MOUNTING HOLES MEASUREMENTS

A strong and level foundation is required to secure the

installation of the base.

It may occur during storage or transport the non-electrical telescope

column fastens in the lower position.

Adjust this easily by fastening the lockable arm for swing,

li up the release handle and pull up the chair.

MOUNTING ON A DECK RAIL

First, make sure to have mounted the deck rail according

to its user manual. The bolts for mounting the chair to the

deck rail is already in place in the carrier wagon.

If you have an electrical deck rail and the cabling of the

switch is done by quick-connections already implemented

in the chairs column.

CARE AND MAINTENANCE OF LEATHER

As a natural product, leather is very durable and hardwearing, but all leather products require cleaning

and protection. By following these instructions, you will ensure a long and lasting leather quality. Never

place leather furniture closer than 20-30 cm to a radiator or in direct sunlight.

CARE AND MAINTENANCE OF FABRIC

Regular light vacuuming. Occasional cleaning should be done with a reputable brand of upholstery

shampoo following the manufacturer’s instructions

LEATHER CLEANING

Cleaning removes everyday dirt and stains from

your leather. Without proper cleaning the leather

will over a period of time leave grease spots or dis-

coloration’s. To avoid this, clean with So Cleaner

on a regular basis. We advise once a month.

LEATHER PROTECTION

Protect your leather to guarantee that the origi-

nal quality of the leather will be maintained. Use

Leather Protection Cream, we advise 2-4 times a

year. This will protect against spots and preserve

the leathers soness.

MAINTENANCE OF MOVING PARTS

Glide parts of the chair can be lubricated with a silicone-based lubricant. If the chair is on a deck rail, it is

important that the deck rails railway is NOT lubricated.

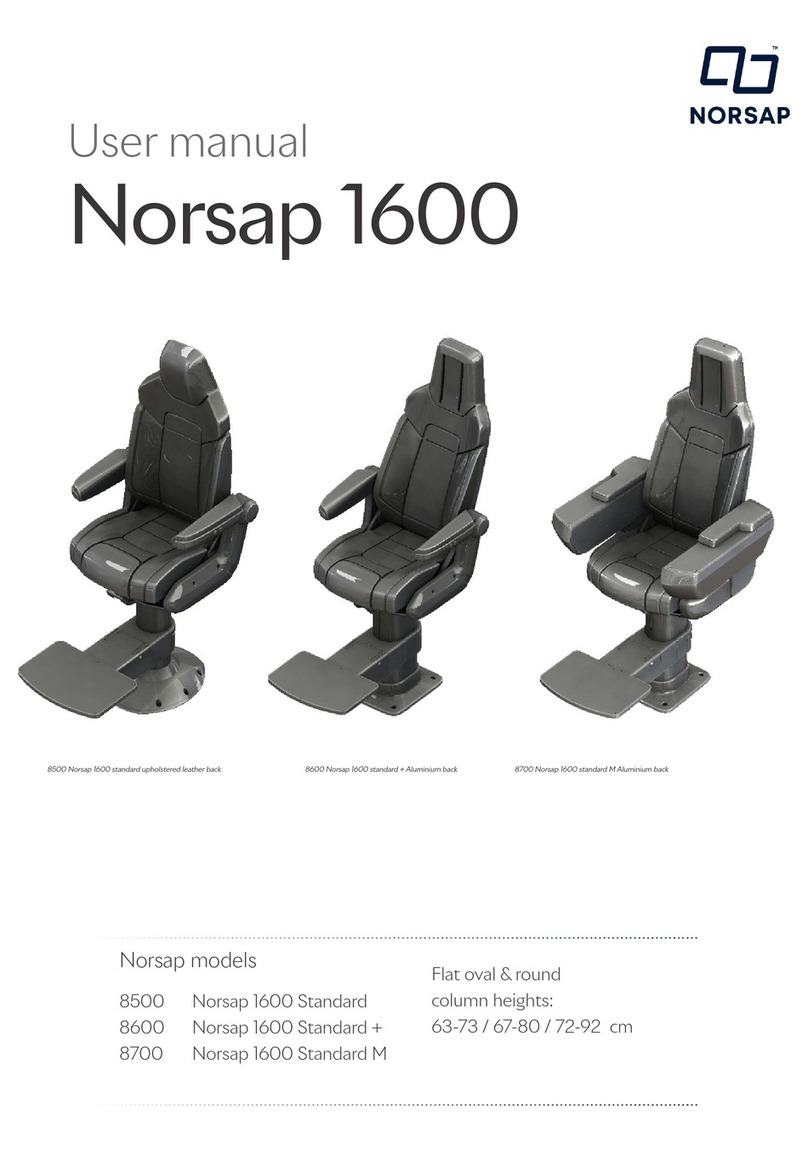

XL COLUMN

FLATOVAL COLUMN

XL column boom plate, may vary on chair setup and model.