6

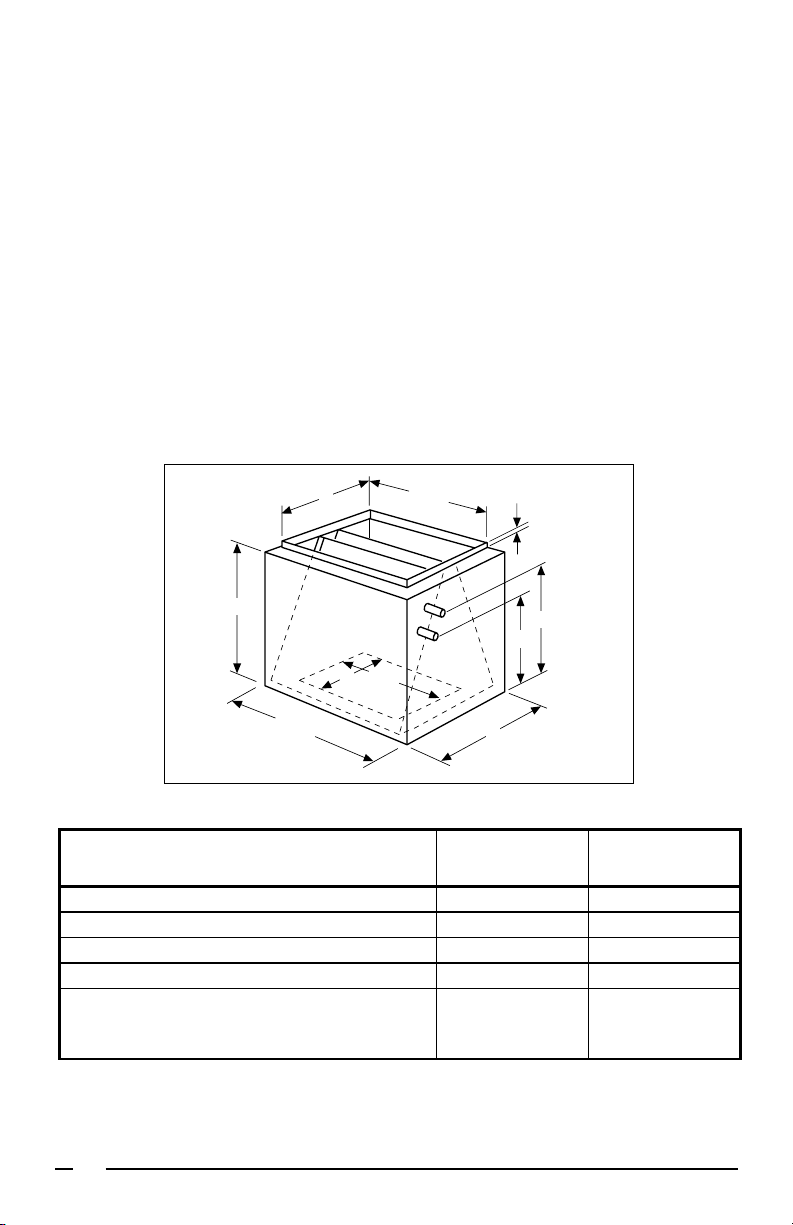

To Configure Horizontal Ready Coils for

Horizontal LEFT Installations:

1) Remove the coil access door.

2) IMPORTANT:Removetheplugfromoneof

thethreadedholes inthehorizontaldrain

pan.Completelyremovethewebbinglocated

inthethreadedholesofthehorizontaldrain

pan.Ifwebbingisnotremoved,thedrainwill

not function properly and ceiling damage

may occur.

3) Insertaplug(fromthehorizontaldrainpan)

into the open and unused drain hole in the

drain pan at the bottom of the unit to block

bypass air.

4) Remove the corresponding drain line knock-

outfromthecoilaccessdoortoallowaccess

tothehorizontaldrain.

5) Replace the door.

To Configure Horizontal Ready Coils for

Horizontal RIGHT Installations:

1) Removethecoilaccessdoor.Unscrewthe

line-settubeclose-offplatefromthefront

left cabinet rail.

2) Slide the coil and drain pan assembly out

of the unit.

3) IMPORTANT: Remove the plug from one of

thethreadedholesinthehorizontaldrainpan.

Completelyremovethewebbinglocatedinthe

threadedholesofthedrainpan.Ifwebbing

is not removed, the drain will not function

properly and ceiling damage may occur.

4) Remove the sheet metal hairpin covers

(if supplied) from the back of the coil and

discard.

5) Placethehorizontaldrainpanontheoppo-

sitesideofthecoil.Onunitswith2setsof

knockouts, remove the other set of knockouts

in the coil spacing plates and insert support

rod.

6) Insertaplug(fromthehorizontaldrainpan)

into the open and unused drain hole in the

drain pan at the bottom of the unit to block

bypass air.

7) Slidethecoilandthehorizontaldrainpan

assembly back into the unit. Reattach the

tube close off plate.

8) Remove the corresponding drain line knock-

outfromthecoilaccessdoortoallowaccess

tothehorizontaldrain.

9) Replace the door.

Note: All condensate pans have primary and

secondary drain connections to meet FHA

requirements. If the application is located in

or above a living space where damage may

result from condensate overflow, a separate

3/4 inch drain must be provided from the

secondary drain connection and a secondary

drain pan must be installed under the entire

unit. Run secondary drain lines to a place

where they are noticeable if used.

4. REFRIGERANT LINE

CONNECTIONS

Line Connections:

1. Remove the protective caps from the coil

and refrigerant line set and also remove the

holegrommetsandtubeclose-offinsulation

from around the tubes.

2. Cutthelinesettubingtotheproperlength.

Besurethatthetubinghasbeensizedin

accordancewiththeoutdoorunitspecica-

tions.

3. Inspectbothrefrigerantlines.Theendsof

the lines must be round, clean, and free of

any burrs.

4. Insertthelinesettubesintothecoiltube

stubs until they bottom out.

5. Brazethe individual connections withdry

nitrogenowingthroughthejointstoelimi-

nate internal oxidation and scaling.

CAUTION:

It is recommended to wrap a wet rag

around both the pressure transducer

and sensor while brazing to prevent

damage to these components unique

to the IQ DriveTM System.

6. Check the assembly for leaks with dry

nitrogen.

7. On horizontal applications re-position the

sensing bulb on the suction line so it is in

the 4 o'clock or 8 o'clock position on the

suction tube.

NOTE: Sensor bulb must be secure and

insulated.