NORPOLE NPCIM500M User manual

NORPOLE

Commercial Modular Ice Maker

User’s Manual

READ THIS MANUAL CAREFULLY BEFORE USING YOUR COMMERCIAL ICE MAKER AND KEEP IT FOR

FUTURE REFERENCE.

Models: NPCIM350M NPCIM500M

NORPOLE

PRODUCT REGISTRATION

Thank you for purchasing a Norpole Commercial product. The first step to protect your new product is to complete the product registration on our

website: https://mcappliance.com/product-registration. The benefits of registering your product include the following:

1. Registering your product will allow us to contact you regarding a safety notification or product update.

2. Registering your product will allow for more efficient warranty service processing when warranty service is required.

3. Registering your product could act as your proof of purchase in the event of insurance loss.

Once again, thank you for purchasing a Norpole Commercial product.

2

TABLE OF CONTENTS

REGISTRATION ......................................................................................................................................................2

IMPORTANT INFORMATION .................................................................................................................................4

IMPORANT SAFETY INSTRUCTIONS .......................................................................................................................5

SPECIFICATIONS.....................................................................................................................................................7

INSTALLATION INSTRUCTIONS...............................................................................................................................8

OPERATION INSTRUCTIONS.................................................................................................................................10

CARE AND MAINTENANCE...................................................................................................................................12

TROUBLESHOOTING ............................................................................................................................................14

WARRANTY ..........................................................................................................................................................16

3

Important Information

Please pay attention to the following warning labels on the ice maker:

The label indicates a hazardous voltage. There is a risk of

electric shock.

The label indicates a flammable foaming agent

“Cyclopentane” used. There is a risk of fire.

The label indicates a hazardous voltage. There is a risk of

electric shock.

The label indicates a flammable refrigerant “R290” used. There

is a risk of fire.

The label indicates rotating components inside. There is a risk

of serious mechanical injury.

Instruction of symbols in this Manual

Warning sign, special attention is required.

Warning sign, special attention is required, and operation is prohibited.

4

IMPORTANT SAFETY INSTRUCTIONS

WARNING

Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION

Hazards or unsafe practices which COULD result in minor personal injury or property damage.

1. Read all instructions before using the appliance.

2. CAUTION: Installation, maintenance and repair should only be performed by certified professionals. Improper installation could result in serious

harm or death and may void your warranty.

3. This unit may not be used in any outdoor or unregulated environment.

4. Any self-modification, improper installation, adjustment or maintenance can lead to property loss or casualty. Please contact customer service for

any adjustment or maintenance, and have the work done by a trained & qualified person.

5. To minimize shock and fire hazards, be sure not to overload the outlet or circuit. Please designate one outlet for the unit.

6. DO NOT install the ice machine in a wet or easily splashed location.

7. The power supply for this unit must be properly grounded with leakage protection.

8. DO NOT ground the ice machine by connecting to a gas pipe, water pipe, telephone line or lightning rods, etc..

9. WARNING: DO NOT insert or pull out the plug with wet hands.

10. The power cord is equipped with a 3-prong grounding plug to protect against shock hazards. ALWAYS plug cord into a properly installed and

grounded 3-prong wall receptacle. Refer to the manufactures rating label for electrical and other technical data specific to this unit.

11. DO NOT modify or cut the power cord, or use any other cord or plug. DO NOT use an extension cord.

12. This appliance should not be operated by anyone that is not able to follow proper safety procedures or does not have experience with this type of

equipment, unless under close supervision. Keep children away from the device.

13. DO NOT allow children to play in or on the ice maker.

14. WARNING: DO NOT store anything flammable or explosive in or near the unit.

15. DO NOT insert any objects into ventilation or exhaust ports, or serious mechanical injury may occur due to rotating components in the unit.

16. DO NOT connect the ice maker to hot water.

17. DO NOT store or freeze any food in the ice machine.

18. ALWAYS make sure the unit is installed on a floor capable of supporting its weight when full. Failure to do so can cause the unit to tip, leading to

injury or damage to the unit.

19. The unit must be installed in a location where there is plenty of space for ventilation around it.

20. ALWAYS unplug the unit if it is not being used for long periods.

21. If the unit malfunctions or is damaged in any way, immediately turn off and disconnect the power, and have the unit inspected by qualified

personnel.

22. ALWAYS unplug the unit and remove all water and ice before cleaning, repair, or maintenance.

23. DO NOT allow water to splash directly onto the unit during cleaning, repair, or maintenance to avoid damaging electric components.

24. Flammable foaming agents are used for the insulation process. Be sure to dispose of and recycle the unit properly.

25. WARNING: DO NOT put your hands or feet under the unit when moving it.

26. CAUTION: DO NOT hang on the doors.

READ AND FOLLOW THIS

SAFETY INFORMATION CAREFULLY

SAVE THESE INSTRUCTIONS

5

ONLY BY TRAINED SERVICE PERSONNEL. DO NOT

PUNCTURE REFRIGERANT TUBING.

•CAUTION – RISK OF FIRE OR EXPLOSION.

FLAMMABLE REFRIGERANT USED. CONSULT REPAIR

MANUAL/OWNER'S GUIDE BEFORE ATTEMPTING TO

SERVICE THIS PRODUCT. ALL SAFETY

PRECAUTIONS MUST BE FOLLOWED.

•CAUTION – RISK OF FIRE OR EXPLOSION. DISPOSE

OF PROPERLY IN ACCORDANCE WITH FEDERAL OR

LOCAL REGULATIONS. FLAMMABLE REFRIGERANT

USED.

•CAUTION – RISK OF FIRE OR EXPLOSION DUE TO

PUNCTURE OF REFRIGERANT TUBING; FOLLOW

HANDLING INSTRUCTIONS CAREFULLY. FLAMMABLE

REFRIGERANT USED.

General

The ice machine is fully automatic. With proper installation and connection to

potable water and power source, the ice making will start properly. When the

ice cubes fill up the ice bin, the machine will automatically stop. The ice

machine is generally used in the following and similar occasions:

▪The kitchen area of a store, office or other workplace;

▪Farm, hotel, car hotel and restaurant;

▪Catering and similar non-retail occasions;

▪This ice machine is not intended for used at home.

For the ice maker with flammable refrigerant R290:

•DANGER - RISK OF FIRE OR EXPLOSION.

FLAMMABLE REFRIGERANT USED. DO NOT USE

MECHANICAL DEVICES TO DEFROST

REFRIGERATOR. DO NOT PUNCTURE REFRIGERANT

•DANGER – RISK OF FIRE OR EXPLOSION.

FLAMMABLE REFRIGERANT USED. TO BE REPAIRED

6

SPECIFICATIONS

Model

NPCIM350M 22.1” x 24.3” x 22.4”

(560 x 618 x 568 mm) 350 lbs. (159 kg)/ 24 hrs 230 lbs. (104kg) 110.2 lbs.

(50 kg)

NPCIM500M 29.9” x 24.3“ x 22.4”

(760 x 618 x 568 mm) 275 lbs. (125 kg) 143.3 lbs.

(65 kg)

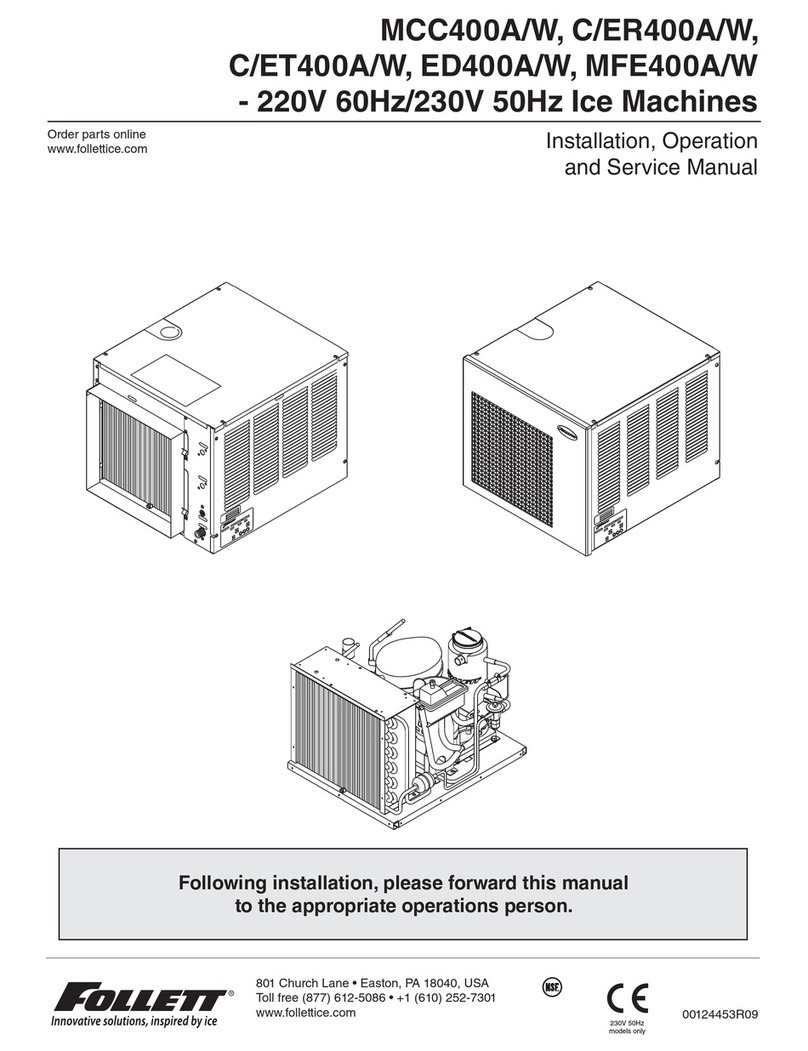

Figure 1

▲Model NPCIM350M

a

c

b

▲

Model NPCIM500M

Dimensions (LxWxH)

Inches (mm)

Ice Making

Capacity Bin Capacity Weight

500 lbs. (227 kg)/ 24 hrs

d

f

e

a. 22.4" (568mm)

b. 22.1" (560mm)

c. 24.3" (618mm)

d. 22.4" (568mm)

e. 29.9" (760mm)

f. 24.3" (618mm)

7

7

INSTALLATION

CAUTION: Read all instructions before installing

INSTALLATION LOCATION

The ice maker should be installed in a proper location meeting the following conditions:

•Indoors, not more than 6,560 ft (2,000 meters) above sea level.

•Ambient temperature: 40° - 104°F (5-40°C). For optimal ice making performance, unit should be operated in an ambient temperature of 60°- 80°F

(16°C - 27°C).

•Properly installed and grounded power supply that matches the rated voltage indicated on the machine nameplate.

•Water source: potable water, with water pressure from 1.3 Bar to 5.5 Bar; water temperature: 40° - 95°F (5-35°C). For optimal ice making

performance, operate with water temperature between 45°F - 55°F (7°C - 13°C)

•The ice machine should be kept away from heat sources, and should not be used in an extremely high or low temperature environment, and

away from direct sunlight. For optimal ice making performance, operate with water temperatures between 45°F - 55°F

•There should be sufficient space around the unit for ventilation. The distance from the ice maker to the wall should be no less than 12 in. (30 cm) for

the front, 6 in. (15cm) for the sides, and 8in. (20 cm) for the rear.

•The ice machine must be placed on a floor sufficient to support its weight when filled with water or ice.

•The electrical outlet for the ice maker must be properly grounded and with leakage protection;

•Proper floor drainage must be provided near the installation location of the ice machine.

ELECTRICAL SUPPLY

ALWAYS make sure that the unit is plugged into a properly installed and grounded dedicated outlet that meets the requirements listed on the ratings

label and that has appropriate overcurrent protection. Voltage that is too high or too low can detrimentally affect the operation of, or damage, the

unit.

DO NOT modify or cut the power cord, or use any other plug or an extension cord.

INSTALLATION SCHEMATIC

8

1. Verify that the unit is in good condition and all parts and accessories are present. Check the model and serial number onthe label and write

them down for reference.

2. Clean all surfaces of the unit, including the ice making area and ice bin with a sponge soaked in warm potable water and soda. Wash and dry

the unitthoroughly.

5.

3. Place the unit inthe location inwhich itwill be used. Make sure the surface is level and can support the weight, and that there is water

drainage near, and plenty of space forventilation around the unit.

4. Use the adjustable leg levelers if needed to level the ice maker.

6.

Connect the machine's inlet water filter and water pipe referring tothe schematic diagram ofinstallation; ifthe installation site is already

equipped with a water filtration system, the filter may not be needed.

NOTE: Make sure to install the filter so the water is flowing inthe direction noted on the filter head cover orfilter body.

NOTE: This machine is equipped with aninlet water filter. The filter will remove impurities from the water used as the machine is running.

Generally, itneeds to be replaced every month to every 3 months.

7.

Connect the machine to the water supply using the 3/4" inlet pipe supplied with the machine. It is recommended to install a water valve

(not supplied with this machine) onthe water supply line.

8.

Connect the drain pipe to the drain connection. It is recommended that the drain pipe should have a difference of level more than 1 in per 3

ft (3cm per meter); and confirm that the drain pipe is not blocked. It is recommended that the drain pipe be connected to anopen drainage

port.

9.

No part ofthe drain pipe should be higher than the drain port onthe unit, and must not have any inclines.

10.

Confirm that all power requirements stated on the ratings label are met, and that the unit is connected to aproperly installed, working and

grounded circuit breaker.

Make sure the power switch is ‘Off’ before connecting the ice maker tothe power supply.

INSTALLING THE ICE MAKER

9

CONTROL PANEL AND DISPLAY

a. LED Display: Will give information regarding the ice making cycle or errors.

●INIT: Self-check. Display will show ini

●Prep: Display will count up in seconds while the unit prepares to start.

●Make: Shows progress of the ice making process. Will count the seconds up while the water temperature is decreased, and then

count down to show the ice making process.

●Ice Harvest: Counts the seconds for the ice harvesting.

●Cleaning: Will display “CLE” while cleaning and descaling, ‘STL’ during sterilization, and ‘rin’ for rinsing.

b. LED indicators show the current process the ice maker is in.

c. Ice Cube Thickness adjustment: During the ice making process, press and hold the “-” button for 3 seconds, then press “+” or “-” to change

the thickness of the ice being made.

NOTE: Pushing the “+” or “-” button extends or shortens the ice making time by 1.5 minutes.

d. Cleaning: During operation, press the cleaning button for 3 seconds to start the cleaning process. As the display shows the steps of the

process, cleaning agents and disinfectants will need to be added to the water trough. When the cleaning process is completed, the unit will

return to the ice making mode.

e. ON/OFF: When the unit is connected to a power supply, press the “ON/OFF” button to turn the unit on or off.

NOTE: ALWAYS turn the ice maker off and disconnect from the power supply for maintenance, or when not using for a long period.

f. Error Codes: If there is a problem with the ice making process, the LED Display will show an error code indicating the issue. See chart in

the Troubleshooting section for additional information.

OPERATION

After installation, connect the water source and turn on the power supply, and the machine will come on and start working. Please confirm that the

machine is operating normally when you turn it on for the first time..

10

STARTUP AND OPERATION

1. Before starting up the ice maker, please check and confirm the following:

●All packing materials have been removed.

●All accessories have been removed from the ice bin.

●The unit is properly leveled.

●The water pipe is securely connected and the valve is open.

●The plug is properly connected to the power supply outlet and the unit’s power switch is in the ‘Off’ position.

●The ambient temperature, water temperature, and water pressure meet the requirements.

2. Turn thepower switch to the‘On’ position to start the ice maker. Once turned on, the unit will automatically begin making ice.

3. For normal operation of the unit, confirm the following:

●There is water inthe water trough and no overflow isoccuring.

●The pump is working properly and water is flowing evenly on the evaporator.

●The compressor is running normally, the temperature of the evaporator and the ice making water is gradually decreasing.

●For air cooled machines, verify the fan is running normally, and there isstable air flowinthe inlet and outlet of the ice machine.

●There are no abnormal noises or vibrations.

1

It takes about 10 to 20 minutes to make one batch ice, depending on the ambient temperature and the temperature of the water. The higher the

temperature is, the longer the ice making will take.

When you turn the power switch ‘On’, the unit will run a self check and pump any water out of the system. The inlet valve will then open and the

water trough will fill up with water and the unit will pre-cool the evaporator for about 30 seconds. Water then flows over the evaporator to be

frozen into ice cubes, which are then dropped in the Harvest cycle when the defrost valve turns on allowing hot gas to flow into the evaporator,

freeing the ice to drop.

WARNING: DO NOT put your hand into the ice bin while the ice is dropping.

When the ice bin is filled to the point where the ice sliding board cannot return to its normal position, the ice making process will stop until the

ice has either melted enough to let the board fall into position, or ice is removed from the bin. Once the bin is clear, the ice making process will

resume.

11

If the unit is not going tobe used for a long period or stored away, turn off the water and disconnect from the power supply. Clean the interior and

exterior ofthe unit, and be sure to drain all water from the water trough, inlet pipe, and drain pipe.

INTERIOR CLEANING

Cleanthe inside of the ice bin with clean, potable water and wipe as needed.

For the air-cooled ice maker, the condenser should be cleaned every three weeks.

Use a soft brush oravacuum cleaner with a brush tobrush it up and down along

the fin direction, to avoid damage tothe fins and further affecting the cooling

effect. The condenser filter should be removed and carefully cleaned every 2

weeks.

NOTE: Be careful when doing the condenser cleaning as the edges of the fins

are sharp.

INLET WATER FILTER

The filter should be inspected regularly and replaced every 1-3 months based on

usage andwater quality.

WATER PIPE

To ensure food safety, the water pipe should be cleaned regularly.

WINTERING

NOTE: Maintenance must be done by a qualified service technician.

WARNING: Before maintenance or cleaning can be performed, the water supply should be shut off and the unit should be disconnected to the

power supply.

EXTERIOR CLEANING

ALWAYS make sure to keep the area around the ice maker clean, and that nothing is blocking the vents. Clean the exterior of the unit with a mild

detergent and wipe clean. If necessary, use a commercial stainless steel cleaner or polish.

NOTE: Stainless steel may rust without proper care and maintenance.

CARE AND MAINTENANCE

12

CLEAN FUNCTION

NOTE: ALWAYS empty the ice bin and make sure there is no ice on the evaporator before running the cleaning function.

NOTE: ALWAYS clean and sterilize the ice bin, ice sliding board, water distribution pipe, water supply pipe, and water pump, then rinse completely.

•Turn on the ice maker and push the “Clean” button for 3 seconds. Put the proper amount of commercial ice maker cleaning or descaling

solution into the water trough manually per the products instructions, let it sit there for about 1 minute, then push the 'Clean' button again.

The ice maker will enter the cleaning process and will run an auto clean cycle for about 15 minutes. Spray the evaporator with some

solution while this is running to ensure complete cleaning. When finished, the “Clean” LED will flash slowly.

•Manually put sterilization solution into the water trough per the product instructions and press the “Clean” button again. The process will

run about 15 minutes. Be sure to spray some of the solution onto the evaporator while this is running to ensure complete sterilization.

•When sterilization is complete, the unit will enter a rinsing cycle that lasts about 5 minutes. This will repeat 5 times.

•When the entire cleaning cycle is complete, the unit will go back into the ice making mode. Allow it to make 5 batches of ice, and be sure

to dispose of these first 5 batches after cleaning. It is recommended that the ice maker be cleaned and maintained at least every 4 weeks.

Failure to do so may result in the unit malfunctioning. The maintenance of the ice machine or malfunctions due to improper maintenance

are not covered by the manufacturer's warranty.

Put cleaner in front right or right

side of tank

Cleaners are discharged from

the outlet

NOTE: Be sure to use a sterilization solution specifically meant for commercial ice makers

13

TROUBLESHOOTING

Before requesting any service on your unit, please check the following points:

1. Check the water supply:

●Verify that there is water in the water trough.

●Make sure the water pressure is between 1.3-5.5 bar, and the water temperature is between 41-95°F (5-35°C).

●Make sure the water valve is open and there are no leaks.

2. Check the power supply:

●Check the display to verify that that unit is turned on.

●Verify that power to the outlet is on, that the outlet is good, and the plug is properly connected.

Use the following table to try to diagnose common issues. Please note that this guide serves only as a reference for solutions to common problems. If a

service call is needed, be sure to obtain the model and serial number before calling customer service.

Symptom

Possible Cause

Corrective Action

Not working

Power switch not on

Turn on the power switch

Plug is loose

Verify plug is securely connected to a working outlet

Indicator is ‘Off’

Power switch not on

Turn on the power switch

Plug is loose

Verify plug is securely connected to a working outlet

Display shows ‘E04’ high temperature

error code

The ambient temperature is too high

Make sure the unit is installed somewhere with an

ambient temperature of 41-104°F (5-40°C)

Condenser is dirty or blocked

Clean the condenser and make sure nothing is blocking

air flow

Fan is not running

Make sure nothing is blocking the fan from running.

Display shows ‘E06’ High pressure error

code

High pressure switch wires disconnected

Check and connect the wires on the high pressure

switch

Not defrosting

Ambient temperature too low

Make sure the unit is installed somewhere with an

ambient temperature of 41-104°F (5-40°C)

Defrost valve does not start normally

Check the defrost valve, correct issues if found

Ice is too thin or too thick

Check the ice thickness setting

Poor transparency of ice cubes; ice

cubes too thin or incomplete

Ice thickness too thin

Check the ice thickness setting

Water pressure too low

Verify that the water supply pressure is 1.3 Bar to 5.5

Bar

Water temperature too high

Make sure the water temperature is between 41-95°F

(5-35°C)

Water inlet valve does not work

Check the water inlet valve and correct any issues

Water leaking

Check all water connections and tighten as needed

Water inlet filter has not been replaced for a long time

Replace the filter

Ice making process too slow

Condenser or air filter is dirty

Clean the condenser and filter or replace filter

Ambient temperature too high

Make sure the unit is installed somewhere with an

ambient temperature of 41-104°F (5-40°C)

Not enough ventilation air flow

Make sure there is adequate space around unit

Water temperature too high

Make sure the water temperature is between 41-95°F

(5-35°C)

Making noise

Unit is not level or on a level surface

Make sure unit is correctly installed and leveled

14

DISPLAY ERROR CODES

If the display shows any of these codes, check the unit before calling for customer service.

CODE

CAUSE

MODE

E01

Water Curtain or Ice Full Switch Fault

Sleep mode. Unit will recover

after water curtain is reset.

E03

Ice Harvest Overtime

Sleep Mode

E04

High Temperature Fault

Sleep Mode

E05

Water Shortage Fault

Sleep Mode. Unit will retry every

30 minutes.

E06

Over-Pressure Fault

Sleep Mode

E07

Condenser Temperature Sensor Open

Circuit Fault

Keep Working

E08

Condenser Temperature Sensor Short

Circuit Fault

Keep Working

E09

Water Temperature Sensor Open Circuit

Fault

Keep Working

E10

Water Temperature Sensor Short Circuit

Fault

Keep Working

E13

Water Level Control Fault

Sleep Mode

15

NORPOLE

LIMITED WARRANTY

Norpole, Inc. warrants each new Commercial Ice Maker tobe free from defects in material and workmanship and agrees to remedy any such defect orto

furnish a new part(s) (at the company’s option) for any part(s) ofthe unit that has failed during the warranty period. Parts and labor expenses are

covered on this unit for a period of one year from the date of purchase.

In addition, Norpole, Inc. warrants the compressor (parts only) tobe free from defects in material and workmanship for a period of 5 years. The

consumer is responsible for all labor and transportation expenses related to the diagnosis and replacement ofthe compressor after the initial three-year

warranty expires. In the event that the unit requires replacement orrefund under the terms of this warranty, the consumer is responsible for all

transportation expenses to return the unit to our factory prior to receiving a replacement unit or refund. A refund or replacement will beissued at the

discretion ofNorpole, Inc.. A copy ofthe dated sales receipt/invoice is required to receive warranty service or a refund.

This warranty covers appliances in use within the contiguous United States, Alaska, Hawaii and Puerto Rico. The warranty does not cover the following:

●Damages due to shipping damage or improper installation.

●Damages due to misuse or abuse.

●Punctures to the evaporator system due to improper defrosting of the unit.

●Content losses due to failure of the unit.

●Inside components such as the shelves, etc.

●Repairs performed by unauthorized service agents.

●Service calls that do not involve defects in material and workmanship, such as instructions on proper use of the product or improper installation.

●Replacement or resetting of fuses or circuit breakers.

●Failure of this product if used for purposes other than its intended purpose.

●Disposal costs for any failed unit not returned to our factory.

●Any delivery or installation costs incurred as the result of a unit that fails to perform as specified.

●Expenses for travel and transportation for product service if your appliance is located in a remote area where service by an authorized service

technician is not available.

●The removal and reinstallation of your appliance if it is installed in an inaccessible location or is not installed in accordance with published

installation instructions.

●Refunds for non-repairable products are limited to the price paid for the unit per the sales receipt or invoice.

●This warranty is non-transferable. This warranty applies only to the original purchaser and does not extend to any subsequent owners.

LIMITATIONS OF REMEDIES AND EXCLUSIONS

Product repair in accordance with the terms herein, is your sole and exclusive remedy under this limited warranty. Any and all implied warranties

including merchantability and fitness for a particular purpose are hereby limited to three years or the shortest period allowed by law. Norpole, Inc. is

not liable for incidental or consequential damages and no representative or person is authorized to assume for us any other liability in connection with

the sale of this product. Under no circumstances is the consumer permitted to return this unit to the factory without the prior written consent of

Norpole, Inc.

Some states prohibit the exclusion or limitation of incidental or consequential damages, or limitations on implied warranties. This warranty gives you

specific legal rights, and you may also have other rights which vary from state to state.

Model Parts &Labor Compressor (Part Only) Type of Service

NPCIM350M NPCIM500M 1 Year 5 Years In-Field

For Service or Assistance please call 888-775-0202 or visit us on the web at https://mcappliance.com/product-registration.

16

NORPOLE

Máquina de hielo modular comercial

Manual del usuario

LEA ATENTAMENTE ESTE MANUAL ANTES DE USAR LA MÁQUINA DE HIELO COMERCIAL Y

CONSÉRVELO PARA FUTURAS REFERENCIAS.

Modelo: NPCIM350M NPCIM500M

NORPOLE

REGISTRO DEL PRODUCTO

Gracias por comprar un producto Norpole Commercial. El primer paso para proteger su nuevo producto es completar el registro del producto en nuestro sitio

Web: https://mcappliance.com/product-registration. Beneficios de registrar este producto:

1. El registro del producto nos permitirá contactarlo con relación a un aviso de seguridad o actualización del producto

2. El registro del producto nos permitirá procesar con más eficiencia el servicio de garantía cuando este servicio sea

requerido.

3. El registro del producto puede servir como prueba de compra en el caso de pérdida cubierta por el seguro.

Una vez más, gracias por comprar un producto Norpole Commercial.

18

CONTENIDO

REGISTRO .......................................... ..................................................................................................................18

INFORMACIÓN IMPORTANTE ............................................................................................................................20

INSTRUCCIONES DE SEGURIDAD IMPORTANTES ...............................................................................................21

ESPECIFICACIONES ...............................................................................................................................................23

INSTRUCCIONES DE INSTALACIÓN .......................................................................................................................24

INSTRUCCIONES DE OPERACIÓN .........................................................................................................................26

CUIDADO Y MANTENIMIENTO ............................................................................................................................27

SOLUCIÓN DE PROBLEMAS ...............................................................................................................................29

GARANTÍA ...........................................................................................................................................................31

19

Información importante

Preste atención a las siguientes etiquetas de advertencia en la máquina de hielo:

La etiqueta indica tensión peligrosa. Riesgo de descarga

eléctrica.

La etiqueta indica un agente espumante inflamable.

Se utiliza "ciclopentano". Riesgo de incendio.

La etiqueta indica tensión peligrosa. Riesgo de

descarga eléctrica.

La etiqueta indica que se usa el refrigerante inflamable

“R290”.

Riesgo de incendio.

La etiqueta indica componentes giratorios en el interior.

Riesgo de lesiones mecánicas graves.

Instrucción de los símbolos en este manual.

Signo de advertencia: es necesario prestar especial atención.

Signo de advertencia: es necesario prestar especial atención y se prohíbe la operación.

20

This manual suits for next models

1

Table of contents

Languages:

Other NORPOLE Ice Maker manuals