Nordyne C8BA Series User manual

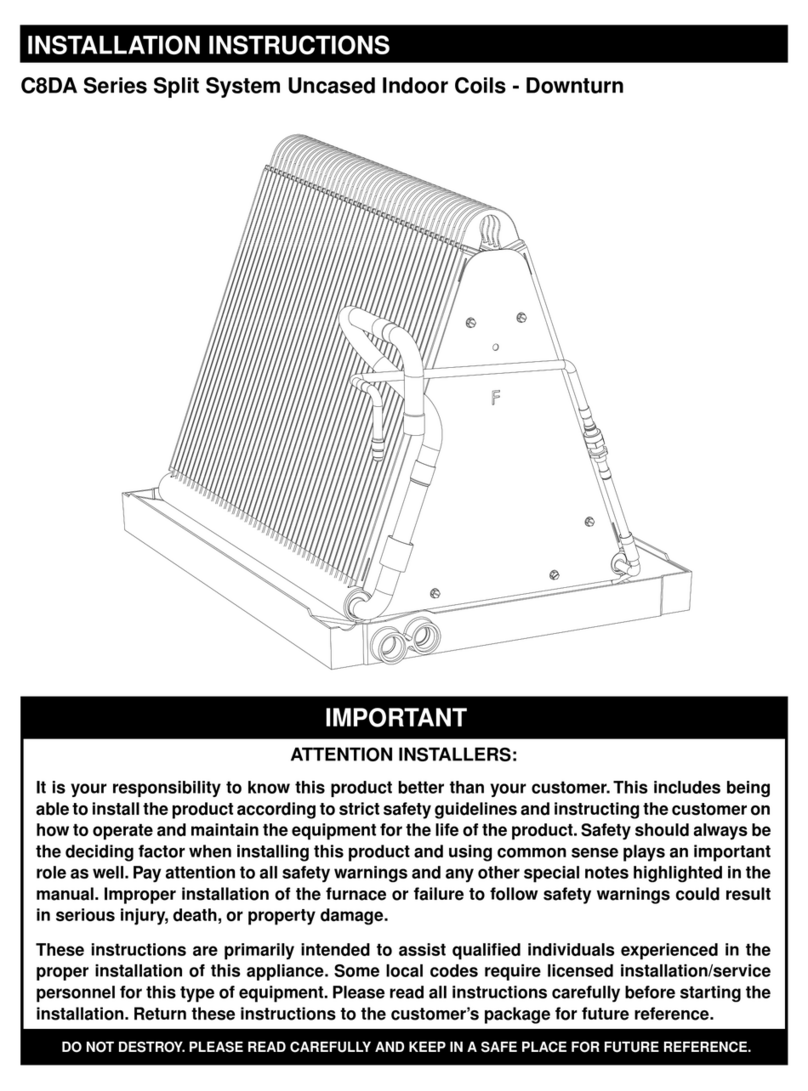

C8BASeriesSplitSystemUncasedIndoorCoils-Brazed

INSTALLATION INSTRUCTIONS

DO NOT DESTROY. PLEASE READ CAREFULLY AND KEEP IN A SAFE PLACE FOR FUTURE REFERENCE.

IMPORTANT

ATTENTION INSTALLERS:

It is your responsibility to know this product better than your customer.This includes being

abletoinstall the productaccording to strictsafetyguidelines and instructingthe customer on

how to operate and maintain the equipment for the life of the product.Safety should always be

the deciding factor when installing this product and using common sense plays an important

role as well.Pay attention to all safety warnings and any other special notes highlighted in the

manual. Improper installation of the furnace or failure to follow safety warnings could result

in serious injury, death, or property damage.

These instructions are primarily intended to assist qualified individuals experienced in the

proper installation of this appliance. Some local codes require licensed installation/service

personnel for this type of equipment. Please read all instructions carefully before starting the

installation. Return these instructions to the customer’s package for future reference.

2

IMPORTANT SAFETY INFORMATION

Pleasereadallinstructionsbeforeservicingthisequipment.

Payattentiontoallsafetywarningsandanyotherspecial

notes highlighted in the manual. Safety markings are

used frequently throughout this manual to designate a

degreeorlevelofseriousnessandshouldnotbeignored.

WARNINGindicatesapotentiallyhazardoussituationthat

if not avoided, could result in personal injury or death.

CAUTIONindicatesapotentiallyhazardoussituationthat

if not avoided, may result in minor or moderate injury or

property damage.

WARNING:

PROPOSITION 65 WARNING: This product

contains chemicals known to the state of

Californiatocausecancer,birthdefectsorother

reproductive harm.

WARNING:

Improper installation, service, adjustment,

or maintenance may cause explosion, fire,

electricalshockorother hazardousconditions

whichmayresultinpersonalinjury orproperty

damage. Unless otherwise noted in these

instructions, only factory authorized kits or

accessories may be used with this product.

WARNING:

C8BAcoilsarepressurizedwithNitrogenatthe

factory. Avoid direct face exposure or contact

withvalvewhengasisescaping.Alwaysensure

adequate ventilation is present during the

depressurization process. Any uncertainties

should be addressed before proceeding.

NITROGEN

HEALTH

FLAMMABILITY

REACTIVITY

0 Minimal Hazard 1 Slight Hazard

1

0

0

WARNING:

This unit must be installed in accordance

with the instructions outlined in this manual

during the installation, service, and operation

of this unit. Unqualified individuals should

not attempt to interpret these instructions or

install this equipment. If you do not posses

mechanicalskillsortools,callyourlocaldealer

forassistance.Undernocircumstancesshould

the equipment owner attempt to install and/or

service this equipment.Failure to follow safety

recommendations could result in possible

damage to the equipment, serious personal

injury or death.

• The installer must comply with all local codes and

regulations which govern the installation of this type

of equipment. Local codes and regulations take

precedence over any recommendations contained in

these instructions. Consult local building codes for

special installation requirements.

• Familiarizeyourselfwiththecontrolsthatshutoffthe

electrical power to the unit. If the unit needs to be shut

down for an extended period of time, turn off electrical

power at the circuit breaker. For your safety always

turn off the electrical power before performing service

or maintenance on the unit.

• Installationofequipmentmayrequirebrazingoperations.

Installer must comply with safety codes and wear

appropriate safety equipment (safety glasses, work

gloves,fireextinguisher,etc.)whenperformingbrazing

operations.

• Read the Installation Instructions supplied with the

furnace or air handler. Always observe all safety

requirementsoutlinedinthismanualandonthefurnace

or air handler markings before installing the coil.

• Follow all precautions in the literature, on tags, and

on labels provided with the equipment. Read and

thoroughly understand the instructions provided with

the equipment prior to performing the installation and

operational checkout of the equipment.

3

GENERAL INFORMATION

C8 series coils are designed for upflow or downflow

applicationsandareequippedwithbrazetyperefrigerant

connections for easy installation.

• Checkthecoilsoricesizeandconrmthatit’ssuitable

forapplicationwiththeintendedoutdoorunit.Depending

on application, additional installer supplied orifice or

TXVmayberequired.

• Optional cooling/heating equipment must be

properly sized and installed in accordance with the

furnace manufacturer’s specications and approved

recommendations.

• Heating only furnace air circulators may have to be

replacedwithmulti-speedHeating/Coolingblowersto

upgradetheairdelivery(CFM)whenanadd-oncoilis

installed.RefertoTable1(page6)forcoilspecications,

recommendedCFM,andallowancesforpressuredrop

across the coil and filters.

• Verifythattheairdeliveryofthefurnace/airhandleris

adequate to handle the static pressure drop of the coil,

filter, and duct work.

• Ifpreciseformingofrefrigerantlinesisrequired,acopper

tubingbenderisrecommended.Avoidsharpbendsand

contact of the refrigerant lines with metal surfaces.

• Refrigerant lines should be wrapped with pressure

sensitive neoprene or other suitable material where

they pass against sharply edged sheet metal.

• Close-off plates are available in some air lter kits.

RefertotheReplacementPartsListforavailablepart

numbers. Install the necessary close-off plates around

the refrigerant lines and drain line where required.

Reinstallallinnerandouterpanelsofthefurnace/air

handler that were previously removed when installing

the indoor coil.

COIL INSTALLATION

WARNING:

ELECTRICAL SHOCK, FIRE OR EXPLOSION

HAZARD

Failure to follow safety warnings exactly could

result in serious injury or property damage.

Improper servicing could result in dangerous

operation, serious injury, death or property

damage.

to the furnace and outdoor condensing unit.

to disconnecting. Reconnect wires correctly.

CAUTION:

The coil must be level to ensure proper

condensate drainage. An unlevel installation

may result in structural damage, premature

equipment failure, or possible personal injury.

Upflow Installations

1.Disconnectallelectricalpowertothefurnace.

2.Installthecoilcaseonthefurnaceairdischargeopening

and level it as needed to ensure proper condensate

drainage. If needed, make a plate to adapt the coil to

theairdischargeopening.SeeFigure5(page6)for

coil dimensions.

3.Makeandinstalltheplenumoverthecoil.Insulateas

required.

4.Seal the enclosureasrequiredtominimizeairleakage.

5.Connect the refrigerant lines as outlined in the

RefrigerantLineConnectionsection.

Downflow Installations

Thesecoilsmaybeinstalledindownowapplications.It

isrequiredthatthefurnace andcoilcabinetsaresecurely

mounted together before setting in place. Fossil fuel

applications require the coil to be placed in the supply

air stream only.

Refrigerant Line Connections

System Depressurization

1.Removethecap(Figure1)fromtheendoftheliquid line.

2.VerifypressurizationbydepressingtheSchradervalve

ontheendoftheliquidline.Listenforanyescapinggas.

If there is no pressure, test the coil for leakage.

• Ifleakageisfound,clearlymarkthelocationofthe leak

and return the coil to the distributor for processing.

• Ifnoleaksarefound,thecoilmaybeinstalled.

3.Depress the valve to relieve all pressure from the coil.

Suction

Line

Liquid

Line

Cap

Schrader

Valve

Figure 1. Suction & Liquid Line Locations

4

OriceRemoval&Installation

NOTE:Beforeproceeding,performsteps1-3intheSystem

Depressurization section and confirm that the restrictor orifice

size meets the requirements outlined in the outdoor unit

installation manual.

CAUTION:

To prevent damage to the unit or internal

components, it is recommended that two

wrenchesbeusedwhenlooseningortightening

nuts. Do not over tighten!

1.Usingtwowrenches,loosenthenutanddistributorbody

asshowninFigure2.Turntheassemblynutcounter-

clock-wise until the orifice body halves are seperated.

2.Insert a light-gauge wire hook between the distributor

body and the restrictor orifice while being careful not

to scratch either part. Carefully remove the restrictor

oricefromthedistributorbody.SeeFigure3.

FactorysuppliedoricesizesarelistedinTable1(page

6).Iftheoricemustbereplaced,followsteps1-5.

Figure 2. Loosening of Nut & Distributor Body

Install restrictor with

rounded end down

in the distributor

Figure 4. Restrictor Insertion into Distributor Body

Figure 3. Removal of Orifice

Carefully remove the

restrictor orifice from

the distributor body

3.Checktheactual sizeofthe neworice.Thesizeis

stampedonitsside.Donotusepingaugestomeasure

the orifice diameter.

4.Insert the new orifice into the distributor body, rounded

enddown.SeeFigure4.

CAUTION:

To prevent damage to the unit or internal

components, it is recommended that two

wrenchesbeusedwhenlooseningortightening

nuts. Do not over tighten!

5.Realigntheassemblynutonthedistributorbodyand

hand tighten both components. Mark a line on both

bodiesandthentightenanadditional1/4turnusingtwo

wrenches.Themovementofthetwolineswillshowhow

much the nut is tightened. If a torque wrench is used,

tightento10-12ft.lbs.or14-16Nm.

Connecting the Linesets

1.Routeand cutbothlinesettubes to properlengthin

accordancewiththeoutdoorunitspecications.Verify

the ends are round, clean, and free of any burrs.

2.Connect the suction and liquid lineset tubes.

CAUTION:

It is recommended that a wet rag be wrapped

around the suction line in front of the close

off plate before applying heat. Failure to keep

components cool during brazing may result

in structural damage, premature equipment

failure, or possible personal injury.

3.Brazetheindividualconnectionswithdrynitrogenflowing

throughthejoints.Thiswillpreventinternaloxidation

and scaling from occurring.

IMPORTANT:Topreventinternaloxidationandscaling

fromoccuring,brazeallconnectionswithdrynitrogen

flowing through the joints.

4.Wrap the refrigerant lines with pressure sensitive

neoprene or other suitable material especially where

the lines enter the opening in the sheet metal.

5.Evacuatethesystemofmoistureandnon-condensables

to prevent low efficiency operation or damage to the

unit.Thesuggestedrangeofevacuationis250-500

microns.

6.Chargethesystemwithrefrigerant.Please Refer to

the outdoor unit installation manual for additional

charging instructions.

7.Checkthesystemforleaks,includingthelinesetandthe

brazedjoints.NOTE:Applyasoapandwatersolutionon

each joint or union with a small paintbrush. If bubbling

is observed, the connection is not adequately sealed.

8.Properly dispose of all removed parts.

5

Condensate Drain

CAUTION:

The coil must be level to ensure proper

condensate drainage. Improper condensate

disposal may result in structural damage,

premature equipment failure, or possible

personal injury.

• Methodsfordisposingofcondensatevaryaccording

tolocalcodes.Refertolocalcodesorauthorityhaving

jurisidiction for restrictions and proper condensate

disposal requirements.

• Allcondensatepanshaveprimaryandsecondarydrain

connectionstomeetFHArequirements.Iftheapplication

is located in or above a living space where damage

mayresultfromcondensateoverow,aseparate3/4

inch drain must be provided from the secondary drain

connectionandasecondarydrainpanmustbeinstalled

undertheentireunit.Runsecondarydrainlinestoa

place where they are noticeable if used.

• Thecoilcondensatepanisdesignedwith3/4”NPSC

drainconnections.UseaPVCorsimilarmaterialtting

to attach the drain line to the pan.

NOTE: The tting should be hand tightened only.

Overtightening may crack the drain pan and cause

condensate to leak.

• The drain pan MUST be drained with eld supplied

tubing and looped to form a trap.

IMPORTANT: Failure to install a trap may result in

condensation overflowing the drain pan, resulting

in substantial water damage to surrounding area.

• Primethetrapwithwater.Insulatethedrainifitislocated

inanunconditionedspace,andtestthecondensateline

forleaks. Consult localcodes for additional restrictions

or precautions.

• Routethelinestoasuitabledrain,avoidingsharpbends

andpinchingofthelines.Thedrainshouldmaintaina

minimum horizontal slope in the direction of discharge

ofnotlessthan1”verticalforevery10ftofhorizontal

run.

• During system checkout, inspect the drain line and

connections to verify proper condensate drainage.

WARNING:

ELECTRICAL SHOCK, FIRE OR EXPLOSION

HAZARD

Failure to follow safety warnings exactly could

result in serious injury or property damage.

Improper servicing could result in dangerous

operation, serious injury, death or property

damage.

power to the furnace or air handler.

to disconnecting. Reconnect wires correctly.

CAUTION:

Do not operate the system without a suitable

filter in the return air duct system. Always

replace the filter with the same size and type.

Toensureoptimumperformanceandtominimizepossible

equipmentfailure,thefollowingmaintenancetasksshould

be performed periodically on this equipment:

1.Theairlterinstalledwiththesystemshouldbechecked

and cleaned or replaced twice per year.

2.Check the coil, drain pan, and condensate drain line

for cleanliness at the start of each heating and cooling

season. Clean as needed.

Air Filter

Air filters are not supplied as an integral part of this

coil; however, an air lter kit is available. Refer to the

ReplacementPartsListforavailablepartnumbers.

The lter must be installed upstream of the coil and

inspected frequently. When the filter becomes clogged

with dust or lint, it should be replaced (disposable type)

orcleaned(washabletype).Itisrecommendedthatfilters

be inspected and replaced at least twice during the year.

Generally it is best to replace or clean the filters at the

start of each heating and cooling season.

6

Figure 5. C8BA Coil Dimensions

2 1/2”

W

19 1/2”

1 3/8” 1”

12 1/8”

14 1/2” H

Table 1. Coil Specifications

C8BA- 01830 036 042

NominalCapacity(BTUH) 18,000-30,000 36,000 42,000

NominalAirow(CFM) 600-1,000 1,200 1,400

W - Width (in.) 181/8 181/8 181/8

H-Height(in.) 18 18 243/4

Connection - Liquid Line (in.) 3/8 3/8 3/8

Connection - Suction Line (in.) 3/4 3/4 7/8

InstalledOriceSize(in.) .061 .067 .071

NOTES:

1. Individualrestrictorsareavailablebypartnumber-PN664***(where***representsthesize).

Example:664103isarestrictor0.103indiameter.

2. RefertosalesspecicationsheetsforListed/Certiedcombinationsofequipmentandrequiredaccessories.

3. RefertothecurrentAHRIdirectoryforcertiedratingsofsplitsystems.

4. Basedonanominal0.3”W.C.pressuredropacrossthecoil.

5. TXVvalvemayberequiredtoachieveAHRIrating

COIL SPECIFICATIONS & DIMENSIONS

7

Specications&illustrationssubjecttochangewithoutnoticeorincurringobligations.

O’Fallon,MO|PrintedinU.S.A.(02/12) 709278A (Replaces7092780)

INSTRUCTIONS WITHTHE EQUIPMENT OWNER.

This manual suits for next models

3

Table of contents

Other Nordyne Industrial Equipment manuals