Nomix Frontline Classic User manual

frontlineclassic

The original

low volume

TDC herbicide

application

system

INSTRUCTIONS

Contents

Section 1:

Introduction

3

Section 2:

Component List

4

Section 3:

Quick Start

6

Section 4:

Controls and Features

Battery and charger 8

Shaft 9

Trigger 9

Backpack and herbicide box 9

Pacing control 10

Spray width control 10

LCD readout 11

Onboard electronics 12

Flow rate 12

Section 5:

Preparing the Frontline Classic for Use

Personal Protective Equipment (PPE) 13

Inserting the battery 13

Connecting the herbicide box 14

Priming 14

Selecting a disc 15

Calibrating 16

Section 6:

Operating the Frontline Classic

Spraying 18

Avoiding spray drift 18

Optimum spray pattern 18

Section 7:

Cleaning the Frontline Classic 19

Section 8:

Storing the Frontline Classic 21

Section 9:

Safety Tips 22

Section 10:

Troubleshooting 23

Section 1: Introduction

The Frontline Classic is a lightweight hand-held low

volume herbicide applicator, designed for use with our

range of Nomix Total Droplet Control (TDC) herbicides.

Nomix TDC is a unique system, combining pre-mixed,

highly eective herbicides with easy to use,

ecient applicators.

Nomix TDC delivers a constant, uniform droplet size and

spray pattern, significantly reducing run-o and virtually

eliminating spray drift and droplet bounce. In times

of increased environmental and legislative pressure,

the Frontline Classic delivers ecient, compliant, cost

eective and accurate herbicide applications every time.

Nomix TDC herbicides are supplied in ready to use,

lightweight 5 litre packs that connect directly to the

lance, eliminating the risk of spillages and operator

exposure from mixing and measuring.

3

Section 2: Component List

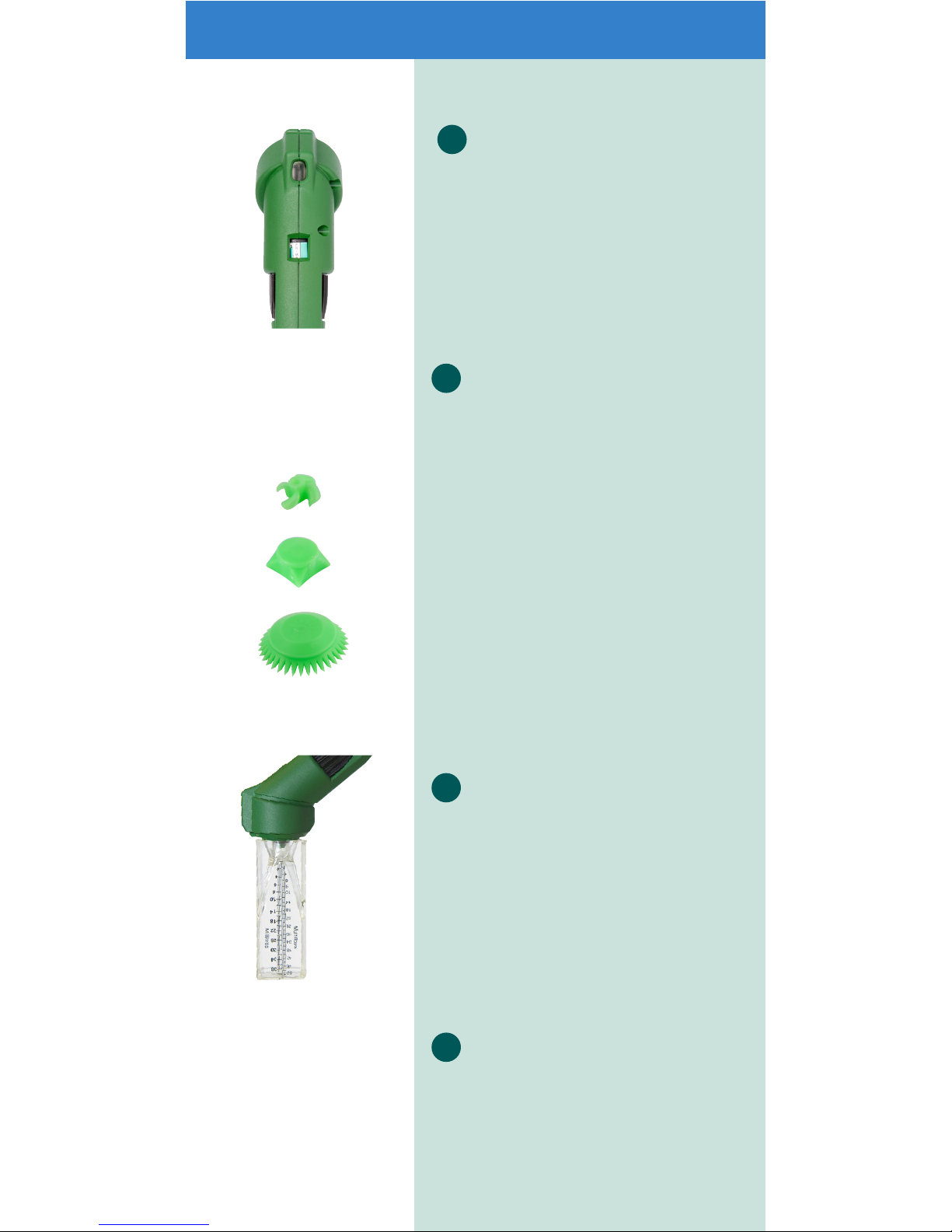

1 Spray head

a) Flow rate window

b) Flow rate indicator

c) Flow rate control

2 Control panel

a) Spray width control

b) Pacing control

3 Trigger

4 LCD readout

5 Spiral disc

6 Square disc

7 Serrated disc

8 Disc ejector tool

b

a

c

a

b

4

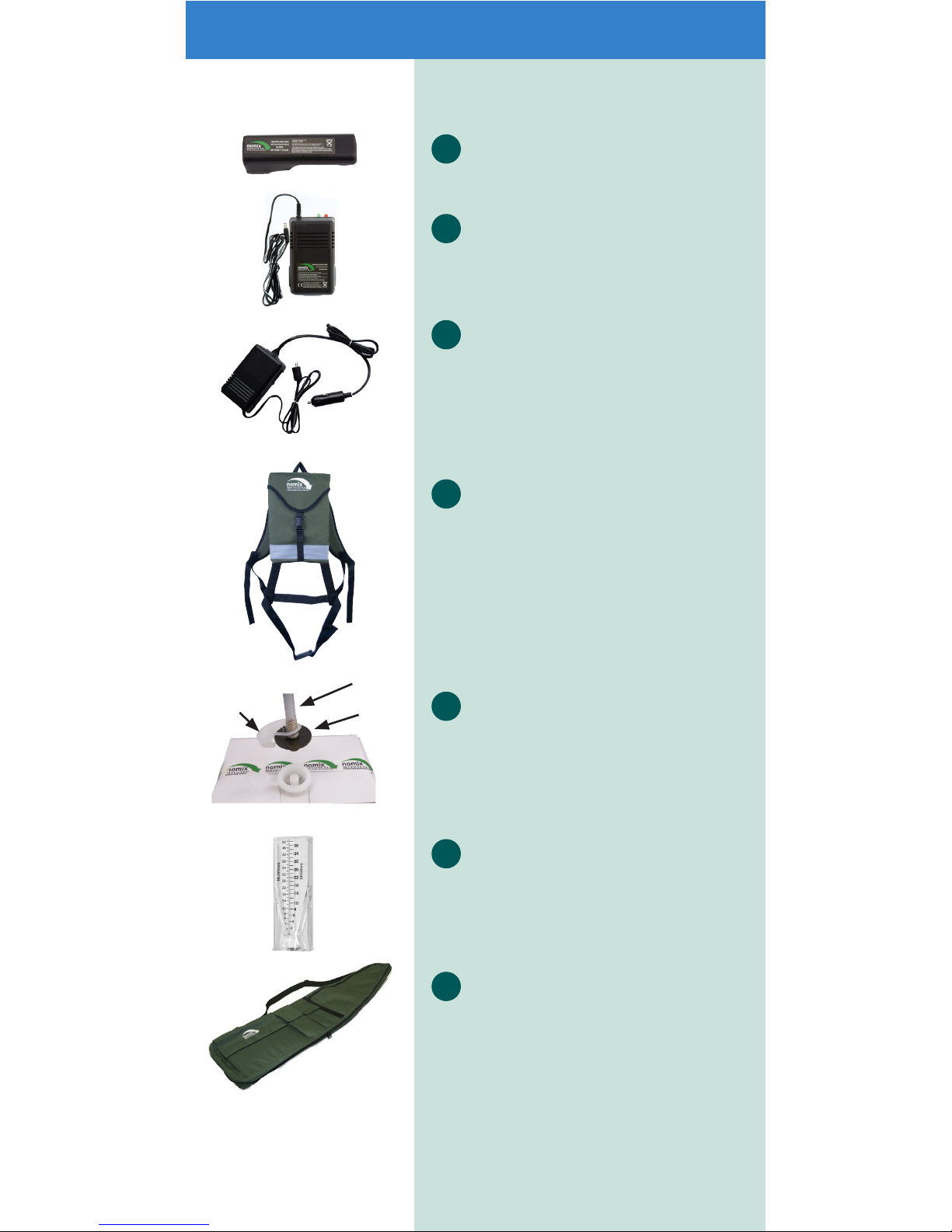

9 Rechargeable battery

10 Battery charger

11 Car charger*

12 Backpack

13 Box connector

a) Feed tube

b) C-clip

c) Connector

14 Calibration cup

15 Carry case*

* These items do not form part of our

standard components. They can be

purchased from Nomix Enviro.

Please telephone 01264 388050.

a

bc

5

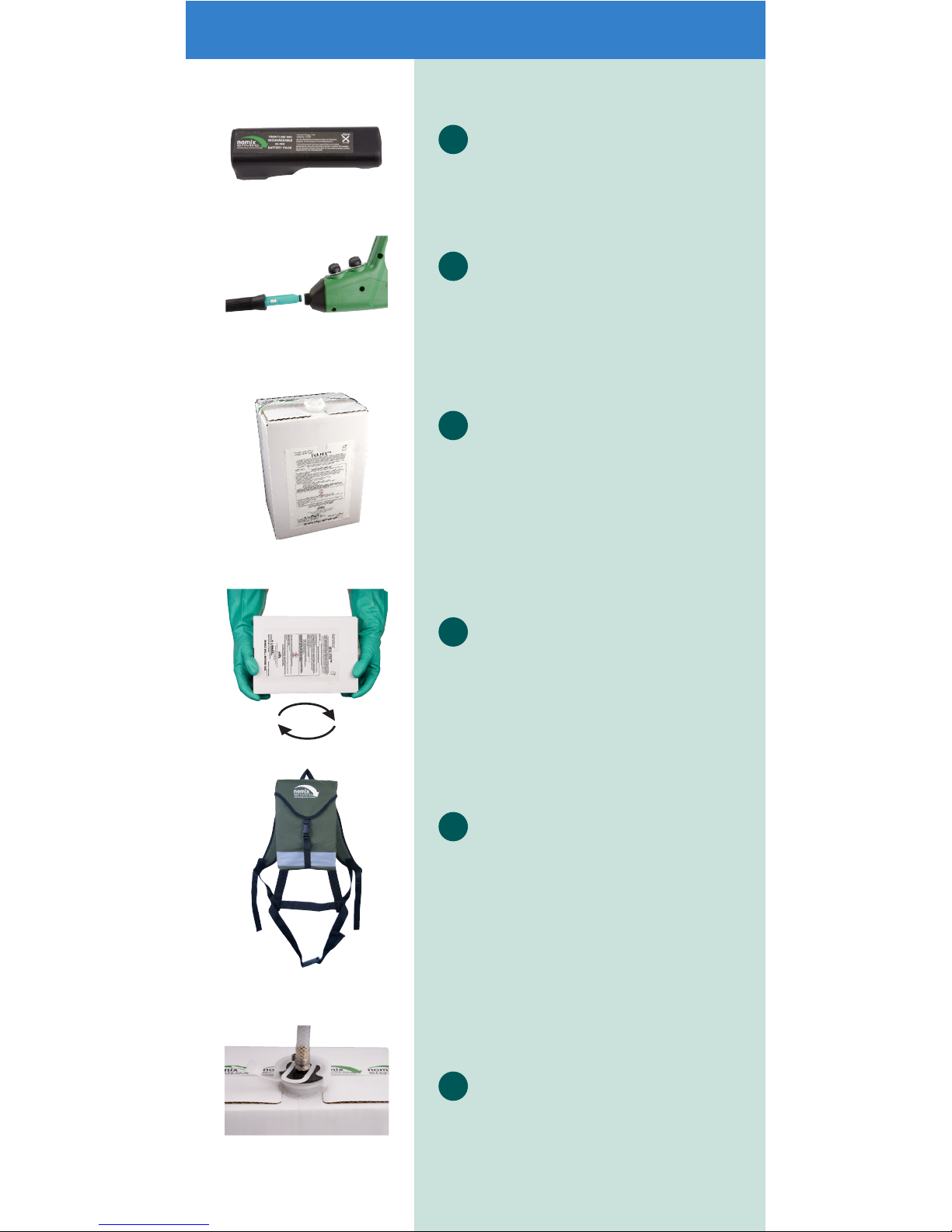

Section 3: Quick Start

1 Charge the battery for a

minimum of eight hours

2 Attach the shaft

3 Select an approved Nomix

TDC herbicide

4 Shake the herbicide box

vigorously for at least

one minute, in a circular

motion

5 Place the herbicide box in

the backpack

6 Attach the lance to the

herbicide box, ensuring

the c-clip is in place

6

7 Prime your Frontline Classic

8 Before calibrating the Frontline

Classic you will need to select

a disc. Do not attach the disc

until calibration is complete

Spiral - Narrow spray

Square - Medium Spray

Serrated - Wide Spray

9 Calibrate your Frontline Classic

10 You are ready to spray

Please Note: For full operator

instructions, always refer to sections

5 and 6.

7

Section 4: Controls and Features

Battery and charger

Please Note: The battery must

be charged before connecting it

to the handset. Always connect

the battery before connecting the

herbicide pack.

• Plug the charger supplied into a

mains outlet (do not switch on).

• Connect the battery to the

charger.

• Switch the charger on at the

mains supply.

• Charge the battery for a

minimum of eight hours.

• The charger will monitor the

battery state. Whilst charging,

the red and green lights will

remain on. When fully charged,

the red light will go out and the

green light will remain on.

• We recommend that you charge

the battery after each full day’s

use.

• When the battery is fully

charged, switch o the charger

at the mains and disconnect the

battery from the charger.

• Check the handset controls are

in the ‘OFF’ position.

• Place the battery into the

handset (point the handset

downwards as you insert the

battery).

• Close the battery compartment.

• The state of the art nickel metal

hydride battery technology

allows the battery to receive a

part charge from a car charger,

without any detrimental battery

performance.

8

• Batteries should be fully charged

prior to storage through the

closed season. Store the batteries

in a clean and dry environment.

Shaft

• To insert the shaft into the

handset, align the shaft

connector’s raised spine with the

handset’s receptor.

• Push the shaft completely into

the handset.

• Screw the shaft nose cone fully

onto the handset. Take care

not to over tighten, screwing to

finger-tight only.

Trigger

• Press the trigger to power the

lance functions and allow the

chemical to flow to the spray

head.

• The electronic single function

(on/o) trigger mechanism

ensures fast and accurate

application. Press the trigger to

start spraying and again to stop.

Backpack and

herbicide box

The Frontline Classic should only

be used with approved Nomix TDC

herbicides, carried in a

Nomix backpack.

9

Section 4: Controls and Features (cont.)

Pacing control

• When in the ‘OFF’ position,

the usage clock is visible on

the LCD readout for a short

time.

• The calibrate position disables

the motor whilst calibrating.

• The other positions are used

to set the lance to beep,

indicating when to step to

maintain the walking pace.

• Using the pacer will ensure

the most accurate application.

However it is not essential for

it to be switched on during

operation and it can be turned

to the o position if preferred.

Spray width control

• When in the ‘OFF’ position

the lance will not activate,

although the power is still on.

• Disc positions indicate the

disc selection.

• Turn the control clockwise

to increase the spray width

available for the disc selected.

10

LCD readout

The LCD readout is activated when

the spray width control is set or

the trigger button is pressed. Press

the trigger to power the lance

functions and allow chemical to

flow to the spray head.

• Battery Information:

o The five battery segments

display the amount of battery

charge remaining

o The last two segments will

flash to warn of low battery

o When the last segment shows

as ‘LO’, the battery must be

charged or replaced

o Shortly after the ‘LO’ reading

displays, the processor will

shut down and herbicide

will not flow. This is a safety

precaution to make sure the

valve is not left in an open

position.

11

Section 4: Controls and Features (cont.)

• Clock:

o The clock enables you

to measure the hours of

operation

o To display the hours of

operation, set the spray

width and pacing controls

to ‘OFF’

o Hours will show on the LCD

readout for approximately 3

seconds

o The clock is activated when

the spray button is pressed

o ‘SER’ will appear when a

service is due

Onboard electronics

• The onboard processor is

activated when the trigger is

pressed and monitors:

o Battery condition

o Valve operation

o Spray width control

o Pacer control

o Usage time.

Flow rate

• Eight settings (A-G and

Prime) on the flow rate control

regulate the chemical flow.

• The flow rate window shows

the chemical flowing to the

spray head.

• Always refer to the herbicide

label for the correct flow rate

setting.

12

Section 5: Preparing for use

Personal Protective

Equipment (PPE)

The minimum PPE recommended

for use is:

• Coveralls

• Suitable protective gloves

• Wellington boots.

Always refer to the herbicide

product label for the recommended

PPE.

Inserting the battery

• Check the handset controls are in

the ‘OFF’ position.

• Place the fully charged battery

into handset (pointing the

handset downwards as you insert

the battery).

• Close the battery compartment.

13

Section 5: Preparing for use (cont.)

Connecting the herbicide

box to the lance

• Select an approved TDC

herbicide.

• Read the label for full product

information and application

rates.

• Shake the herbicide box

vigorously for at least one

minute in a circular motion.

• Place the herbicide box in

the backpack with the bung

positioned facing down and

fasten the pack clips.

• Return the backpack to an

upright position.

• Remove the bung stopper.

• Line the feed tube connector

up with the bung, placing your

fingers underneath the bung

and pushing the connector in

with your thumbs. The bung

will then be pierced.

• IMPORTANT: Ensure that the

c-clip fits securely over all

three flanges as shown. The

connector could pull out if it is

not fitted correctly.

• Position the backpack

comfortably on your back and

adjust straps as required.

Priming

ALWAYS PRIME THE LANCE

BEFORE USE

Priming fills the lance with

herbicide and removes air

bubbles, which could interrupt

the chemical flow or cause the

lance to drip.

14

• Ensure there is no disc attached.

If a disc is present, remove it

using the disc ejector tool.

• Turn the spray width control to

the ‘OFF’ position.

• Turn the pacer control to the

calibrate position.

• Set the flow rate indicator to

‘Prime’.

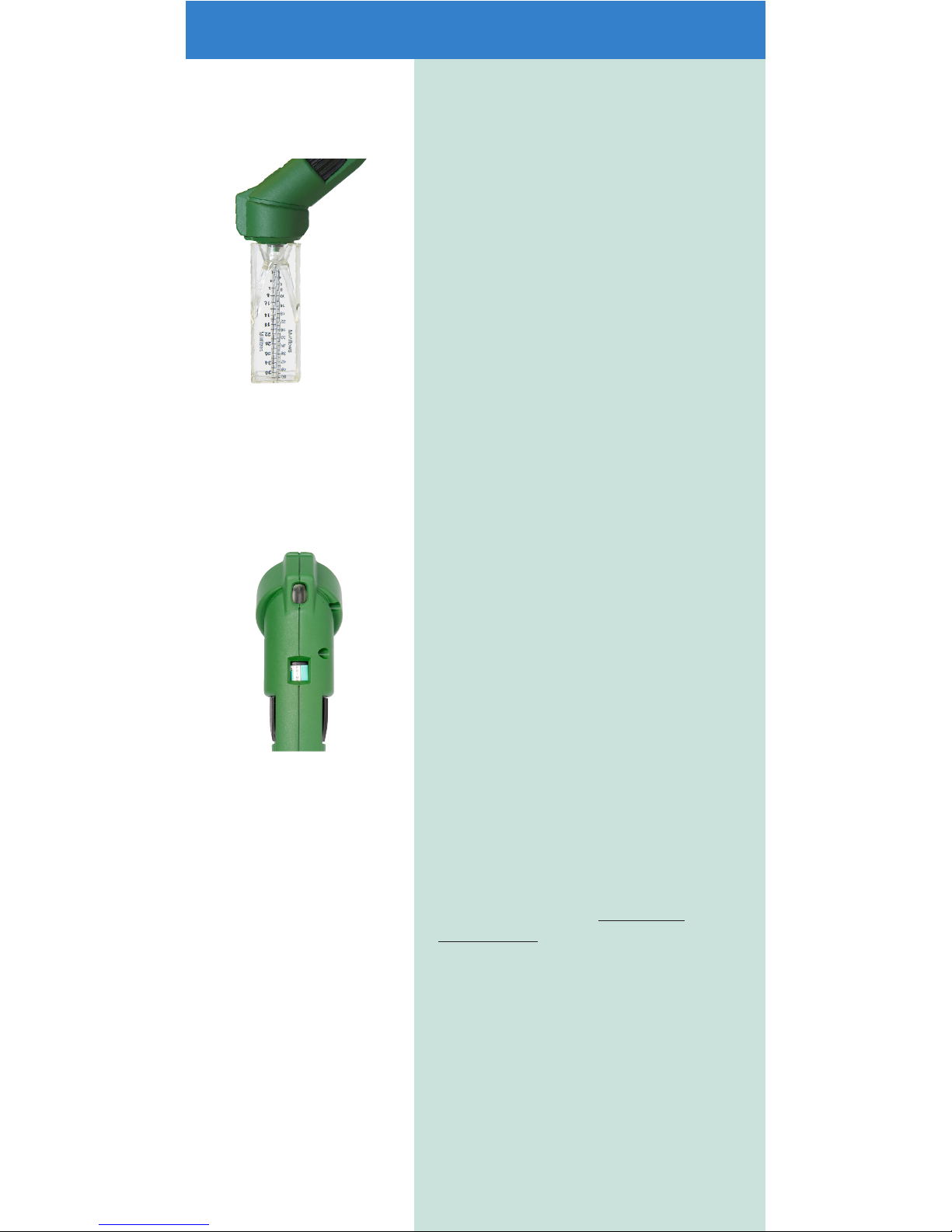

• Push the calibration cup on to

the spray head.

• Select the calibration setting on

the pacer control.

• Press the trigger ‘on’.

• Wait up to 20 seconds for

herbicide to appear in the flow

rate window.

• Press the trigger ‘o’.

• Press the trigger ‘on’ and

invert the lance to empty the

calibration cup.

• Press the trigger ‘o’ when the

calibration cup is empty.

Selecting a disc

Select a disc using the following

table. Before connecting the disc, you

must carry out the full calibration

procedure on pages 16 & 17.

15

Disc Spray Width Recommended areas of use

Spiral

15cm – 30cm

(6” – 12”)

Spot treatment, narrow

trim and edge work

Square

30cm – 75cm

(12” – 30”)

Trim and edge work, spot

treatment and fence lines

Serrated

75cm – 100cm

(30” – 40”) Broadcast spraying

Section 5: Preparing for use (cont.)

Calibrating

The Operator should carry out

a full calibration procedure

according to the corresponding

product label. This should take

account of:

• Walking Speed: This should

be accurately measured. The

Pacing Control on the applicator

will assist with determining

accurate walking speed.

Walking speed can be

accurately determined using the

following formula:

360 / time taken to walk 100m

(seconds) = Walking Speed

(kph)

• Product Application Rate: This

can be found on the product

label and will be the correct

approved rate for the product

and situation concerned.

• Spray Width: This will be

dependent on disc selection,

disc speed and height.

• Flow Rate: This is the rate of

herbicide flow through the

applicator, and is measured

using the Calibration Cup.

The correct Flow Rate for the

herbicide can be calculated using

the following formula:

Walking Speed (kph) x Product

Application Rate (l/ha) x Spray

Width (cm) / 120 = Flow Rate

(ml/30secs).

16

Example:

For a walking speed of 3.2 kph,

product application rate 10 litres per

hectare, spray width of 60cm:

3.2 x 10 x 60 / 120 = 16 ml/30

seconds

The product label will give a guide

as to the best applicator settings

to be used, in order to achieve the

correct flow rate, as determined

by the above formula. However,

the flow rate must be measured

using the Calibration Cup (having

measured walking speed and spray

width) and the applicator adjusted

as necessary, to achieve the

approved application rate.

Connecting the disc

Once calibration is complete,

connect the disc to the head of the

lance by placing it onto the spindle

and pushing it until secure.

17

Section 6: Operating

18

Spraying

• Hold the lance in a comfortable

operating position.

• Set the spray width control to

the required disc setting.

• Set the pacing control to your

desired walking speed.

• Press the trigger to begin

spraying.

• Press again to stop spraying.

• Always clean the lance at the end

of a day’s use. (Refer to section 7).

Avoiding Spray Drift

The Frontline Classic produces

uniform droplets and significantly

reduces spray drift. However, care

should always be taken to avoid

drift, particularly when using wider

spray width settings. If the spray

pattern is being aected by wind,

do not spray until the wind drops.

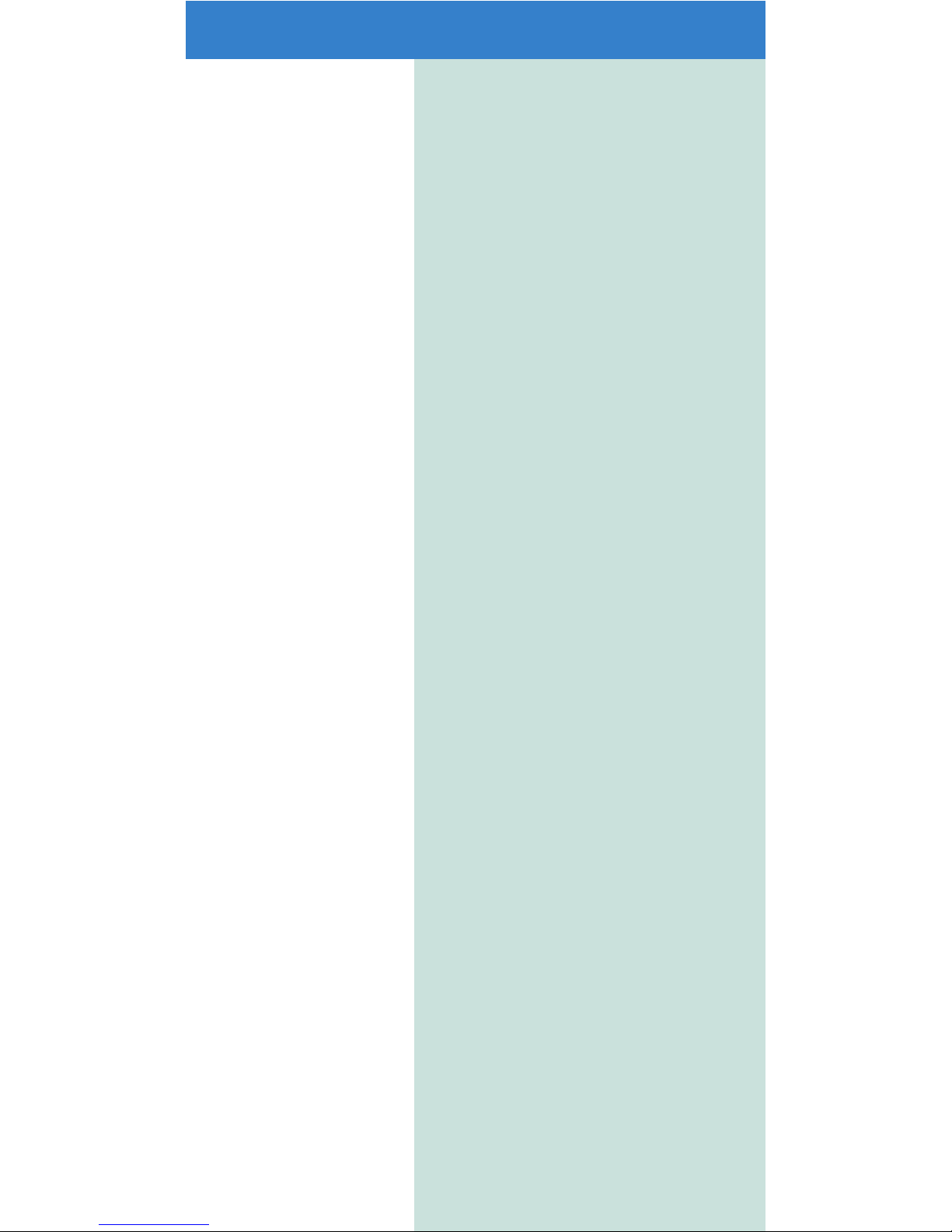

Optimum Spray Pattern

Just a few drops of Nomix TDC

herbicide will control weeds.

This is the optimum spray pattern.

• Under applied.

• Optimum spray pattern.

• Over applied.

Section 7: Cleaning

Please Note: You MUST clean the

Frontline Classic at the end of each

day’s spraying and also before

using a dierent herbicide. The

ONLY way to clean the lance is

with specially formulated Nomix

Universal Cleaner.

Always refer to the Code of Practice

for full instructions on the cleaning

of herbicide application equipment.

• Switch the spray width control to

the ‘OFF’ position.

• Place the backpack on the ground

and hold the lance up.

• Press the trigger to allow the

herbicide to drain back into the

box.

• Once all the herbicide is drained,

press the trigger again to stop the

flow and disconnect the box.

• Remember to replace the bung

cap in the herbicide box.

• Connect a box of Nomix Universal

Cleaner to the lance.

19

• Run cleaner through the lance

with the settings in the Prime

position until liquid runs clear.

Spray on an approved site or

collect the liquid for disposal.

DO NOT allow contaminated

cleaner to drain back into the

cleaner pack.

• Disconnect the cleaner box from

the lance.

• Press the trigger to empty the

lance of cleaner. When the flow

stops, press the trigger again.

• Wipe any herbicide residue from

the spray head with a paper towel

and dispose of safely.

• DO NOT forget to recharge the

battery.

THE LANCE WILL CONTAIN

HERBICIDE UNTIL CLEANED

20

Table of contents

Popular Paint Sprayer manuals by other brands

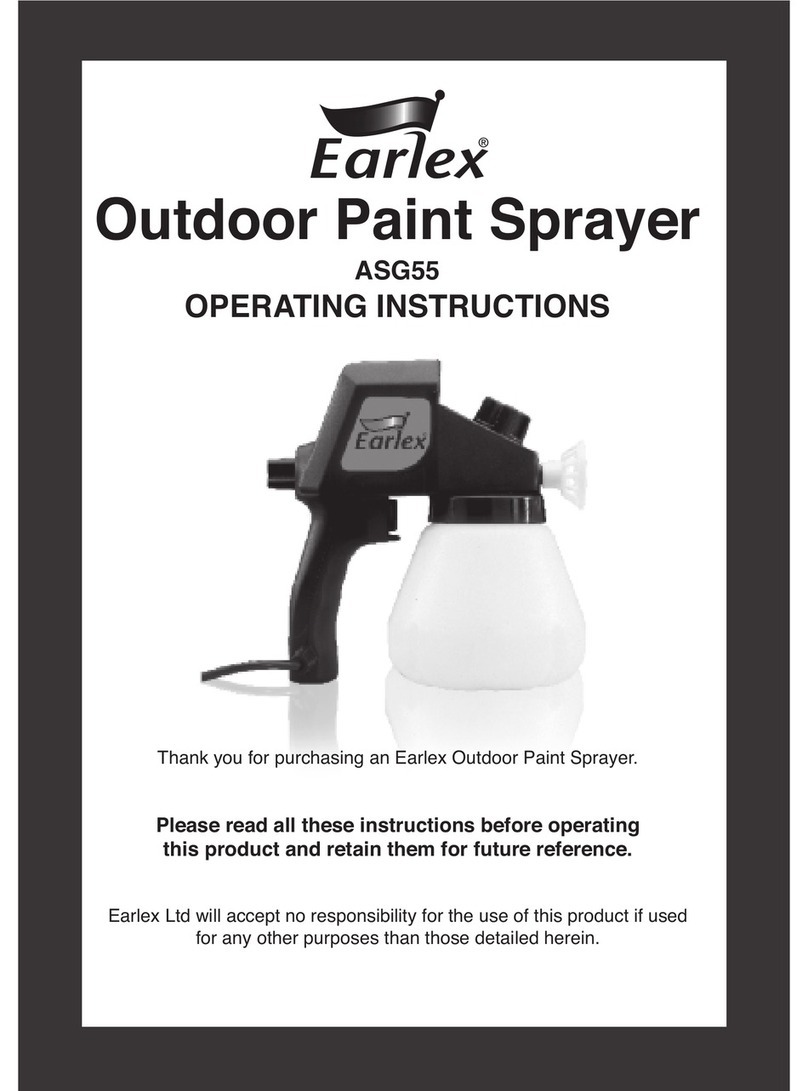

Earlex

Earlex ASG55 operating instructions

Ozito

Ozito ASG-7000 instruction manual

Task Force Tips

Task Force Tips PROTECTOR INSTRUCTIONS FOR SAFE OPERATION AND MAINTENANCE

Mesto

Mesto CLEANER 3275PP Instructions for use

ground logic

ground logic Pathfinder Operator's manual

Decoproyec

Decoproyec CP19 Instruction and maintenance manual