NorAM 65ET T4 FINAL User manual

-1

1

7),1$/

65

E7

|

Motor Grader

Operator’s Manual

2FWREHU, 201

Part # ϯϰϰϵϭ

S/N: Tier ϰ&ŝŶĂů65ETϭϬϭϬϭͲ hW

This page intentionally left blank.

NORAM 65ET GRADER

Table of Contents 1

NORAM 65ET GRADER

TABLE OF CONTENTS

SAFETY

Safety Messages ....................................1-1

Safety Symbol Explanation .................. 1-2

Safety Decal Locations ......................... 1-6

GENERAL INFORMATION

Intended Use ......................................... 2-1

Introduction to this Manual ................. 2-1

Orientation ............................................ 2-2

Machine Description .............................2-2

Identification Numbers ........................ 2-3

Component Identification and

Locations .......................................... 2-5

Electronic Display ............................... 2-28

OPERATION

Mounting and Dismounting ................. 3-1

Daily Pre-Starting Inspection .............. 3-1

Rollover Protective Structure (ROPS) .3-3

Driving the Machine .......................... 3-8

Moldboard and Implement Operation 3-11

LUBRICATION AND MAINTENANCE -

GRADER COMPONENTS

Safety Messages ....................................4-1

General Information ............................. 4-4

Accessing Lubrication and

Check Points ....................................4-6

Maintenance Intervals ....................... 4-10

Every 10 Hours or Daily ..................... 4-12

Every 50 Hours or Weekly ................. 4-17

Every 100 Hours ................................. 4-21

Every 250 Hours or Monthly .............. 4-23

Every 500 Hours or 3 Months ............ 4-26

Every 500 Hours or 6 Months ............ 4-30

Every 1000 Hours or 6 Months .......... 4-33

Every 2000 Hours or 1 Year ............... 4-36

When Required ................................... 4-40

LUBRICATION AND MAINTENANCE -

CUMMINS TIER 4 FINAL

General Information ............................. 5-1

Maintenance Intervals ......................... 5-3

Every 10 Hours or Daily ....................... 5-4

Every 250 Hours or Every 3 Months ... 5-7

Every 500 Hours or Every 6 Months ... 5-8

Every 1000 Hours or 1 Year ............... 5-11

Every 2000 Hours or 2 Years ............. 5-12

When Required ................................... 5-13

LUBRICATION AND MAINTENANCE -

CAT TIER 4 FINAL

General Information ............................. 6-1

Maintenance Intervals ......................... 6-3

Every 10 Hours or Daily ....................... 6-4

Every 50 Hours or Weekly ................... 6-7

Every 250 Hours ................................... 6-9

Every 500 Hours ................................... 6-9

Every 500 Hours or 1 Year ................. 6-10

Every 1000 Hours ............................... 6-18

Every 1500 Hours ............................... 6-18

Every 2000 Hours ............................... 6-19

When Required ................................... 6-20

NORAM 65ET GRADER

2 Table of Contents NORAM 65ET GRADER

SPECIFICATIONS

Options .................................................7-15

TROUBLESHOOTING

Engine ....................................................8-1

Transmission .........................................8-1

Hydraulics and Implements .................8-2

NORAM 65ET GRADER

1-1

Safety 1

Safety Messages

SECTION 1: SAFETY

SAFETY MESSAGES

General safety messages appear in this Safety Messages section. Specific safety messages are located

in appropriate sections of the manual where a potential hazard may occur if the instructions or

procedures are not followed.

Personal Safety

A signal word “DANGER”, “WARNING”, or “CAUTION” is used with the safety alert symbol.

Safety signs with signal word “DANGER”, “WARNING”, or “CAUTION” are located near specific

hazards.

DANGER Indicates a hazardous situation that, if not avoided, will result in death or serious

injury.

WARNING Indicates a hazardous situation that, if not avoided, could result in death or serious

injury.

CAUTION Indicates a hazardous situation that, if not avoided, could result in minor or

moderate injury.

Machine Safety

NOTICE: The word “NOTICE” is used to inform the reader of something that needs to be known to

prevent machine damage and/or property damage if a certain procedure is not followed.

1

NORAM 65ET GRADER

1-2

Safety

1

Safety Symbol Explanation

SAFETY SYMBOL EXPLANATION

This is the safety alert symbol. This symbol is used in combination with an exclamation

mark or other symbols to alert you to the potential for bodily injury or death.

Read Operator’s Manual and safety signs before operating machine.

Check machine before operating. Machine must be in good operating condition

and all safety equipment installed and functioning properly.

Wear personal protective equipment as required by the job. Dress properly.

Wear close fitting clothing and confine long hair. Avoid wearing jewelry such as

rings, wrist watches, necklaces or bracelets. Consult your employer, site

supervisor or OSHA for specific requirements for:

• a hard hat

• safety glasses

• work shoes or boots

• reflective clothing

• hearing protection

• gloves, as needed

Keep spectators away.

NORAM 65ET GRADER

1-3

Safety 1

Safety Symbol Explanation

Refer to and follow the Shutdown Procedure before servicing, cleaning,

repairing, or transporting machine.

Pressurized fluid can penetrate body tissue and result in serious injury or death.

Leaks can be invisible. Keep away from any suspected leak. Relieve pressure in

the hydraulic system before searching for leaks, disconnecting hoses, or

performing any other work on the system. If you must pressurize the system to

find a suspected leak, use an object such as a piece of wood or cardboard rather

than your hands. When loosening a fitting where some residual pressure may

exist, slowly loosen the fitting until oil begins to leak. Wait for leaking to stop

before disconnecting the fitting. Fluid injected under the skin must be removed

immediately by a surgeon familiar with this type of injury.

Contact with moving parts can cause death or serious injury.

• Keep hands, feet, and clothing away from power-driven parts.

• Wear close-fitting clothing and confine long hair. Avoid wearing jewelry,

such as rings, wristwatches, necklaces, or bracelets.

• Keep all shields and guards in place and properly secured.

Explosion and separation of a tire can cause serious injury or death.

• Never stand beside the tire when inflating.

• Never inflate beyond the tire manufacturer’s recommended tire pres-

sure.

• Always mount, demount or inflate tires with properly trained and quali-

fied personal.

Diesel Exhaust Fluid (DEF) may cause eye irritation and can be moderately

irritating to the skin. Exposure to decomposition products may cause a health

hazard. Serious effects may be delayed following exposure.

DEF is not expected to produce significant adverse health effects when the

recommended instructions for use are followed.

• DO NOT breathe DEF vapor or mist.

• DO NOT eat, drink, or smoke when using DEF.

• Avoid DEF contact with eyes, skin, and clothing.

• Wash thoroughly after handling DEF.

1

NORAM 65ET GRADER

1-4

Safety

1

Safety Symbol Explanation

General Safety Messages

• Only responsible persons, delegated to do so, should operate any machine.

• Be sure safety shields, guards, and barriers are in place and in good condition before starting

the machine.

• Check to see that all personnel are clear of the machine before starting.

• Place all controls in NEUTRAL or OFF position when shutting the machine down. Apply the

park brake. Be sure all controls are in NEUTRAL or OFF position and the park brake is applied

before starting the engine.

• When parking the machine for the night, provide the appropriate lighting and marking if the

machine is adjacent to a roadway or a construction area where work is in progress.

• DO NOT leave the machine unattended when the engine is running.

• Keep the machine clean. The process of cleaning will reveal loose bolts, hydraulic lines, fittings

and other trouble spots.

• Always keep the operator’s platform clean and free from grease, oil, rags, and loose tools to help

prevent slipping and falling.

• Before cleaning, adjusting or servicing the machine, shut engine down and place all controls and

switches in neutral or off position. Completely lower all attachments, or securely support raised

components. A variation of the above procedure may be used if instructed within this manual.

• Refuel the machine only with the engine OFF. Never smoke or have an open flame in area when

refueling.

• Refill or check the radiator only when the engine is OFF and the radiator is not hot. Turn cap

slowly to the first stop to relieve the pressure before removing the cap.

• Before starting or continuing operation, correct or report any mechanical deficiency that may

cause further damage.

• Securely support with suitable blocking the mainframe, moldboard or other components that

are suspended or held aloft by slings, hoists, jacks or hydraulic cylinders before working under

or between them.

• Make no modifications to your equipment unless specifically requested by NorAm.

• No riders allowed on machine. Only a seated operator, with seat belt securely fastened, is per-

mitted on the machine during grading operation or when roading between job sites. Operator’s

platform is for properly trained and qualified personnel only.

The following general safety rules are important for safe operation of the

machine.

NORAM 65ET GRADER

1-5

Safety 1

Safety Symbol Explanation

Slope Operation Safety

Drive the machine at a speed suitable for the terrain. Avoid sudden stopping, starting or turning.

Avoid traveling across slopes. Drive up and down slopes when possible. Safe operating slope depends

upon many factors, including:

• Keep moldboard low and close to the ground. Lower moldboard to ground if machine starts to

slip.

• Select the same gear when going downhill as would be used going uphill. Select the gear before

starting down slope. DO NOT freewheel down slopes or hills.

• Uphill or downhill position of moldboard

• Uneven, rough or slippery ground conditions

• Potential for ground giving way, causing either unplanned forward, reverse, or sideways tilt

• Nearness of ditches, ruts, stumps, or other obstructions and sudden changes in slope

• Travel speed and turning rate

• Front axle only steering versus frame articulation and front axle steering

• Braking performance

• Skill of operator

Safety Decals - Inspect

Safety decals located on your machine contain important and useful information that will help you

operate your equipment safely. To assure that all decals remain in place and in good condition, follow

the instructions given below:

• Keep decals clean. Use soap and water, not mineral spirits, abrasive cleaners, or other similar

cleaners that will damage the decal.

• Replace any damaged or missing decals. When attaching decals, the temperature of the mount-

ing surface must be at least 40°F (5°C). The mounting surface must also be clean and dry.

• When replacing a machine component with a decal attached, replace the decal also.

• Replacement decals can be purchased from your NorAm dealer.

Check Laws And Regulations

Know and obey all federal, state, and local laws and regulations that apply to your work situation.

Fire Extinguisher

Fire extinguisher (not supplied with machine) should be mounted on the machine for easy access to

the operator.

Failure to follow any of the preceding safety instructions or those that follow

within this manual, could result in serious injury or death. This machine is to be

used only for those purposes for which it was intended as explained in this

operator’s manual.

1

NORAM 65ET GRADER

1-6

Safety

1

Safety Decal Locations

SAFETY DECAL LOCATIONS

NORAM 65ET GRADER

2-1

General Information 2

Intended Use

SECTION 2: GENERAL INFORMATION

INTENDED USE

The 65ET motor grader is intended for construction and maintenance of dirt and gravel roads, site

preparation for paved roads and buildings, and maintenance of road shoulders and ditches.

Always use the machine in accordance with the instructions contained in this Operation and

Maintenance Manual, safety signs on the machine, and other material provided by NorAm.

Proper maintenance and repair is essential for safety, and for efficient operation of the machine. DO

NOT use the machine if it is not in suitable operating condition.

INTRODUCTION TO THIS MANUAL

This manual provides correct procedures for break-in, driving, operating and maintaining your

machine.

Read this manual carefully and keep it tethered to the manual holder on the machine for future

reference. If at any time a question arises concerning the equipment, contact an authorized NorAm

dealer. Factory trained personnel, genuine replacement parts and the necessary equipment are

available for all service requirements.

This machine has been designed and built to give outstanding performance and ease of operation

under a variety of operating conditions. To maintain your machine and ensure trouble free operation,

the routine maintenance as specified in this manual must be carried out at the recommended

intervals. Prior to delivery, the machine was carefully inspected at the factory and by your dealer.

All information in this manual is based on the latest information available at the time of publication.

Dimensions and weight are approximate and the illustrations may not show the equipment in

standard configuration. Your machine may have product improvements and features not yet

contained in this manual.

NorAm reserves the right to make changes at any time without notice or obligation.

1

NORAM 65ET GRADER

2-2

General Information

2

Orientation

ORIENTATION

References are made throughout this manual to describe

location and direction. Unless otherwise specified,

reference to direction is from the operator's seat.

MACHINE DESCRIPTION

The grader is a construction machine with a long moldboard blade used to create a flat surface during

the grading process. The grader has a front and rear axle, with the engine and operator station

located on the rear module.

The grader is articulated between the front and rear axles. Articulation allows the grader to bend at a

pivot point between the front and rear modules. Steering is achieved through the front tires, together

with front tire lean, and frame articulation.

The moldboard is attached to the turn circle suspended from the front frame by an “A” frame drawbar

positioned by a series of hydraulic cylinders.

Power from a Caterpillar C3.4B Tier 4 Final or Cummins QSF3.8 Tier 4 Final engine is delivered

through a full power shift transmission, with torque converter, to the rear axle, equipped with a

torque proportioning rear differential, and through tandem cases to the rear wheels.

An optional dozer blade, ripper and scarifier implements and cab, with heater and optional air

conditioning are available. The cab is ROPS and FOPS certified.

NORAM 65ET GRADER

2-3

General Information 2

Identification Numbers

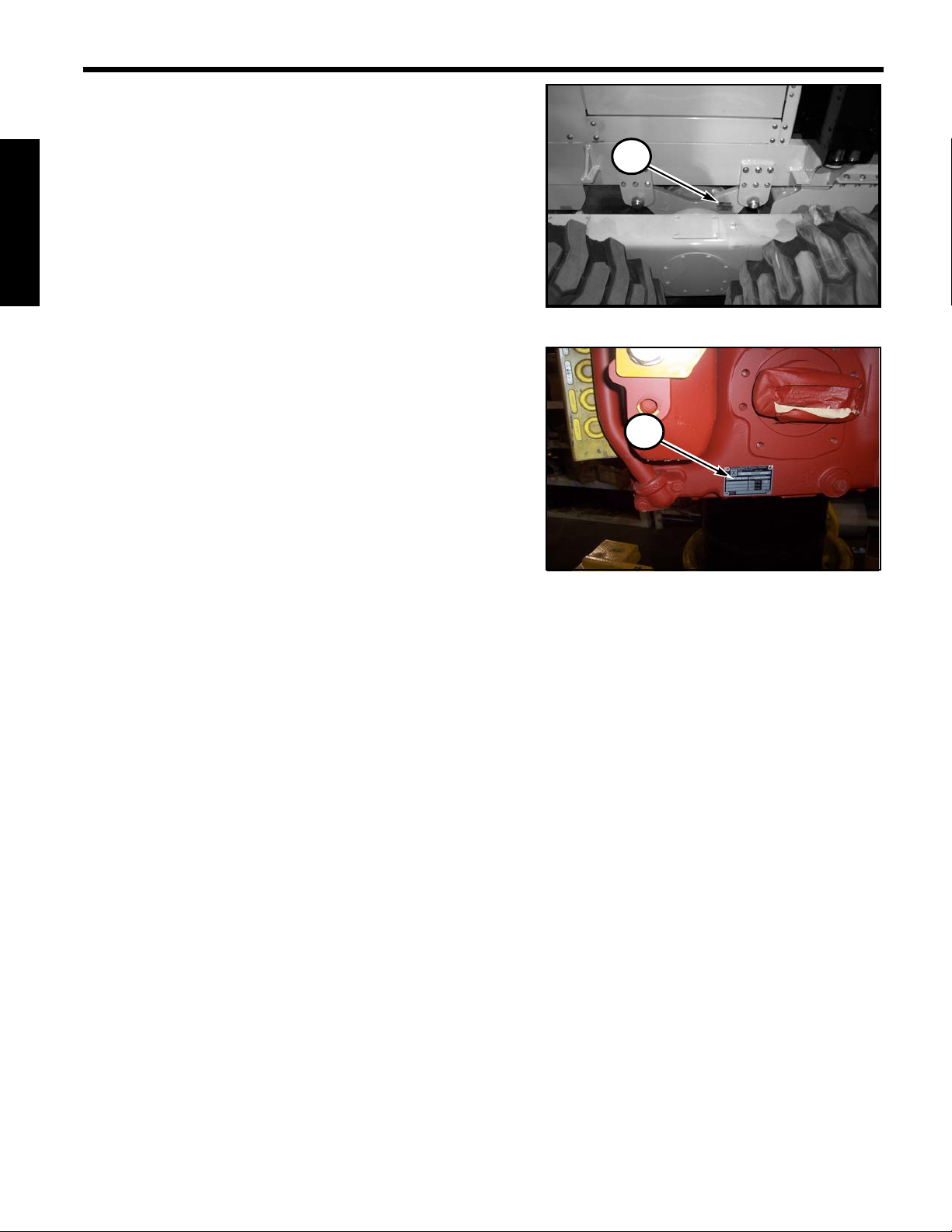

IDENTIFICATION NUMBERS

The motor grader and major components are identified by serial numbers. The serial numbers are

required when ordering parts. For easy reference the identification data should be recorded and kept

in a safe place away from the machine.

The vehicle serial number and point of manufacture is

stamped into the serial tag (1) placed on the left side of

the steering column.

The vehicle serial number (1) is also stamped into to

right side of the frame below the operators platform.

An engine identification plate (1) is located on the top of the Cummins engine and on the left side of

the Cat engine.

CUMMINS T4 FINAL ENGINE CAT T4 FINAL ENGINE

1

1

1

1

1

NORAM 65ET GRADER

2-4

General Information

2

Identification Numbers

The differential identification plate (1) is located on the

right tandem support.

The transmission identification plate (1) is located on the

front side of the transmission below the drive shaft.

1

1

NORAM 65ET GRADER

2-5

General Information 2

Component Identification and Locations

COMPONENT IDENTIFICATION AND LOCATIONS

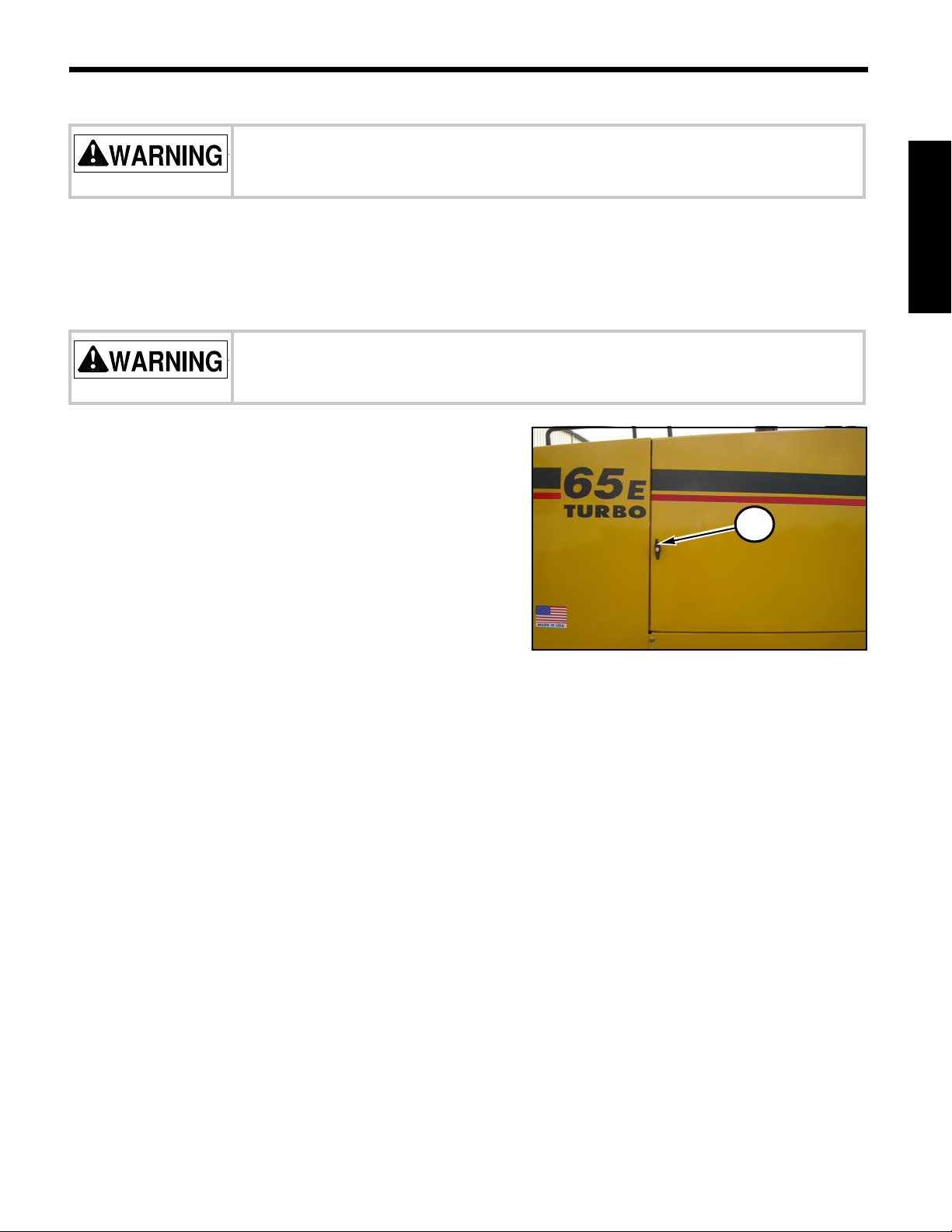

Protective Shield

The engine and transmission are enclosed to protect personnel from hot and moving parts. An

additional guard encloses the cooling fan.

Engine access doors are located on each side of the engine

cover. A lock is in the handle (1). Turn the handle

clockwise 180° to unlatch and counter-clockwise 180° to

latch.

DO NOT operate machine until thoroughly familiar with the location and operation

of all controls.

DO NOT operate motor grader with engine enclosure removed or access doors

open and unlatched. DO NOT operate with fan guard removed or broken.

1

1

NORAM 65ET GRADER

2-6

General Information

2

Component Identification and Locations

When equipped with the Cummins QSF3.8 Tier 4 Final engine, opening the left side engine

compartment door provides access to the following:

1Electronic Control Module (ECM) 6Fuel Pump

2Crankcase Breather 7Oil Fill

3Water Pump 8Water Separator

4Oil Filter 9Fuel Primer

5Fuel Filter 10 Air Cleaner

3

2

4

1

8

7

6

5

Cummins QSF3.8 Tier 4 Final

10

9

NORAM 65ET GRADER

2-7

General Information 2

Component Identification and Locations

When equipped with the Cummins QSF3.8 Tier 4 Final engine, opening the right side engine

compartment door provides access to the following:

1Air Filter Indicator 10 SCR System

2Hydraulic Tank Filter 11 Heater Core Shutoff Valve

3Hydraulic Tank Fill 12 Heater Control Circuit Breaker

4Hydraulic Tank Sight Gauge 13 Stud Fuse

5A/C Dryer 14 Main Power Circuit Breaker

6Master Switch 15 Alternator

7Engine Diagnostic Port 16 Washer Fluid Tank

8Fuse Panel 17 Starter

9Turbocharger 18 A/C Condenser

Cummins QSF3.8 Tier 4 Final

110

2

34

6

578

9

11

13

14

15

16

17 18

12

1

NORAM 65ET GRADER

2-8

General Information

2

Component Identification and Locations

When equipped with the CAT C3.4B Tier 4 Final engine, opening the left side engine compartment

door provides access to the following:

1Engine Electronic Control Module (ECM) 8Fuel Primer

2Glow Plug Control Unit (GPCU) 9Water Separator

3Diesel Exhaust Fluid (DEF) Injector 10 Fuel Filter

4Selective Catalytic Reduction (SCR) 11 Engine Oil Filter

5A/C Compressor 12 Engine Oil Fill

6A/C Dryer 13 Hydraulic Tank Access Cover

7Heater Core Shutoff Valve 14 Air Cleaner

2

5

1

3

CAT C3.4B Tier 4 Final

10

9

13

8

12

11

4

6

7

14

NORAM 65ET GRADER

2-9

General Information 2

Component Identification and Locations

When equipped with the CAT C3.4B Tier 4 Final engine, opening the right side engine

compartment door provides access to the following:

1Hydraulic Tank Filter 10 NOx Sensors

2Hydraulic Filter Gauge 11 Ammonia Sensor (on back of panel)

3Hydraulic Tank Fill 12 Air Filter Indicator

4Hydraulic Tank Sight Gauge 13 Heater Control Circuit Breaker

5Master Switch 14 Main Power Circuit Breaker

6Wait To Disconnect Lamp 15 Alternator

7Engine Diagnostic Port 16 Washer Fluid Tank

8Fuse Panel 17 Engine Oil Dipstick

9Turbocharger 18 Starter

1

CAT C3.4B Tier 4 Final

10

2

34

6

5

78

9

11

12

13

14

15

16

18

17

1

NORAM 65ET GRADER

2-10

General Information

2

Component Identification and Locations

The radiator access door (1) is located on top of the engine cover. The hydraulic reservoir fill cap (2)

and transmission oil fill and dipstick (3) are located behind the right side engine access door.

The fuel fill neck (4) and DEF fill neck (5) are located

behind the left side access door.

FOPS and ROPS

All motor graders are equipped with a Roll Over Protection System (ROPS), Falling Object Protection

System (FOPS) and a seat belt.

Optional for the 65ET is an enclosed cab with heater and optional air conditioning. The cab is also

FOPS and ROPS certified.

1

2

3

54

Table of contents

Other NorAM Construction Equipment manuals