3

1 Introduction 4

1.1 To the very beginning 4

1.2 Notes on the operating instructions 4

2 For your safety 6

3 Product Overview 8

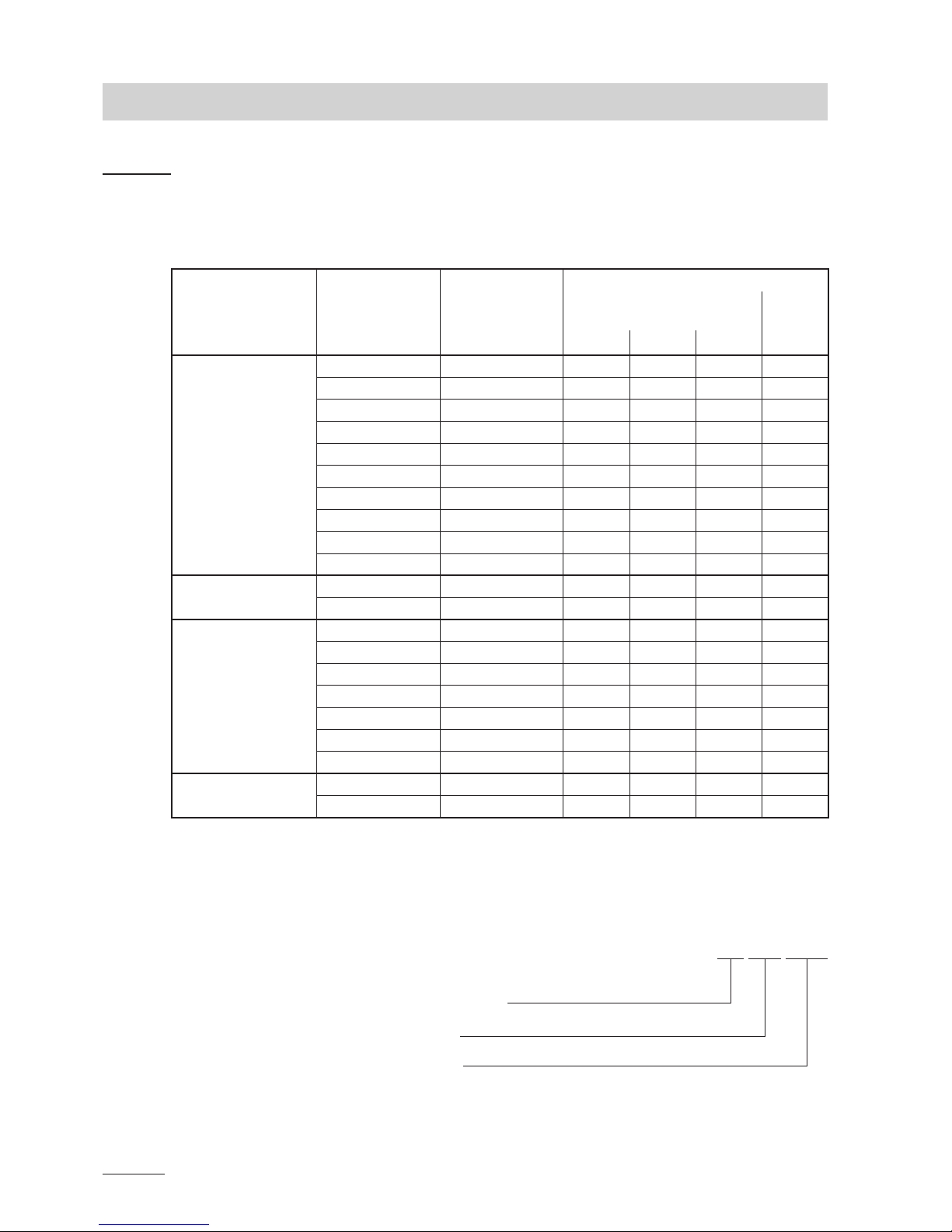

3.1 Models overview 8

3.2 Identicationoftheunit 9

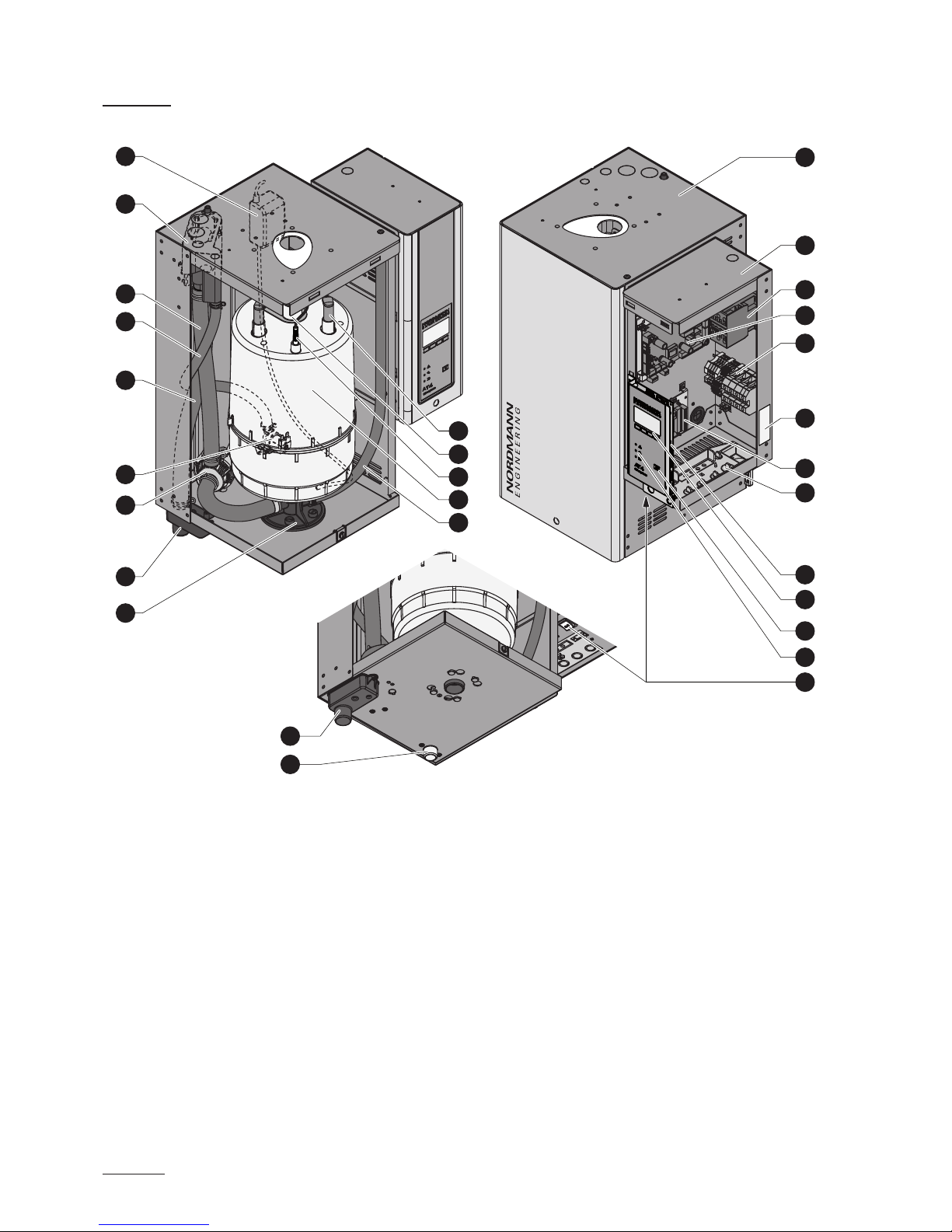

3.3 Steamhumidierconstruction 10

3.4 Functional description 11

3.5 Humidicationsystemoverview 13

4 Operation 17

4.1 Commissioning 17

4.2 Notes on operation 18

4.2.1 Functionofthedisplayandoperatingelements 18

4.2.2 Remoteoperatingandfaultindication 19

4.2.3 Notes on the operation at ambient

temperatures≤0°C 19

4.2.4 Inspections during operation 19

4.3 Carrying out manual draining 20

4.4 Takingtheunitoutofoperation 20

5 Working with the unit control 21

5.1 Factory settings 21

5.2 Operating the control unit and menu overview 22

5.3 Interrogationoftheoperatinginformationin

the indication level 23

5.4 Unit settings 24

5.4.1 Launching the unit settings menu 24

5.4.2 Selecting the dialogue language 24

5.4.3 Control settings 24

5.4.3.1 Selecting the signal source 25

5.4.3.2 Selecting the regulation mode 25

5.4.3.3 Selecting the control signal 25

5.4.3.4 Conguringhumiditysetpoint 26

5.4.3.6 Settingtheproportionalrangefortheinternal

P/PI controller 27

5.4.3.7 SettingtheintegraltimefortheinternalPIcontroller 27

5.4.3.8 Activating/Deactivating the supply air limitation 27

5.4.3.9 Selecting the supply air limitation signal 28

5.4.3.10 Settingthelowerlimitvalueforthe

supply air limitation 28

5.4.3.11 Settingtheupperlimitvalueforthe

supply air limitation 28

5.4.4 Selecting the cylinder type 29

5.4.5 ConguringtheSCsystem 29

5.4.5.1 Activating/deactivating the SC system 29

5.4.5.2 SettingtheoperationtimeoftheSC-Pump 30

5.4.6 Conguringthecapacitylimitation 30

5.4.7 ConguringtheOn/Offtimer 32

5.4.8 Water management settings 33

5.4.8.1 Selectingtheconductivityrangeofthesupplywater 33

5.4.8.2 Settingthedrainfactor 33

5.4.8.3 Settingtheoperatingmodeforstandbyoperation 34

5.4.8.4 Activating/Deactivatingtheforceddraining 36

5.4.8.5 Settingthetimeofoperationafterwhicha

forceddrainingtakesplace 37

5.4.9 Setting the date 37

5.4.10 Setting the time 37

5.4.11 Setting the display contrast 37

5.5 Modbus settings 38

5.5.1 SettingsforModbusnetworks 38

5.5.2 Settingsforthecommunicationwiththe

optional remote terminal 39

Contents

5.6 Diagnosticfunctions 40

5.6.1 Interrogationoftheerrorhistory 40

5.6.2 Interrogationofunitinformation 41

5.6.3 Performingremoterelaytests 42

5.6.4 PerformingModuletests 42

5.7 Working with the remote terminal 43

5.7.1 Menu overview remote terminal 43

5.7.2 Remote terminal settings 44

5.7.2.1 Selecting the dialogue language 44

5.7.2.2 Settingthenumberofhumidiersconnected

to the remote terminal 44

5.7.2.3 Interrogationoftheerrorhistoryofthe

remote terminal 44

5.7.2.4 Resettingtheerrorhistorylistofthe

remote terminal 45

5.7.2.5 Setting the baudrate 45

5.7.2.6 Setting the display contrast 45

6 Maintenance 46

6.1 Important notes on maintenance 46

6.2 Maintenance list 47

6.3 Removingandinstallingpartsformaintenance 48

6.3.1 Removalandinstallationofthesteamcylinder 48

6.3.2 Removalandinstallationofthedraincup 51

6.3.3 Removalandinstallationofthewatercup

and the water hoses 52

6.3.4 Removalandinstallationofthedrainpump 53

6.3.5 Removalandinstallationoftheinletvalve 54

6.3.6 Removalandinstallationofthecylinderreceptacle 55

6.4 Notes on cleaning the unit components 56

6.5 Notes on cleaning agents 58

6.6 Resetting the maintenance indication 58

7 Fault elimination 59

7.1 Fault indication 59

7.2 Malfunctionlists 60

7.2.1 Systemfaults 60

7.2.2 Unitfaults 61

7.3 Resetting the error indication (red LED lights) 63

7.4 Notesonfaultelimination 63

7.5 Replacing the backup battery on the control board 64

8 Taking out of service/Disposal 65

8.1 Takingoutofservice 65

8.2 Disposal/Recycling 65

9 Productspecications 66

9.1 Technical data 66

9.2 Wiring diagram Nordmann AT4 67

9.2.1 Wiring diagram Nordmann AT4 single units 67

9.2.2 Wiring diagram Nordmann AT4 double units 68