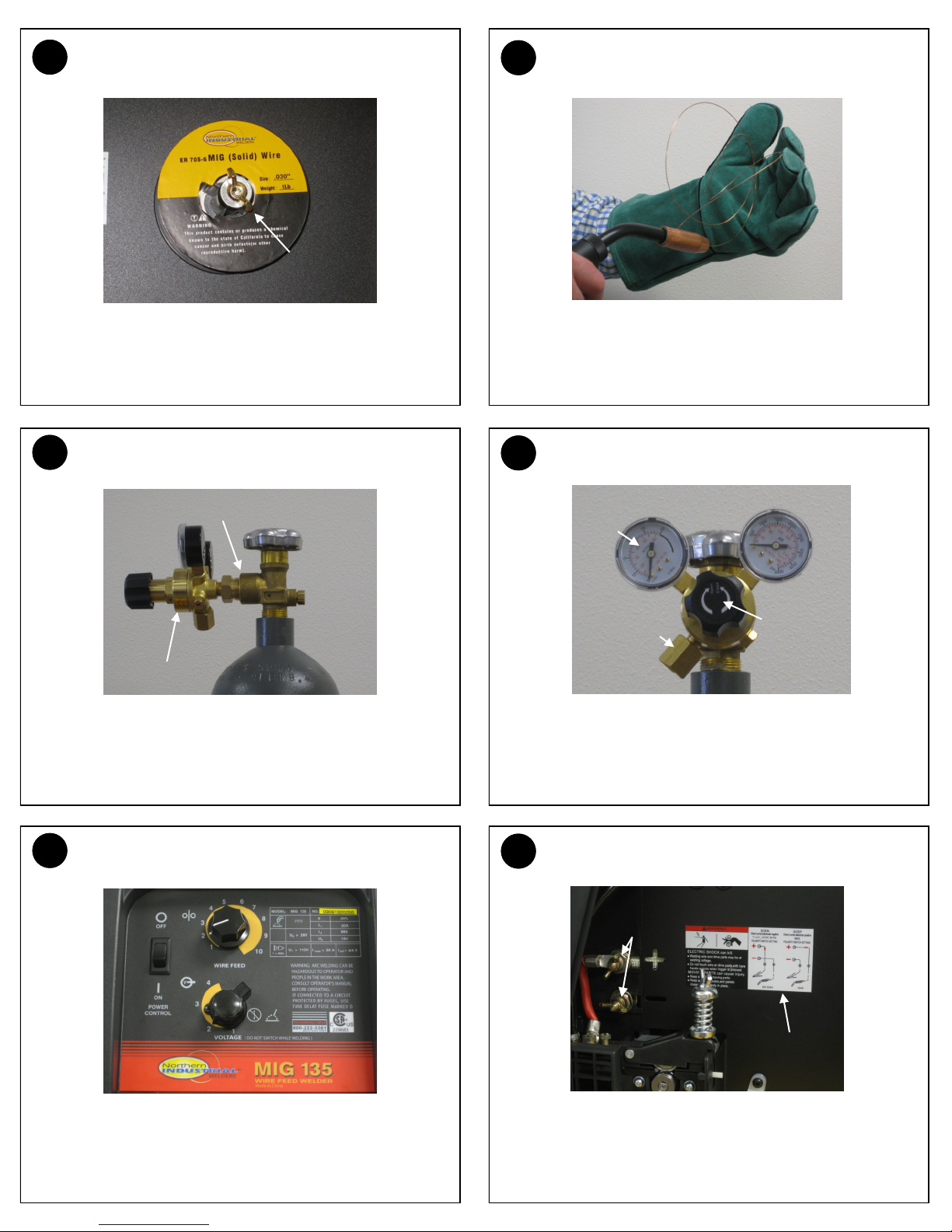

13 ADJUSTING SPOOL TENSION 14 ADJUSTING DRIVE ROLL TENSION

15 INSTALL SHIELDING GAS 16 SET GAS FLOW

17 SETTING FRONT PANEL CONTROLS 18 SETTING POLARITY - CHECK WIRE TYPE

Adjust the wing nut in the center of the spool to adjust spool ten-

sion. A small amount of slack should be in the weld wire when

wire feeding stops. Too much tension will cause poor feeding.

Too little tension will cause the wire on the spool to uncoil.

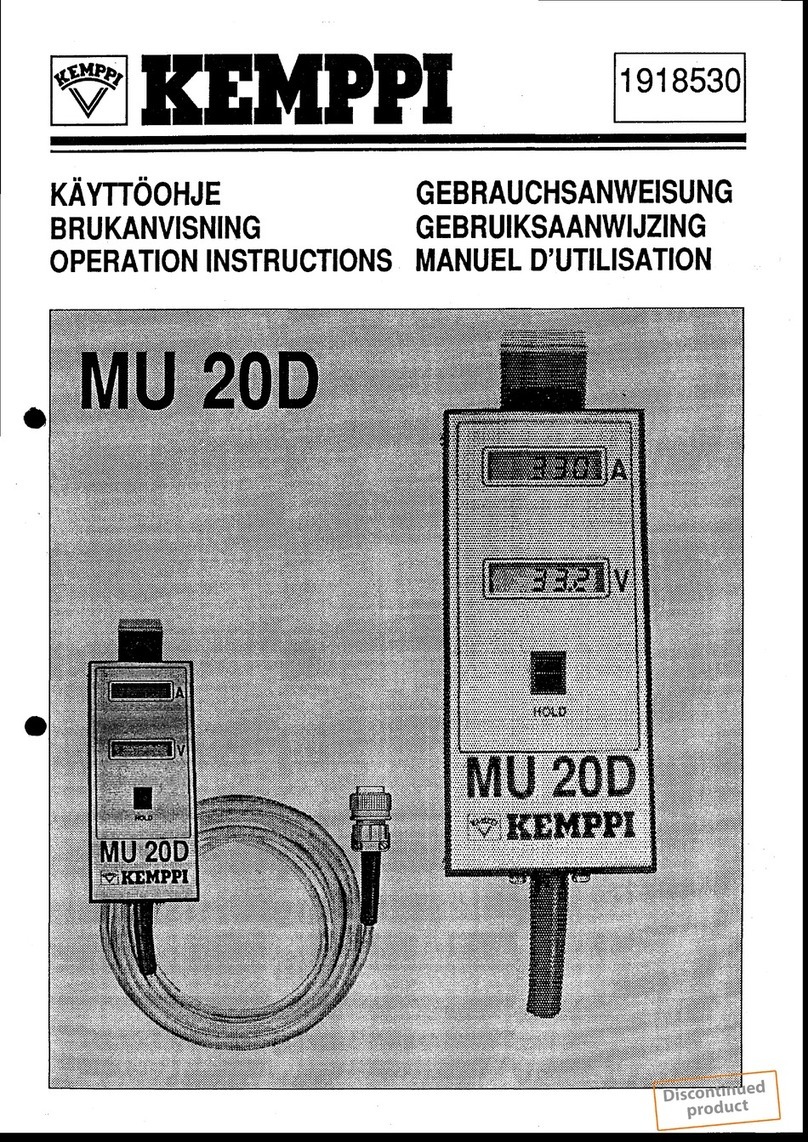

Test drive roll tension by feeding wire into a gloved hand from

about 4 inches away. Loosen tension to apply little pressure.

Slowly increase tension until the wire coils up in your hand with-

out slipping in the drive rolls.

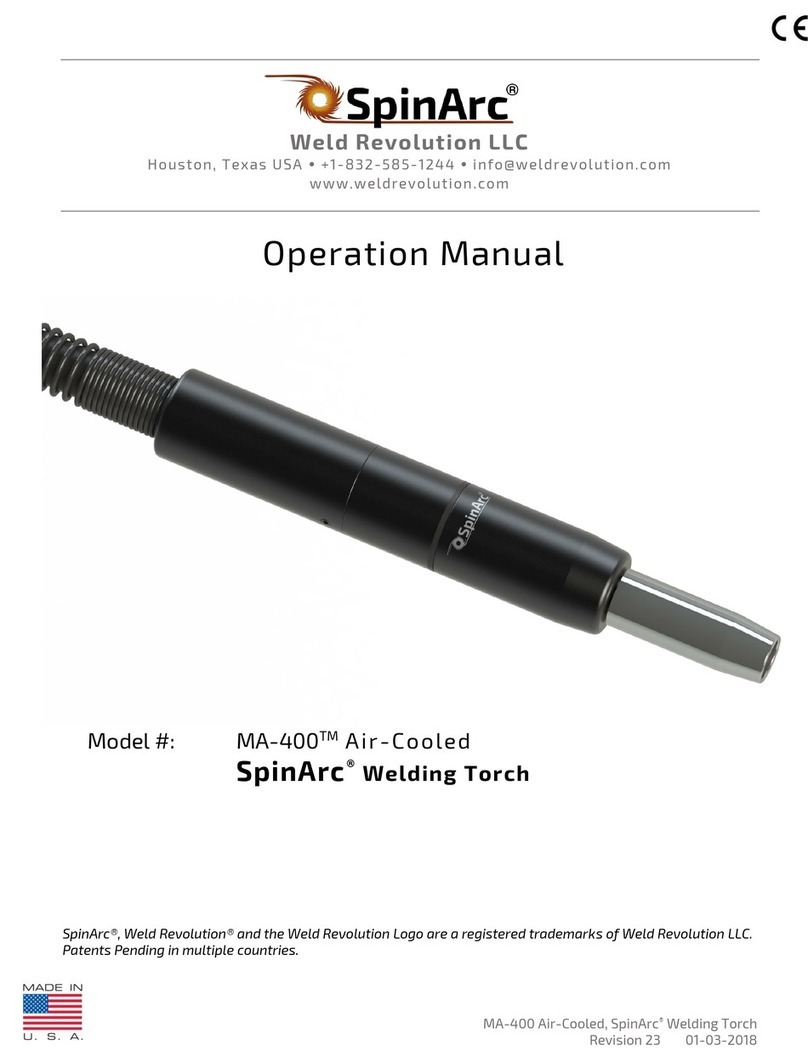

Thread the regulator directly to the bottle. A CO2 adapter will be

needed if using straight CO2 gas. One end of the supplied gas

hose connects to the regulator. The other end connects to the gas

valve on the back of the machine.

Open the drive roll tension arm on the wire feeder. Open the

valve on the shielding gas bottle. Turn on the unit power and pull

the trigger. Adjust the regulator to set for 20 cubic feet per min-

ute. Reinstall the drive roll tension arm on the wire feeder.

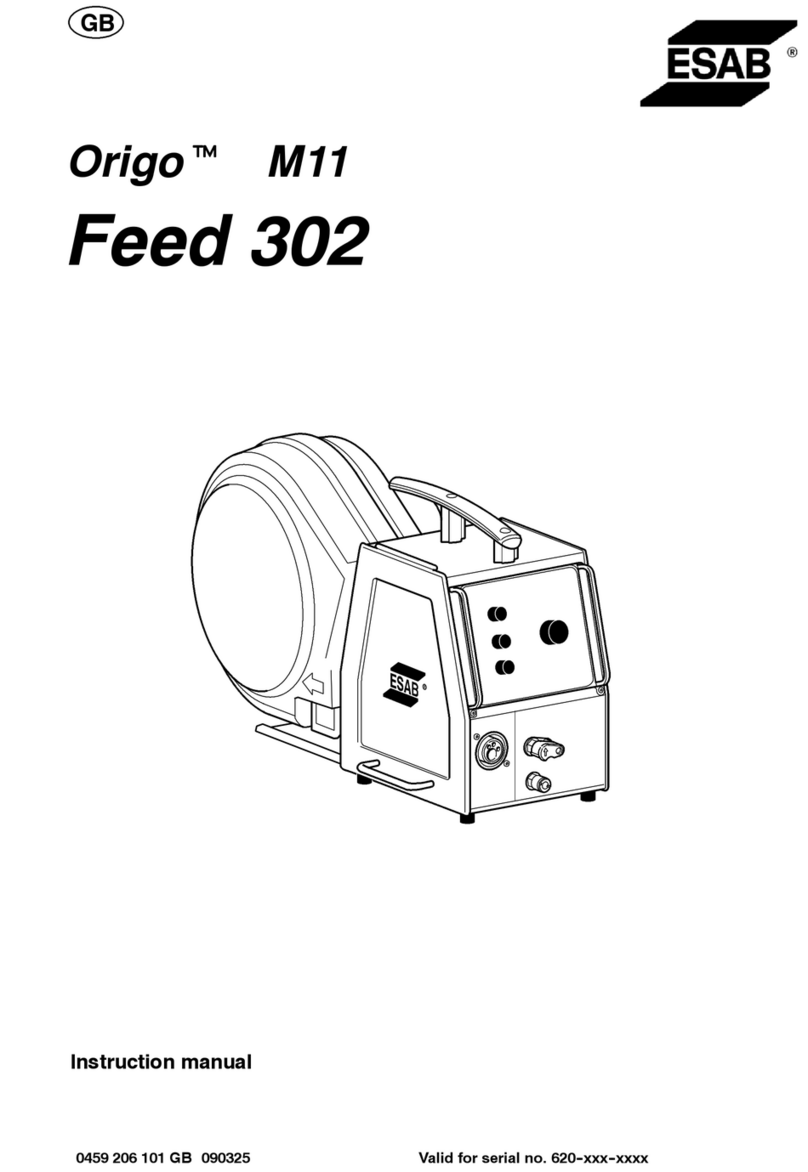

On the wire compartment access panel is a set-up guide. Find the

type of material being welded and the size of wire you are using.

Slide over to the thickness of the thinnest material you are weld-

ing. Set the voltage and wire feed speed on the front of the unit.

Feed ground cable through the front opening. Install on the open

polarity terminal. Solid wire uses Electrode Positive (DCEP) po-

larity. Flux-cored wire use Electrode Negative (DCEN) polarity.

See polarity label in the wire compartment and change as needed.

Tighten

Clockwise

Polarity

Terminals

Polarity

Label

20

CFH

Connect

Gas Hose Increase

Clockwise

Regulator

Threaded Connection