Dillon FI-90 User manual

Table of contents

Other Dillon Measuring Instrument manuals

Dillon

Dillon ED-2000plus User manual

Dillon

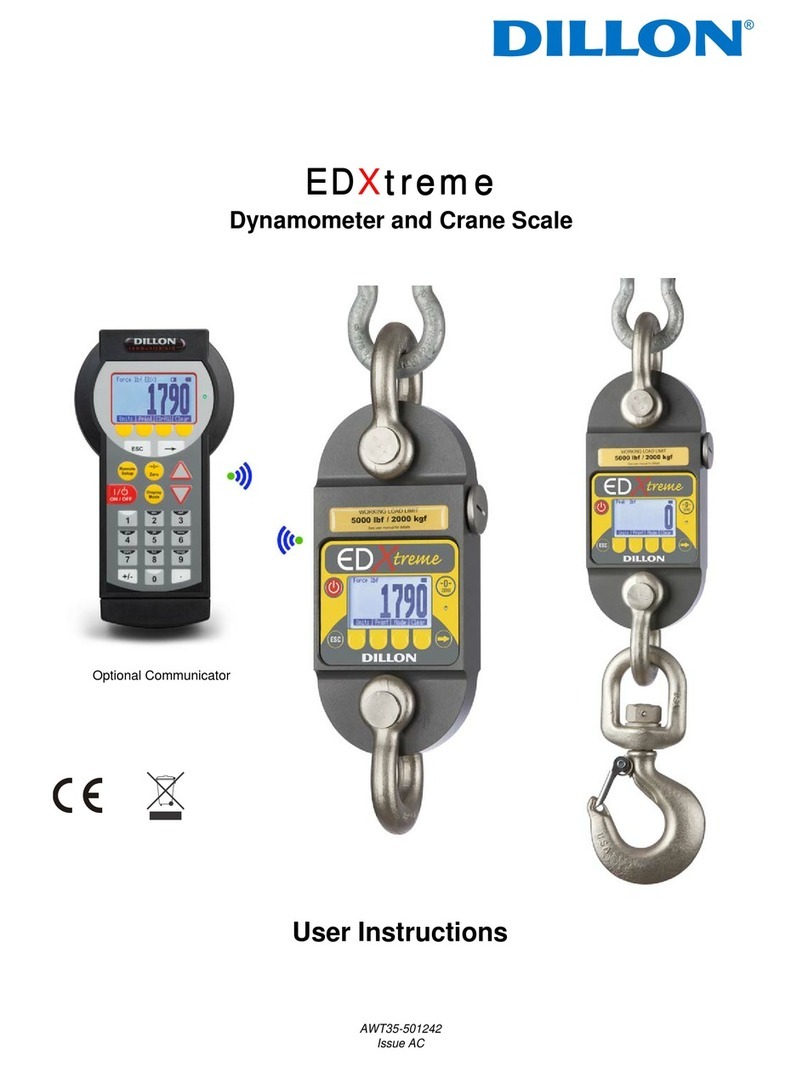

Dillon EDXtreme EDX-1T User manual

Dillon

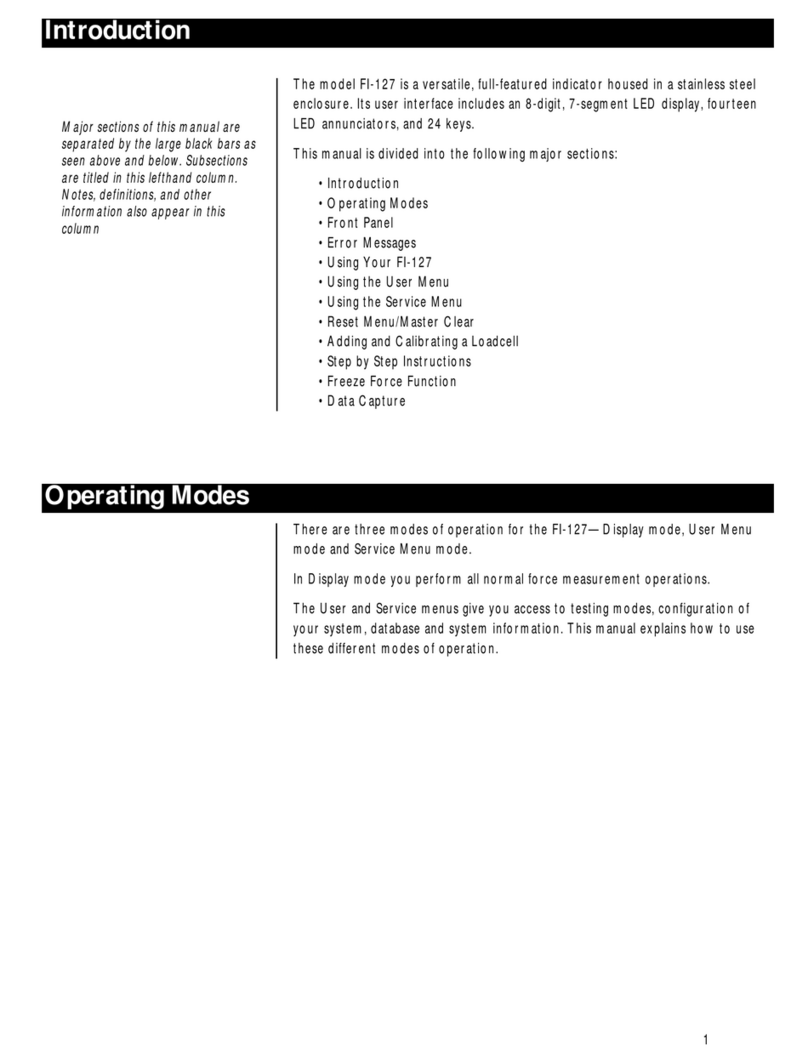

Dillon FI-127 User manual

Dillon

Dillon AP User manual

Dillon

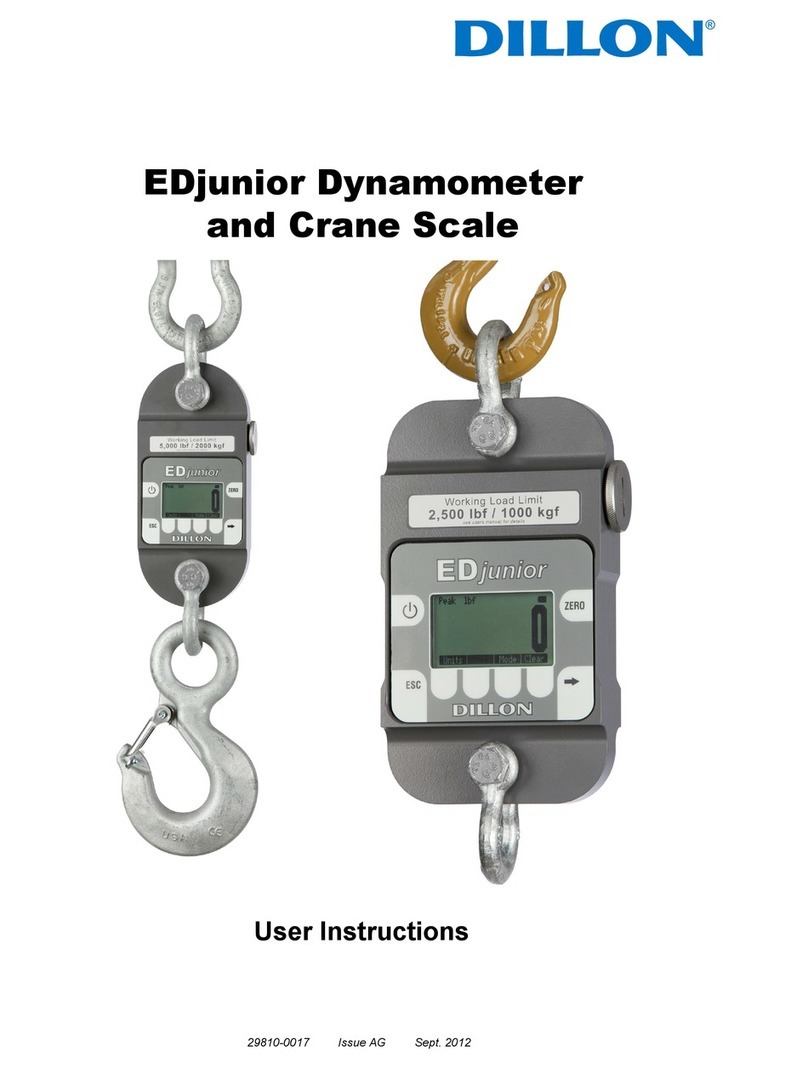

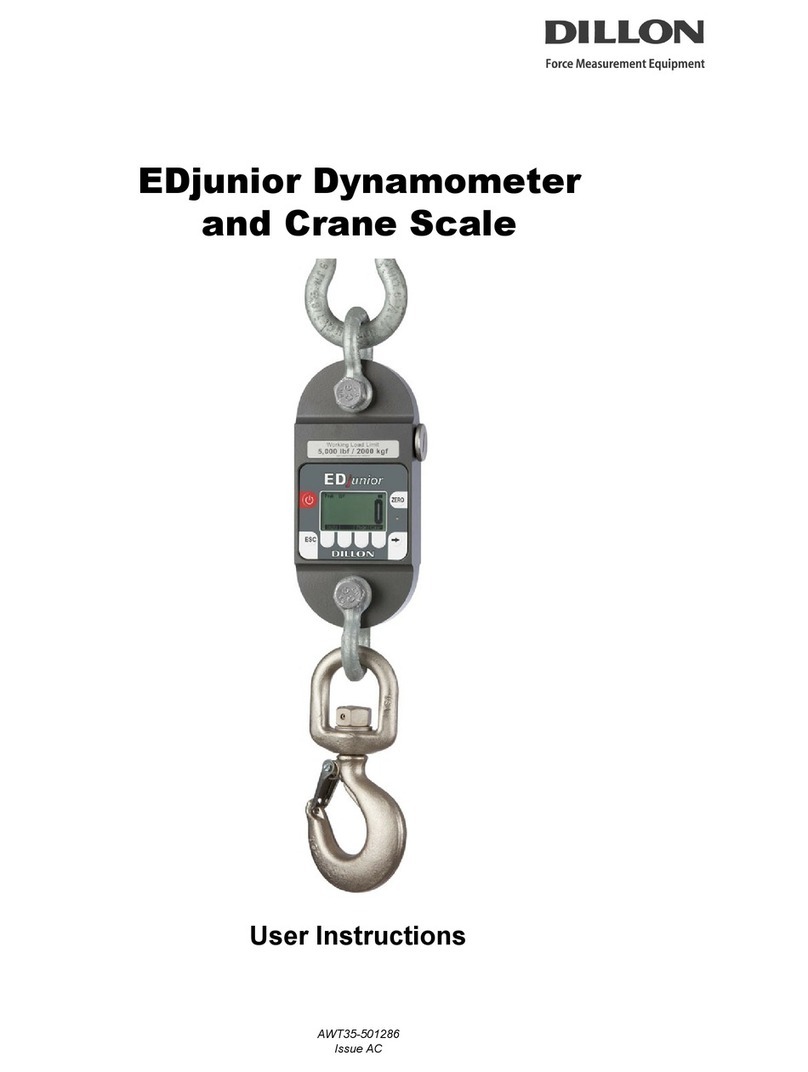

Dillon EDjunior User manual

Dillon

Dillon AFG Series User manual

Dillon

Dillon GTX-Plus Series User manual

Dillon

Dillon EDjunior EDJR-25K User manual

Dillon

Dillon FI-80 LCD User manual

Dillon

Dillon Quantrol BFG 10 User manual

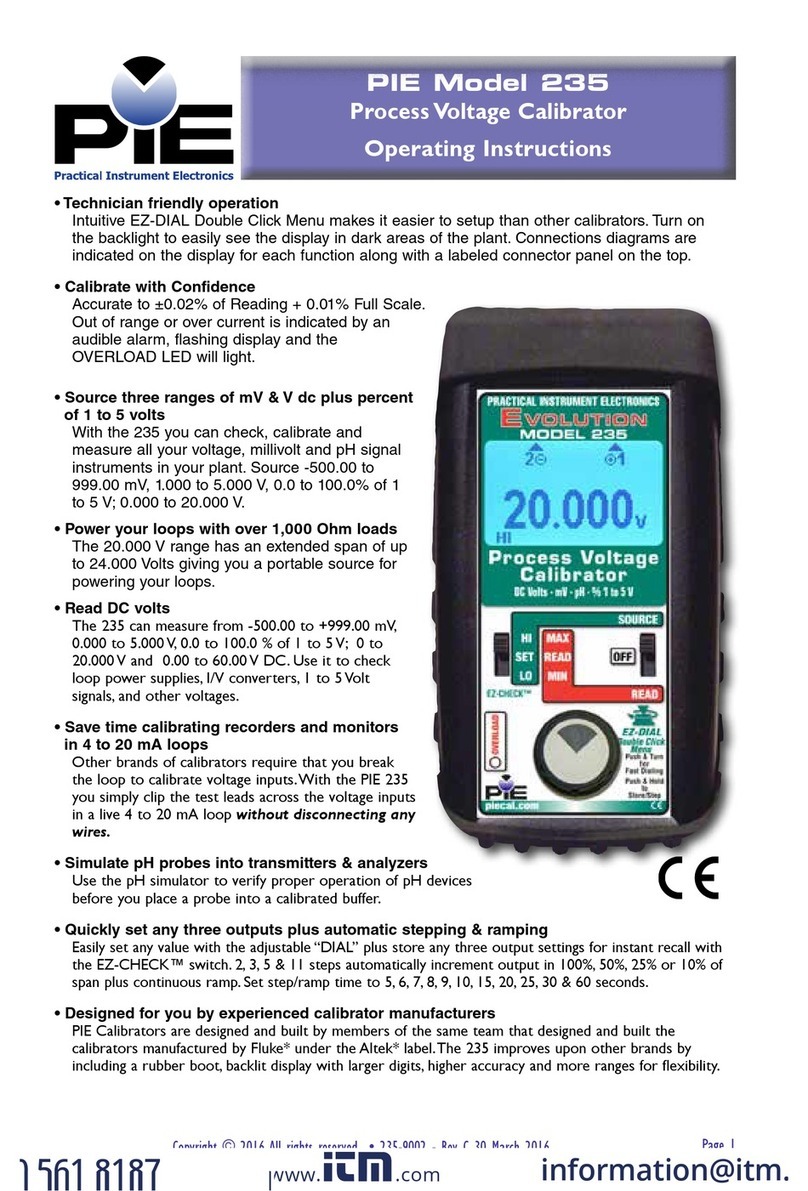

Popular Measuring Instrument manuals by other brands

Bender

Bender isoPV1685 manual

Dwyer Instruments

Dwyer Instruments RTI2 Series instructions

Compac

Compac L40P Installation and setup instructions

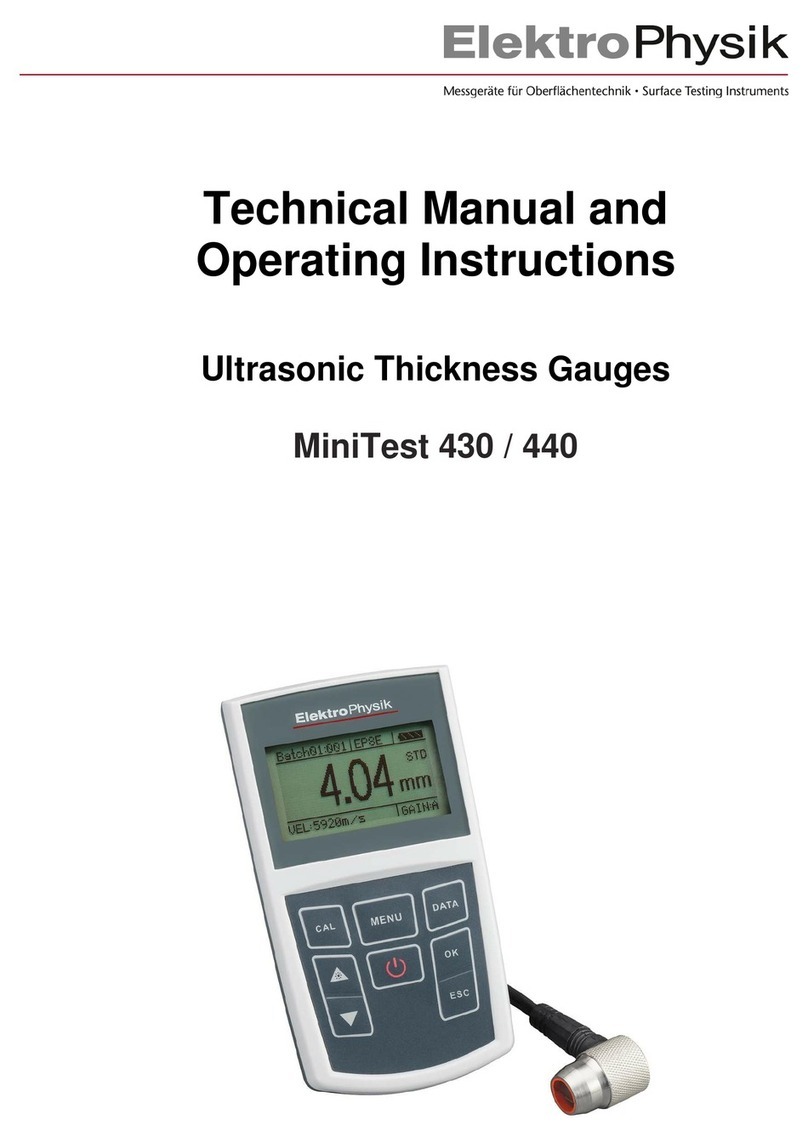

ElektroPhysik

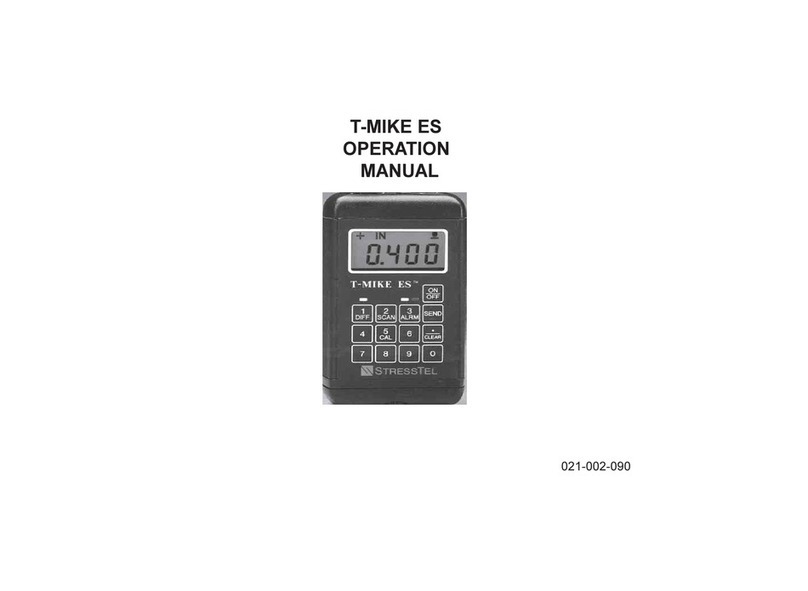

ElektroPhysik MiniTest 430 Technical manual and operating instructions

Protherm

Protherm Exacontrol operating instructions

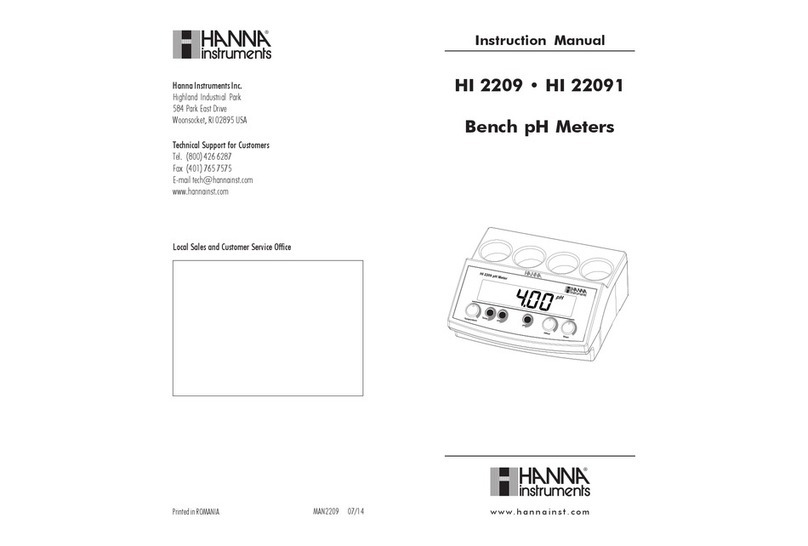

Hanna Instruments

Hanna Instruments HI 22091 instruction manual