NorSap 6650 Series User manual

Users Manual

October 11, 2012 1:10 PM

NorSap Basic Deck Rail

Art. No.: 6650-XXXX, 6651-XXXX for the NorSap 1500 and NorSap 2000

Art. No.: 6652-XXXX, 6653-XXXX for the NorSap 1000

Art. No.: 6676-XXXX, 6677-XXXX for the NorSap 800

Introduction

Congratulations with your purchase of a NorSap chair and thank you for your condence in our company

products. NorSap is among the leading producers of helmsmen and operator seats for the maritime mar-

ket.

This manual will assist you in making the best use of the functional capabilities of the NorSap chair and

will ensure you will quickly become familiar with its use. If you have any questions regarding the safe and

eective operation of you NorSap chair or accessories after reading this manual, immediately contact our

head oce marketing department for further assistance.

NorSap AS

Mjåvannsveien 35

NO-4626 Kristiansand

NORWAY

Telephone

+47 38 18 52 00

Telefax

+47 38 18 20 86

E-mail

Web

norsap.com

Contents

Introduction 2

Mounting the top mounted deck rails 3

Detailed view 4

Installation of Deck Rails IMPORTANT NOTE 5

Installation of chair on a basic deck rail 6

Installation of chair on a basic deck rail part II 7

Installation of Basic Deck Rail release handle on chair 8

Wagon details 9

Flange modication necessary for the 800 Chair 10

Release handle details 11

Maintenance of moving parts 11

Safety 11

Shipping and storage specications 11

2

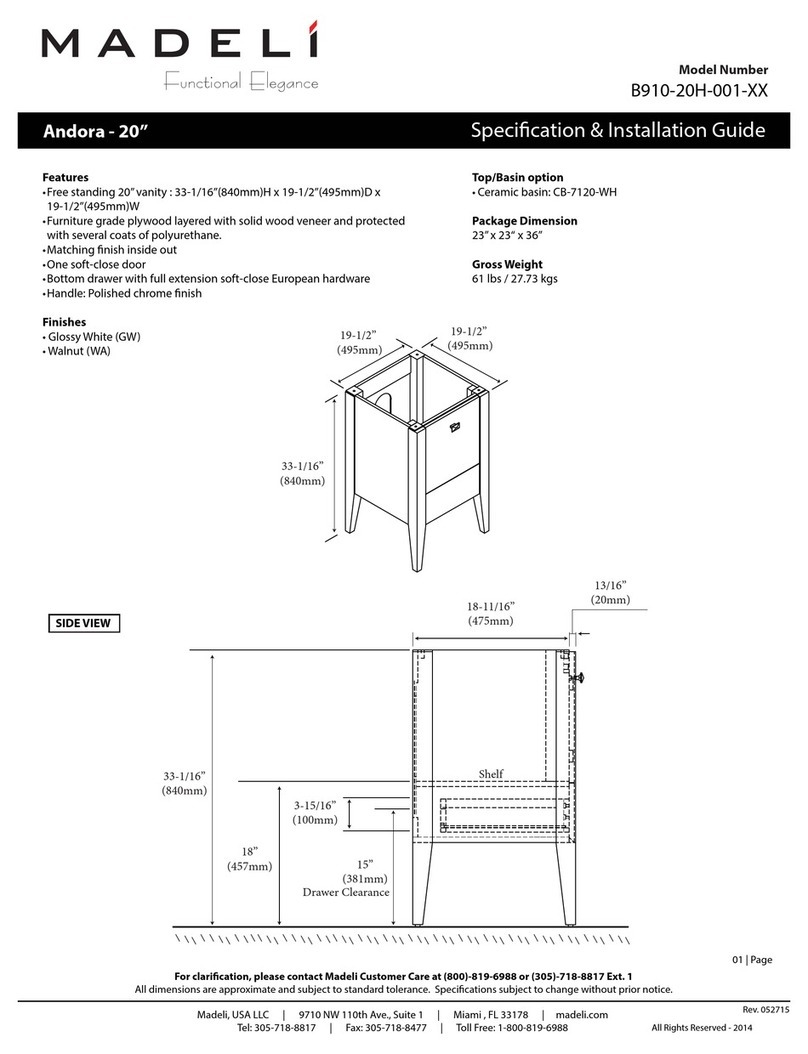

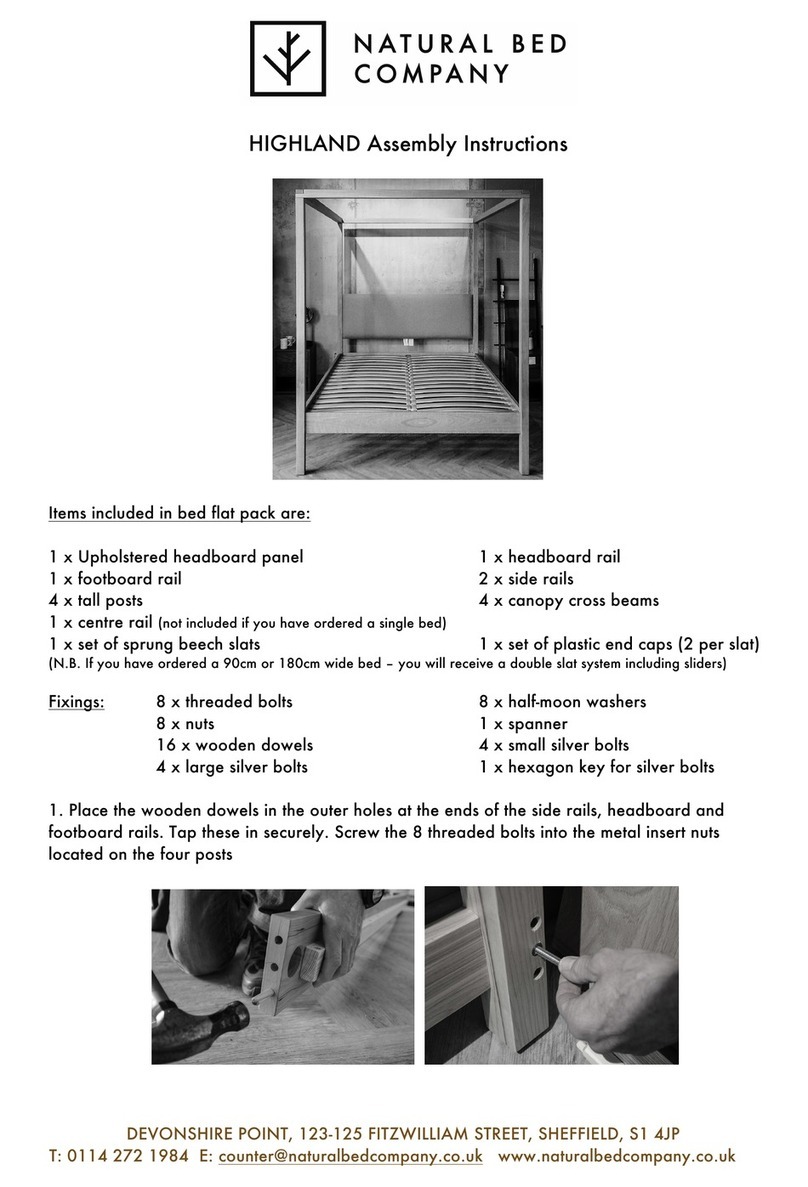

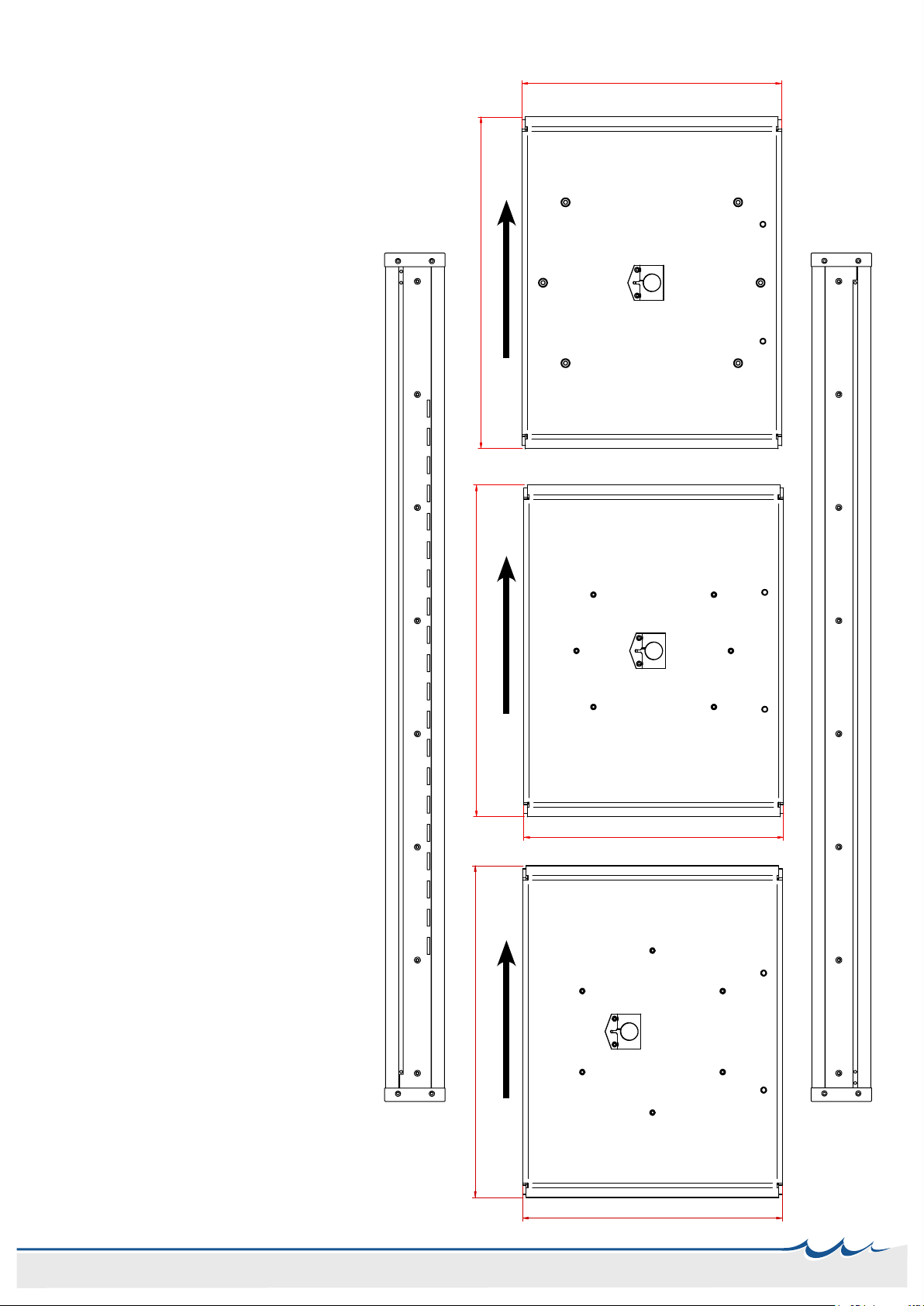

Mounting the top mounted deck rails

Due to material dierences of the wagon, the deck rail should be mounted in the following order:

1. Mount the rail with the locking tracks rst at desired place. This is your LEFT rail facing forward.

2. When the rail is mounted, place the plain rail parallel besides it, and slide the wagon on both rails.

3. Place the wagon to the one end of the mounted rail, and the mounting template on the other end,

and make sure the loose rail is parallel with the end of the mounted rail.

4. Make sure the distance is 367mm +/- 0,5mm between the mounting holes - and that the wagon is not

too tight nor too loose so that it travels rmly. Mount one screw at the current end of the rail.

5. Move the wagon to the other side, check for rm function and mount the second screw.

Test the rails function before mounting the rest of the screws.

This procedure ensures that the deck rail will function optimally and without any loose play.

When function of the deck rail is adequate, mount the stopping block

and end plugs on the rails, shown on the next page.

1

5

Front

2

33

4

90°

367 +/- 0,5mm

3

Detailed view

1. End plug for Top Mounted Basic Deck Rail MP248

2 x bolts for mounting 4.8x19 B430 4.8x19

2. Stop block for wagon SAP-3948

2 x bolts for mounting 6x10 B424 M6x10

3. Top rail cover without locking holes SAP-3949-XXXX (XXXX = length of rail)

To be mounted on the RIGHT side facing front

X number of bolts (depending on length) B434 4.8x50

4. Top rail cover with locking holes SAP-3950-XXXX

To be mounted on the LEFT side facing front

X number of bolts (depending on length) B434 4.8x50

5. 2 x Bottom rail prole, top mounted SAP-7135-XXXX

2 x Bottom rail prole, ush mounted SAP-3988-XXXX

1

5

2

4

3

Article numbers

Deck rails

Complete

6650-XXXX Basic Deck Rail for 1500 and 2000 Top Mounted

6651-XXXX Basic Deck Rail for 1500 and 2000 Flush Mounted

6652-XXXX Basic Deck Rail for 1000 Top Mounted

6653-XXXX Basic Deck Rail for 1000 Flush Mounted

6676-XXXX Basic Deck Rail for 800 Top Mounted

6677-XXXX Basic Deck Rail for 800 Flush Mounted

Spare parts

DEL-1190-XXXX Rail prole with locking holes Top mounted (single)

DEL-1189-XXXX Rail prole Top mounted (single)

DEL-1207-XXXX Rail prole with locking holes Flush mounted (single)

DEL-1208-XXXX Rail prole Flush mounted (single)

Wagons

Complete

DEL-1193 For the 1500 and 2000

DEL-1192 For the 1000

DEL-1206 For the 800

Spare parts

KLA-011 Spare Wheel

WIRE-022 Wire

DEL-1231 Release handle

4

Wagons

Complete

DEL-1193 For the 1500 and 2000

DEL-1192 For the 1000

DEL-1206 For the 800

Spare parts

KLA-011 Spare Wheel

WIRE-022 Wire

DEL-1231 Release handle

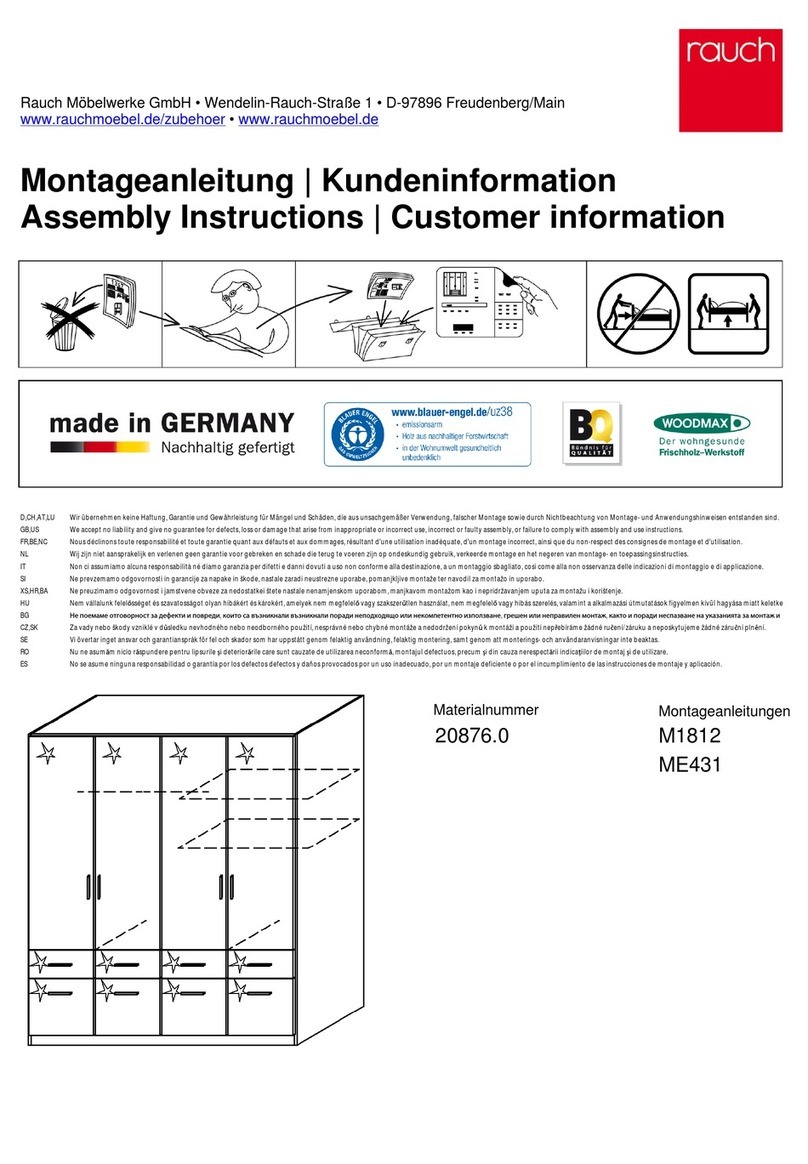

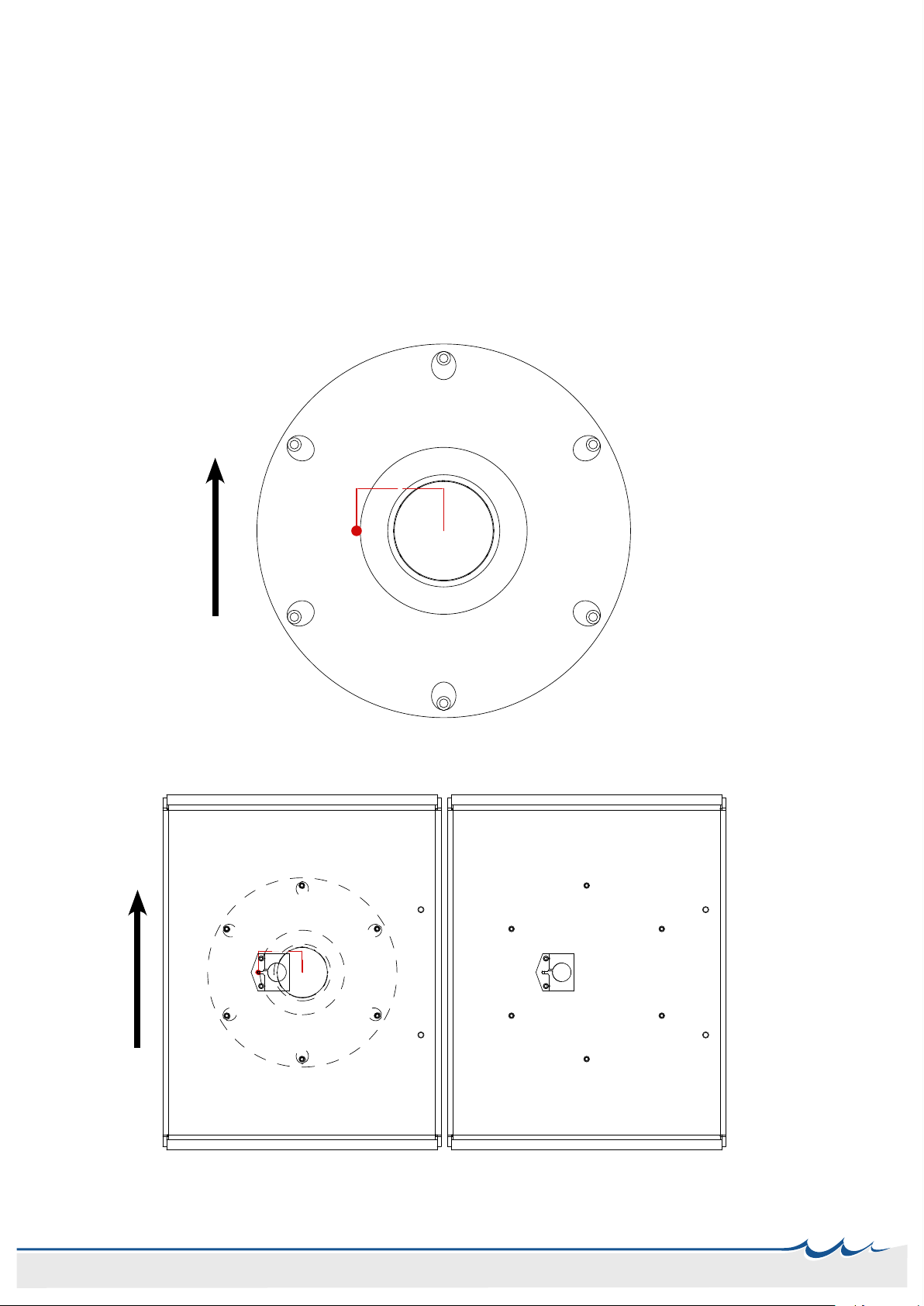

Installation of Deck Rails IMPORTANT NOTE

• A strong and level foundation is required to install the Deck Rail securely

• The assembly area and sliding tracks must be

free from scraps of metal or other items during installation

• Do not apply grease in the wheel tracks

• We do not stand liable if alterations are made by cutting or disassembling the Deck Rails;

any such work will be done at your own risk

Mounting holes

The mounting holes must be parallel with a distance of 367+/-0.5 mm, this is standard for all lengths. Due

to material dierences the mounting procedure explained on page 2 is the recommended way to

mount the basic deck rail. This procedure should prevent the deck rails wagon to be mounted too

loosely.

107 282 107

496

367

37.8

367

444

446

107 282 107

496

367

37.8

367

444

446

50 200 200 200 200 200 200 200 50

200 200 200 200 200 200 200 250 50

250

50

200 200 200 200 200 200 200 200 200 100 50

200200100

50

200 200 200 200 200 200 200

200

200200

15050 200 200 200 150 50

37.8

367

444

306

446

567.2

70

70

306

1300

1500

1600

2200

3400

4600

5200

The following diagrams shows the spacing between the mounting holes from a 1500mm deck rail to a

3000mm deck rail. The two deck rail rails has a parallel distance of 282 mm, and the mounting holes are

367 mm. The mounting hole patterns length distance may vary.

50 | 200 | 200 | 200 ... ... 200 | 200 | 200 | 50

50 | 250 | 200 | 200 ... ... 200 | 200 | 250 | 50

50 | 100 | 200 | 200 ... ... 200 | 200 | 100 | 50

50 | 150 | 200 | 200 ... ... 200 | 200 | 150 | 50

1500mm2000mm2500mm3000mm

Top Mounted Flush Mounted

5

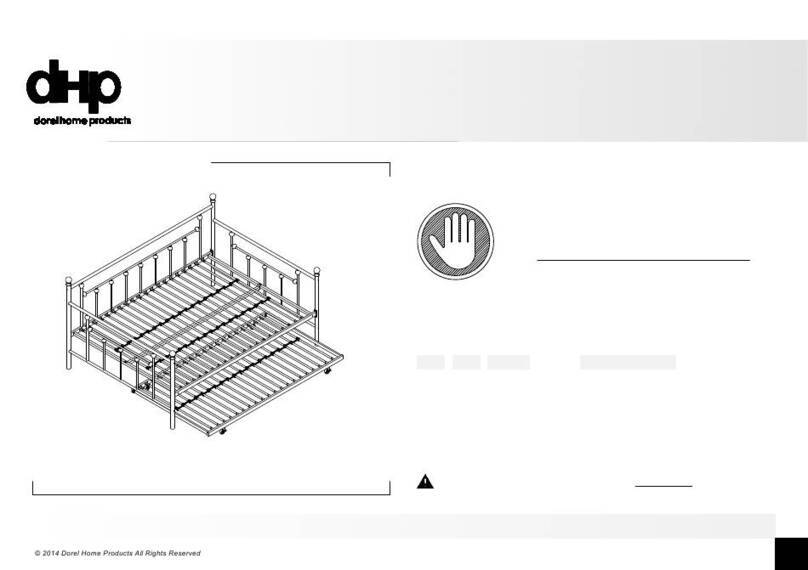

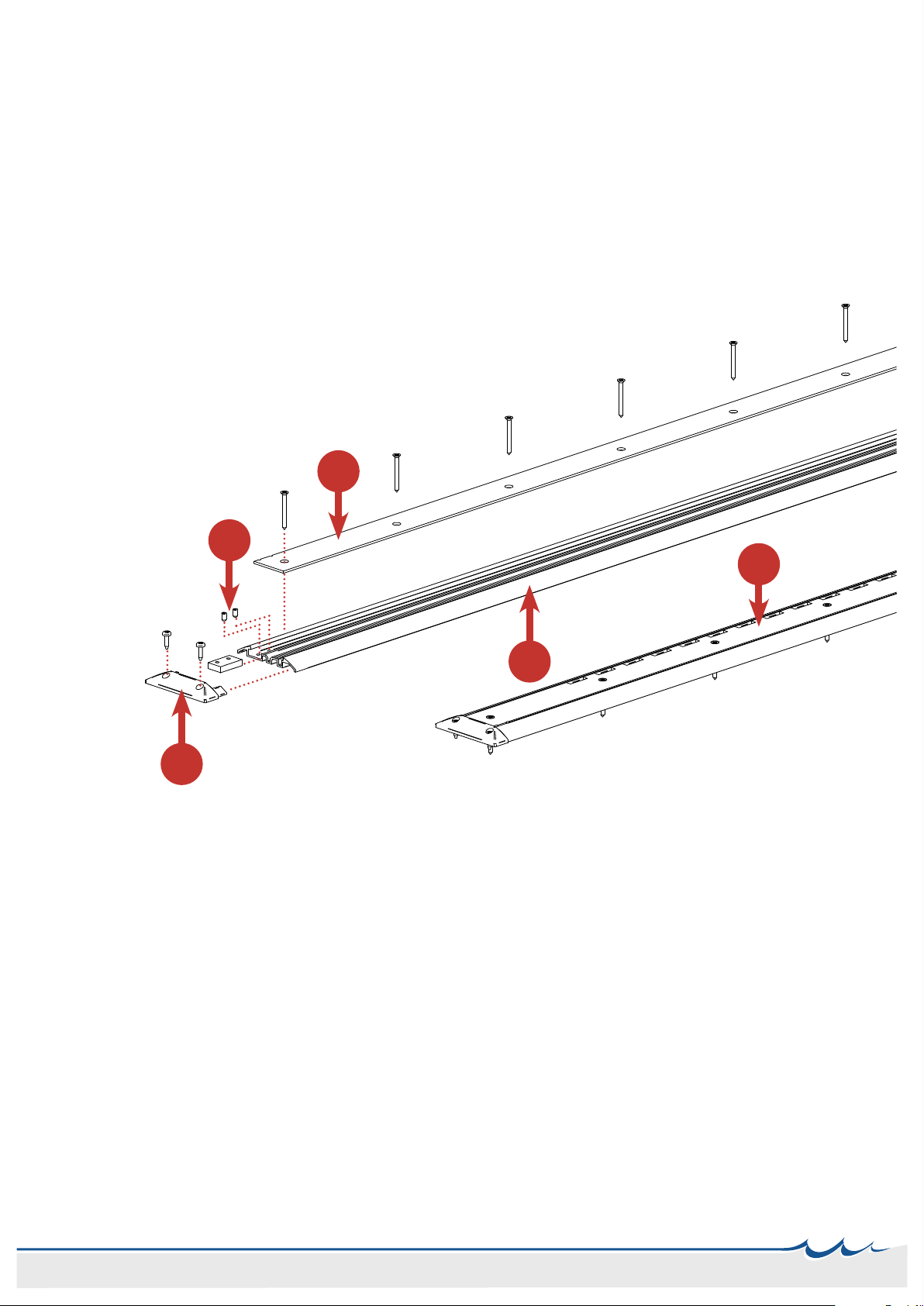

Installation of chair on a basic deck rail

S

T

E

P

0

1

S

T

E

P

0

3

Place the wire thru the designated hole in the seat

frame and down the column, nd a suitable path

for the wire from the release handle to the column.

(The chair top is hidden due to visualization) Use a

strip to fasten the wire.

Remember to leave some play for the wire

S

T

E

P

0

2

Remove the hand wheels on the side completely

and push the seat frame backwards until you gain

access to the center of the column.

Do not push the seat top all the way o.

Place the chair in the lower position and mount the

release handle according to chair model if not all

ready mounted (see page 8)

N

O

T

O

K

O

K

S

T

E

P

0

4

For NorSap 800 chairs, the wire will not t inside the

column and needs to be placed on the outside. The

wire should go thru the plastic ring on the side of

the footrest. See last page for ange modications

regarding the 800 series of NorSap chairs.

The wire needs soft corners, if its bent too

much the wire will be destroyed.

The wire is placed as shown on the image, down,up

and down within the column - to ensure that the

wire follows the movement of the columns rise and

lower.

6

IMPORTANT

Make sure the release cable goes straight from the release

handle on the wagon and up thru the column. Not under the

locking bolt of the column or any unnecessary twists.

Installation of chair on a basic deck rail part II

N

O

T

O

K

O

K

Place the chair on the wagon of the basic deck rail

- use a piece of cardboard for protective measures

when tilting the chair to gain access to the wire.

Place the wire end as shown on the illustration.

Place the ange over the designated hole pattern

and mount the ange onto the deck rails wagon

with the included bolts.

S

T

E

P

0

6

7

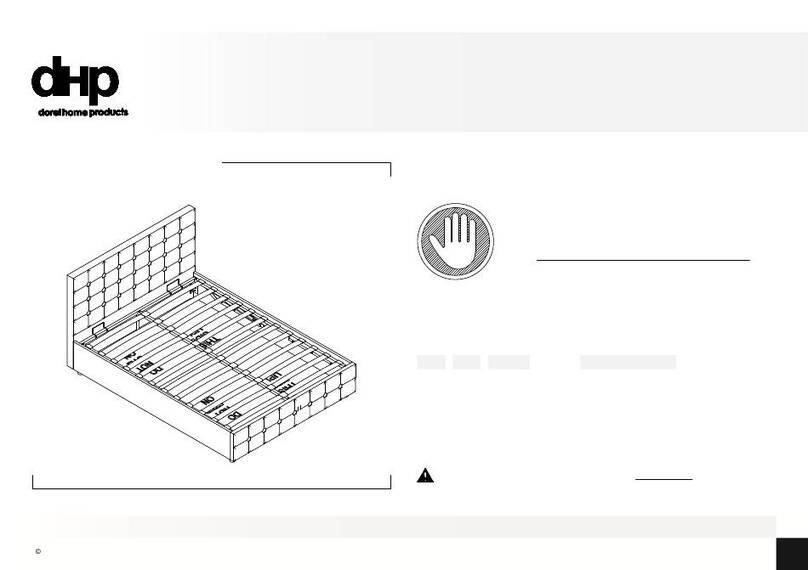

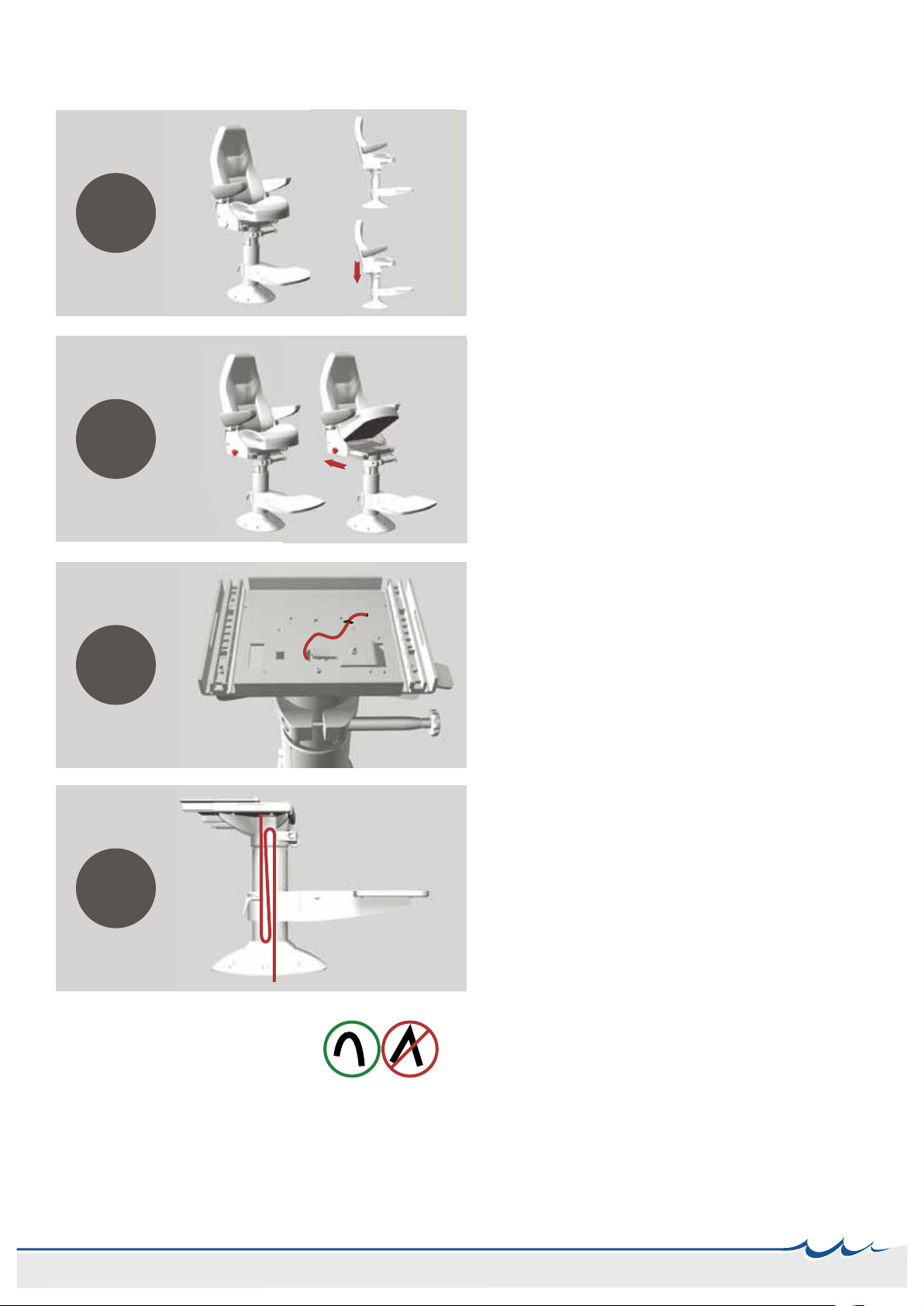

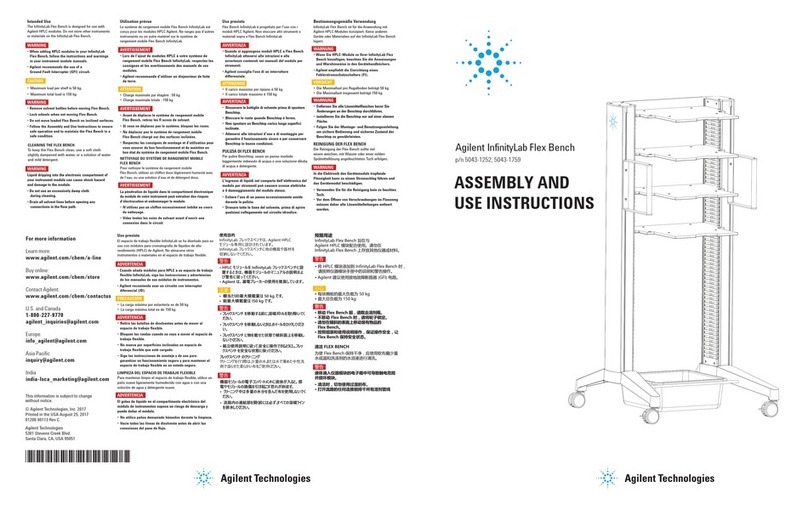

Installation of Basic Deck Rail release handle on chair

Back side

With adaptor plate (only applies to the NorSap 1500)

All other models

The handle is placed

bending towards the chair.

The handle is ipped to bend

away from the chair.

Make sure the release handle is “reversed”

/ pointing away from the seat.

Placement of the release handle on a

NorSap 800 chair. Use two M5 screws to

mount the handle.

NB, see illustration to the left.

Placement of the release handle on

a NorSap 1500 and 1700 chair.

Mount the adapter plate as shown

on the images above.

Countersink the two holes marked

with red circles (M5) if not present.

Use two M5 screws to mount the

handle. Mounts on the inside of

the plate. Use the adapter plate for

measurements.

Placement of the

release handle on

a NorSap 1000

chair. Use two M5

screws to mount

the handle.

Placement of the release

handle on a NorSap 2000

chair. Use two M5 screws to

mount the handle.

Flip up the seat rest to gain

access to the area.

NorSap 1000

NorSap 1500/1700

NorSap 2000

NorSap 800

8

Wagon details

- For the 1500 - 2000 Chairs

Complete 1500/2000 wagon DEL-1193

* Spare Wheel KLA-011

* Wire WIRE-022

* Release handle DEL-1231

- For the 1000 Chair

Complete 1000 wagon DEL-1192

* Spare Wheel KLA-011

* Wire WIRE-022

* Release handle DEL-1231

Navn:

FØRSTE TEGNING 10.05.2010

01

01 Vogn Basic 800

Name:

Weight:

Rev.

Author:Date:

REV: REVISION ISSUED FOR: EC no.

Filepath:

Toleranser for ikke toleransesatte mål: NS-ISO 2768-1 "MIDDELS" \\DC01\Tegninger\Standardprodukter SAP\Sammensatt 1001-\DEL-1206.asm

A4

Approved:

SOLID EDGE ST

Model Filename:

DEL-1206

Thickness:

Material:

Scale:

6,715 kg

1:5

_____

___

__

_____

___

__

_____

___

__

arild

_

567.2

444

36.2

2 stk. skruer til utløserhendel må leveres løst med

B434-4,2x19

- For the 800 Chair

Complete 800 wagon DEL-1206

* Spare Wheel KLA-011

* Wire WIRE-022

* Release handle DEL-1231

FRONT FRONT FRONT

Rail with locking track

Plain rail track

9

Ø8mm

70mm

Ø8mm

70mm

Ø8mm

70mm

Ø8mm

70mm

Flange modication necessary for the 800 Chair

The NorSap 800 chairs columns is too small to have the release wire for the deck rail concealed within the col-

umn. To be able to mount the NorSap 800 chair on a Basic Deck Rail, the ange needs to be modied.

70mm from the center of the ange towards the side where the wagons release cable goes,

drill a Ø8mm hole for the release wire insertion.

FRONT

FRONT

10

Maintenance of moving parts

The glide parts of the chair can be lubricated with a silicone based lubricant.

If the chair is on a deck rail, its important that the deck rails railway is NOT lubricated.

Safety

All moving parts has a potential squeezing hazard. Be sure to keep hands and ngers out of moving

parts areas when operating the chair.

Shipping and storage specications

The chair should be shipped and stored in an upright condition.

No other materials should be shipped or stored on top of a the chair or deck rail.

The chair should be shipped and stored at temperatures between -20°C and +40°C.

The chair should not be operated until its been acclimatized between 0°C and +30°C.

The chair should be kept in a clean, dry environment.

Upon receipt, we recommend that the shipping packaging be immediately examined for damage. Any

damage should be noted on the delivery receipt and a request for inspection by the transportation com-

pany should be made. The shipping packaging should be opened immediately and the chair or the deck

rail examined for concealed shipping damage.

If the chair appears to be damaged, a concealed bad order report should be immediately

led with the transportation company.

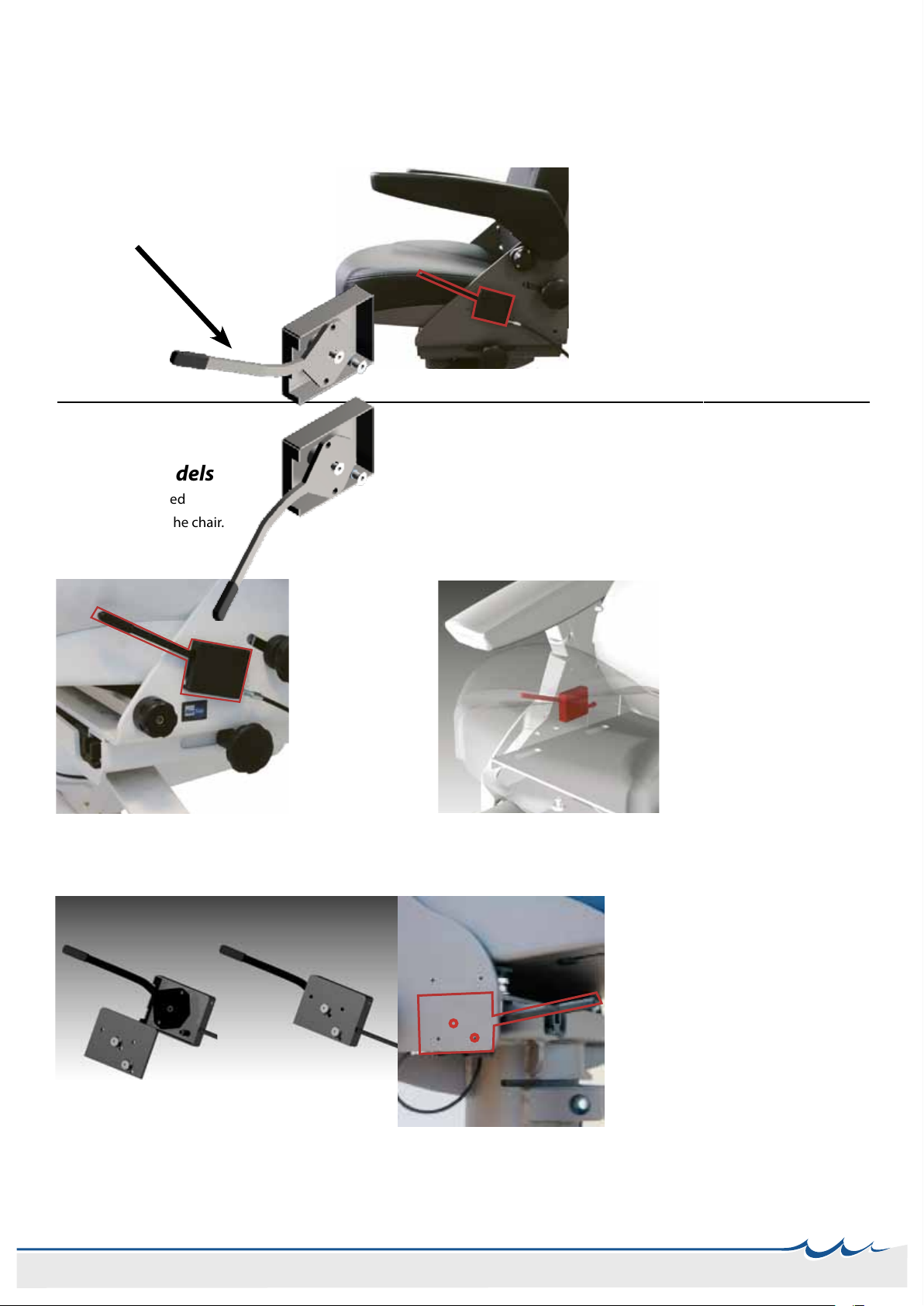

1

3

4

5

2

6

Pos. Ant. Vare Navn Vare Nr. Rev.

1 1 Boks for utløserspak basicsystem 02

2 1 Utløserspak for basic system. 02

3 2 Press avstandsstykke M5 tett B366-M5X14

4 3 SKIVE MYK PVC M6x16 KLAR B783-M6

5 2 UNBRACO SENK M5X16 B420-M5X16

6 1 Gummikappe for spak 01

1 Casing SAP-8037

2 Release handle SAP-8038

3 Spacer B366-M5x14

4 Washer B783-M6

5 Countesunk umb. B420-M5X16

6 Rubber tting GASDEL-019

Release handle details

11

NorSap as

Mjåvannsveien 35

4628 Kristiansand

Norway

Tel +47 38 18 52 00

Fax +47 38 18 20 86

sale@norsap.no

norsap.com

norsap.com

This manual suits for next models

5

Table of contents

Other NorSap Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

Agilent Technologies

Agilent Technologies InfinityLab Flex Bench Assembly and use instructions

Home Styles

Home Styles 20 05050 0941 quick start guide

GAMA

GAMA HUDS822 Assembling Instruction

DAVIDSEN

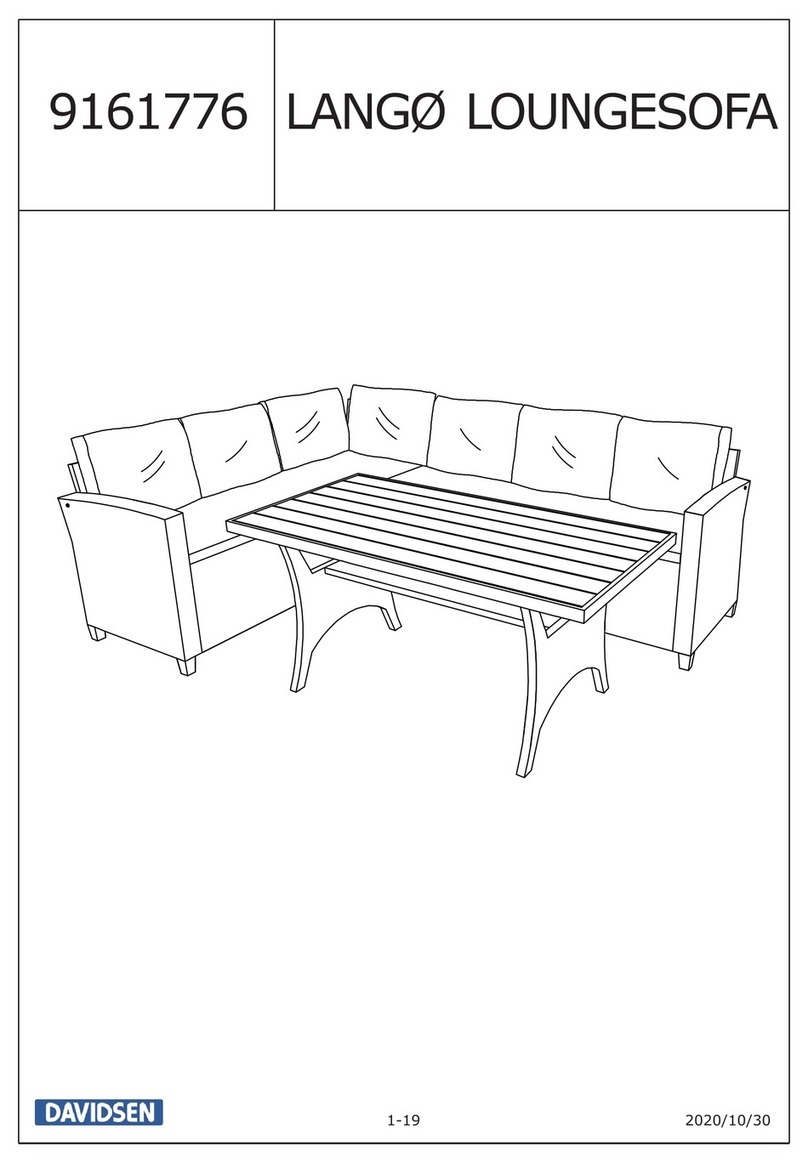

DAVIDSEN LANGO 9161776 Assembly manual

mlmeble

mlmeble Laptop Assembling Instruction

Baumax

Baumax Dreamer RMRS62411 Assembling Instruction