Nordson EFD E2V User manual

EV Series Automated Dispensing Systems

Operating Manual

™

Electronic pdf les of Nordson EFD

manuals are also available at

www.nordsonefd.com

www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

EV Series Automated Dispensing Systems

2

You have selected a reliable, high-quality dispensing system from Nordson EFD, the world leader in

uid dispensing. Nordson EFD automated dispensing systems are designed specically for industrial

dispensing and will provide you with years of trouble-free, productive service.

This manual will help you maximize the usefulness of your automated dispensing system.

Please spend a few minutes to become familiar with the controls and features. Follow our recommended

testing procedures. Review the helpful information we have included, which is based on more than

50years of industrial dispensing experience.

Most questions you will have are answered in this manual. However, if you need assistance, please do

not hesitate to contact EFD or your authorized EFD distributor. Detailed contact information is provided

on the last page of this document.

The Nordson EFD Pledge

Thank You!

You have just purchased the world’s nest precision dispensing equipment.

I want you to know that all of us at Nordson EFD value your business and will do everything in our power

to make you a satised customer.

If at any time you are not fully satised with our equipment or the support provided by your Nordson

EFD Product Application Specialist, please contact me personally at 800.556.3484 (US), 401.431.7000

I guarantee that we will resolve any problems to your satisfaction.

Thanks again for choosing Nordson EFD.

Srini Subramanian, General Manager

Srini Subramanian

www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

EV Series Automated Dispensing Systems

3

Contents..........................................................................................................................................................................3

Introduction .....................................................................................................................................................................5

Nordson EFD Product Safety Statement ........................................................................................................................6

Halogenated Hydrocarbon Solvent Hazards ...............................................................................................................7

High Pressure Fluids....................................................................................................................................................7

Qualied Personnel......................................................................................................................................................7

Intended Use ...............................................................................................................................................................8

Regulations and Approvals..........................................................................................................................................8

Personal Safety............................................................................................................................................................8

Fire Safety....................................................................................................................................................................9

Preventive Maintenance ..............................................................................................................................................9

Important Disposable Component Safety Information ..............................................................................................10

Action in the Event of a Malfunction..........................................................................................................................10

Disposal .....................................................................................................................................................................10

Equipment-Specic Safety Information.....................................................................................................................11

Specications................................................................................................................................................................12

Operating Features........................................................................................................................................................13

EV Series System Component Identication.............................................................................................................13

EV Front Panel........................................................................................................................................................14

EV Back Panel........................................................................................................................................................14

Camera ......................................................................................................................................................................15

Joystick......................................................................................................................................................................15

Installation .....................................................................................................................................................................16

Unpack the System Components..............................................................................................................................16

Position the Robot and Install and Connect Components ........................................................................................17

Check the Camera and Dispenser Installation ..........................................................................................................19

Prepare the Work Surface or Fixture Plate ................................................................................................................20

Connect Inputs / Outputs (Optional)..........................................................................................................................20

Power On the System................................................................................................................................................21

Concepts.......................................................................................................................................................................22

About Programs and Commands..............................................................................................................................22

About Offsets.............................................................................................................................................................23

About Marks ..............................................................................................................................................................24

Overview of the DispenseMotion Software...................................................................................................................25

Primary View Screen and Tab Bar .............................................................................................................................26

Secondary View Screen.............................................................................................................................................27

Horizontal and Vertical Toolbar Icons ........................................................................................................................28

Setup and Dispense Command Icons.......................................................................................................................29

Navigation and Jogging Window...............................................................................................................................30

System Setup Screen ................................................................................................................................................31

Camera Screen, Tab Bar, and Icons ..........................................................................................................................32

Camera Setup Screen ...............................................................................................................................................33

Keypad.......................................................................................................................................................................33

Continued on next page

Contents

www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

EV Series Automated Dispensing Systems

4

Setup .............................................................................................................................................................................34

Setting System Parameters .......................................................................................................................................34

Restoring the System to the Factory Default Settings ..............................................................................................36

Setting Password Protection .....................................................................................................................................36

Setting Up and Calibrating the System (Required)....................................................................................................37

Verifying the Robot Model and Tip Detector Selection..........................................................................................37

(Only EV Systems With a Tip Detector) Setting Up the Tip Detector.....................................................................38

Focusing and Calibrating the Camera ...................................................................................................................39

Setting the Camera-to-Tip Offset...........................................................................................................................41

Setting the Tip-to-Workpiece Offset (Z Clearance) Using the Camera Focus .......................................................43

Testing the System Setup and Calibration.............................................................................................................44

How the System Responds to Needle Z Detect or Needle XY Adjust...................................................................44

Setting Up Inputs / Outputs.......................................................................................................................................45

Conguring Input / Outputs for a Special Purpose ...................................................................................................45

Setting How the System Responds When a Mark is Absent (Optional) ....................................................................46

Setting How the System Finds Marks (Optional).......................................................................................................46

Setting How the System Captures Z Height Values (Optional)..................................................................................47

Programming.................................................................................................................................................................48

How to Automatically Update Offsets .......................................................................................................................48

How to Create and Run a Program ...........................................................................................................................49

How to Lock or Unlock a Program ............................................................................................................................50

How to Measure a Path or Circle on a Workpiece.....................................................................................................50

How to Create Patterns .............................................................................................................................................51

Dispense Dot Sample Program..............................................................................................................................51

Lines and Arcs Sample Program............................................................................................................................51

Circle Sample Program ..........................................................................................................................................52

How to Use the Example Icon ...................................................................................................................................52

How to Create a Mark................................................................................................................................................53

How to Use Marks or Fiducial Marks in a Program...................................................................................................54

How to Dispense on Multiple Workpieces in an Array...............................................................................................55

How to Disable Dispensing for Specic Workpieces in an Array ..............................................................................56

How to Set Up Auto Purge, Program Cycle Limits, or Fluid Working Life Limits ......................................................57

How to Use Point Offset to Adjust All Points in a Program .......................................................................................58

Operation.......................................................................................................................................................................59

Starting the System and Running a Program ............................................................................................................59

Running a Program by Scanning a QR Code ............................................................................................................60

Pausing During a Dispense Cycle..............................................................................................................................60

Purging the System ...................................................................................................................................................60

Shutting Down the System ........................................................................................................................................60

Accessories ...................................................................................................................................................................61

Pre-Congured Output Cables ..................................................................................................................................61

Fixture Plates .............................................................................................................................................................61

Start / Stop Box .........................................................................................................................................................61

Tip Detector ...............................................................................................................................................................61

Height Sensor ............................................................................................................................................................62

Mounting Brackets ....................................................................................................................................................62

Technical Data ...............................................................................................................................................................63

Dimensions ................................................................................................................................................................63

Mounting Hole Template............................................................................................................................................63

Wiring Diagrams ........................................................................................................................................................64

Dispenser Port .......................................................................................................................................................64

Ext. Control Port.....................................................................................................................................................64

I/O Port...................................................................................................................................................................65

Example Input / Output Connections.....................................................................................................................66

Contents (continued)

Continued on next page

www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

EV Series Automated Dispensing Systems

5

Introduction

This manual provides installation, setup, programming, operation, and service information for all components of a

Nordson EFD EV Series automated dispensing system. Nordson EFD’s automated dispensing systems dispense

uid in a preprogrammed pattern onto a workpiece. They are specically designed and congured for use with

Nordson EFD industrial syringe barrel and valve systems. Automated dispensing systems offer the exibility of

working either as a stand-alone system or as a key part of an automated solution and are easily integrated into in-

line transfer systems, rotary tables, and pallet assembly lines.

The primary components of an automated dispensing system are the DispenseMotion™controller, the robot, and the

dispensing system components. The robot executes a computer program to dispense uid in a specic pattern onto

a workpiece. Programs are created using the DispenseMotion software installed on the DispenseMotion controller.

The dispensing system may be contact or non-contact, with material being dispensed through either a dispensing

tip or nozzle. For the purposes of this manual, “dispensing tip” refers to either a tip or a nozzle.

Using the precision-vision camera, the robot can automatically adjust the dispensing program for each workpiece,

allowing for variations in the workpiece position or orientation. To accomplish this, the software compares the

current workpiece location to within +/- 2.5 mm (0.098") of a reference location that is stored as an image le (called

a mark le) in the program. If the robot detects a difference in the X and Y positions and/or the angle of rotation of

the workpiece, it adjusts the dispensing path to correct for the difference.

Appendix A, Command Function Reference.................................................................................................................67

Appendix B, DXF File Import.........................................................................................................................................84

Overview of the DXF Screen......................................................................................................................................84

Setting DXF Import Preferences ................................................................................................................................85

Importing a DXF File ..................................................................................................................................................86

Appendix C, QR Code Scanning Setup ........................................................................................................................89

Appendix D, Multi-Needle Setup and Use ....................................................................................................................92

Appendix E, Height Sensor Setup and Use ..................................................................................................................97

Appendix F, I/O Pin Function Setup ............................................................................................................................101

Contents (continued)

www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

EV Series Automated Dispensing Systems

6

Nordson EFD Product Safety Statement

The safety messages that follow have a CAUTION level hazard.

Failure to comply may result in minor or moderate injury.

CAUTION

READ MANUAL

Read manual for proper use of this equipment. Follow all safety instructions. Task- and equipment-

specic warnings, cautions, and instructions are included in equipment documentation where

appropriate. Make sure these instructions and all other equipment documents are accessible to

persons operating or servicing equipment.

The safety message that follows has a WARNING level hazard.

Failure to comply could result in death or serious injury.

WARNING

ELECTRIC SHOCK

Risk of electric shock. Disconnect power before removing covers and/or disconnect, lock out, and

tag switches before servicing electrical equipment. If you receive even a slight electrical shock, shut

down all equipment immediately. Do not restart the equipment until the problem has been identied

and corrected.

MAXIMUM AIR PRESSURE

Unless otherwise noted in the product manual, the maximum air input pressure is 7.0 bar (100 psi).

Excessive air input pressure may damage the equipment. Air input pressure is intended to be applied

through an external air pressure regulator rated for 0 to 7.0 bar (0 to 100 psi).

RELEASE PRESSURE

Release hydraulic and pneumatic pressure before opening, adjusting, or servicing pressurized

systems or components.

BURNS

Hot surfaces! Avoid contact with the hot metal surfaces of heated components. If contact can not be

avoided, wear heat-protective gloves and clothing when working around heated equipment. Failure

to avoid contact with hot metal surfaces can result in personal injury.

www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

EV Series Automated Dispensing Systems

7

Nordson EFD Product Safety Statement (continued)

Halogenated Hydrocarbon Solvent Hazards

Do not use halogenated hydrocarbon solvents in a pressurized system that contains aluminum components.

Under pressure, these solvents can react with aluminum and explode, causing injury, death, or property damage.

Halogenated hydrocarbon solvents contain one or more of the following elements.

Element Symbol Prefix

Fluorine F “Fluoro-”

Chlorine Cl “Chloro-”

Bromine Br “Bromo-”

Iodine I “Iodo-”

Check the Safety Data Sheet (SDS) or contact your material supplier for more information. If you must use

halogenated hydrocarbon solvents, contact your EFD representative for compatible EFD components.

High Pressure Fluids

High pressure uids, unless they are safely contained, are extremely hazardous. Always release uid pressure before

adjusting or servicing high pressure equipment. A jet of high pressure uid can cut like a knife and cause serious

bodily injury, amputation, or death. Fluids penetrating the skin can also cause toxic poisoning.

WARNING

Any injury caused by high pressure liquid can be serious. If you are injured or even suspect an injury:

• Go to an emergency room immediately.

• Tell the doctor that you suspect an injection injury.

• Show the doctor the following note.

• Tell the doctor what kind of material you were dispensing.

Medical Alert — Airless Spray Wounds: Note to Physician

Injection in the skin is a serious traumatic injury. It is important to treat the injury surgically as soon as possible. Do

not delay treatment to research toxicity. Toxicity is a concern with some exotic coatings injected directly into the

bloodstream.

Qualified Personnel

Equipment owners are responsible for making sure that EFD equipment is installed, operated, and serviced by

qualied personnel. Qualied personnel are those employees or contractors who are trained to safely perform

their assigned tasks. They are familiar with all relevant safety rules and regulations and are physically capable of

performing their assigned tasks.

www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

EV Series Automated Dispensing Systems

8

Nordson EFD Product Safety Statement (continued)

Intended Use

Use of EFD equipment in ways other than those described in the documentation supplied with the equipment may

result in injury to persons or damage to property. Some examples of unintended use of equipment include:

• Using incompatible materials.

• Making unauthorized modications.

• Removing or bypassing safety guards or interlocks.

• Using incompatible or damaged parts.

• Using unapproved auxiliary equipment.

• Operating equipment in excess of maximum ratings.

• Operating equipment in an explosive atmosphere.

Regulations and Approvals

Make sure all equipment is rated and approved for the environment in which it is used. Any approvals obtained for

Nordson EFD equipment will be voided if instructions for installation, operation, and service are not followed. If the

equipment is used in a manner not specied by Nordson EFD, the protection provided by the equipment may be

impaired.

Personal Safety

To prevent injury, follow these instructions:

• Do not operate or service equipment unless you are qualied.

• Do not operate equipment unless safety guards, doors, and covers are intact and automatic interlocks are

operating properly. Do not bypass or disarm any safety devices.

• Keep clear of moving equipment. Before adjusting or servicing moving equipment, shut off the power supply

and wait until the equipment comes to a complete stop. Lock out power and secure the equipment to prevent

unexpected movement.

• Make sure spray areas and other work areas are adequately ventilated.

• When using a syringe barrel, always keep the dispensing end of the tip pointing towards the work and away

from the body or face. Store syringe barrels with the tip pointing down when they are not in use.

• Obtain and read the Safety Data Sheet (SDS) for all materials used. Follow the manufacturer’s instructions for

safe handling and use of materials and use recommended personal protection devices.

• Be aware of less-obvious dangers in the workplace that often cannot be completely eliminated, such as hot

surfaces, sharp edges, energized electrical circuits, and moving parts that cannot be enclosed or otherwise

guarded for practical reasons.

• Know where emergency stop buttons, shutoff valves, and re extinguishers are located.

• Wear hearing protection to protect against hearing loss that can be caused by exposure to vacuum exhaust port

noise over long periods of time.

www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

EV Series Automated Dispensing Systems

9

Nordson EFD Product Safety Statement (continued)

Fire Safety

To prevent a re or explosion, follow these instructions:

• Shut down all equipment immediately if you notice static sparking or arcing. Do not restart the equipment until

the cause has been identied and corrected.

• Do not smoke, weld, grind, or use open ames where ammable materials are being used or stored.

• Do not heat materials to temperatures above those recommended by the manufacturer. Make sure heat

monitoring and limiting devices are working properly.

• Provide adequate ventilation to prevent dangerous concentrations of volatile particles or vapors. Refer to local

codes or the SDS for guidance.

• Do not disconnect live electrical circuits when working with ammable materials. Shut off power at a disconnect

switch rst to prevent sparking.

• Know where emergency stop buttons, shutoff valves, and re extinguishers are located.

Preventive Maintenance

As part of maintaining continuous trouble-free use of this product, Nordson EFD recommends the following simple

preventive maintenance checks:

• Periodically inspect tube-to-tting connections for proper t. Secure as necessary.

• Check tubing for cracks and contamination. Replace tubing as necessary.

• Check all wiring connections for looseness. Tighten as necessary.

• Clean: If a front panel requires cleaning, use a clean, soft, damp rag with a mild detergent cleaner. DO NOT USE

strong solvents (MEK, acetone, THF, etc.) as they will damage the front panel material.

• Maintain: Use only a clean, dry air supply to the unit. The equipment does not require any other regular

maintenance.

• Test: Verify the operation of features and the performance of equipment using the appropriate sections of this

manual. Return faulty or defective units to Nordson EFD for replacement.

• Use only replacement parts that are designed for use with the original equipment. Contact your Nordson EFD

representative for information and advice.

www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

EV Series Automated Dispensing Systems

10

Important Disposable Component Safety Information

All Nordson EFD disposable components, including syringe barrels, cartridges, pistons, tip caps, end caps,

and dispense tips, are precision engineered for one-time use. Attempting to clean and re-use components will

compromise dispensing accuracy and may increase the risk of personal injury.

Always wear appropriate protective equipment and clothing suitable for your dispensing application and adhere to

the following guidelines:

• Do not heat syringe barrels or cartridges to a temperature greater than 38° C (100° F).

• Dispose of components according to local regulations after one-time use.

• Do not clean components with strong solvents (MEK, acetone, THF, etc.).

• Clean cartridge retainer systems and barrel loaders with mild detergents only.

• To prevent uid waste, use Nordson EFD SmoothFlow™pistons.

Action in the Event of a Malfunction

If a system or any equipment in a system malfunctions, shut off the system immediately and perform the following

steps:

1. Disconnect and lock out system electrical power. If using hydraulic and pneumatic shutoff valves, close and

relieve pressure.

2. For Nordson EFD air-powered dispensers, remove the syringe barrel from the adapter assembly. For Nordson

EFD electro-mechanical dispensers, slowly unscrew the barrel retainer and remove the barrel from the actuator.

3. Identify the reason for the malfunction and correct it before restarting the system.

Disposal

Dispose of equipment and materials used in operation and servicing according to local codes.

Nordson EFD Product Safety Statement (continued)

www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

EV Series Automated Dispensing Systems

11

Equipment-Specific Safety Information

The following safety information is specic to Nordson EFD automated dispensing systems.

European Community

To meet the requirements of the European Community (CE) safety directives, the robot must be placed in an

enclosure. The enclosure prevents an operator from entering the robot’s work area and generates an emergency

stop signal if the door switch is opened while the robot is running.

WARNING

Install the input/output safety plug only to bypass the door switch. When this plug is installed, the installer assumes

all safety liability.

Installation Location

Do not store, install, or operate the robot in a location where it is exposed to the following:

• Temperatures lower or higher than 0–40° C (50–104° F) or humidity lower or higher than 20–95%

• Direct sunlight

• Electrical noise

• Flammable or corrosive gases

• Dust or iron powder

• Sources of splashing water, oil, or chemicals

• Radioactive materials, magnetic elds, or vacuum rooms

Power and Grounding

• Connect the robot and accessories to a properly grounded power source.

• Make sure the system is connected to the correct voltage.

Operation and Service

• Turn on the dust collection system before operating the robot.

• Do not drop or spill foreign objects or material, such as screws or liquids, into the robot.

• Do not overload the robot.

• Do not touch any part of the robot while it is running. Load and unload workpieces or material only when the

robot is stopped.

• Disconnect and lock out power to the system before changing xtures or tooling.

• Use only a neutral detergent for cleaning. Do not use alcohol, benzene, or thinner.

Nordson EFD Product Safety Statement (continued)

www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

EV Series Automated Dispensing Systems

12

Specifications

Item/Model E2V E3V E4V E5V E6V

Number of axes 3 3 3 3 3

Maximum working area

(X / Y / Z)

150 / 200 / 50 mm

(6 / 8 / 2")

250 / 300 / 100 mm

(10 / 12 / 4")

350 / 400 / 100 mm

(14 / 16 / 4")

450 / 500 / 150 mm

(18 / 20 / 6")

570 / 500 / 150 mm

(22 / 20 / 6")

Workpiece payload 5 kg (11.0 lb) 10 kg (22.0 lb) 10 kg (22.0 lb) 10 kg (22.0 lb) 10 kg (22.0 lb)

Tool payload 1.5 kg (3.3 lb) 3 kg (6.6 lb) 3 kg (6.6 lb) 3 kg (6.6 lb) 3 kg (6.6 lb)

Unit weight 29 kg (64 lb) 47.5 kg (105 lb) 52.5 kg (116 lb) 55 kg (121 lb) 58 kg (128 lb)

Dimensions 480Wx435Hx510Dmm

(19Wx 17Hx 20"D)

595Wx538Hx645Dmm

(23Wx 21Hx 25"D)

695Wx638Hx645Dmm

(27Wx 25Hx 25"D)

795Wx717Hx815Dmm

(31Wx 28Hx 32"D)

915Wx717Hx815Dmm

(36Wx 28Hx 32"D)

Maximum speed

(XY / Z)

500 / 250 mm/sec

(20 / 10"/sec)

800 / 320 mm/sec

(31 / 13"/sec)

800 / 320 mm/sec

(31 / 13"/sec)

800 / 320 mm/sec

(31 / 13"/sec)

800 / 320 mm/sec

(31 / 13”/sec)

Drive system 3-phase micro-

stepping motor

3-phase micro-

stepping motor

3-phase micro-

stepping motor

3-phase micro-

stepping motor

3-phase micro-

stepping motor

Memory capacity PC storage PC storage PC storage PC storage PC storage

Data storage PC storage / USB PC storage / USB PC storage / USB PC storage / USB PC storage / USB

General purpose I/O 8 inputs / 8 outputs

(16 / 16 optional)

8 inputs / 8 outputs

(16 / 16 optional)

8 inputs / 8 outputs

(16 / 16 optional)

8 inputs / 8 outputs

(16 / 16 optional)

8 inputs / 8 outputs

(16 / 16 optional)

Drive method PTP and CP PTP and CP PTP and CP PTP and CP PTP and CP

Dispensing controller External External External External External

Power supply Auto-switching,

AC100–240V, 230 W

Auto-switching,

AC100–240V, 350 W

Auto-switching,

AC100–240V, 350 W

Auto-switching,

AC100–240V, 350 W

Auto-switching,

AC100–240V, 350 W

Interpolation 3 axes (3D space) 3 axes (3D space) 3 axes (3D space) 3 axes (3D space) 3 axes (3D space)

Repeatability* ±0.008 mm/axis ±0.008 mm/axis ±0.008 mm/axis ±0.008 mm/axis ±0.008 mm/axis

Working temperature 10–40° C (50–104° F) 10–40° C (50–104° F) 10–40° C (50–104° F) 10–40° C (50–104° F) 10–40° C (50–104° F)

Precision vision Included Included Included Included Included

DispenseMotion

software Included Included Included Included Included

Tip detection system Optional Optional Optional Optional Optional

Approvals CE, RoHS, WEEE, China RoHS

*Repeatability results may vary depending on the method of measurement.

RoHS标准相关声明 (China RoHS Hazardous Material Declaration)

产品名称

Part Name

有害物质及元素

Toxic or Hazardous Substances and Elements

铅

Lead

(Pb)

汞

Mercury

(Hg)

镉

Cadmium

(Cd)

六价铬

Hexavalent

Chromium

(Cr6)

多溴联苯

Polybrominated

Biphenyls

(PBB)

多溴联苯醚

Polybrominated

Diphenyl Ethers

(PBDE)

外部接口

External Electrical

Connectors

X00000

O:表示该产品所含有的危险成分或有害物质含量依照EIP-A,EIP-B,EIP-C

的标准低于SJ/T11363-2006限定要求。

Indicates that this toxic or hazardous substance contained in all the homogeneous materials for this part, according to EIP-A, EIP-B, EIP-C is below

the limit requirement in SJ/T11363-2006.

X: 表示该产品所含有的危险成分或有害物质含量依照EIP-A,EIP-B,EIP-C

的标准高于SJ/T11363-2006限定要求.

Indicates that this toxic or hazardous substance contained in all the homogeneous materials for this part, according to EIP-A, EIP-B, EIP-C is above

the limit requirement in SJ/T11363-2006.

WEEE Directive

This equipment is regulated by the European Union under WEEE Directive (2012/19/EU). Refer to www.

nordsonefd.com/WEEE for information about how to properly dispose of this equipment.

www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

EV Series Automated Dispensing Systems

13

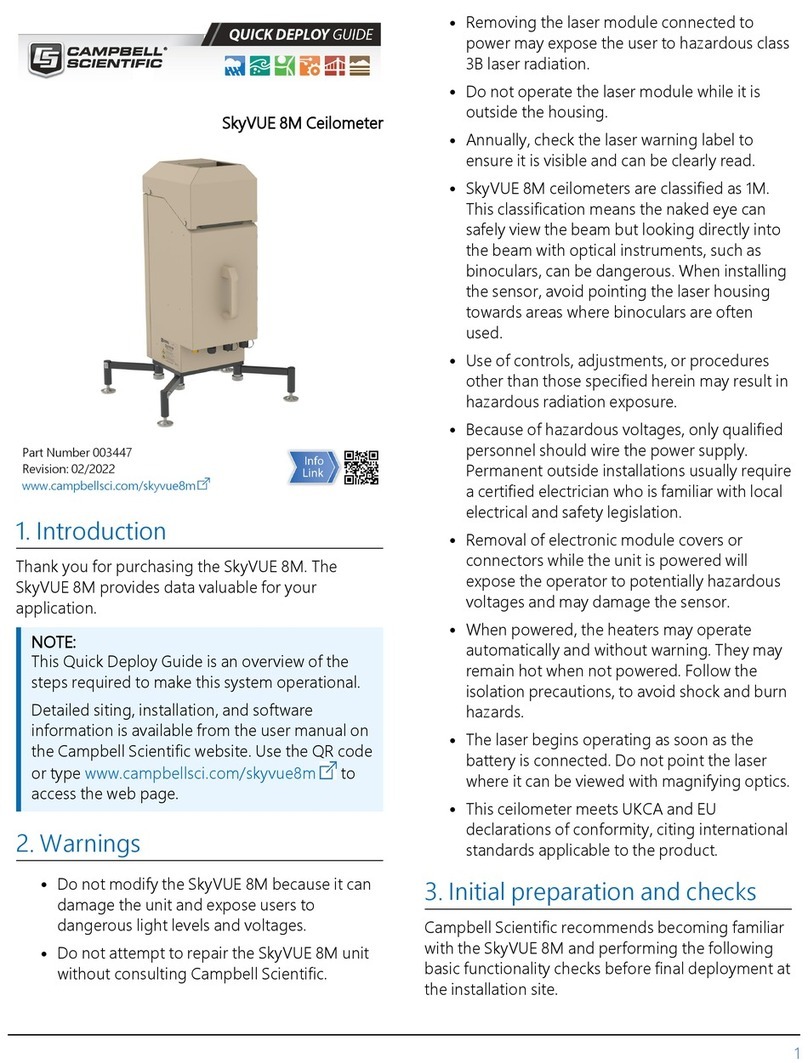

Monitor and

keyboard (mouse

not shown)

Pencil

camera

Robot

DispenseMotion

controller

Syringe

barrel for uid

dispensing

Fixture plate

(optional)

Tip detector

(optional)

Operating Features

EV Series System Component Identification

Joystick

(optional)

www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

EV Series Automated Dispensing Systems

14

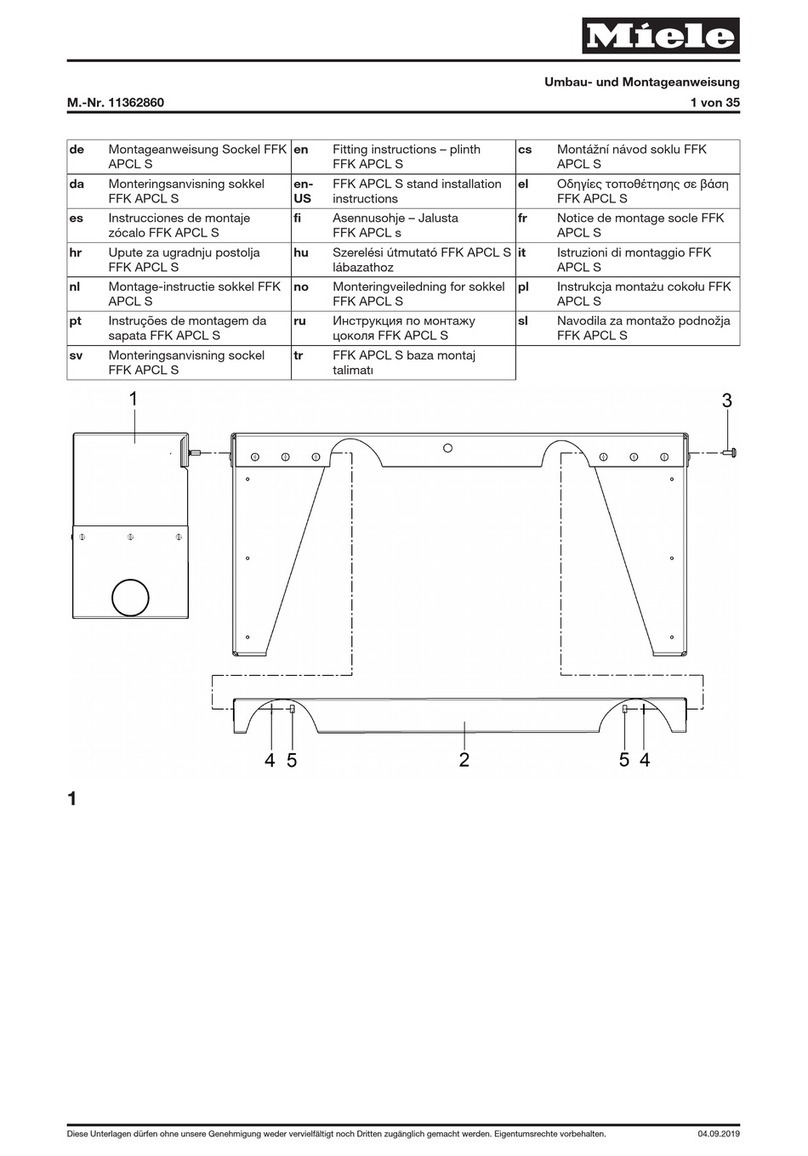

START button

DISPENSER

PURGE button

Power

Switch

EV Back Panel

Dispenser port

(for dispenser /

controller initiation)

I/O PORT (for

input/output

connections)

RS232 port

(connects to the

DispenseMotion

controller)

Ext. Control

port (for the I/O

safety plug)

Operating Features (continued)

EV Front Panel

Tactile port (for

the tip detector,

if present)

EMERGENCY STOP

button

SVC USB port (for

software upgrades)

Power Inlet

www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

EV Series Automated Dispensing Systems

15

Camera

The system includes a simple-vision pencil camera that

allows you to view the xture plate and to focus.

Pencil Camera Features

Combination manual focus and on/off dial

Integrated lighting with an adjustable light-

intensity dial

NOTE: To turn the light off, use a small at-

blade screwdriver to turn the screw inside the

camera bracket fully counterclockwise.

White diffuser cap for image enhancement

(can be removed)

Joystick

The optional joystick can be used instead of the keyboard cursor keys to move the dispensing tip. Refer to

“Accessories” on page 61 for the joystick part number.

CAUTION

Do not connect the joystick to the USB port on the front of the robot.

1. Connect the joystick cable to a USB port on the DispenseMotion controller.

2. Place the selector switch in the D position.

3. On the Program screen of the dispensing software, click the JOYSTICK icon to enable the joystick. Refer to the

illustration below for information on how the joystick functions.

The icon turns yellow when the joystick is enabled.

Use these keys to

jog the robot along

the XY axes

Use this button to

jog the robot along

the Zaxis

To jog faster, press

and hold this button

Place the selector

switch on the bottom

of the joystick in the D

position

Locking bracket

for focus dial

Location of screw used to

adjust light intensity

White diffuser cap

www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

EV Series Automated Dispensing Systems

16

Installation

Use this section in tandem with the Quick Start Guide and the valve system manuals to install all components of the

system.

Unpack the System Components

CAUTION

Unpacking the robot requires a minimum of two people.

Do not attempt to lift the robot without assistance.

1. Remove all system components and ship-with

items from the packaging.

2. With assistance, carefully lift the robot by its base

and transfer it to a stable workbench. Never lift the

robot by its cross member.

NOTE: All units are shipped from the factory with

foam protectors that secure the worktable to

the X axis and the Zaxis to prevent movement

and damage during shipment. Nordson EFD

recommends retaining all packing material for use if

the robot is shipped or moved in the future.

3. Remove the protective foam covers and tape.

4. Double-check the shipping box to ensure you have

removed everything.

Foam

protector

Cross

member (do

not use to

lift the robot)

www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

EV Series Automated Dispensing Systems

17

Position the Robot and Install and Connect Components

Refer to the Quick Start Guide and to this section as needed to install the system components and make

connections.

NOTES:

• The components of an automated dispensing system vary. Steps for a complete system with all available

components are provided in this manual and in the Quick Start Guide. Perform only the steps that apply to your

system.

• If the system is being used in the European Community, the robot is shipped with an enclosure or light curtain

that (1) prevents an operator from entering the robot’s work area and (2) generates an emergency stop signal if

the enclosure door switch is opened while the robot is running.

Before you begin any programming or operation, complete the following tasks as applicable for your system.

Applicability Item Components to Install

or Connect Installation Tasks

All models Input/output

safety plug

(SHORTED)

Connect the input/output safety plug to the

Ext. Control port to bypass the door switch.

CAUTION

Install this plug only if you want to bypass the

door switch. When this plug is installed, the

customer assumes all safety liability.

All models DispenseMotion

controller

Mount the DispenseMotion controller on

the shelf.

Install the shelf-and-controller assembly on

the left upright bracket.

Connect cable(s).

All models Pencil camera Install the bracket.

Install the camera.

Connect the cable to USB-CCD on the

DispenseMotion controller.

Route the cable by using the provided

cable clips to attach it to the Zaxis.

All models Monitor,

keyboard, and

mouse (not

shown); dongle

for wireless

keyboard and

mouse

Connect the monitor.

Connect the wireless keyboard and mouse

dongle to USB 4 on the DispenseMotion

controller.

Continued on next page

www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

EV Series Automated Dispensing Systems

18

Position the Robot and Install and Connect Components (continued)

Applicability Item

Components to Install

or Connect Installation Tasks

All models

(optional)

Joystick Connect the joystick cable to any USB port

on the DispenseMotion controller or USB

expansion cable.

NOTES:

• Do not connect the joystick to the USB port

on the front of the robot.

• Refer to “Joystick” on page 15 for joystick

operating instructions.

All models Dispenser

components

As applicable Mount the syringe barrel or dispensing

valve holder (as applicable) on the Zaxis;

choose mounting holes that allow a

maximum workpiece clearance but also

allow the dispensing tip to reach all areas

on the workpiece where dispensing is

required.

To prevent damage to the camera, make

sure the dispensing tip position is lower

than bottom of the camera. Refer to “Check

the Camera and Dispenser Installation” on

page 19.

Refer to the dispensing equipment manuals

for all other dispensing system installation

steps.

www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

EV Series Automated Dispensing Systems

19

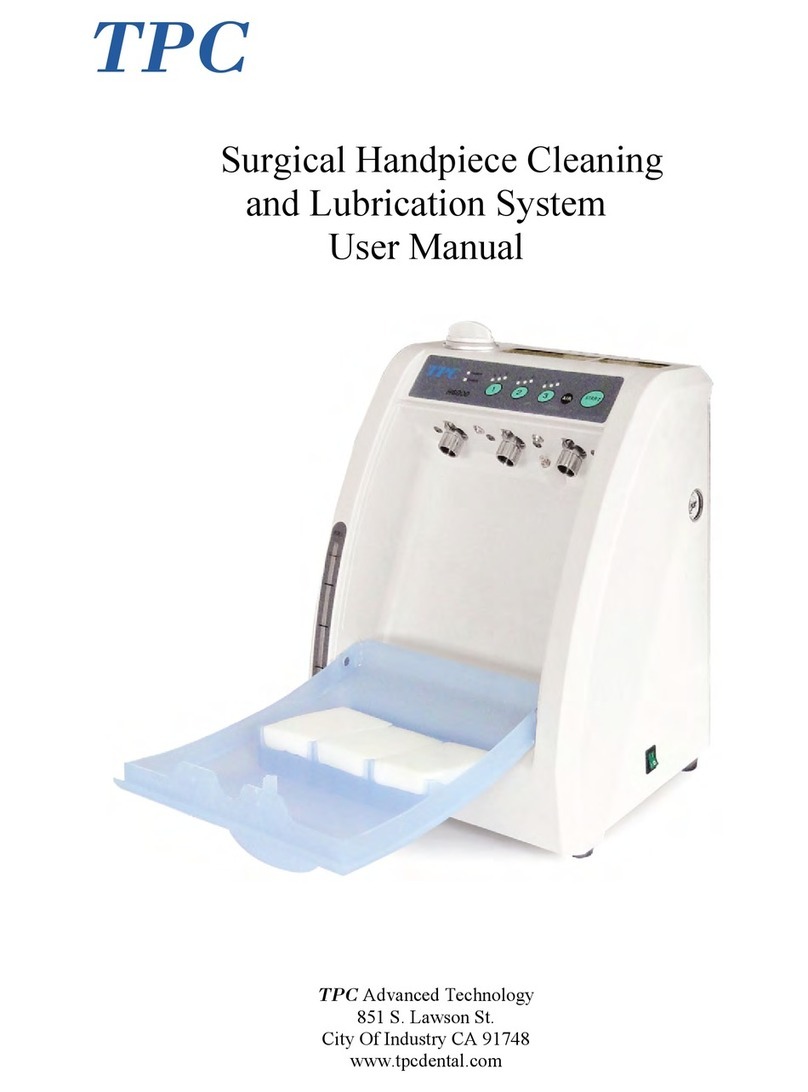

Check the Camera and Dispenser Installation

To prevent damage to the camera, make sure the dispensing tip position is lower than bottom of the camera.

Example of correct camera installation (dispensing tip lower than the bottom of the camera)

Tip bottom

Camera bottom

Work surface

www.nordsonefd.com [email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

EV Series Automated Dispensing Systems

20

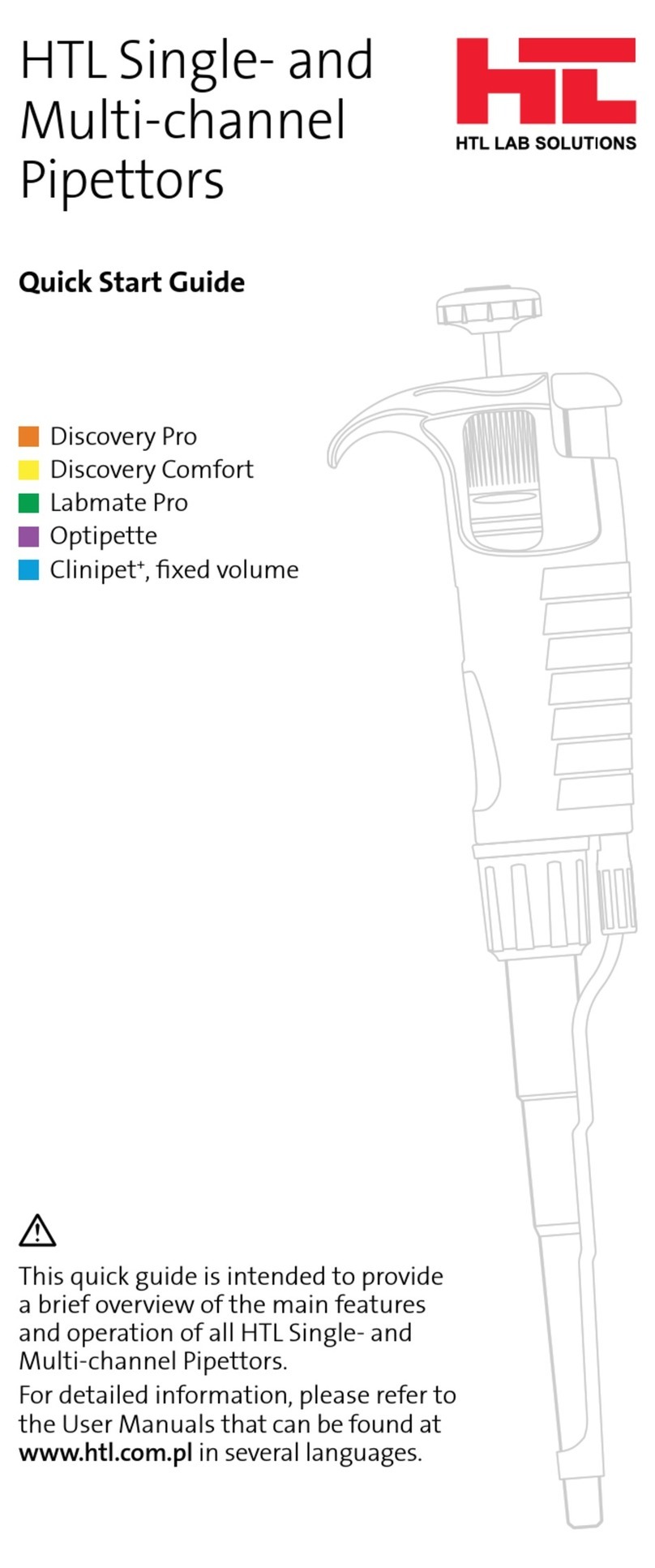

Prepare the Work Surface or Fixture Plate

Prepare the robot work surface or xture plate for secure placement of the workpiece. All Nordson EFD automated

dispensing systems include a standard xture plate. Other xture plate sizes are available. Refer to “Accessories” on

page 61.

200 x 200 standard fixture plate Larger fixture plate (300 x 300, 400 x 400, or 500 x 500)

5.91

150.00

2.36

60.00

6X .79

20.00

2X .79

20.00

21X M4X0.7 - 6H THRU ALL

Connect Inputs / Outputs (Optional)

All automated dispensing systems provide 8 standard inputs and 8 standard outputs. Connect input / output wiring

to the I/O PORT connection on the back of the robot. For a wiring diagram, refer to “I/O Port” on page 65. There

are several ways to use the system inputs / outputs. Refer to “Setting Up Inputs / Outputs” on page 45 for

additional information on inputs / outputs.

7.48

190.00

5.91

150.00

4X 1.57

40.00

3X 1.57

40.00

20X M4X0.7 - 6H THRU ALL

This manual suits for next models

5

Table of contents

Popular Laboratory Equipment manuals by other brands

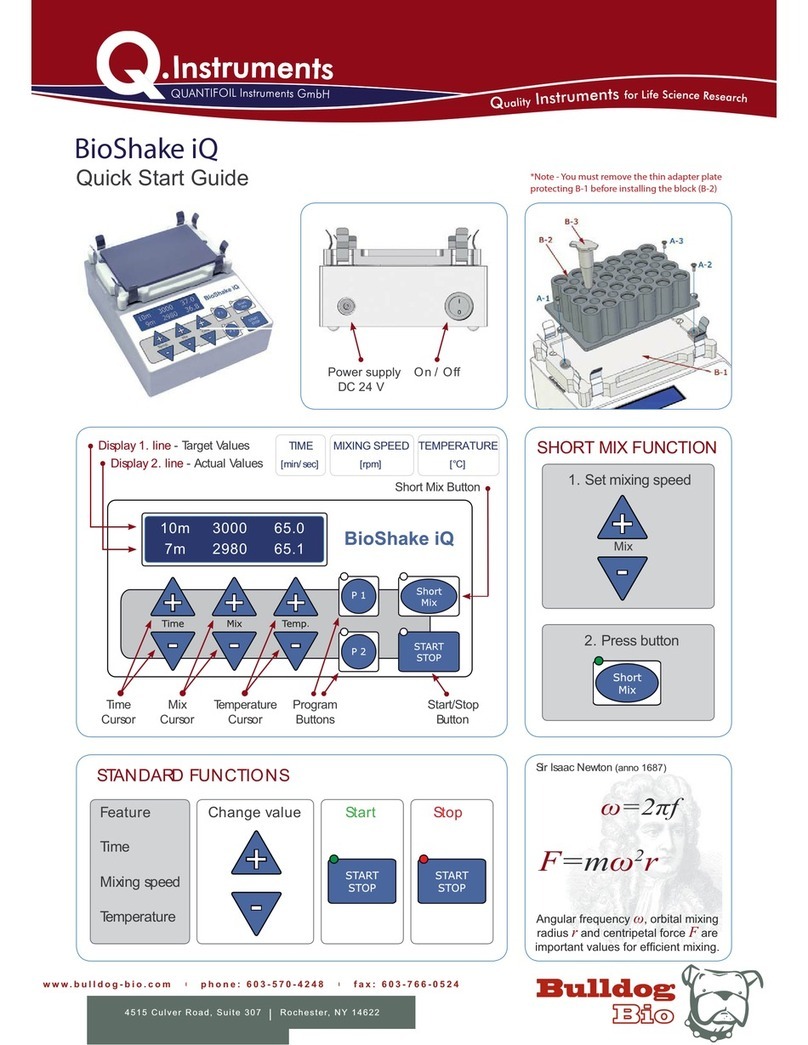

QUANTIFOIL Instruments

QUANTIFOIL Instruments BioShake iQ quick start guide

Thomas

Thomas 351 user guide

Omni

Omni Bead Ruptor 24 user manual

Fritsch

Fritsch premium PULVERISETTE 14 operating instructions

Masterclock

Masterclock CS5-LAN user manual

Thermo Scientific

Thermo Scientific Reacti-Therm I instruction manual