Northern Industrial Tools 3343109 User manual

PowerTools

Made in China

Read carefully and understandRULES FOR SAFEOPERATION and instructions

before operating. Failureto follow thesafety rules andother basic safety

precautions may resultin serious personal injury.

AssemblyandOperationInstructions

Item#3343109

3"VARIABLESPEEDBENCHGRINDER

USER'SMANUAL

For technicalquestions and replacementparts, please call 1-800-222-5381.

Thank you very much forchoosing a NORTHERNTOOL +EQUIPMENT CO., Product!For future

reference, please complete the owner's record below:

Model: _______________ PurchaseDate: _______________

This product isdesigned for certainapplications only.Northern Tool+ Equipment strongly

recommends that thisproduct is not modified and/orused for any application otherthan that

for which itwas designed. Ifyou haveany questionsrelative toa particular application, DONOT

use the productuntil you have first contactedNorthern Tool+ Equipment to determine ifit can

or should beperformed on theproduct.

Before using thisproduct, please readthe followinginstructions carefully.

SPECIFICATIONS

SAVETHISMANUAL

You willneed this manualfor the safety warnings, operatingand maintenance procedures, parts

list and diagram.Keep yourinvoice withthis manual. Write the invoice number onthe inside ofthe

front cover. Keep themanual and invoice in asafe and dryplace for futurereference.

SafetyWarningsandPrecautions

WARNING:

When using thistool, basic safety precautions shouldalways befollowed toreduce the riskof

personal injury and damageto equipment. Read all instructionsbefore using thisproduct.

1.Avoidworkingalone.Should an accidentoccur, anassistant can bringhelp.

2.Disconnectpower.Unplug toolwhen not inuse, before servicingand when changingaccessories

such as grindingwheels. Neverwalk awayand leavethe tool running.

3.Keepworkareaclean.Cluttered areas invite injuries.

4.Keepchildrenandpetsaway.Children must never be allowedin the workarea. Do notlet them

handle machines, tools,or extensioncords. Neverallow unsupervised oruntrained personnel to

operate the machine.

5.Storeidleequipment.When not inuse, tool mustbe stored ina dry location to inhibit rust.

Always lockup tools andkeep out ofreach of children.

6.Dressproperly.Do not wearloose clothing orjewelry as theycan be caughtin moving parts.

Protective electricallynonconductive clothes andnonskid footwearare recommended when

working. Wearrestrictive hair covering tocontain long hair. Wear anANSI-approved dustmask

or respirator.

7. Useeyeprotection.Always wearANSI-approved impact-resistantsafety goggles.

8.Donotoverreach.Keep properfooting andbalance at alltimes. Do notreach overor across

electrical cables orframes.

9.Maintaintoolswithcare.Inspect grinding wheelsand powercord periodically for cracks and

other damage. ifnecessary, havethem repaired byan authorized technician.

10. Usetherighttoolforthejob.Do not attempt to force a smalltool or attachmentto do thework

of a largerindustrial tool. Thereare certain applications for which thistool was designed.Do not

modify this tooland do notuse this toolfor a purpose for whichit was notintended.

11.Stayalert.Watch what you are doingand use commonsense. Do notoperate anytool when

you are tiredor under theinfluence of alcoholor drugs. Readwarning labels onprescriptions to

determine if your judgment orreflexes areimpaired while takingdrugs. If thereis any doubt,do

not operatethe tool.

Save thereceipt, warranty andthese instructions.It isimportant you readthe entire manualto

become familiar withthis product before you beginusing it.

!

1 of 5

ElectricalRequirements

Speed

GrindingWheel

BuffingWheel

ArborSize

Power Input:110V AC/ 60Hz

Power CordLength: 70-7/8" (180cm)

Power CordPlug Type:3-Prong, Grounded

Variable speed0 ~ 10,000 RPM

3" Diameter x3/4" Thick

3" Diameter x3/4" Thick

1/2" (12mm) Diameter

12.Checkfordamagedparts.Before using thistool, anypart that appears damagedshould be

carefully checked to determine thatit will operateproperly and performas intended. Checkfor

alignment and bindingof moving parts,broken parts ormounting fixtures andany otherconditions

that may affectproper operation. Any part that isdamaged should beproperly repaired or

replaced by aqualified technician. Donot use thetool if any switch doesnot turn onand off

properly.

13. Replacementpartsandaccessories.When servicing use only identical replacementparts.

Use of otherparts will voidthe warranty.Only use accessoriesintended foruse with thistool.

14. Usepropersizeandtypeextensioncord.If an extension cord isrequired. It mustbe of the

proper size andtype to supplythe correct currentto the tool without heatingup; otherwise, the

extension cordcould melt andcatch fire orcause electrical damagedto the tool. This tool

requires use ofan extensioncord of 0to 10Amps capability (upto 50 feet), with wiresize rated

at 18 AWG. Longer extension cordsrequire a largersize wire. Ifyou are usingthe tool outdoors,

use an extension cord rated for outdooruse (signified by"WA" on thejacket).

15. Takecautionassomewoodscontainpreservativessuchascopperchromiumarsenate(CCA) whichcan

betoxic.When using thesematerials, extracare should betaken toavoid inhalation

and minimize skincontact. Wear anapproved duskmask or respirator.

16. Maintenance.For yoursafety, serviceand maintenance shouldbe performed regularlyby a

qualified technician.

ADDITIONALSPECIFICSAFETYINSTRUCTIONSFORBENCHGRINDERS

1. When grindingany metals, thegrinder can producesparks which mayland on yourclothing or

hit your face.You shoulduse a fullface mask andappropriate protective clothing. Alsoensure

that you arenot operating thegrinder around flammablematerials of liquids. Alwaysmake sure

the safetyshields and wheelguards are inplace at alltimes. Keep guards in placeand in good

working order.

2. Make surethe grinding wheelsare of theproper speed (RPM)rating for thegrinder.

3. Frequentlyquench the workpiecein waterto preventoverheating; becareful not toget water

on the benchgrinder.

4. Use thetool rest to steady theworkpiece. If thetool rest isnot used thetorque ofthe spinning

grinding wheel maypull the workpiecefrom yourhands.

5. Do notuse aluminum oxidewheels when grindingnonferrous metalssuch as aluminumand

brass. Use siliconcarbide wheels fornonferrous metals.

6. When buffing material, alwayshold the materialon the lower side ofthe buffing wheel. Always

keep fingers clearof the grindingwheel and thetool rest.

Note:Performance of thistool mayvary depending onvariations in localline voltage. Extension

cord usage may also affecttool performance.

WARNING

The warnings, cautions,and instructions discussedin this instructionmanual cannot cover all

possible conditions andsituations that mayoccur. Itmust be understoodby the operator that

common sense andcaution are factors which cannotbe built intothis product, butmust be

supplied by theoperator.

UNPACKING

When unpacking, checkto makesure the following parts are included:

(1) 3" BenchGrinder

(1) Flex Shaft

(1 ) Wrench

(1) Grinder wheel

(1) Fiber Wheel

(2) Grinding StoneBits

OPERATION

Turning theBench Grinder ONand OFF

1. Insert the pluginto an electricaloutlet.

2. Turnthe speed controlknob (46) clockwiseto turn themotor ON andadjust its speed.

3. Toturn OFF, turn theknob counterclockwiseuntil it clicks.

4. Neverleave thebench grinder runningunattended. Alwaysturn off the tool when notin use.

!

2 of 5

USINGTHEGRINDER

WARNING

The grinding wheelcan fly apart andcause injury. Grindingwheels must always be checkedfor

cracked forcracks or imperfections.This is donewith the "ringtest". Tap the wheelgently near

the outer rimwith the handleof a screwdriver. You should heara clear bell-likering. If adull thud

occurs, do notuse the wheel.The wheel maybe damaged andcould come apart duringoperation.

CAUTION:Always wearANSI-approved safetyglasses when grinding.

1. Alwaysbring the workpieceinto the wheelgently, withoutjarring.

2. The workpiecewill quickly becomeheated; therefore,frequent quenching inwater isrequired.

3. When grindinghigh speed steelssuch as drilland tool bits,avoid hightemperature buildupas

this can affectthe temper ofthe steel.

4. For smallworkpieces such asdrill bits orchisels, avoidapplying pressure tothe wheel ata high

angle that couldcause the workpieceto become lodgedbetween the tool rest andthe wheel.

5. When usingthe Flexible Shaft,be sure theGrinder is turnedOFF and waitfor it to stop before

setting down theFlexible Shaft.

MAINTENANCE

Dressing the GrindingWheel

Note:New wheels frequentlyare not trueand during operationwill often becomegrooved, glazed

(build up), outof round, ormisshapen. Youwill need agrinding wheel dresserfor this operation.

1. Stand tothe side ofthe wheel for this operation.

2. If thewheel is newlet it runfor a minute with noload. If thewheel runs straightand true youwill

not need todress it priorto operation. Ifit dose not,proceed with thefollowing instructions.

3. If youare using a"pistol grip" dresser, grip thehandle firmly withone hand andthe arm oft

he dresser withthe other.Allow the wheelto reach fullspeed. Use thetool rest to support your

hand and thedresser, andevenly applythe dresser toall surfaces ofthe wheel. Thewheel can be

dressed in afew minutes.

4. If youare using an"inline" dresser,hold the handlefirmly, putthe dresser onthe tool test so

that its wheelscan movefreely (i.e., theexposed part ofthe wheel shouldbe facing up). Let the

wheel reach fullspeed and applythe dresser evenly to allsurfaces.

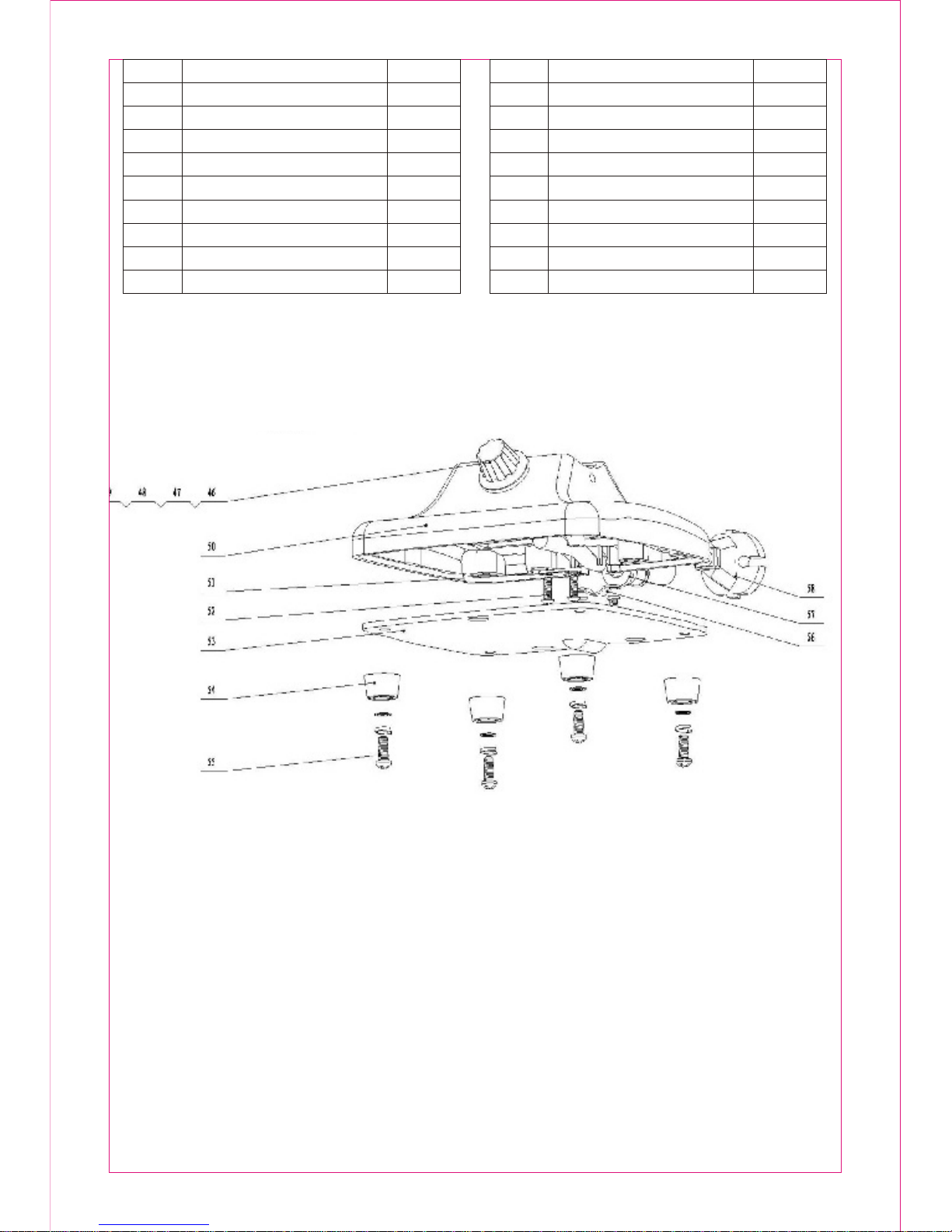

PARTLIST

!

Part No. Quantity

Description Part No. Quantity

Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Left Nut M10

Wheel Pushing Ring

Polishing Wheel

Nut M4

Spring Washer M4

Flat Washer (4.3x12x1)

Steel Sleeve

Wheel Cover

Bearing Cover

Brush Cover

Bearing

Brush

Motor Housing

Flat Washer (4.3x8x0.5)

Short Sleeve

Brush Holder

Long Sleeve

Stator

Stator Bolt

Snap Ring

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

Plastic Shield

Lock Nut M4

Plastic Shield Mounting Plate

Flat Washer

Spring Washer

Pan Head ScrewM6x20

Pan Head ScrewM4x40

Cover

Grinding Wheel

Gasket

Nut M10

Flexible Shaft Connector

Rotating Guard

Wheel Cover

Pan Head ScrewM5x10

Flexible Shaft Connector Nut

Knob

Nut M10

Washer

Switch

2

2

2

2

2

2

2

1

1

2

1

1

1

1

1

1

1

1

1

1

1

4

1

6

13

4

2

1

1

2

1

2

1

9

2

1

2

1

2

2

3 of 5

21

22

Fan Shroud

Rotor

50

51

Base

Circuit Board

1

1

1

1

Part No. Quantity

Description Part No. Quantity

Description

24

25

26

27

28

29

Workpiece Holder

Pan Head ScrewM5x8

Spring Washer M5

Flat Washer

Bearing

Grinding Wheel Cover

53

54

55

56

57

58

Plastic Cover

Rubber Feet

Pan Head ScrewM5x18

Sleeve Plate

Circuit Sleeve

Cord

1

4

4

1

1

1

2

11

16

16

1

1

23 Rubber Gasket 52 Pan Head ScrewM4x10 5

2

4 of 5

Table of contents

Other Northern Industrial Tools Grinder manuals

Popular Grinder manuals by other brands

Meterk

Meterk S1M-GW20-115 Translation of the original instructions

U.S.SAWS

U.S.SAWS SX65000C operating manual

Parkside

Parkside PWS 230 C3 Translation of the original instructions

SUHNER ABRASIVE

SUHNER ABRASIVE ASC 9 Technical document

PTA

PTA P1322 Operation manual

Craftsman

Craftsman CMCG400 instruction manual