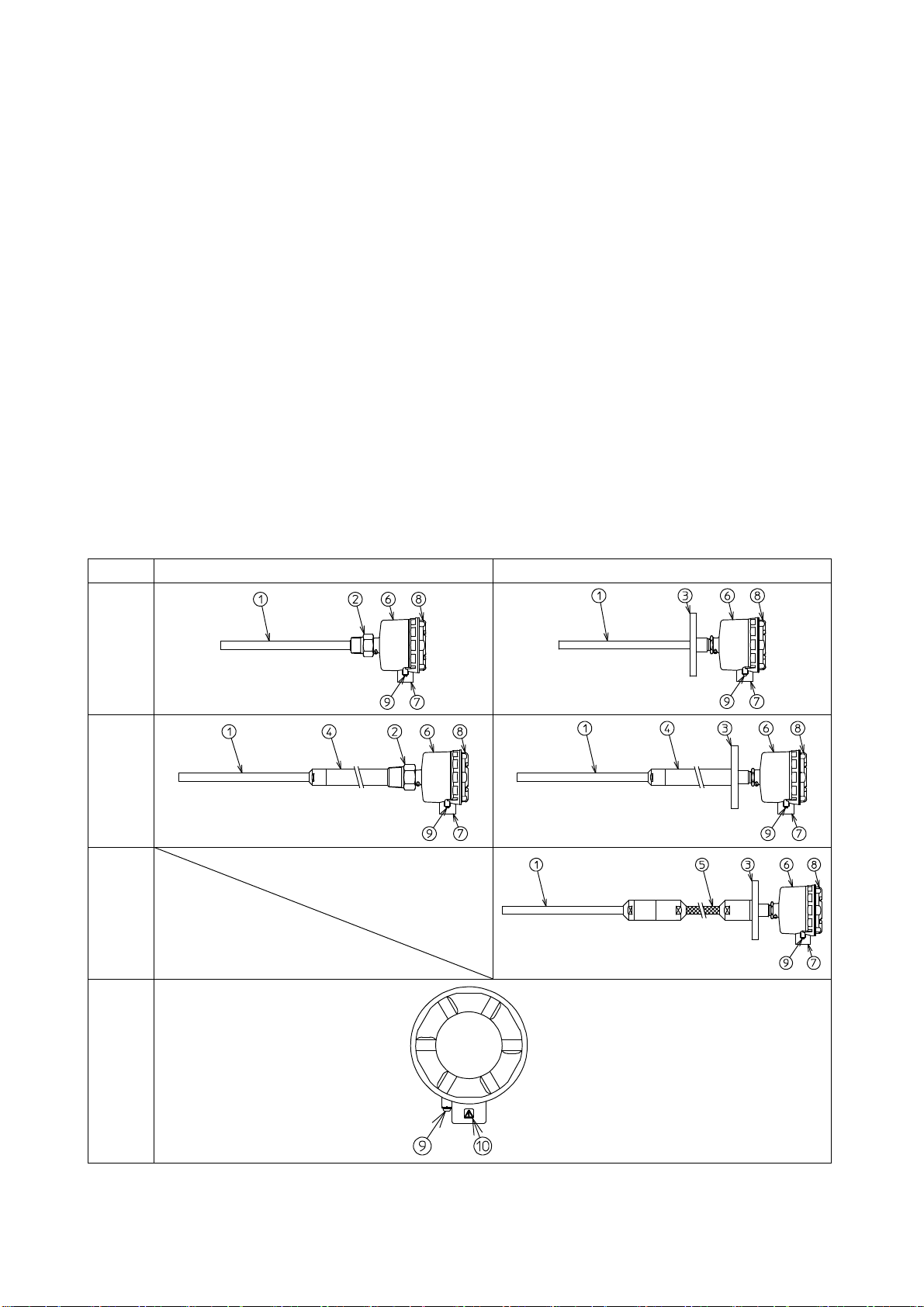

3.3 Outline Drawing

① Detecting pipe

Directly contacts material and detects it. Vibrates without contacting material.

Vibration decreases as material covers the pipe.

② Threaded connection (VL13N/T, VL23N/T)

Process connection to mount the sensor on a hopper.

③ Flange (VL13F/T, 23F/T, 33F)

Process connection to mount the sensor on a hopper.

④ Extension pipe (VL23N/T, VL23F/T)

Component to extend measurement range.

⑤ Extension tube (VL33F)

Component to extend measurement range.

⑥ Housing

Enclose electric circuit.

⑦ Cable inlet

Size: G3/4 or equivalent

⑧ Cover

Cover for the housing.

⑨ External earth terminal

Terminal to ground the product.

⑩ Warning sign

Indication to reference the first warning on page ADD 2 of this manual.

Model Threaded type Flanged type

VL13

VL23

VL33

Common Top view

Fig. 3-1

-4-

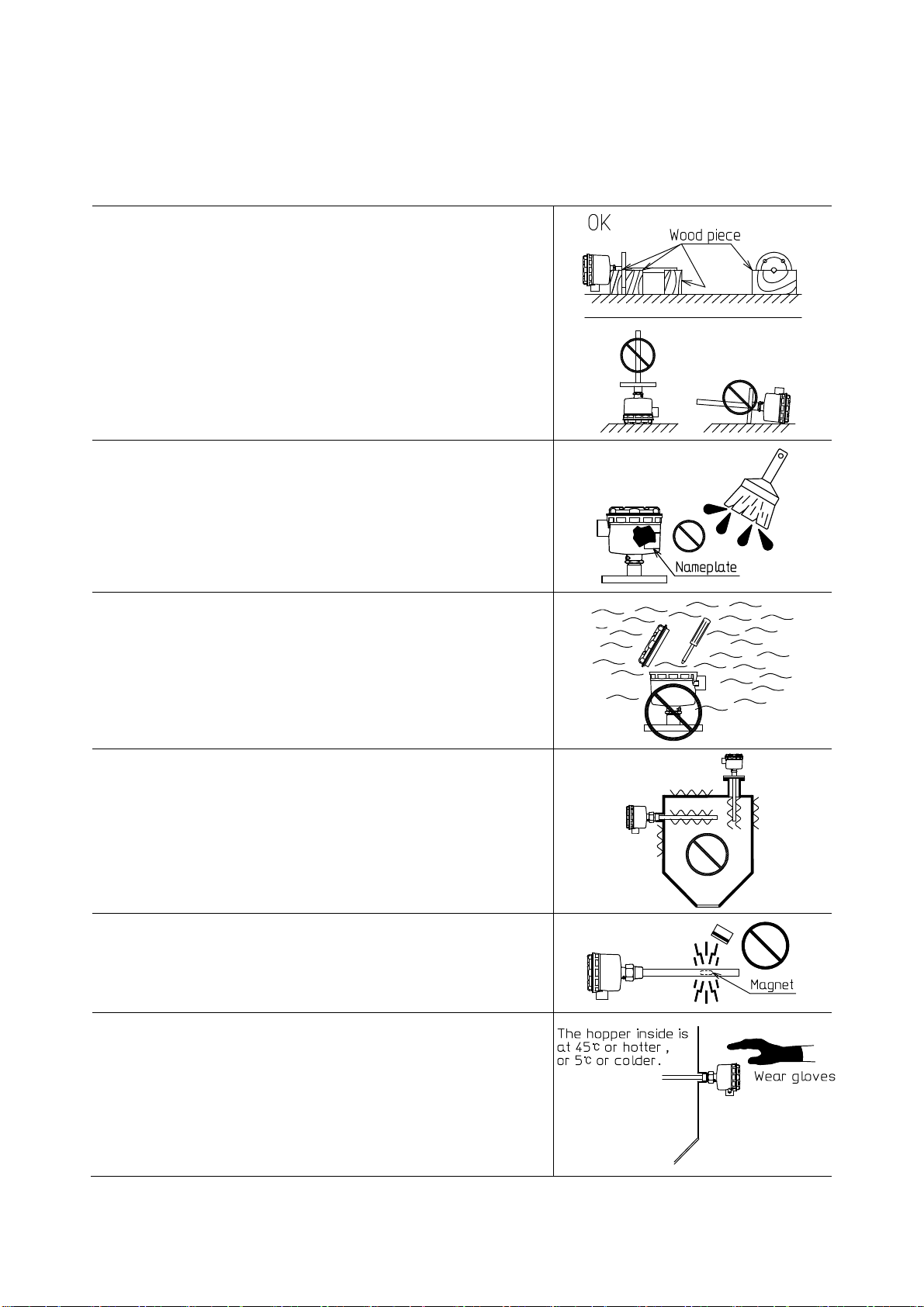

4. HANDLING NOTES

Observe instructions below when handling the product, or faulty operation or user injury may

result.

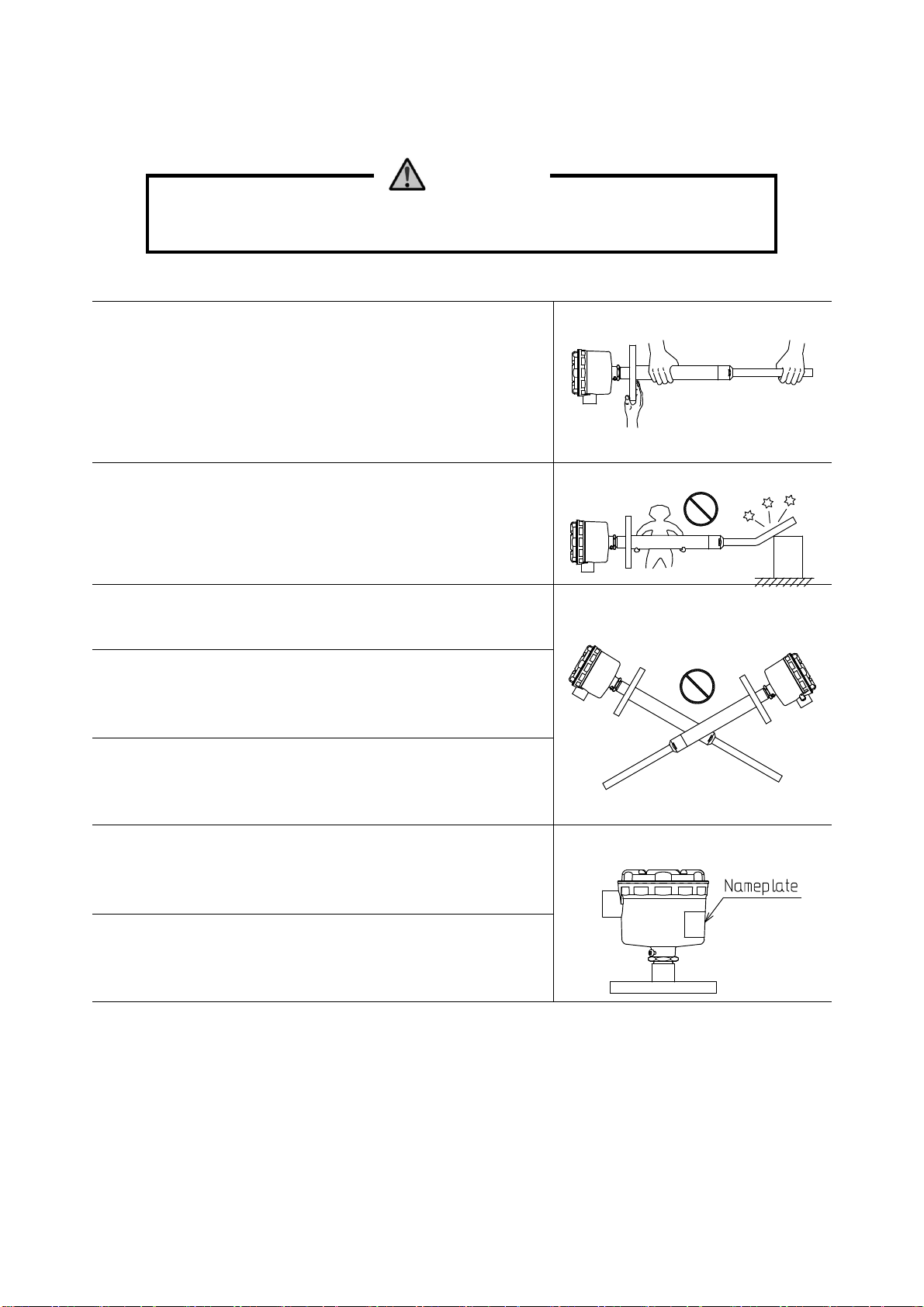

(1)

Lay the product on a flat surface to prevent it from

falling down. Provide support such as wo

od pieces

beneath the product to prevent it from rolling and

damaging the detecting pipe. Be extra-

careful not to

damage the pipe.

(2) Nameplate contains important information for

maintenance and other services. Ensure such

information is legible when painting the product.

(3) Avoid corrosive atmosphere (NH3, SO2, Cl2) for

installation, wiring, maintenance or adjustment.

Such atmosphere will enter inside when the cover is

opened and corrode internal components.

(4) Avoid places subjected to e

xcessive vibration. If such

location is inevitable, remove the source or isolate

the sensor from vibration.

(5) The detecting pipe incorporates a magnet.

Ensure magnetic media and other devices are not

adversely affected by the magnetic field.

(6) Wear gloves before touching the housing or process

connection if the hopper inside is at 45℃ or hotter,

or 5℃ or colder. These components become hot/cold

enough to cause a burn/frostbite.

-5-

5. INSTALLATION

WARNING

This product is not of the explosion proof model*. Never use it in areas

where flammable or explosive gases or vapors are expected to be generated.

5.1 Unpacking

(1) Open the packaging and take out the product.

When handling the product, always hold the process

connection (threaded or flanged) or the part of pipe

close to the process connection, and somewhere else.

Otherwise the detecting pipe may bend due to the

heavy process connection and cause vibration failure.

(2) Products longer than 1500mm require two people to

carry them.

Otherwise the detecting pipe or the incorporated

vibration plate may be damaged by mistake.

(3) Do not drop, throw, crush, drag or give a shock to

the product to avoid damage.

(4) Completely remove tape, vinyl, cupboard and other

packing material.

Otherwise they may cause faulty operation.

(5) Do not place anything on the product to avoid

applying undesirable force to or deforming the

product.

(6) Check against the nameplate if the product is as

you have ordered. If not, please contact our sales

office.

(7) Check the product for damage.

If any, it may have been caused during transport.

Please contact our sales office.

* See chapter 12 GLOSSARY.

-6-

5.2 Mounting

5.2.1 Mounting location

Ensure ample space above and around the mounting point

for easy handling and maintenance. Note that the space

between ceiling/wall and the hopper must be large

enough to accommodate overall length of the product.

This must be ensured after the product is mounted for

future maintenance. (Fig. 5-1)

Also observe the following instructions, otherwise

faulty operation may result.

Fig. 5-1

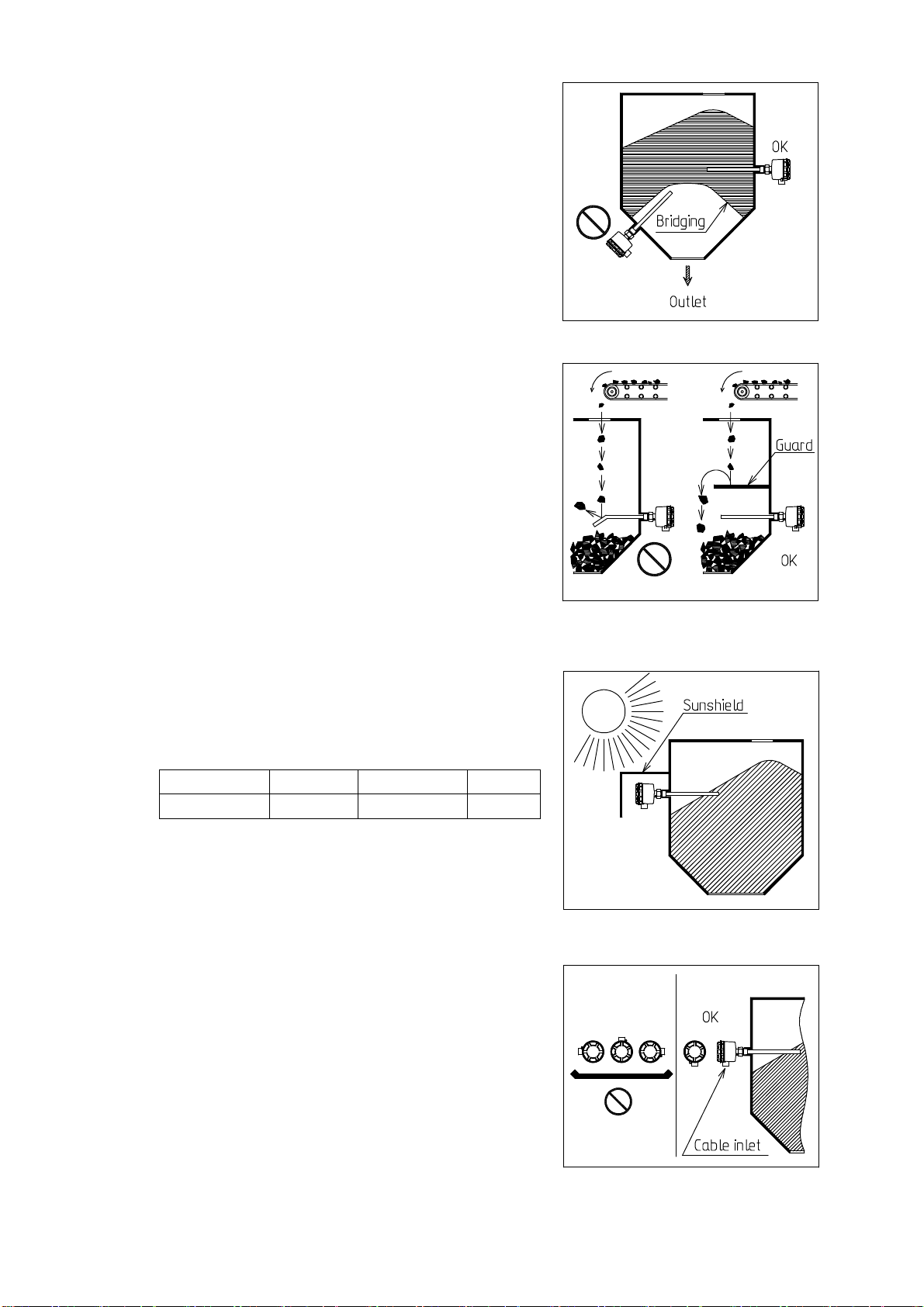

(1) Beware of the angle of repose*.

Avoid locations where the material does not reach

the detecting pipe. (Fig. 5-2)

Fig. 5-2

(2) Avoid locations where vibration occurs.

Mounting close to a vibrator*or a knocker*may

cause malfunction or damage the product.

(Fig. 5-3)

Fig. 5-3

(3) Avoid areas susceptible to deposit*to prevent

faulty operation. (Fig. 5-4)

Fig. 5-4

* See chapter 12 GLOSSARY.

-7-

(4) Beware of bridge formation*.

Avoid locations adversely affected by bridging.

Ensure the product will not be damaged when the

bridge falls. (Fig. 5-5)

Fig. 5-5

(5) Avoid fill path to prevent faulty operation and

product damage.

Provide a guard*above the product, if necessary.

(Fig. 5-6)

Fig. 5-6

(6) Avoid locations where temperature becomes high.

High temperatures may cause faulty operation.

The chart below shows maximum temperatures for

wetted parts and the housing.

Wetted parts

Model VL13, 23 VL13T, 23T VL33

Temperature +150℃ +180℃ +70℃

Housing: +60℃

(7) Avoid exposure to direct sunlight. In summer

especially, direct sunlight causes internal Fig. 5-7

temperature to exceed the ratings. Provide a

sunshield*if necessary. (Fig. 5-7)

(8) Properly tighten the cover and treat the cable

gland. Water entering inside may cause faulty

operation. The IP rating (IP65 or equivalent) is

achieved only when the cover is properly tightened

and the cable inlet properly treated.

If the product is mounted horizontally, ensure the

cable inlet points downwards. (Fig. 5-8)

Fig. 5-8

* See chapter 12 GLOSSARY.

-8-

(9) Ensure lateral load applied to the detecting pipe

will not exceed the rating. Maximum load at the

end of the pipe (φ17.3mm, 270mm long) is 0.55kN

(static load). Load greater than this may cause

faulty operation or product damage. (Fig. 5-9)

In applications where material rapidly moves or

excessive load is expected, provide a guard*

(Fig. 5-6), or mount the product at an angle to

avoid load.

Fig. 5-9

(10) Do not mount VL33 (flexible type) horizontally, or

faulty operation may result.

(11) Ensure the detecting pipe (φ17.3mm, 270mm long)

will not contact standpipe wall, hopper bottom or

walls to avoid faulty operation.

(12) Do not mount VL23 (long type) longer than 1m

horizontally. Otherwise the extension pipe may be

bent or come off due to material load. (Fig. 5-10)

Fig. 5-10

(13) Use a standpipe as short as possible and ensure

material will not remain inside. Ensure the

detecting pipe projects into the hopper for at

least 200 mm. For a standpipe of size 50A and sch20,

the maximum length is 70mm. Note that the maximum

length depends on material properties and

standpipe size. (Fig. 5-11)

Fig. 5-11

(14) Avoid corrosive atmosphere. Detecting pipe is in stainless steel (304 stainless steel

as standard), but most of the electronic components inside the housing uses cupper lead

wire. Corrosive atmosphere may attack lead wire and break it, resulting in faulty

operation.

(15) If the extension pipe of VL23 (long type) needs to be secured, please contact our sales

office.

* See chapter 12 GLOSSARY.

-9-

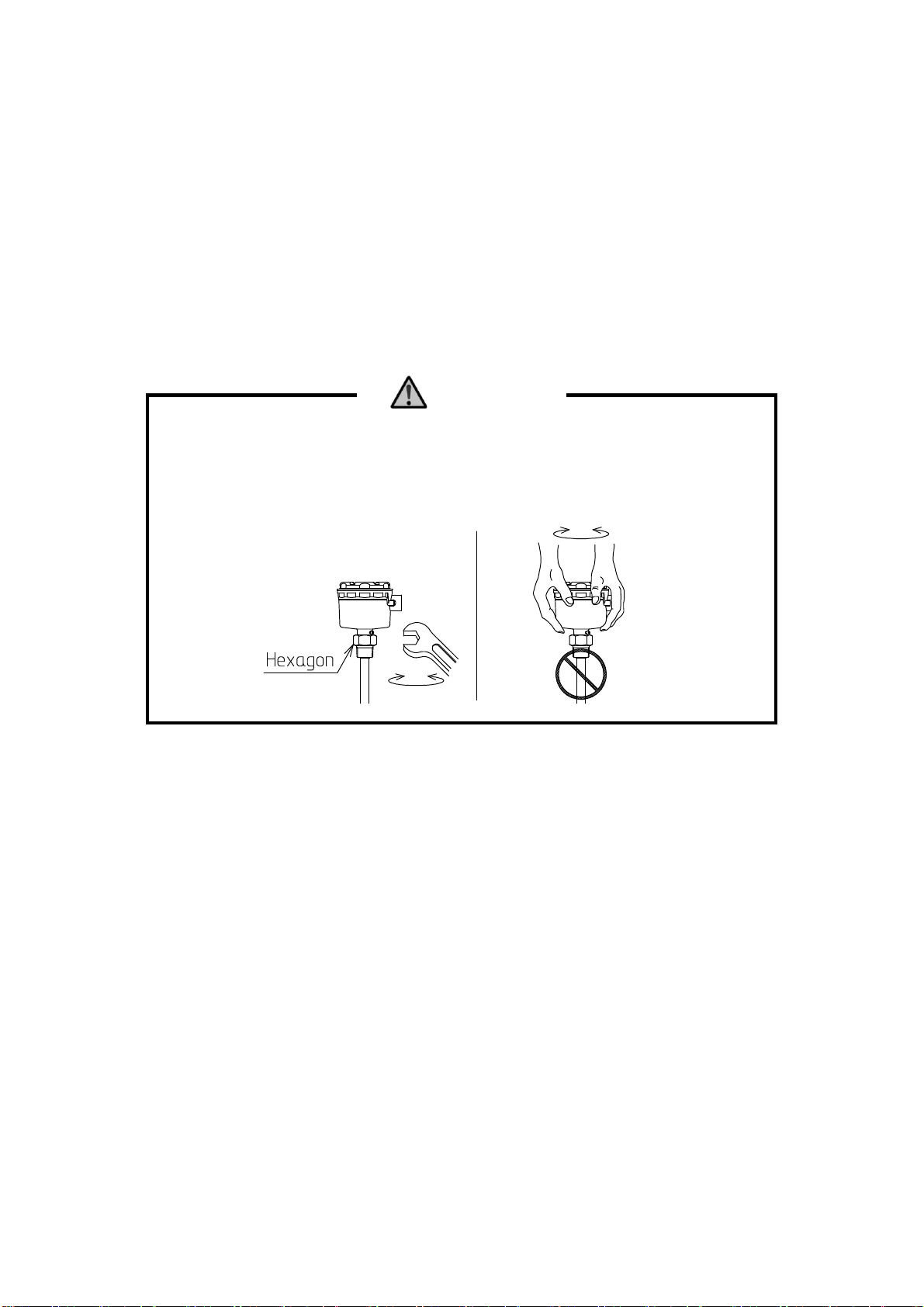

5.2.2 Mounting the Products

(1) Flanged units

Fit the hopper flange and the product flange, and secure them using bolts according to

standards and a suitable tool. Use a gasket in pressure applications to prevent leak.

Note that bolts and gaskets are optional parts.

(2) Threaded units

Secure the product using a suitable tool. Always rotate the hexagon above the threaded

connection and never the housing. Using the housing may apply excessive force and break

wiring inside the housing. For pressure applications, use sealing material on the thread

to prevent leak.

CAUTION

When removing the threaded unit from the hopper, rotate the hexagon above

the

threaded connection with a suitable tool. Never rotate the housing, otherwise

connection between the housing and the threaded connection will be

loosened,

breaking internal wiring or sealing.

- 10 -

6. WIRING

6.1 Before Wiring

(1) Disconnect power to cabling.

WARNING

Disconnect power before wiring. Otherwise electric shock, or ignition or human injury

due to leakage or short circuit of energized parts may result.

(2) Use cable rated for 35℃ higher than the rated temperatures for the housing.

The cable inlet accommodates cables of 10 to 18mm in diameter.

Suitable conductor sizes are:

0.75 to 2mm2for terminal block

2 to 3.5mm2for protective earth and external earth terminal on the housing

(3) Always provide a power switch and a fuse close to the product. Connect the fuse to

L1+ (Live) line (Fig.6-3). Indicate these components are used for the product.

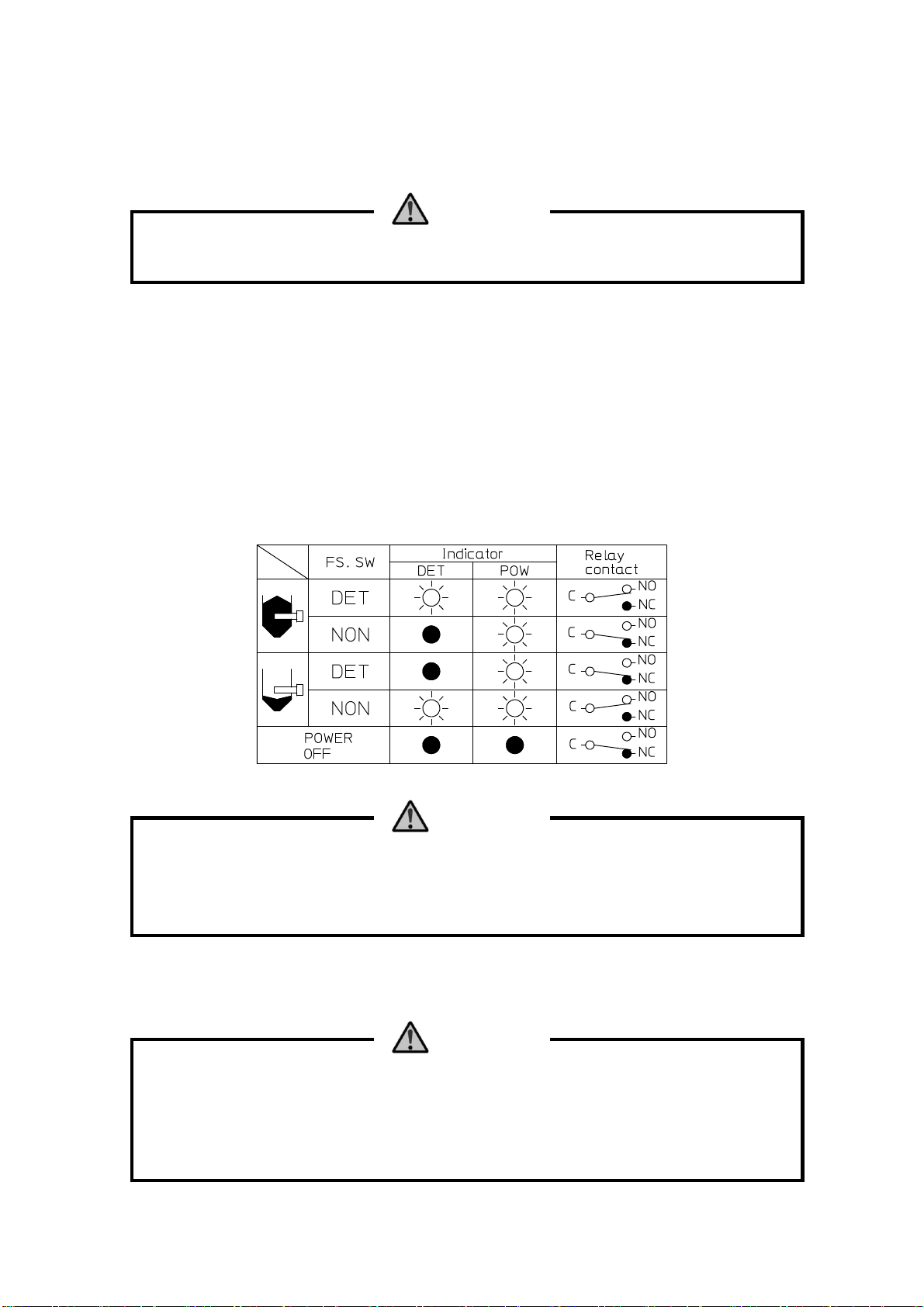

(4) Relay wiring

Fail-safe setting determines relay operation. See Fig. 6-1.

Fig. 6-1

CAUTION

Relay ratings are 250V, 3A AC (resistive) or 30V, 3A AC (resistive)

. Do not exceed

these ratings, or relay contacts may be damaged. Provide a suitable relay between

the load and the output terminals of the product when switching loads that

exceed

the product ratings.

(5) Grounding

Always ground the protective earth (PE) inside the housing.

(grounding resistance: 100Ω Max.)

CAUTION

Always ground the protective earth (PE)

inside the housing (grounding resistance:

100Ω Max.). Without grounding, electric shock or injury may result due to high

voltages on the housing in case of the power line contacting the housing.

Ground the external earth terminal on the housing when necessary (grounding

resistance: 100Ω Max.).

(6) Remove the cover of the sensor housing.

- 11 -

6.2 Wiring

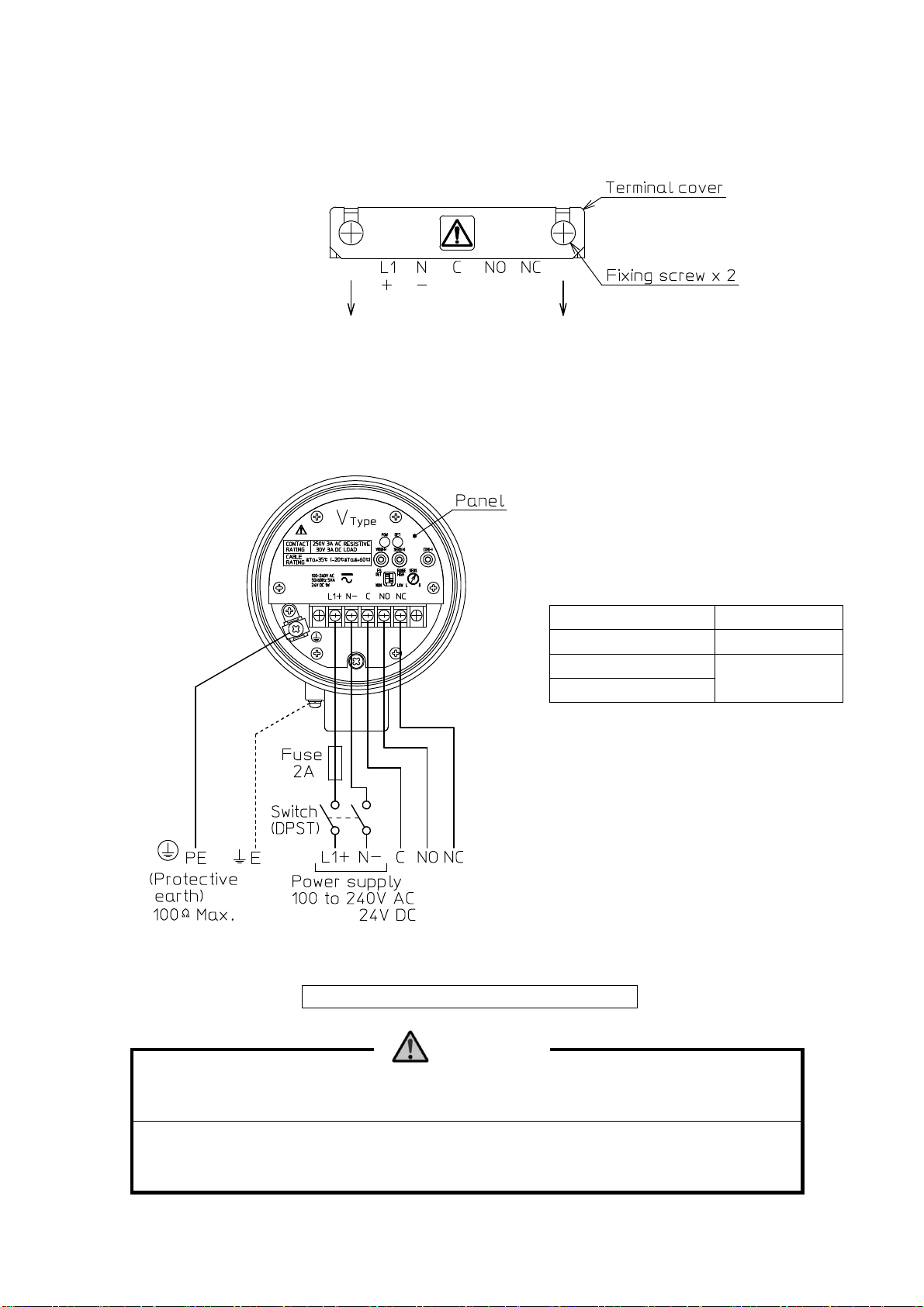

(1) Loosen the two fixing screws on the terminal cover, and remove the cover.

Do not lose the cover as it is used after wiring is complete.

Fig. 6-2

(2) Figure 6-3 shows wiring diagrams. Use a suitable tool when wiring.

Terminal screws are of M3.5. Use cable lug of R1.25-3.5 or equivalent size.

The screws of protective earth (PE) and the external earth terminal on the housing are

of M4. Use cable lugs of R1.25-4 or equivalent size.

Terminal Torque

Terminal block 1.0 N・m Max.

Protective earth 1.2 N・m Max.

External earth

Fig. 6-3

This product is polarity insensitive.

WARNING

The panel prevents contact with the internal circuit. Never remove it.

Voltages exceeding the rating may result in product damage or injury due to

overvoltage on the product.

- 12 -

(3) Place the terminal cover, and secure it with the two fixing screws.

Fig. 6-4

6.3 Cable Inlet

Cable inlet is of G 3/4 or equivalent size.

Use a cable gland or a conduit to secure the cable. In either case, lead the cable downward

in front of the cable inlet to prevent water entry.

Secure the cable using a sealing compound when a conduit is used, and by tightening the gland

with a suitable tool when a cable gland is used, to prevent entry of dust, debris or rain

into the housing. If water or moisture can enter from inside the conduit, putty the inside.

(Fig. 6-5)

Fig. 6-5

6.4 Operation Check

(1) Remove dust and debris from the housing. Ensure metal debris is not left since it may

cause shortcircuit.

(2) Before actual operation, fill the hopper with the material and check product performance.

If the product does not operate as it should, check for incorrect wiring, and read this

instruction manual once again. Please contact our sales office for any questions.

6.5 Placing the Cover

Properly tighten the cover on the housing. If loose, rain or dust may enter and corrode

inside components, causing short circuit or faulty operation.

OK OK

- 13 -

7. PART NAME AND FUNCTION

Fig. 7-1

① Terminal block

For power and relay output connection.

② Power lamp [POW]

Lights when powered. (green LED)

③ Alarm lamp [DET]

Lights when relay is energized. (red LED)

④ Vibration check terminal [VIBR(+)]

Gives output of 0 to 5V DC that represents sensor vibration level.

⑤ Sensitivity check terminal [SENS(+)]

Gives output of 0 to 5V DC that represents sensitivity level.

⑥ COM terminal [COM(-)]

Negative terminal used to check vibration or sensitivity level.

⑦ Sensitivity trimmer [SENS]

Sets sensitivity level.

⑧ Sensitivity range switch [RANGE]

Switches high and standard sensitivity ranges.

⑨ Fail-safe switch [FS]

Reverses output signals.

⑩ Protective earth terminal

Grounds the product. Connect this terminal to ground.

(Grounding resistance: 100Ω Max.)

- 14 -

8. OPERATION

This product is basically adjustment free. Use them in the as-delivered state. Changing switch

or trimmer setting may cause faulty operation.

Sensitivity adjustment may be necessary when:

- Material has low bulk density or high fluidity, and the product cannot detect the level.

- Material builds up on the detecting pipe and erratic signals are sent.

- Switch is switched or trimmer turned accidentally.

In these cases, follow instructions below and make adjustment.

8.1 Tools Used for Sensitivity Adjustment/Check

- Digital tester for measuring 0 to 5V DC and with input resistance 1MΩ or greater. Analog

testers and voltmeters can also be used if their input resistance is 1MΩ or greater.

- Slotted screwdriver for sensitivity trimmer. Slot on the trimmer is 0.7mm x 5mm.

8.2 Notes on Sensitivity Adjustment/Check

CAUTION

Sensor output may switch during adjustment. Ensure controlled devices

are not

adversely affected.

The product gives detection signal when voltage at the vibration check terminal*undershoots

voltage at the sensitivity check terminal*.

Voltage at the vibration check terminal decreases when detecting pipe vibration is restricted

by material. The tighter the restriction, the further the voltage decreases. This means high

voltages at the sensitivity check terminal result in high sensitivity level, and vice versa.

Voltage at the sensitivity check terminal is changed using the sensitivity range switch and

the sensitivity trimmer. Fig. 8-1 shows how the voltage changes.

Fig. 8-1

* See chapter 12 GLOSSARY.

This manual suits for next models

15

Table of contents

Other Nohken Accessories manuals