Contents

Revision history.................................. iii

1Introduction................................... 4

2Minimum requirements............................ 5

3Kit content.................................... 6

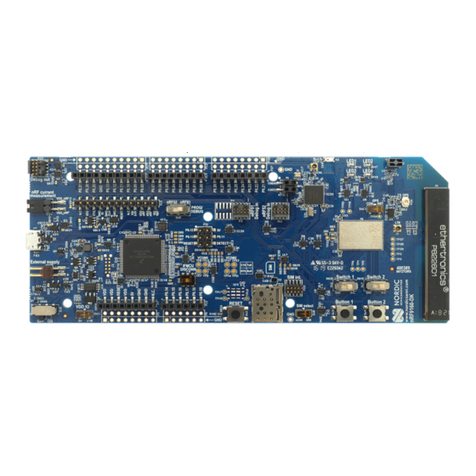

4Hardware description.............................. 7

4.1 Hardware figures .................................7

4.2 Block diagram .................................. 8

4.3 Power supply .................................. 8

4.4 LEDs ...................................... 9

4.5 Switches .................................... 9

4.5.1 Charge voltage termination .......................... 9

4.5.2 Charge current limit ............................. 10

4.5.3 Output voltage configuration ......................... 10

4.5.4 Buck regulator mode ............................. 11

4.5.5 VBUS current limit .............................. 11

4.6 Buttons .................................... 11

4.6.1 Ship mode activation .............................11

4.6.2 Ship mode disabling ............................. 12

4.7 Solder bridge configuration ............................ 12

4.8 NTC configuration ................................ 12

5Measuring current............................... 13

5.1 Preparing the nPM1100 EK ............................ 13

5.1.1 Preparing for VBUS current measurements ....................14

5.1.2 Preparing for VBAT current measurements .................... 14

5.1.3 Preparing for VOUTB current measurements ................... 14

5.2 Using an oscilloscope for current profile measurement ................ 15

5.3 Using an ampere meter for current measurements .................. 16

5.4 Using the Power Profiler Kit II for current measurements ................16

5.4.1 Measuring VBUS current ........................... 16

5.4.2 Measuring VBAT current ........................... 17

5.4.3 Measuring VOUTB current .......................... 18

Glossary ..................................... 20

Acronyms and abbreviations............................21

Recommended reading.............................. 22

Legal notices................................... 23

4477_012 ii