Nordson Sealant Equipment PRO-METER V2K Reference guide

PRO-METER® V2K

CUSTOMER PRODUCT MANUAL

COMPONENT MANUAL P/N: 7440274

ISSUED /2017

For parts and technical support, call the Nordson Sealant Equipment customer support at

(734) 459-8600, or contact your local Nordson Sealant Equipment Representative.

This document is subject to change without notice.

Please check with customer service for the latest version.

Nordson Sealant Equipment٠Plymouth, Michigan٠U.S.A

Part 7440274 2017 Nordson Corporation

Nordson Corporation welcomes requests for information, comments, and

inquiries about its products. General information about Nordson can be

found on the Internet using the following address:

http://www.nordson.com.

Notice

This is a Nordson Corporation publication which is protected by copyright.

Original copyright date 08/2016. No part of this document may be

photocopied, reproduced, or translated to another language without the

prior written consent of Nordson Corporation. The information contained

in this publication is subject to change without notice.

Trademarks

Nordson and the Nordson logo are registered trademarks of Nordson

Corporation.

Pro-Meter is a trademark of Nordson Corporation.

All other trademarks are the property of their respective owners.

Table of Contents i

Part 7440274

2017 Nordson Corporation

Table of Contents

Safety 1-1..................................................

Introduction 1-1.............................................

Qualified Personnel 1-1......................................

Intended Use 1-1...........................................

Regulations and Approvals 1-1...............................

Personal Safety 1-2.........................................

High−Pressure Fluids 1-3.....................................

Fire Safety 1-4.............................................

Grounding 1-5..............................................

Halogenated Hydrocarbon Solvent Hazards 1-6.................

Action in the Event of a Malfunction 1-6........................

Disposal 1-6...............................................

Description 2-1.............................................

Meter 2-1..................................................

Meter Assembly Standard Components 2-2....................

Meter Connections 3-1......................................

Connection Overview 3-1....................................

Electrical Harness Connectors 3-2..........................

Material, Air, And Other Connections 3-2....................

Specifications 4-1..........................................

Thread Locker Application 5-1..............................

Loctite Product Application, Cleanup, And Storage 5-2...........

Blind and Thru Holes 5-2..................................

Sealing Applications 5-2...................................

Cleanup 5-2.............................................

Storage 5-3..............................................

Table of Contents

ii

Part 7440274 2017 Nordson Corporation

System Setup and Calibration 6-1...........................

System Unpack 6-2.........................................

Air Line Routing 6-2.........................................

Electrical Wiring 6-2.........................................

Fluid Flow Path 6-2.........................................

HMI Pendant 6-2...........................................

Initial System Startup 6-3....................................

Adjustment And Calibration 6-6...............................

HMI Pendant Login 6-6....................................

Air Actuator Flow Adjustment 6-6...........................

Cylinder Position Sensor Calibration 6-7.....................

Linear Speed Control Calibration 6-7........................

Lead/Lag Calibration 6-8..................................

Low Level Sensor Calibration 6-9...........................

Pressure Transducer Calibration 6-10........................

Stroke Adjustment 6-11....................................

Operation 7-1..............................................

Dispense Mode Descriptions 7-2..............................

Auto Flow Mode 7-2......................................

Auto Shot Mode 7-2......................................

Manual Flow Mode 7-2....................................

Manual Shot Mode 7-2....................................

Operation 7-3..............................................

Maintenance 8-1...........................................

Consumables 8-2...........................................

Preparation For Maintenance and Service 8-3..................

Air Pressure Relief 8-3....................................

Material Pressure Relief 8-4...............................

Power Disconnect 8-6.....................................

Preventative Maintenance Schedule 8-7.......................

Troubleshooting 9-1........................................

Removal and Installation 10-1................................

Air Actuator 10-2.............................................

Removal 10-2.............................................

Installation 10-6...........................................

Ball Valve Assembly 10-8.....................................

Removal 10-8.............................................

Installation 10-11...........................................

Carriage 10-12...............................................

Removal 10-12.............................................

Installation 10-13...........................................

Cylinder Position Sensor (If Equipped) 10-14.....................

Removal 10-14.............................................

Installation 10-15...........................................

Gravity Tank (If Equipped) 10-16................................

Removal 10-16.............................................

Installation 10-18...........................................

Limit Switch 10-19............................................

At Metering Cylinder Housing 10-19...........................

Removal 10-19..........................................

Installation 10-20.........................................

Table of Contents iii

Part 7440274

2017 Nordson Corporation

At Strike Stop 10-21........................................

Removal 10-21..........................................

Installation 10-22.........................................

Linear Speed Control (If Equipped) 10-23........................

Removal 10-23.............................................

Installation 10-25...........................................

Low Level Sensor (If Equipped) 10-26............................

Removal 10-26.............................................

Installation 10-26...........................................

Metering Cartridge Assembly 10-27.............................

Removal 10-27.............................................

Installation 10-30...........................................

Micro PLC 10-32..............................................

Removal 10-32.............................................

Installation 10-34...........................................

Pneumatic Valve Manifold 10-35................................

Removal 10-35.............................................

Installation 10-37...........................................

Pneumatic Valve Manifold Solenoid 10-38........................

Removal 10-38.............................................

Installation 10-39...........................................

Power Supply Fuse 10-40......................................

Removal 10-40.............................................

Installation 10-42...........................................

Power Supply Cover 10-43.....................................

Removal 10-43.............................................

Installation 10-44...........................................

Power Supply Module 10-45....................................

Removal 10-45.............................................

Installation 10-46...........................................

Power Supply Switch 10-47....................................

Removal 10-47.............................................

Installation 10-47...........................................

Pressure Transducer (If Equipped) 10-48.........................

Removal 10-48.............................................

Installation 10-49...........................................

Disassembly and Assembly 11-1.............................

Metering Cartridge Assembly 11-2.............................

Disassembly 11-3.........................................

Assembly 11-12............................................

PanelView Specifications 12-1................................

PanelViewC800 12-1.......................................

Table of Contents

iv

Part 7440274 2017 Nordson Corporation

Common Screen Description Elements 13-1...................

Elements 13-1...............................................

Pilot Light Indicators 13-1...................................

Push Buttons 13-1.........................................

Push Buttons With Indicator Lights 13-1......................

Data Displays 13-2........................................

Data Entry Fields 13-2.....................................

Dashboard Indicators 13-2..................................

Bar Graphs 13-2..........................................

Typical Screen Layout 13-10...................................

Mode Indicator 13-10.......................................

Navigation Buttons 13-10...................................

Status Indicator 13-10.......................................

Title Bar 13-10.............................................

Screen Descriptions 14-1....................................

Normal Operation Screens 14-1...............................

Main Menu 14-1...........................................

Dispense 1 14-2..........................................

Dispense 2 14-3..........................................

Faults & Warnings 1 and 2 14-4.............................

Faults & Warnings 1 14-4................................

Faults & Warnings 2 14-5................................

Interlock Status 14-7.......................................

Material Pressure 14-8.....................................

Material Pressure History 14-9..............................

Meter Status 14-10.........................................

Options Setup 14-11.........................................

Purge Control 14-12........................................

Setup Login 14-14..........................................

Setup Screens 14-15..........................................

Confirm Exit To Config Mode 14-15...........................

Cylinder Setup 14-16........................................

Flow Mode Setup 14-17.....................................

Interlock Setup 14-18.......................................

Level 1 Setup Menu 14-19...................................

Level 2 Setup Menu 14-20...................................

Miscellaneous Setup 14-21..................................

Options Setup 14-22.........................................

Position Sensor Calibration 14-23.............................

Pressure Limits Setup 14-24.................................

Pressure Sensor Calibration 14-26............................

Pressure Setup 14-28.......................................

Purge Setup 14-29..........................................

Reset Password 14-30......................................

Stroke Setup 14-31.........................................

Valve Setup 14-32..........................................

Table of Contents v

Part 7440274

2017 Nordson Corporation

Parts 15-1...................................................

Introduction 15-1.............................................

Using the Illustrated Parts List 15-1..........................

3-Column Parts List 15-2.................................

Customer Product Manual 15-3.............................

Pro−Meter V2K Assembly Top Level Assembly 15-3............

Pro−Meter V2K Basic Assembly 15-6........................

Base Plate Assembly 15-16..................................

Cover Assembly 15-21......................................

Gravity Feed Tanks (If Equipped) 15-23.......................

HMI Pendant 15-25.........................................

Metering Cartridge Assembly 15-28..........................

Power Supply Assembly 15-30...............................

Optional Components 15-34.................................

Metering Cartridge Assembly Service Kit 15-34................

Safety 1-1

Part 7440274

2017 Nordson Corporation

Section 1

Safety

Introduction

Read and follow these safety instructions. Task- and equipment-specific

warnings, cautions, and instructions are included in equipment

documentation where appropriate.

Make sure all equipment documentation, including these instructions, is

accessible to all persons operating or servicing equipment.

Qualified Personnel

Equipment owners are responsible for making sure that Nordson

equipment is installed, operated, and serviced by qualified personnel.

Qualified personnel are those employees or contractors who are trained to

safely perform their assigned tasks. They are familiar with all relevant safety

rules and regulations and are physically capable of performing their

assigned tasks.

Intended Use

Use of Nordson equipment in ways other than those described in the

documentation supplied with the equipment may result in injury to persons

or damage to property.

Some examples of unintended use of equipment include:

Using incompatible materials

Making unauthorized modifications

Removing or bypassing safety guards or interlocks

Using incompatible or damaged parts

Using unapproved auxiliary equipment

Operating equipment in excess of maximum ratings

Regulations and Approvals

Make sure all equipment is rated and approved for the environment in which

it is used. Nordson equipment warranties may be voided if instructions for

installation, operation, and service are not followed.

All phases of equipment installation must comply with all federal, state, and

local codes.

Safety

1-2

Part 7440274 2017 Nordson Corporation

Personal Safety

To prevent injury, follow these instructions.

Do not operate or service equipment unless you are qualified.

Do not operate equipment unless safety guards, doors, or covers are

intact and automatic interlocks are operating properly. Do not bypass or

disarm any safety devices.

Keep clear of moving equipment. Before adjusting or servicing any

moving equipment, shut off the power supply and wait until the

equipment comes to a complete stop. Lock out power and secure the

equipment to prevent unexpected movement.

Relieve (bleed off) hydraulic and pneumatic pressure before adjusting or

servicing pressurized systems or components. Disconnect, lock out, and

tag switches before servicing electrical equipment.

While operating manual dispense valves, make sure you are grounded.

Wear electronically conductive gloves or a grounding strap connected to

the dispense valve handle or other true earth ground. Do not wear or

carry metallic objects such as jewelry or tools.

If you receive even a slight electrical shock, shut down all electrical and

electrostatic equipment immediately. Do not restart the equipment until

the problem has been identified and corrected.

Obtain and read Safety Data Sheets (SDS) for all materials used. Follow

the manufacturer’s instructions regarding the safe handling and use of

materials. Use recommended personal protection devices.

Make sure the dispensing area is adequately ventilated.

To prevent injury, be aware of less-obvious dangers in the workplace

that often cannot be completely eliminated, such as hot surfaces, sharp

edges, energized electrical circuits, and moving parts that cannot be

enclosed or otherwise guarded for practical reasons.

Safety 1-3

Part 7440274

2017 Nordson Corporation

High−Pressure Fluids

High pressure fluids, unless they are safely contained, are extremely

hazardous. Always relieve fluid pressure before adjusting or servicing high

pressure equipment. A jet of high−pressure fluid can cut like a knife and

cause serious bodily injury, amputation, or death. Fluids penetrating the skin

can also cause toxic poisoning. If you suffer a fluid injection injury, seek

medical care immediately.

WARNING: Any injury caused by high pressure liquid can be serious. If you

are injured or even suspect an injury:

Go to an emergency room immediately.

Tell the doctor that you suspect an injection injury.

Inform medical staff regarding the type of material dispensed.

MEDICAL ALERT −AIRLESS SPRAY WOUNDS: NOTE TO A PHYSICIAN

Injection into the skin is a serious traumatic injury. It is important to treat the

injury surgically as soon as possible. Do not delay treatment to research

toxicity. Toxicity is a concern with some exotic coatings injected directly into

the bloodstream. Consultation with a plastic surgeon or a reconstructive

hand surgeon may be advisable. The seriousness of the wound depends on

where the injury is on the body, whether the substance hit something on its

way in and deflected causing more damage, and many other variables

including skin micro−flora residing in the plant or gun which are blasted into

the wound. If the injected material contains acrylic latex and titanium dioxide

which damages the tissue’s resistance to infection, bacterial growth will

flourish. The treatment that doctors recommend for an injection injury to the

hand includes immediate decompression of the closed vascular

compartments of the hand to release the underlying tissue distended by the

injection material, judicious wound debridement, and immediate antibiotic

treatment.

Safety

1-4

Part 7440274 2017 Nordson Corporation

Fire Safety

To avoid a fire or explosion, follow these instructions:

Shut down all equipment immediately if you notice static sparking or

arcing. Do not restart the equipment until the cause has been identified

and corrected.

Do not smoke, weld, grind, or use open flames where flammable

materials are being used or stored.

Do not heat materials to temperatures above those recommended by

the manufacturer. Make sure heat monitoring and limiting devices are

working properly.

Provide adequate ventilation to prevent dangerous concentrations of

volatile materials or vapors. Refer to local codes or your SDS for

guidance.

Do not disconnect live electrical circuits while working with flammable

materials. Shut off power at a disconnect switch first to prevent sparking.

Know where emergency stop buttons, shutoff valves, and fire

extinguishers are located. If a fire starts in a spray booth, immediately

shut off the spray system and exhaust fans.

Shutoff electrostatic power and ground the charging system before

adjusting, cleaning, or repairing electrostatic equipment.

Clean, maintain, test, and repair equipment according to the instructions

in your equipment documentation.

Use only replacement parts that are designed for use with original

equipment. Contact your Nordson representative for parts information

and advice.

Safety 1-5

Part 7440274

2017 Nordson Corporation

Grounding

WARNING: Operating faulty electrostatic equipment is hazardous and can

cause electrocution, fire, or explosion. Make resistance checks part of your

periodic maintenance program. If you receive even a slight electrical shock

or notice static sparking or arcing, shut down all electrical or electrostatic

equipment immediately. Do not restart the equipment until the problem has

been identified and corrected.

Grounding inside and around the booth openings must comply with NFPA

requirements for Class II, Division 1 or 2 Hazardous Locations. Refer to

NFPA 33, NFPA 70 (NEC articles 500, 502, and 516), and NFPA 77.

All electrically conductive objects in spray areas shall be electrically

connected to ground with a resistance of not more than 1 megohm as

measured with an instrument that applies at least 500 volts to the circuit

being evaluated.

Equipment to be grounded includes, but is not limited to, the floor of the

spray area, operator platforms, hoppers, photoeye supports, and

blow-off nozzles. Personnel working in the spray area must be

grounded.

There is ignition potential from a charged human body. Personnel

standing on a painted surface, such as an operator platform, or wearing

non-conductive shoes, are not grounded. Personnel must wear shoes

with conductive soles or use a ground strap to maintain a connection to

ground when working with or around electrostatic equipment.

Operators must maintain skin-to-handle contact between their hand and

the gun handle to prevent shocks while operating manual electrostatic

spray guns. If gloves must be worn, cut away the palm or fingers, wear

electrically conductive gloves, or wear a grounding strap connected to

the gun handle or other true earth ground.

Shut off electrostatic power supplies and ground gun electrodes before

making adjustments or cleaning powder spray guns.

Connect all disconnected equipment, ground cables, and wires after

servicing equipment.

Safety

1-6

Part 7440274 2017 Nordson Corporation

Halogenated Hydrocarbon Solvent Hazards

Do not use halogenated hydrocarbon solvents in a pressurized system that

contains aluminum components. Under pressure, these solvents can react

with aluminum and explode, causing injury, death, or property damage.

Halogenated hydrocarbon solvents contain one or more of the following

elements:

Element Symbol Prefix

Fluorine F “Fluoro−”

Chlorine Cl “Chloro−”

Bromine Br “Bromo−”

Iodine I “Iodo−”

Check your material SDS or contact your material supplier for more

information. If you must use halogenated hydrocarbon solvents, contact

your Nordson Sealant representative for information about compatible

Nordson Sealant Equipment components.

Action in the Event of a Malfunction

If a system or any equipment in a system malfunctions, shut off the system

immediately and perform the following steps:

Disconnect and lock out electrical power. Close pneumatic shutoff

valves and relieve pressure.

Identify the reason for the malfunction and correct it before restarting the

equipment.

Disposal

Dispose of equipment and material used in operation and servicing

according to federal, state, and local codes.

Description 2-1

Part 7440274

2017 Nordson Corporation

Section 2

Description

Meter

See Table 2-1

See Figure 2-1

The Pro−Meter V2K from Nordson Sealant Equipment is designed to

dispense two part adhesives and sealants at precisely controlled flow rates.

The dispense system is a positive displacement, two component, single

acting metering system. Major system components consist of an air

actuator, ball valve assemblies, metering cartridge assemblies, power

supply assembly, valve manifold, micro PLC, and an interactive HMI control

panel. Each metering cartridge assembly contains metering rods, seals,

O−rings, and bearings. This design accommodates ease of service and

minimal maintenance. Features and benefits are as follows:

Positive rod displacement

Material is either pressure fed or supplied via gravity feed tanks

Mechanically adjustable stroke and dispense/reload rates

Table top unit which occupies a very small spatial footprint

Description

2-2

Part 7440274 2017 Nordson Corporation

Meter Assembly Standard Components

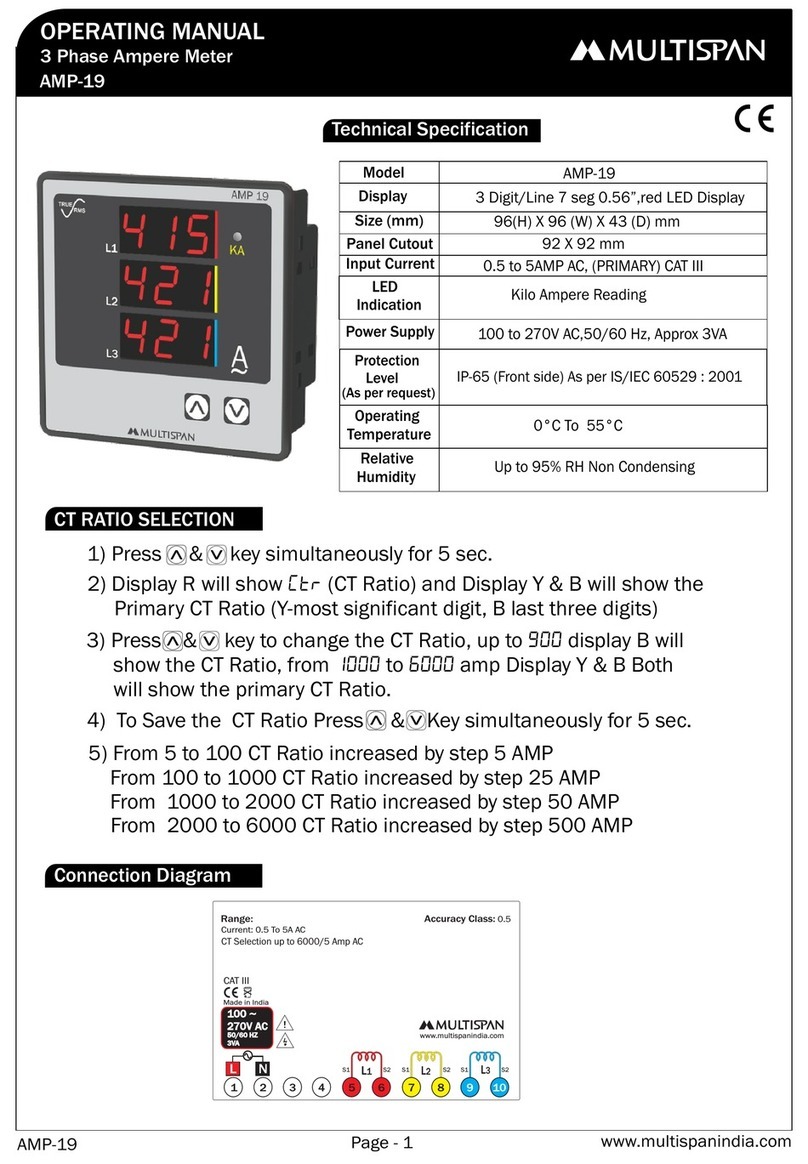

Table 2-1 Pro−Meter V2K Description

Item Description

1Gravity tank (if equipped) −supplies material to dispense system

2Air actuator −drives the carriage in a reciprocating motion. This reciprocating motion moves the

metering rods within the metering cartridge assemblies. This movement drives material through

the metering cartridge assembly discharge port where it is later dispensed via a dispense valve.

3Ball valve −serves as the inlet valve for the dispense system

4Metering cartridge assembly −metering rods, along with associated seals and bearings, displace

material through the discharge port and on to the dispense valve

5Power supply assembly −contains power switch, power supply, power connections, and filter

regulator assembly

6Micro PLC −serves as the system logic controller and directly interacts with HMI control panel

7Pneumatic valve manifold −contains air solenoids that routes air to system components

1

2

3

4

56

7

Figure 2-1 Pro−Meter V2K Standard Components

Meter Connections 3-1

Part 7440274

2017 Nordson Corporation

Section 3

Meter Connections

Connection Overview

See Figure 3-2

See Table 3−2

It is imperative to follow the safety instructions outlined in this manual. Refer

to Safety (page 1−1) for additional information. Contact a Nordson Sealant

Equipment representative regarding these procedures, if necessary.

WARNING:

Safety glasses are to be worn at all times while installing, servicing,

operating, or observing equipment. The sudden release of air or fluid

can cause damage to eyes.

Allow only qualified personnel to perform the following tasks. Follow the

safety instructions in this document and all other related documentation.

Relieve system air pressure, material pressure, and disconnect power

prior to servicing Pro−Meter V2K components. Refer to Maintenance,

Preparation For Maintenance And Service (page 8−3) for additional

information.

Apply Loctite properly to fasteners. Refer to Thread Locker Application

(page 5−2) for Loctite application information.

Clean any material that has spilled. Be sure to follow all applicable

safety and environmental guidelines when cleaning spilled material.

Refer to Safety (page 1−1) for additional information.

WARNING: Any material injected into flesh can cause severe injury or

death. Keep body parts away from material discharge ports. If injection

occurs, seek medical attention immediately.

WARNING: Operating faulty electrostatic equipment is hazardous and can

cause electrocution, fire, or explosion. Make resistance checks part of your

periodic maintenance program. If you receive even a slight electrical shock

or notice static sparking or arcing, shut down all electrical or electrostatic

equipment immediately. Do not restart the equipment until the problem has

been identified and corrected.

Meter Connections

3-2

Part 7440274 2017 Nordson Corporation

CAUTION:

Relieve air and material pressure when equipment is not in use for

prolonged periods of time. Do not allow pressure to remain static when

equipment is idle as this may cause material to pack and harden.

Only apply removable thread locker and sealant as specified by the

procedures in this manual.

Electrical Harness Connectors

Connect electrical harness connectors to components in accordance with

the Electrical Circuit Diagram.

Material, Air, And Other Connections

Refer to System Setup and Calibration (page 6−1) for additional information

regarding material and air connections.

Meter Connections 3-3

Part 7440274

2017 Nordson Corporation

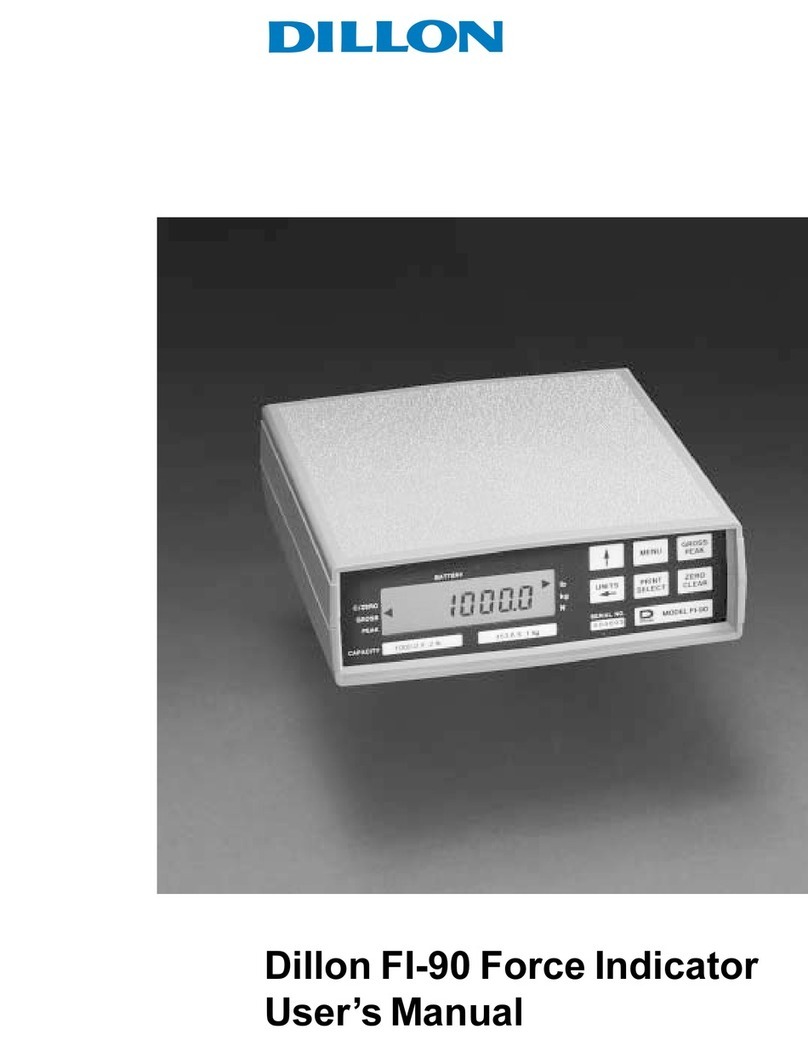

Table 3−2 Pro−Meter V2K Shown With Material, Air, And Other Connections

Item Description

1Ball valve −serves as an inlet valve

2Gravity tank (if equipped) −supplies material to the Pro−Meter V2K

3Metering cartridge assembly discharge port −routes material to dispense valve

4Pressure transducer (if equipped) −records system pressure

5Metering cartridge assembly bleed valve −allows air to be bleed from metering cartridge assembly

6Weep plug −plug to inspect condition of metering cartridge assembly primary seal. Material ob-

served from the weep plug denotes metering cartridge assembly primary seal failure.

7Metering cylinder housing oil cup −allows Seal Sav’r oil to be added to the metering cylinder

housing.

8Micro PLC −serves as the system logic controller and directly interacts with HMI control panel

9Power supply assembly −contains power switch, power supply, power connections, and filter reg-

ulator assembly

10 Pneumatic valve manifold −contains air solenoids that routes air to system components

11 Air actuator flow control valve −meters air actuator air flow to control dispense and reload speed

2

1

3

4

5

8

9

10

11

6

7

Figure 3-2 Pro−Meter V2K Shown With Material, Air, And Other Connections

Table of contents