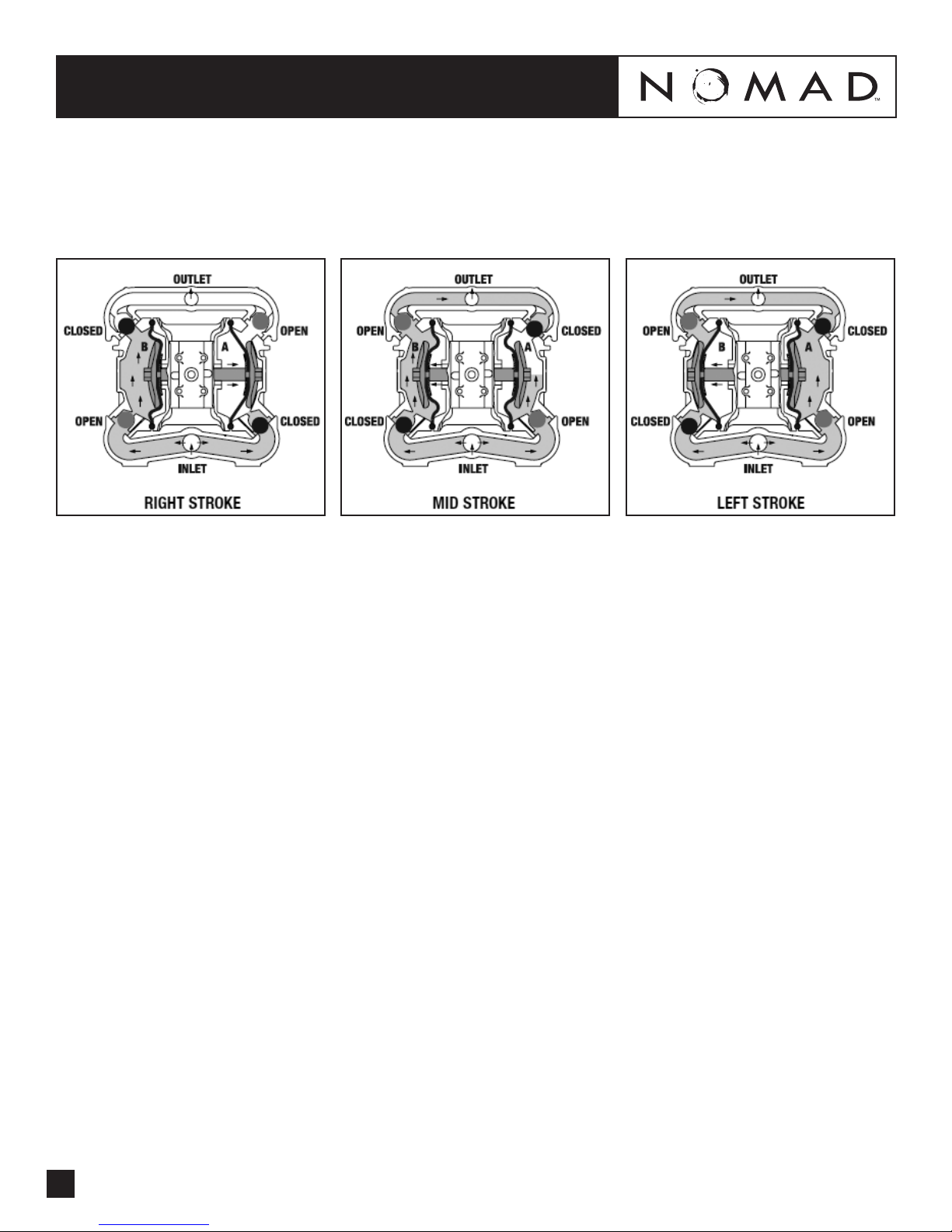

AIR OPERATED DOUBLE DIAPHRAGM PUMPS

FUNCTIONALITY AND FLOW PATTERN

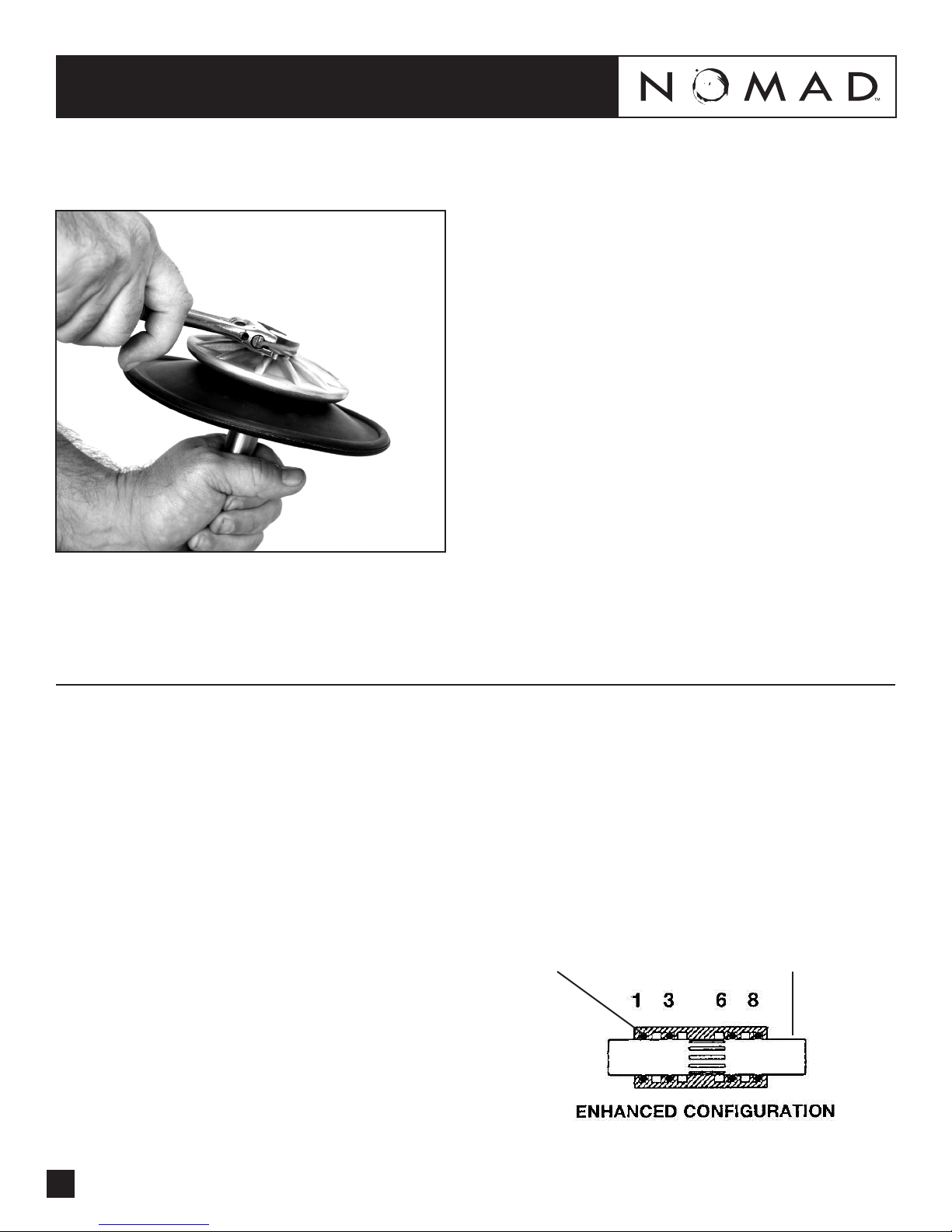

Figure 1: Air valve directs

pressurized air to the back side

of diaphragm A. Compressed air

is applied directly to the liquid

column separated by elastomeric

diaphragms. The diaphragm

acts as a separation membrane

between the compressed air

and liquid, balancing the load

and removing mechanical

stress from the diaphragm. The

opposite diaphragm is pulled

in by the shaft connected to

the pressurized diaphragm.

Diaphragm B is on its suction

stroke; air behind the diaphragm

has been forced out to the

atmosphere through the exhaust

port of the pump. Atmospheric

pressure forces uid into the

inlet manifold forcing the inlet

valve ball o its seat. Liquid is

free to move past the inlet valve

ball and ll the liquid chamber

(see shaded area).

Figure 2: When the pressurized

diaphragm, diaphragm A,

reaches the limit of its discharge

stroke, the air valve redirects

pressurized air to the back

side of the diaphragm B. The

pressurized air forces diaphragm

B away from the center block

while pulling diaphragm A to

the center block. Diaphragm B

is now on its discharge stroke.

These same hydraulic forces

lift the discharge valve ball o

its seat, while the opposite

discharge valve ball is forced

ontoitsseat,forcinguidtoow

through the pump discharge.

Atmospheric pressure forces

uid into the inlet manifold of

the pump. The inlet valve ball is

forced o its seat allowing the

uid being pumped to ll the

liquid chamber.

Figure 3: At completion of

the stroke, the air valve again

redirects air to the back side

of diaphragm A, which starts

diaphragm B on its exhaust

stroke. As the pump reaches

its original starting point, each

diaphragm has gone through

one exhaust and one discharge

stroke. This constitutes one

complete pumping cycle. The

pump may take several cycles to

completely prime depending on

the conditions of the application.

NTG25 NOMAD TRANS-FLO™

3