1

CS505 FUEL MOISTURE SENSOR

1. GENERAL DESCRIPTION

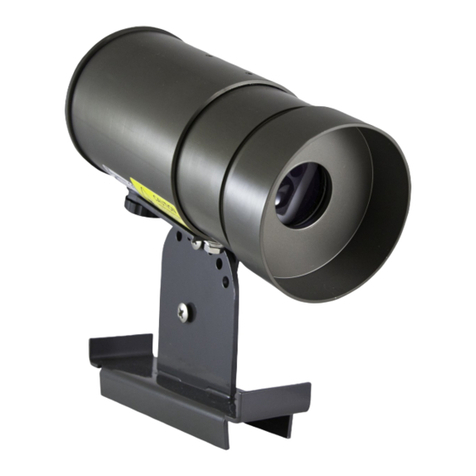

The CS505 Fuel Moisture Sensor provides an

automated measurement of the moisture

content of a standard 10-hour fuel moisture

dowel. The moisture content of the 10-hour fuel

sensor represents the moisture content of

small-diameter (10-hour time lag) forest fuels.

Traditionally, the standard fuel moisture stick

consists of a rack of four 1/2 inch diameter

ponderosa pine dowels. The resulting rack is

about 20 inches long with an oven-dry weight of

100 grams. The characteristic time constant of

the rack is 10 hours. The rack is mounted 12

inches or about 30 centimeters above the forest

floor. The rack is left outside continually

exposed to the same conditions as forest fuels.

The rack absorbs and desorbs moisture from

its surroundings. As the rack transfers

moisture, its weight changes. Periodic weighing

of the rack determines changes in moisture

content provides an indication of moisture

changes in forest fuels.

The CS505 sensor incorporates the same

carefully selected USFS standard ponderosa

dowels as the traditional weighing fuel moisture

racks. No artificial materials (e.g., epoxy

sealant) are added to the dowel that would

adversely influence the natural behavior

characteristics of the dowel. Because the

complete dowel surface is accessible for

moisture exchange, the response of the CS505

is similar to that of the traditional weighing

racks. To optimize probe-to-probe repeatability

and to allow probe interchangeability without

individual calibration, two additional sorts are

performed on the dowels before they are

selected to be used as a sensor. First, the

dowels are sorted dry by density to improve

accuracy in the dry range of 0 to 15%. Second,

the dowels are sorted after a 50-minute soak by

weight to reduce probe-to-probe time response

variation and minimize variability in the wet

range of 20 to 50%.

Even after careful selection and sorting is

performed to choose the most representative

dowels, the majority of measurement error is

due to the variability of wood. Wood’s ability to

transfer moisture is dependent on many

variables, primarily cell structure and wood

resin content. These variables change over

time and after repeated wetting and drying

cycles. Only a small amount of overall

measurement error is due to the electronic

circuitry.

2. SPECIFICATIONS

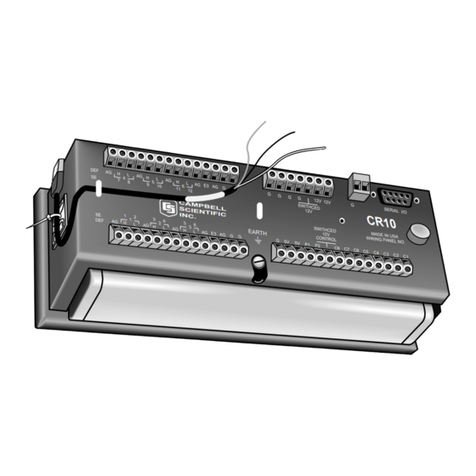

The fuel moisture sensor consists of two

stainless steel strips pressed into groves in a

standard 1/2 inch ponderosa pine dowel and

secured with nylon tie wraps. The probe

connects to the electronics with two Phillips

head screws. A shielded four-conductor cable

is connected to the circuit board to supply

power, enable the electronics, and monitor the

signal output. The printed circuit board is

encapsulated in a water proof epoxy housing.

High speed electronic components on the

circuit board are configured to oscillate when

power is applied. The output of the circuit is

connected to the fuel moisture probe which acts

as a wave guide. The oscillation frequency and

therefore output signal of the circuit is

dependent on the dielectric constant of the

media surrounding the stainless steel strips.

The dielectric constant is predominantly

dependent on the water content of the wood.

Digital circuitry scales the oscillation frequency

to an appropriate range for measurement with

a datalogger. The CS505 output is essentially a

square wave with an amplitude of ±2.5 VDC.

The frequency of the square wave output

ranges from approximately 600 to 1500 Hz.

*Fuel moisture accuracy:

(with a new stick)

90% of all

range measurements rms error

0 to 10% ±2% ±1.0%

10 to 20% ±3% ±1.5%

20 to 30% ±5% ±2.2%

30 to 50% ±6% ±2.4%

Range: 0-50%

Power Supply: 9 VDC minimum to

18 VDC maximum

Enable voltage: off at 0 V (<1 VDC)

on at 5 V (>1.5 VDC maximum

12 VDC)