WARNING! When using mains-powered tools, basic safety precautions, including the

following, should always be followed to reduce risk of re, electric shock, personal injury and

material damage.

Read the whole manual carefully and make sure you know how to switch the tool o in an emergency,

before operating the tool.

Save these instructions and other documents supplied with this tool for future reference.

The charger has been designed for 230V and 240V only. Always check that the power supply corresponds

to the voltage on the rating plate.

Note: The supply of 230V and 240V on Ozito tools are interchangeable for Australia and New Zealand.

If the supply cord is damaged, it must be replaced by an electrician or a power tool repairer in order to

avoid a hazard.

Using an Extension Lead

Always use an approved extension lead suitable for the power input of this tool. Before use, inspect the

extension lead for signs of damage, wear and ageing. Replace the extension lead if damaged or defective.

When using an extension lead on a reel, always unwind the lead completely. Use of an extension lead

not suitable for the power input of the tool or which is damaged or defective may result in a risk of re and

electric shock.

The power supply for this products charger should be protected by a residual current device (rated at

30mA or less). A residual current device reduces the risk of electric shock.

WARNING! The appliance is not to be used by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction.

Young children should be supervised to ensure that they do not play with the appliance.

Before connecting a tool to a power source (mains switch power point receptacle, outlet, etc.) be sure

that the voltage supply is the same as that specied on the nameplate of the tool. A power source with a

voltage greater than that specied for the tool can result in serious injury to the user, as well as damage to

the tool. If in doubt, do not plug in the tool. Using a power source with a voltage less than the nameplate

rating is harmful to the motor.

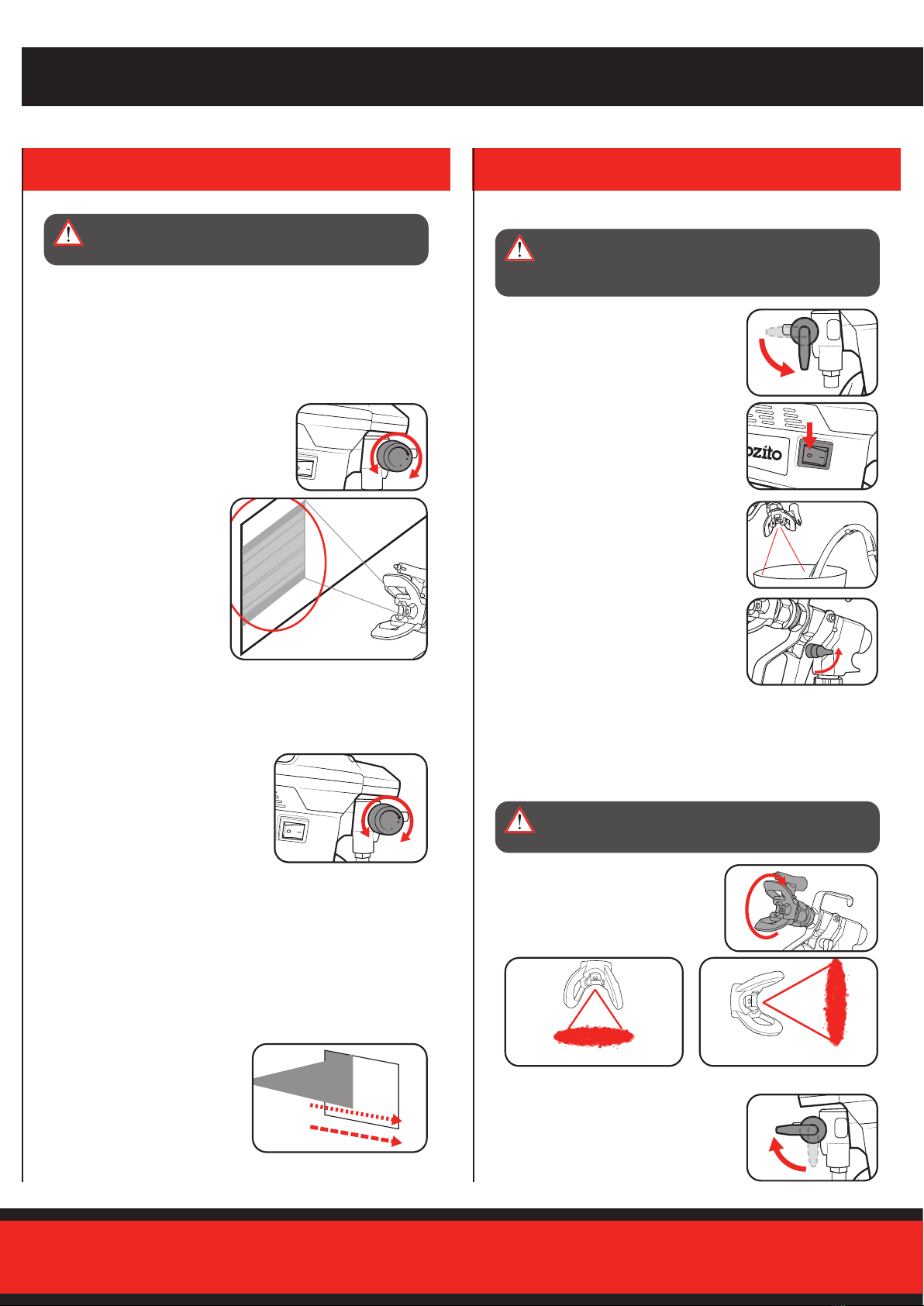

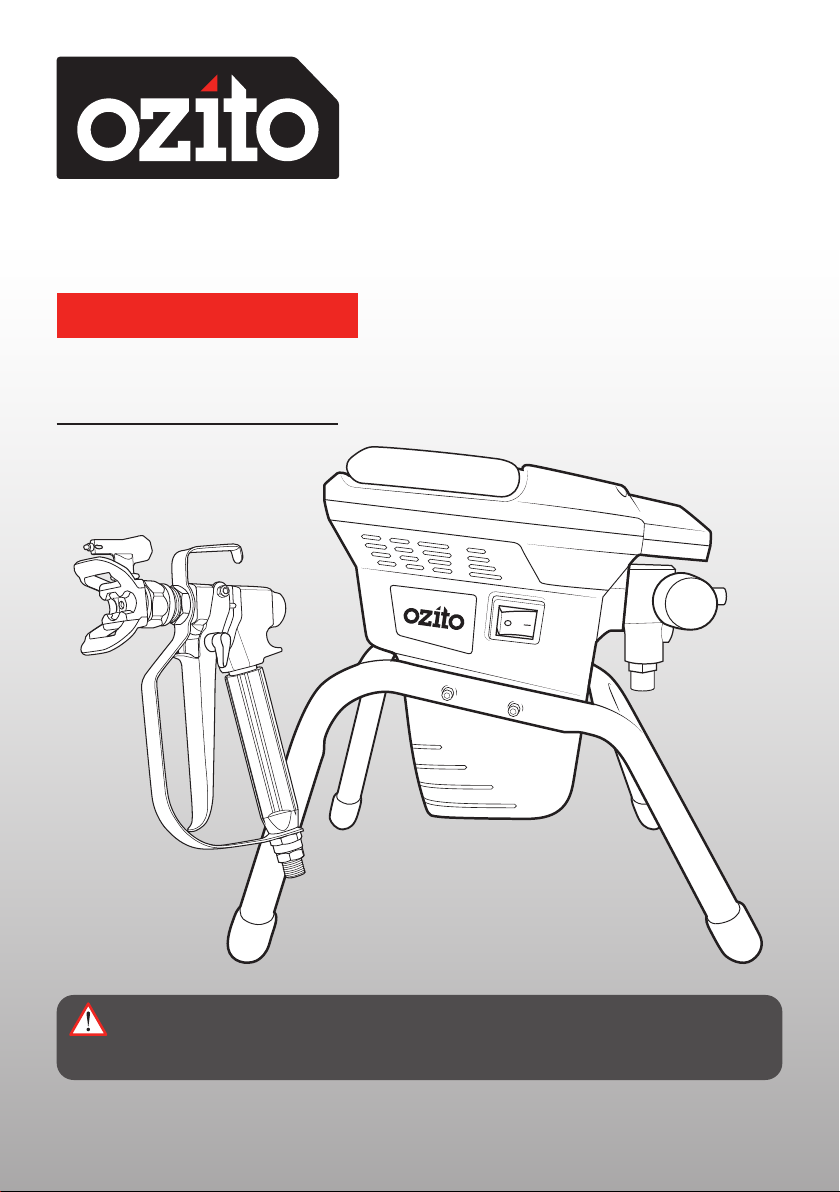

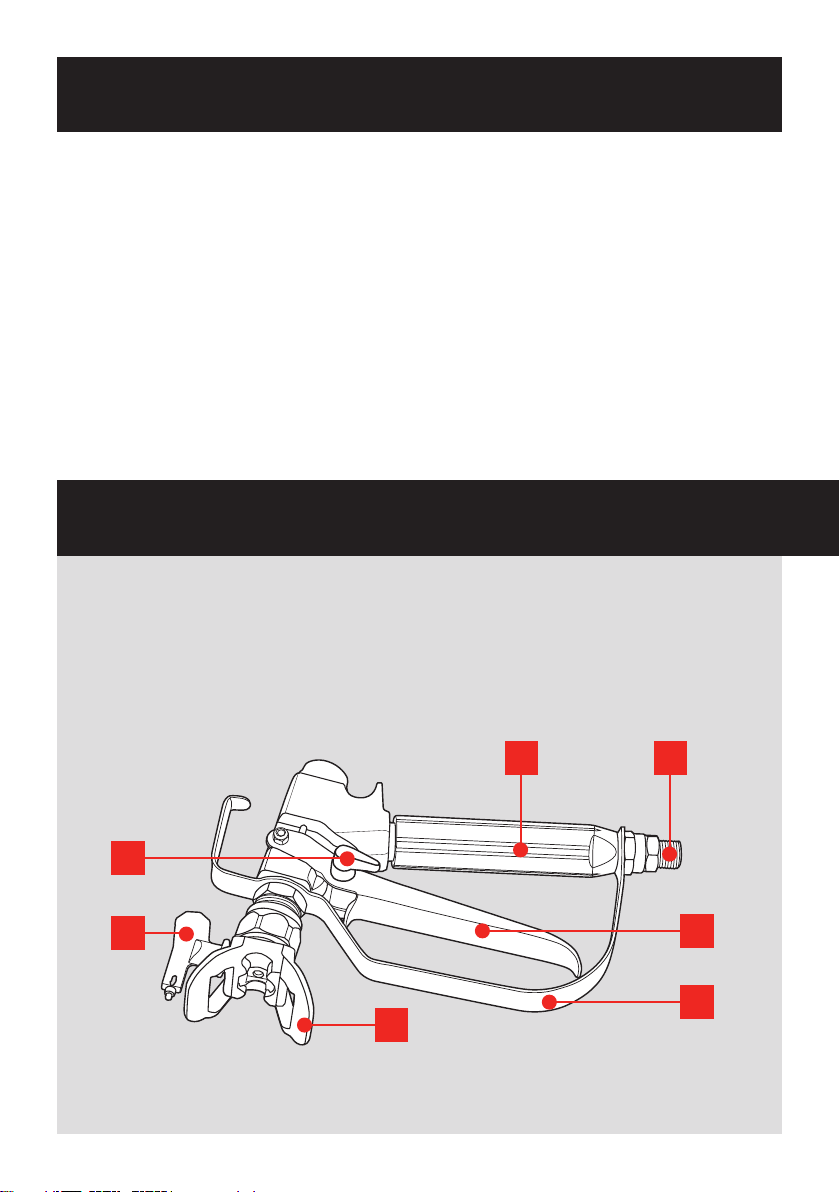

The ASG-7000 Airless Spray Gun operates at very high pressure. For safe operation the following must be

observed at all times.

• Do not point the spray gun at yourself or any other person. Injury from penetration to the skin and paint

solvents being injected into the body can result.

• Always check for leaks and correct operation before use. Never operate the spray gun if there are any

leaks or faults. Faults or leaks can cause injury.

• Release the pressure when not in use. Pressure can remain in the unit and hose when switched o.

• Always remove the plug from the mains socket before making any adjustments or performing

maintenance.

• Recommendations for the use of a residual current device with a rated residual current of 30mA or

less.

• NEVER under any circumstances aim the nozzle at another person or animal. In the event of an injury

occurring, seek medical advice immediately.

• The spray gun must not be used for spraying ammable paints and solvents with a ash point of less

than 21ºC.

• Always ensure there is adequate ventilation when spraying.

• The use of ear protection is recommended.

• Eye protection is recommended to keep hazardous vapours and liquids out of eyes.

• Always wear a face mask when spraying.

• Always read the paint manufacturers thinning instructions before using.

• Always keep the spray basket nozzle in place during use. Never allow the spray to come in direct

contact with the skin.

• Never immerse the spray gun in liquid. This could lead to electric shock, personal injury and material

damage.

• The spray gun must not be cleaned by using ammable liquids with a ash point of less than 21ºC.

• NEVER spray near a naked ame, including an appliance pilot light.

• NEVER smoke whilst spraying.

• NEVER allow children to operate or play with the spray gun.

• Before cleaning, always disconnect the appliance from the mains supply.

• After every use ensure you clean your spray gun thoroughly.

• NEVER use the spray gun outside when it is raining.

• Injury where paint or solvent injection into the skin or body occurs can be very serious. Always seek

professional medical help and advise the paints or solvents used.

• NEVER use the spray gun without the trigger safety guard tted.

• NEVER put your hand in front of the gun. Gloves will not provide protection against an injection injury.

• ALWAYS lock the gun trigger, shut the uid pump o and release all pressure before servicing,

cleaning the tip guard, changing tips, or leaving unattended. Pressure will not be released by turning

o the machine. The PRIME/SPRAY valve or pressure bleed valve must be turned to their appropriate

positions to relieve system pressure.

• NEVER use a spray gun without a working trigger lock and trigger guard in place.

• All accessories must be rated at or above the maximum operating pressure range of the sprayer. This

includes spray tips, guns, extensions, and hose.

• High-pressure hoses must be checked thoroughly before they are used. Replace any damaged high-

pressure hose immediately.

• Never pull on the high-pressure hose to move the device.

• Do not twist the high-pressure hose.

• Do not put the high-pressure hose into solvents. Use only a wet cloth to wipe down the outside of the

hose.

• Lay the high-pressure hose in such a way as to ensure that it cannot be tripped over.

• Follow material and solvent manufacturer’s warnings and instructions. Be familiar with the coating

material’s SDS sheet and technical information to ensure safe use.

• Use lowest possible pressure to ush equipment.

• Protective clothing, gloves and possibly skin protection cream are necessary for the protection of the

skin. Observe the regulations of the manufacturer concerning coating materials, solvents and cleaning

agents in preparation, processing and cleaning units.

• ALWAYS follow the material manufacturer’s instructions for safe handling of paint and solvents.

• Do not spray on windy days.

• Never leave this equipment unattended. Keep away from children or anyone not familiar with the

operation of airless equipment.

AIRLESS SPRAYER SAFETY WARNINGS

GENERAL POWER TOOL SAFETY WARNINGS

ELECTRICAL SAFETY

WARNING! Read all safety warnings and all instructions. Failure to follow the

warnings and instructions may result in electric shock, re and/or serious injury.

Save all warnings and instructions for future reference. The term “power tool” in the warnings

refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

1. Work area safety

a. Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b.Donotoperatepowertoolsinexplosiveatmospheres,suchasinthepresenceofammable

liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

c. Keep children and bystanders away while operating a power tool. Distractions can cause you to

lose control.

2. Electrical safety

a. Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power tools. Unmodied plugs and matching outlets will

reduce risk of electric shock.

b. Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

c. Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the

risk of electric shock.

d. Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase

the risk of electric shock.

e. When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of electric shock.

3. Personal safety

a. Stay alert, watch what you are doing and use common sense when operating a power tool. Do

notuseapowertoolwhileyouaretiredorundertheinuenceofdrugs,alcoholormedication. A

moment of inattention while operating power tools may result in serious personal injury.

b.Use personal protective equipment. Always wear eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce

personal injuries.

c.Preventunintentionalstarting.Ensuretheswitchisintheo-positionbeforeconnectingto

power source and/or battery pack, picking up or carrying the tool. Carrying power tools with your

nger on the switch or energising power tools that have the switch on invites accidents.

d. Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may result in personal injury.

e. Do not overreach. Keep proper footing and balance at all times. This enables better control of the

power tool in unexpected situations.

f. Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

g. If devices are provided for the connection of dust extraction and collection facilities, ensure

these are connected and properly used. Use of dust collection can reduce dust-related hazards.

h. Do not let familiarity gained from frequent use of tools allow you to become complacent and

ignore tool safety principles. A careless action can cause severe injury within a fraction of a second.

4. Power tool use and care

a. Do not force the power tool. Use the correct power tool for your application. The correct power

tool will do the job better and safer at the rate for which it was designed.

b.Donotusethepowertooliftheswitchdoesnotturnitonando.Any power tool that cannot be

controlled with the switch is dangerous and must be repaired.

c. Disconnect the plug from the power source and/or the battery pack from the power tool before

making any adjustments, changing accessories, or storing power tools. Such preventive safety

measures reduce the risk of starting the power tool accidentally.

d. Store idle power tools out of the reach of children and do not allow persons unfamiliar with the

power tool or these instructions to operate the power tool. Power tools are dangerous in the hands

of untrained users.

e. Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any

other condition that may aect the power tool’s operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly maintained power tools.

f. Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking

into account the working conditions and the work to be performed. Use of the power tool for

operations dierent from those intended could result in a hazardous situation.

h. Keep handles and grasping surfaces dry, clean and free from oil and grease. Slippery handles and

grasping surfaces do not allow for safe handling and control of the tool in unexpected situations.

5. Service

a.Haveyourpowertoolservicedbyaqualiedrepairpersonusingonlyidenticalreplacement

parts. This will ensure that the safety of the power tool is maintained.