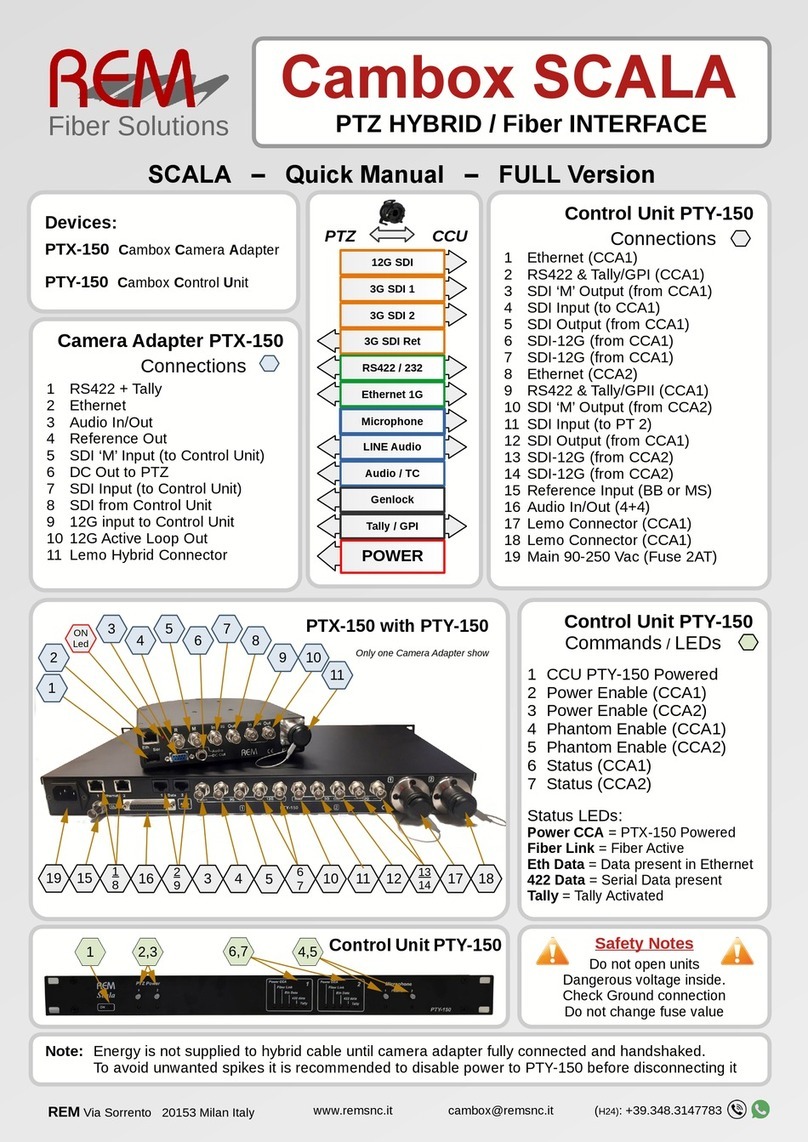

North American Tool 1250 XLT Operating instructions

8807517 12/12

1250 XLT GENERATOR Model: 51769

m

CALIFORNIA PROPOSITION 65

WARNING: You can create dust

when you cut, sand, drill or

grind materials such as wood,

paint, metal, concrete, cement,

or other masonry. This dust

often contains chemicals

known to cause cancer, birth

defects, or other reproductive

harm. Wear protective gear.

WARNING: This product or its

power cord may contain

chemicals, including lead,

known to the State of California

to cause cancer and birth

defects or other reproductive

harm. Wash hands after

handling.

CAUTION:

FOR YOUR OWN SAFETY

READ INSTRUCTION MANUAL

COMPLETELY AND

CAREFULLY BEFORE

OPERATING THIS GASOLINE

ENGINE Failure to follow all

instructions as listed below

may result in electrical shock,

fire, and/or serious personal

injury.

SPECIFICATIONS:

Engine: 2-stroke; Single Cylinder

Horizontal Shaf.

Start Type:Recoil Start

Rated Power: 800W

Fuel Capacity: 1.2 gallons

Run Time:5.5 hours

SAFETY WARNINGS

1) Do not operate this generator

indoors or in enclosed spaces.

Emissions created by this

generator are harmful.

2) Do not operate the generator in

wet conditions. This will increase

the risk of electrical shock.

3) Do not directly connect the

generator to a household power

supply.

4) Do not smoke while refueling

the generator. Do not overflow the

fuel when refueling the generator.

Stop the generator before

refueling. Gasoline is

flammable and the sparks may

cause it to ignite. Keep the

generator at least 3 feet away

from flammable materials.

5) Electrical equipment,

including any lines and plug

connections, should be

insulated.

6) The circuit breakers should

be matched with the generator

equipment. If the circuit

breakers need replacement,

they must be replaced with a

breaker that has identical

ratings and performance

characteristics.

7) Do not operate the generator

before grounding it. An

ungrounded generator could

cause electrical shock to occur.

8) The temperature of the

environment will affect the

overcurrent protector. Please

change the protector so it will fit

with the local environment

temperature.

For customer service, call 1-800-348-5004 or email

1

For warranty purchase, please keep your dated proof of purchase. File or attach to the manual for safekeeping.

Please carefully read and save these instructions before attempting to assemble, maintain, install, or operate this

product. Observe all safety information to protect yourself and others. Failure to observe the instructions may

result in property damage and/or personal injury. Please keep instructions for future reference.

Important Operating Instructions

2

9) Keep your work area clean

and well lit. Do not wear loose

clothing or jewelry. Keep long

hair pulled back.

10) Do not overload the

generator. Do not force a small

generator to do the job of a large

one.

11) Do not use the generator if

the power switch does not

properly turn it on and off.

12) Do not use damaged

generator.

13) Wipe up any gasoline spills

that may have occurred during

refueling before starting the

generator.

14) Do not refill the generator

while it is running or while the

engine is still hot.

15) Use only engine

manufacturer recommended fuel

and oil.

16) Do not attempt to connect or

disconnect load connections

while standing in water or on wet

or soggy ground.

17) Keep all electrical equipment

clean and dry.

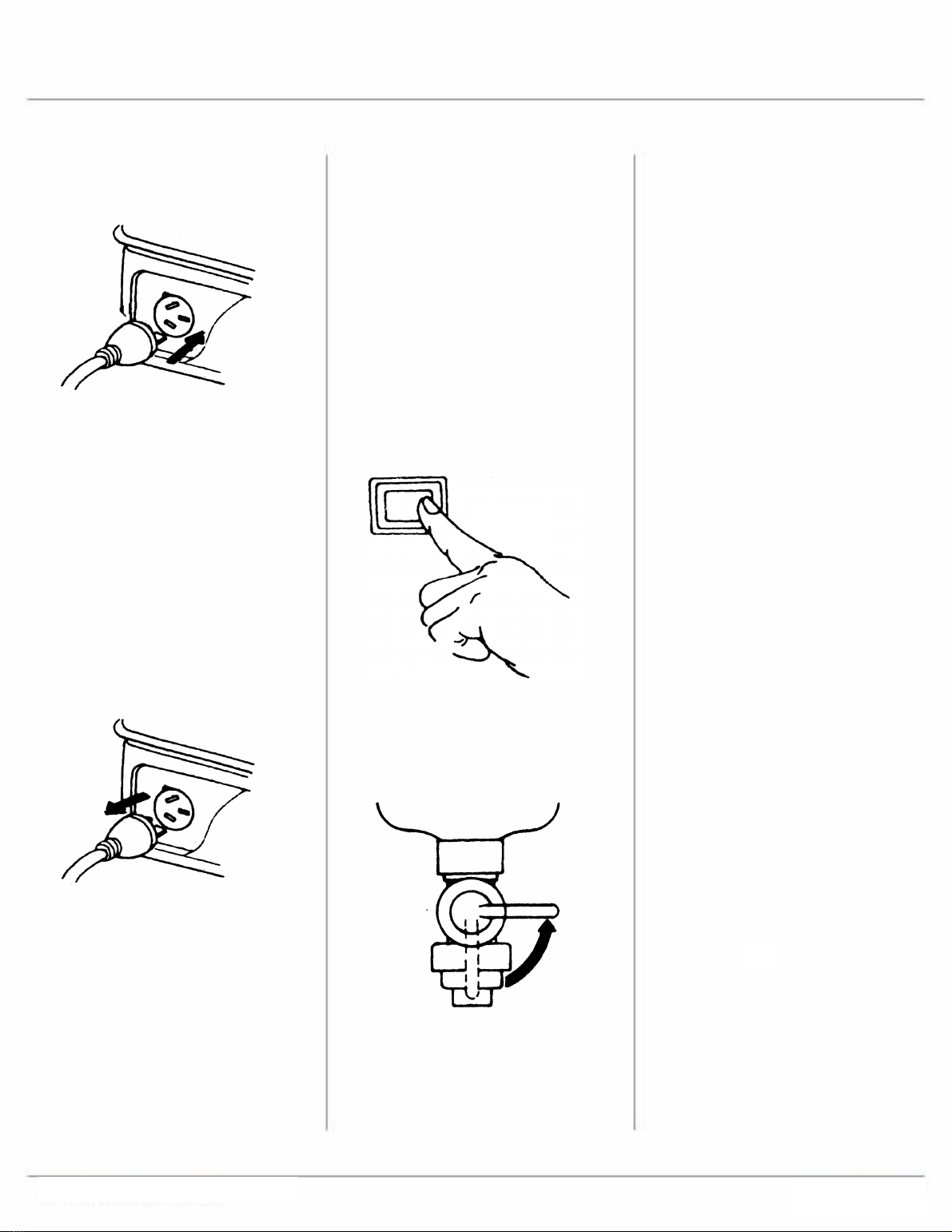

OPERATING

INSTRUCTIONS

GROUNDING THE

GENERATOR

Connect a #10 AWG

groundingwire (not included) from

the generator grounding log on the

front of the generator to a

grounding rod (not included). The

grounding rod must be an earth-

driven copper or brass rod

(electrode) which can adequately

ground the generator.

(See Figure A).

PRE-START CHECKS:

1. Check to make sure the Engine

Power Switch is in its "OFF"

position. (See Figure C)

CAUTION! Your Warranty is VOID

if the Engine’s Fuel Tank is not

filled with the proper mixture (50:1)

of unleaded gasoline and 2-cycle

oil before each use. Before each

use, check the fuel level. Do not

run the Engine with an improper

unleaded gasoline/2-cycle oil

mixture. Running the Engine with

an improper mixture WILL

permanently damage the Engine.

2.The Fuel Tank holds

approximately 1 gallon of fuel.

3. To obtain the proper gasoline

and 2-cycle oil mixture, mix 2.5

fluid ounces of 2-cycle oil with 1

gallon of unleaded gasoline into

an approved container. Then

slowly shake the container to

thoroughly mix the gasoline/2-

cycle oil.(See Figure B.)

4.Remove the Fuel Tank Cap

and check the fuel level. (See

Figure C.)

FIGURE A Grounding Rod

1 GALLON

UNLEADED

GASOLINE

2.5 FLUID OUNCES

2-CYCLE OIL

APPROVED

CONTAINER

FIGURE B

FUEL

TANK

CAP

STRAINER

FIGURE C

3

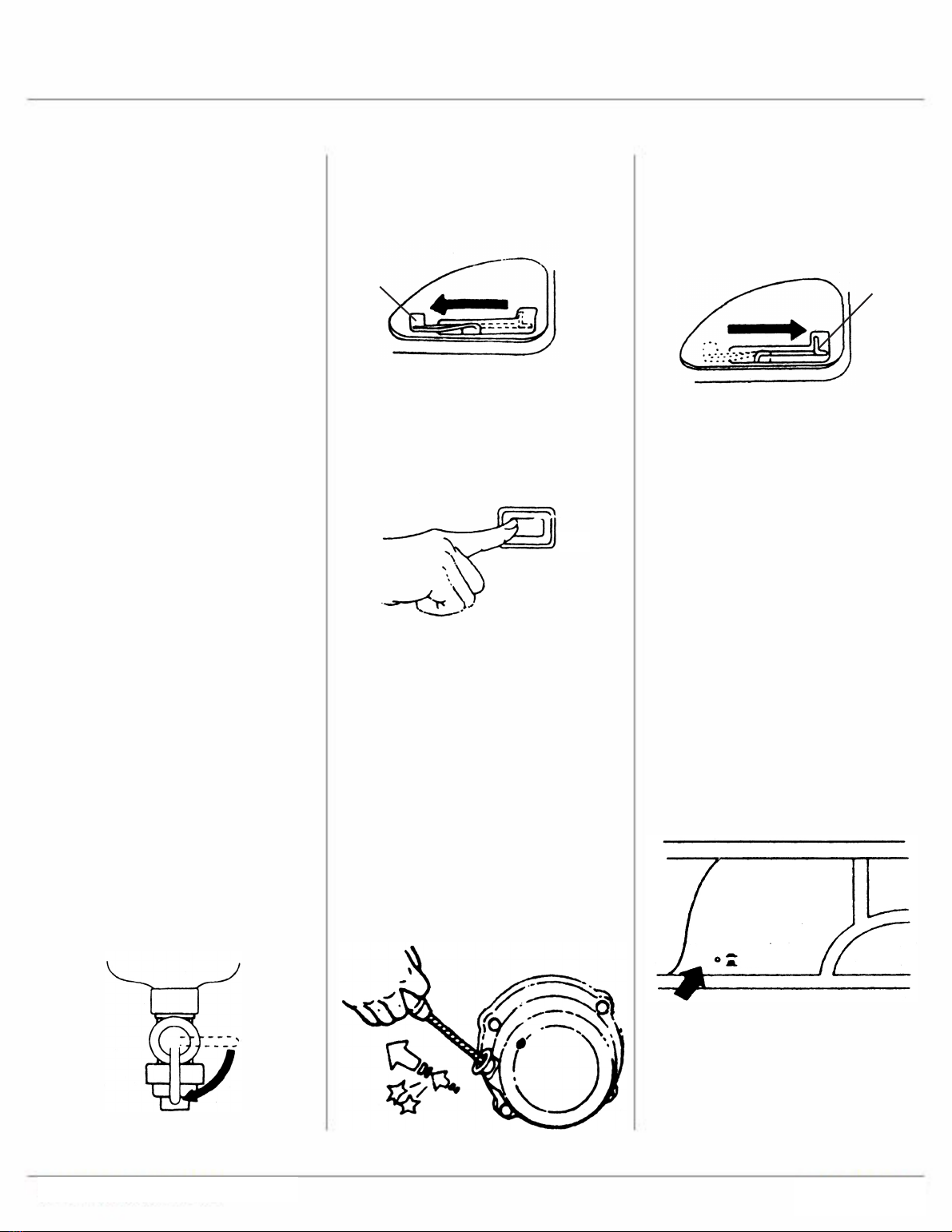

4.Turn the Engine Choke Lever

to its "CHOKE" position. Set the

Choke Lever in the "RUN"

position when starting a warm

Engine. (See Figure E.)

5.Then turn the Engine Power

Switch to its "ON" position. (See

Figure F.)

6.Grasp the Recoil Starter

Handle and pull slowly until

resistance is felt. While holding

the Handle, allow the Starter

Rope to rewind slowly. Then, pull

the Starter Handle with a rapid,

full arm stroke. Once again while

holding the Handle, allow the

Rope to rewind slowly. Repeat as

necessary, until the Engine

starts. (See Figure G.) warm up

for five minutes after starting with

no electrical load.

5. After the Engine starts and

warms up, slowly move the

Choke Lever to its "RUN"

position. (See Figure H.)

IMPORTANT: Allow the Engine

to run at

6. no load until warm (approx. 3

minutes) after each start-up to

allow the Engine to stabilize.

EQUIPMENT OPERATION

1.The total combined load

through the outlet on the

Generator must not exceed the

rated maximum power of the

unit.

2.Always reduce the load if the

AC Circuit Breaker turns off.

Once the load is reduced, press

the Breaker to reset the

Generator and continue

operation. (See Figure I.)

3.Allow the Engine to run at no

load until warm (approx. 3

minutes) after each start-up to

allow the Engine to stabilize.

4.To fill the Fuel Tank, first wipe

off the Fuel Tank Cap and the

surrounding area. (See Figure

C.)

5.Unscrew, and remove the Fuel

Tank Cap (See Figure C.)

6.Remove the Strainer and

remove any dirt and debris.

Then replace the Strainer. (See

Figure C.)

7.Fill the Fuel Tank to about 1

inch under the fill neck of the

Tank with the pre-mixed

unleaded gasoline/2-cycle oil

mixture.

8.Then replace the Fuel Tank

Cap (See Figure C.)

TO START THE ENGINE

1.Check to make sure the

Engine Switch is in its "OFF"

position.

2.IMPORTANT:Make sure to

unplug any load from the

Generator before starting to any

appliance, tool, or equipment.

3.Turn the Engine Fuel Switch to

its "ON" position. (See Figure D.)

"ON"

FIGURE D

Choke

Lever

"CHOKE"

"RUN"

FIGURE E

ON

FIGURE F

FIGURE G

Choke

Lever

"CHOKE"

"RUN"

FIGURE H

RESET

OFF

FIGURE I

CIRCUIT

BREAKER

4

DC cord has been supplied with

the unit.

GENERATOR SHUT OFF

1.Remove all electrical load

devices from the Generator. (See

Figure K.)

2.Allow the Engine to run for

approximately 3 minutes with no

electrical load.3.Turn off the

Generator’s Power Switch to stop

the Engine.(See Figure L.)

4.Turn the Fuel Switch to its

"OFF" position. (See Figure M.)

5.Allow the Generator to

completely cool before

storing.with no electrical load.

MAINTENANCE

Many maintenance

procedures, including those

not detailed in this manual, will

need to be performed by a

qualified technician for safety.

If you have any doubts allow

the Engine to stabilize.about

your ability to safely service

the equipment or Engine, have

a qualified technician service

the equipment instead.

Air Filter Element Maintenance:

1.Wipe off the Air Cleaner Cover.

Then remove the Cover. (See

Figure N.)

2.Remove the Air Filter Element.

3.Wash the Air Filter Element in

warm water and mild detergent

several times. Rinse. Squeeze

out excess water and allow it to

dry completely. Soak the Filter in

lightweight oil briefly, then

squeeze out the excess oil.

4.Install the new Air Filter

Element or the cleaned Filter.

Secure the Air Cleaner Cover

before use.

4.Plug the power cord of the 120

volt appliance/tool into the 120

volt AC Outlet on the Generator.

(See Figure J.)

5.NOTE: Do not allow the

generator to completely run out

of fuel with devices attached. A

generator’s output may sharply

spike as it runs out of fuel,

causing damage to attached

devices.

6.When finished using the

appliance/tool, unplug its power

cord from the AC Outlet on the

Generator. (See Figure K.)

7.For DC current, plug into the

DC plug located on the side of

the generator. To charge your

car battery, connect the alligator

clips to the corresponding

terminals on your battery, The

red lead goes to the positive (+)

terminal and the black lead goes

to the negative (-) terminal. This

FIGURE J

FIGURE K

OFF

FIGURE L

FIGURE M

OFF

5

Spark Plug Maintenance:

1.Disconnect Spark Plug Wire

from end of plug. Clean out

debris from around Spark Plug.

2.Using the spark plug wrench

provided, remove the Spark

Plug.

3.Inspect the Spark Plug:If the

electrode is oily, clean it using a

clean, dry rag. If the electrode

has deposits on it, polish it using

emery paper. If the white

insulator is cracked or chipped,

the Spark Plug needs to be

replaced.

4.When installing a new Spark

Plug, adjust the Plug’s gap to the

specification on the Technical

specification chart and in the

FIGURE N

FIGURE O

illustration below. Do not pry

against the electrode or the

insulator, the Spark Plug can be

damaged. (See Figure O.)

5.Install the new Spark Plug or

the cleaned Spark Plug into the

Engine. Gasket-style: Finger-

tighten until the gasket contacts

the cylinder head, then about

1/2-2/3 turn more.

Non-gasket-style: Finger-tighten

until the plug contacts the head,

then about 1/16 turn more.

Cleaning, Maintenance, and

Lubrication Schedule: Engine

Note: This maintenance

schedule is intended solely as a

general guide. If performance

decreases or if the Engine

operates unusually, check

systems immediately. The

maintenance needs of this

Engine will differ depending on

factors such as temperature, air

quality, fuel quality, and other

factors.

Note: These procedures are in

addition to the regular checks

and maintenance explained as

part of the regular operation of

the Engine.

After Initial 25 Operation Hours:

1.Change unleaded gasoline

and 2-cycle oil fuel mixture.

Every 25 Operation Hours

Thereafter:

1.Clean/replace Air Filter

Element.

2.Inspect/clean Spark Plug.

Every 50 Operation Hours:

1.Change unleaded gasoline

and 2-cycle oil fuel mixture.

Every 100 Operation Hours:

1.Replace Spark Plug.

Replace Air Filter Element.

Note: All maintenance

procedures scheduled for 20, 50,

and 100 operation hours should

be performed at least yearly.

Every 300 Operation Hours:

1.Clean Fuel Tank and

Carburetor assembly.

2.Clean carbon build-up from

Combustion.

Maintenance and Cleaning

Schedule: Generator

Before Every Use:

1.Check to make sure all bolts

and nuts are tight.

2.Check for any damage to the

Generator.If damaged, do not

use until repaired by a qualified

service technician.

After Every Use:

1.Allow the unit to completely

cool. Then clean the exterior of

the Generator with a clean cloth.

6

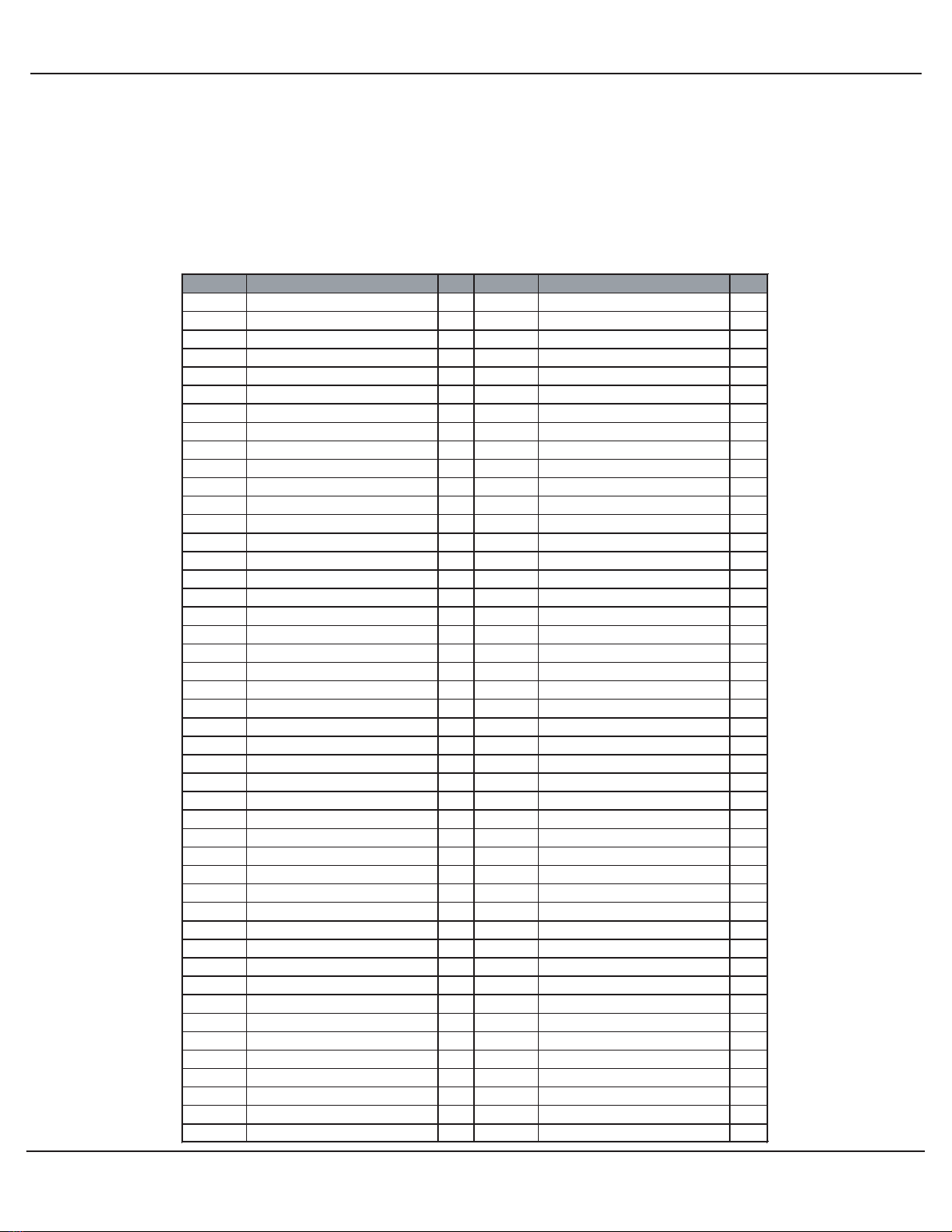

Recommended Maintenance Schedule

each use

first month of

use or first 20

hrs

every 3

months or

50 hrs

every 6

months or

100 hrs

every year

or 300 hrs

As

necessary

Engine oil check level x

Air cleaner check x

Clean x

fuel filter cup Clean x

spark plug check/ clean x

gas tank check gas level x

Clean x

Run generator premix gas out prior to long periods of storage

7

Troubleshooting Guide-Engine

Problem Possible Causes Probable Solutions

Engine will not

start

FUEL RELATED:

Improper gasoline/2 cycle oil mix.1.

No fuel in tank or fuel valve closed.2.

Choke not in start position, especially3.

with cold engine.

Low quality or deteriorated, old4.

gasoline.

Carburetor not primed.5.

Dirty fuel passageways blocking fuel6.

flo .

Carburetor needle stuck. Fuel can be7.

smelled in the air.

Too much fuel in chamber. This can be8.

caused by a stuck carburetor needle.

FUEL RELATED:

Mix 50 parts unleaded gasoline with 11.

part 2-cycle oil.

Fill fuel tank and open fuel valve.2.

Move choke to start position if engine3.

is cold.

Use only fresh 89+ octane unleaded4.

gasoline and 2-cycle oil mixture.

Prime carburetor by pressing priming5.

bulb specified number of times (if

equipped).

Clean out passageways using fuel6.

additive. Heavy deposits may require

further cleaning.

Gently tap side of carburetor float7.

chamber with screwdriver handle.

Turn choke to run position. Remove8.

spark plug and pull the start handle

several times to air out the chamber.

Reinstall spark plug and set choke to

start position.

IGNITION (SPARK) RELATED:

Spark plug wire not connected1.

securely.

Spark plug electrode wet or dirty.2.

Incorrect spark plug gap.3.

Spark plug wire or spark plug broken.4.

Incorrect spark timing or faulty ignition5.

system.

IGNITION (SPARK) RELATED:

Connect spark plug wire properly.1.

Clean spark plug.2.

Correct spark plug gap.3.

Replace spark plug wire and/or spark4.

plug.

Have qualified technician diagnose5.

repair ignition system.

COMPRESSION RELATED:

Cylinder not lubricated. Problem after1.

long storage periods.

Loose or broken spark plug. (Hissing2.

noise will occur when trying to start.)

Loose cylinder head or damaged head3.

gasket. (Hissing noise will occur when

trying to start.)

Engine valves or tappets misadjusted4.

or stuck.

COMPRESSION RELATED:

Pour tablespoon of oil into spark plug1.

hole. Crank engine a few times and try

to start again.

Tighten spark plug. If that does not2.

work, replace spark plug. If problem

persists, may have head gasket

problem, see #3 below.

Tighten head. If that does not remedy3.

problem, replace head gasket.

Adjust valve clearance. If that does not4.

work, clean or replace valves/tappets.

8

Troubleshooting Guide-Engine

Problem Possible Causes Probable Solutions

Engine misfire Spark plug wire loose.1.

Incorrect spark plug gap or damaged2.

spark plug.

Defective spark plug wire.3.

Old or low quality gasoline.4.

Incorrect compression.5.

Check wire connections.1.

Re-gap or replace spark plug.2.

Replace spark plug wire.3.

Use only fresh 89+ octane unleaded4.

gasoline and 2-cycle oil mixture.

Diagnose and repair compression. (Use5.

Engine will not start: C

RELATED section.)

Engine stops

suddenly

Fuel tank empty or full of impure or low1.

quality gasoline.

Defective fuel tank cap creating2.

vacuum, preventing proper fuel flo .

Improper idle speed.3.

Faulty magneto, incorrect timing, or4.

clogged carburetor.

Fill fuel tank with fresh 89+ octane1.

unleaded gasoline and 2-cycle oil

mixture.

Test/replace fuel tank cap.2.

Properly adjust idle speed.3.

Have qualified technician diagnose and4.

service engine.

Engine knocks Old or low quality gasoline.1.

Engine overloaded.2.

Incorrect spark timing, deposit buildup,3.

worn engine, or other mechanical

problems.

Fill fuel tank with fresh 89+ octane1.

unleaded gasoline and 2-cycle oil

mixture.

Do not exceed equipments load rating.2.

Have qualified technician diagnose and3.

service engine.

Engine backfire Impure or low quality gasoline.1.

Engine too cold.1.

Choke not open after engine warm.2.

Engine not properly adjusted for high3.

altitude operation.

Intake valve stuck, choke stuck,4.

incorrect timing, clogged carburetor, or

overheated engine.

Fill fuel tank with fresh 89+ octane1.

unleaded gasoline and 2-cycle oil

mixture.

Use cold weather fuel and oil additives2.

to prevent backfiring

Move choke to run position after engine3.

warms up.

Qualified technician must adjust engine4.

at altitudes greater than 5,000 feet

above sea level.

Have qualified technician diagnose and5.

service engine.

10

Limited Manufacturer Warranty

North American Tool (NAT) Industries makes every effort to ensure that this product meets high quality

and durability standards. NAT warrants to the original retail consumer a 1-year limited warranty from

the date the product was purchased at retail and each product is free from defects in materials.

Warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence or accidents,

repairs or alterations, or a lack of maintenance. NAT shall in no event be liable for death, injuries to

persons or property, or for incidental, special or consequential damages arising from the use of our

products. To receive service under warranty, the original manufacturer part must be returned for

examination by an authorized service center. Shipping and handling charges may apply. If a defect is

found, NAT will either repair or replace the product at its discretion.

DO NOT RETURN TO STORE

For Customer Service:

8807517 12/12

1250 XLT GENERATOR

Model: 51769

m

For customer service, call 1-800-348-5004 or email

11

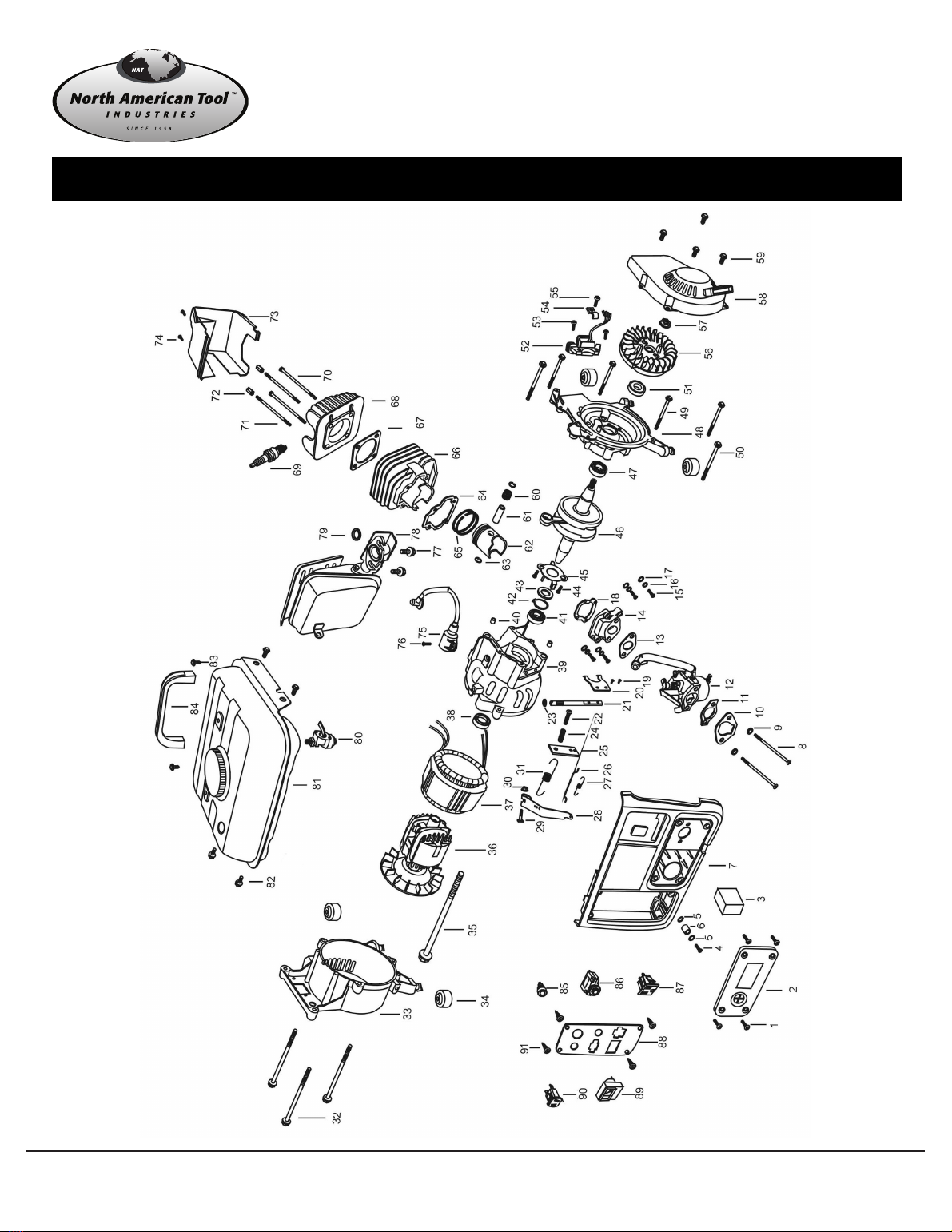

Parts List

8807517 12/12

m

12

Call 1-800-348-5004 for assistance or replacement parts

Please provide the following information

-Model number

-Part description and number as shown in parts list

-Serial number

Address any correspondence to:

North American Tool Industries

84 Commercial Rd

Huntington, IN 46750

Parts List

Part No. Description Q’ty Part No. Description Q’ty

1 Bolt 5x 16 4 47 bearing 6004 1

2 Air cleaner cover 1 48 Left crankcase 1

3 Air filter element 1 49 Flange bolt 6x50 4

4 Bolt rivet 6 x 40 1 50 Flange bolt 6x55 2

5 Flat washer 2 51 Big oil sealing 1

6 Steel set 1 52 Magnetic motor 1

7 Control panel 1 53 Bolt 6x16 2

8 Bolt 6x65 2 54 Press board 1

9 Spring washer 4 55 Flange bolt 1

10 Filter flange 1 56 Flywheel 1

11 Carburetor cushion I 1 57 Flange bolt 10x1.25 1

12 Carburetor assembly 1 58 start cover 1

13 Carburetor cushion II 1 59 Flange bolt 6x12 4

14 Valve 1 60 Needle bearing 1

15 Bolt 6x20 4 61 piston pin 1

16 Spring washer 4 62 Piston 1

17 Flat washer 4 63 Piston pin fender ring 2

18 Seal ring 1 64 Cylinder seal cushion 1

19 Bolt 3x8 2 65 Piston ring 1

20 Adjustable speed fork 1 66 Cylinder block 1

21 Adjustable speed lever 1 67 Cylinder head gasket 1

22 Bolt 6x40 1 68 Cylinder head 1

23 Seal ring 1 69 Sparkle plug 1

24 Press spring 1 70 Flange bolt 6x100 2

25 Adjustable speed piece 1 71 Double head bolt 6x113 2

26 Adjustable speed pull lever 1 72 Long shape nut 6x20 2

27 Adjustable spring 1 73 Cylinder head cover 1

28 Adjustable speed arm 1 74 Flange bolt 6x12 2

29 Square bolt 1 75 High tension line 1

30 Nut 1 76 Bolt 6x20 1

31 Pull Spring 1 77 Flange bolt 6x16 2

32 Flange bolt 6x80 3 78 Muffler 1

33 Back cover 1 79 Washer 1

34 Shock absorber foot 4 80 Fuel switch 1

35 Flange bolt 8x154 1 81 Fuel tank 1

36 Rotor 1 82 Flange bolt 6x12 4

37 Stator 1 83 Round head bolt 6x35 2

38 Big oil sealing 1 84 Handle 1

39 Right crankcase 1 85 Pilot lamp 1

40 Fixing pin sheath 2 86 Circuit breaker 1

41 Bearing 6004 1 87 AC receptacle 1

42 Fender ring 47 1 88 Iron faceplate 1

43 Slide block 1 89 Voltmeter 1

44 Bolt 6x12 2 90 DC plug 1

45 shelf 1 91 Bolt 4

46 Bent axle 1

This manual suits for next models

1

Table of contents

Other North American Tool Portable Generator manuals

Popular Portable Generator manuals by other brands

North Star

North Star M165912I.4 owner's manual

Champion

Champion PRO 100430 Operator's manual

Generac Power Systems

Generac Power Systems MAGNUM MGG200 manual

Craftsman

Craftsman 580.327160 owner's manual

Mase

Mase FM 8000 S Use and maintenance manual

Rohde & Schwarz

Rohde & Schwarz R&S SMU200A Service manual