Page 1

INSTALLATION INSTRUCTIONS

Roof Curb Kit for R7TQ 072/090/120 Series

Curb sides are constructed of 16-gauge coated steel and

wooden nailers. All hardware necessary to assemble the

curb is provided; installation hardware must be field supplied.

Vertical discharge roof curbs include dividers that allow for

inserting ductwork down from the top. Curbs are constructed

of 16-gauge coated steel and 2 × 4 wooden nailers.

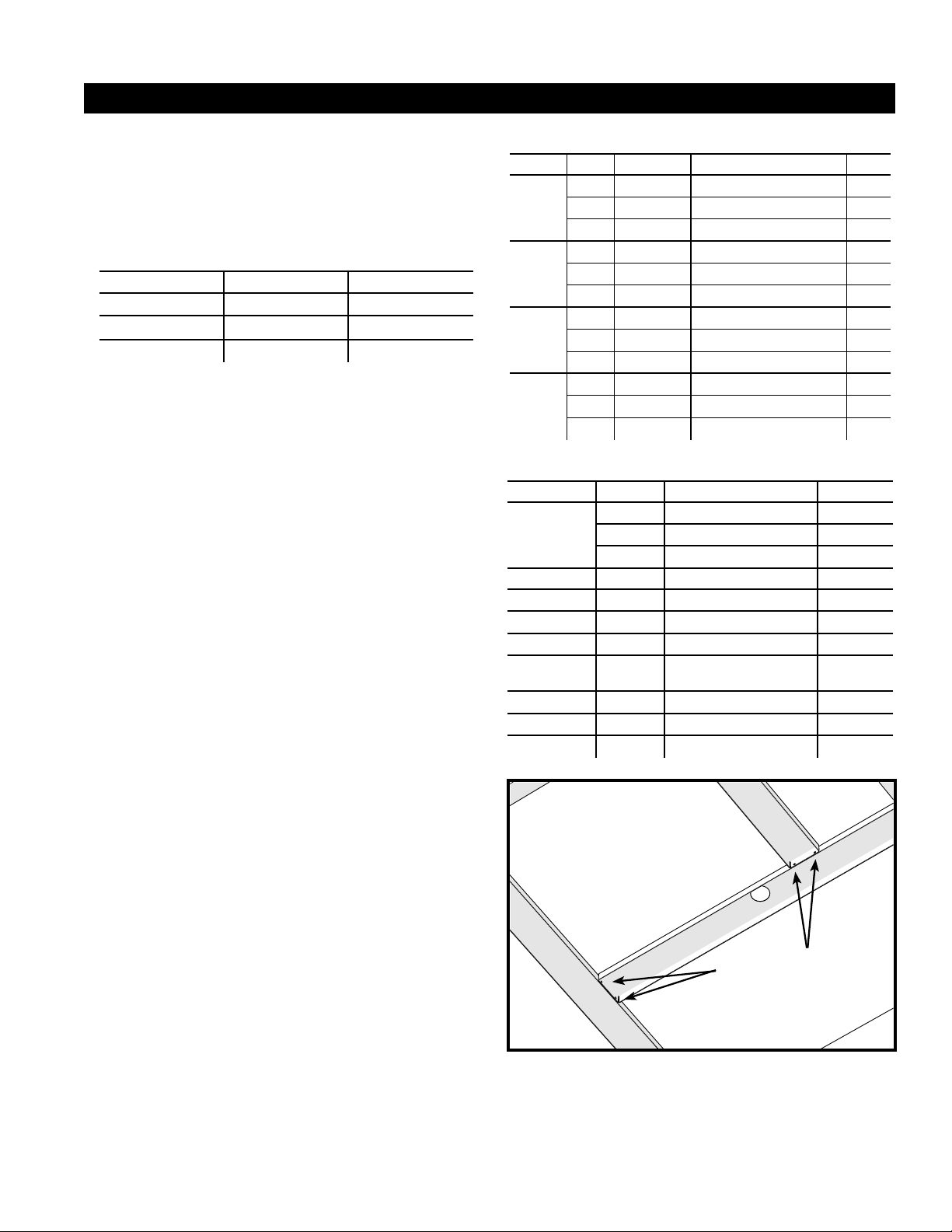

TABLE 1. CURB IDENTIFICATION

1011391 8” 203.2 mm

1011388 14” 355.6 mm

1011389 18” 457.2 mm

1011390 24” 609.6 mm

• Assembly and installation of the curb are the

responsibility of the installer.

• Before installation, verify that the curb ordered is the

appropriate one for the unit. Refer to Tables 1, 2 and 3.

• Depending on the weight and the roof structure, tread

material may be required under the rails. Curb and

equipment must be level.

• If installing more than one system, it is recommended to

minimize structural span deflection to discourage sound

transmission.

• Mounting hardware and flashing must be field supplied.

• Check the roof curb for squareness. The curb must be

adjusted so that the diagonal measurements are equal

within a tolerance of ±1/8” (±3 mm).

• Level the roof curb. To ensure a good weatherproof seal

between the unit curb cap and the roof curb, the roof curb

must be leveled in both directions with no twist end to

end. Shim as required and secure curb to the roof deck

before installing flashing.

• Install field-supplied flashing. If ductwork is being installed

from the top, slide the ductwork down into the discharge

and return air openings. Ductwork should be sized slightly

smaller with a minimum 3/4” duct flange that will rest on

and be attached to all sides of the duct connection. See

the system installation manual for ductwork requirements.

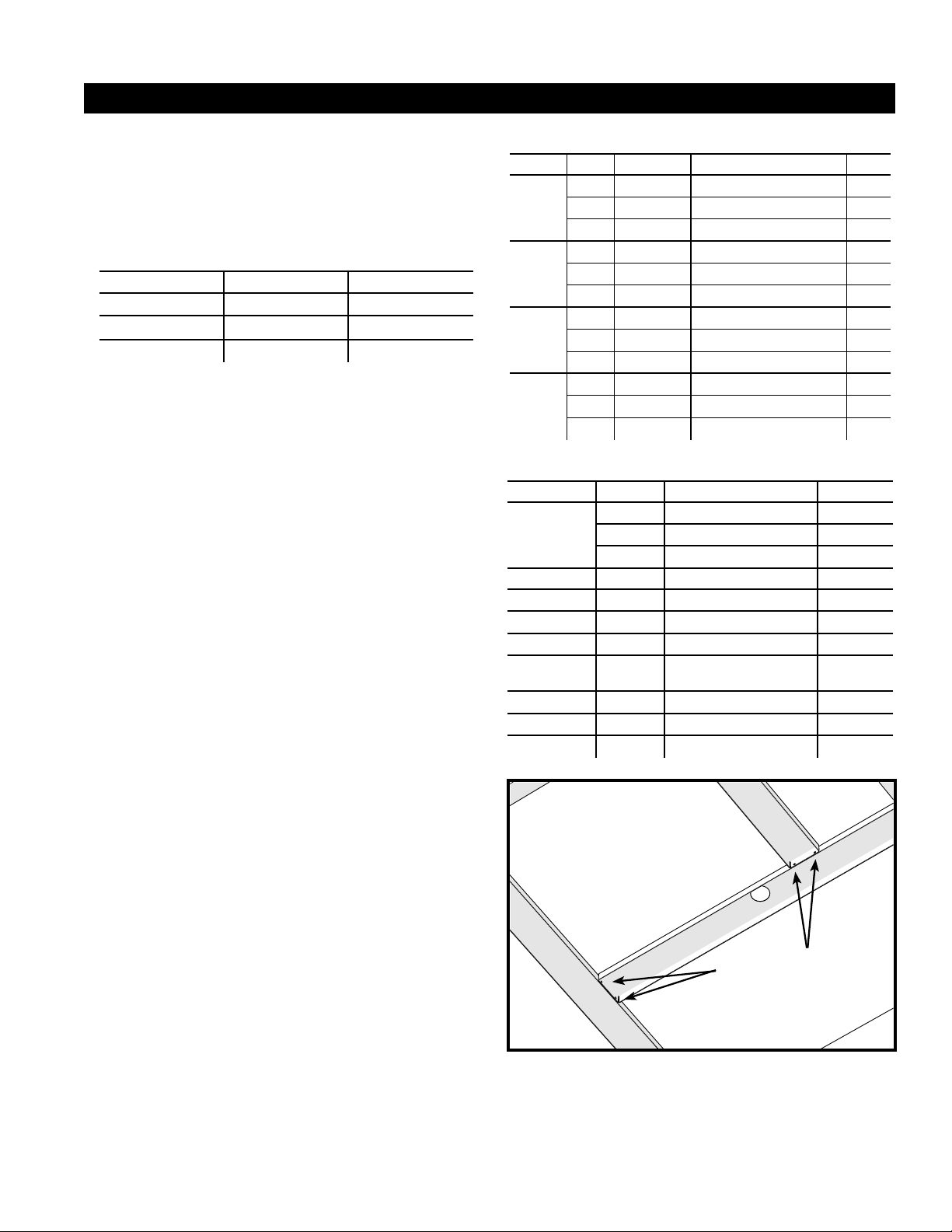

• Apply 1/4” x 1-1/4” foam sealant tape to both the

top surface of the curb rails and the top surface of

the perimeter of the integral dividers, being sure to

make good butt joints at all corners. The sealant

tape must be applied to prevent water leakage into

the curb area due to blown rain and capillary action.

IMPORTANT:Verify that the unit will be placed in the correct

airflow orientation to mate properly with the discharge and

return air openings.

TABLE 2. CURB PART NUMBERS

HEIGHT ITEM # P/N DESCRIPTION QTY

8”

1 1006197 END 2

2 1006198 CONTROL SIDE 1

3 1006199 FILTER ACCESS SIDE 1

14”

1 1006186 END 2

2 1006187 CONTROL SIDE 1

3 1006188 FILTER ACCESS SIDE 1

18”

1 1006191 END 2

2 1006192 CONTROL SIDE 1

3 1006193 FILTER ACCESS SIDE 1

24”

1 1006194 END 2

2 1006195 CONTROL SIDE 1

3 1006196 FILTER ACCESS SIDE 1

P/N ITEM DESCRIPTION QUANTITY

See Curb

Part Number

Table

1 Curb End 2

2 Curb Filter Access side 1

3 Curb Control side 1

TABLE 3. BILL OF MATERIALS

1006182 4 Support 1

1006185 5 RA Support 1

1006184 6 SA Support 1

600255 7 Screws S.M. 10AB x 1/2” 4

16247 8 5/16”-18 x 3/4” Hex Cap

Screws

16

612001 9 Washers 32

1035 10 5/16”-18 Hex Nut 16

66302 11 Gasket 1/4” x 1 1/4” 50 FT

Figure 1. Support and Gasket Locations

5

6

4#7 Fastener

locations

Bottom side view

of supports

Refer to Table 3

for item numbers

Form R7TQ-072/090/120 (03-18) PN1012100A,