Northern Telecom Meridian 1 PC Console Interface Unit User manual

Publication number: 553-3201-200

Document Status: Standard 3.0

Date: April 1993

Application Equipment Module

Installation guide

Meridian 1

Application Equipment Module

Installation guide

Information is subject to change without notice. Northern Telecom reserves the right to make changes in

design or components as progress in engineering and manufacturing may warrant.

Copyright Northern Telecom 1991, 1992, 1993

All rights reserved.

Meridian 1 and SL-1 are trademarks of Northern Telecom. UNIX is a trademark of AT&T. Motorola is a

trademark of the Motorola Corporation. MVME products are trademarked by the Motorola Corporation.

Publication number: 553-3201-200

Document Status: Standard 3.0

Date: April 1993

Application Equipment Module

Installation guide

Meridian 1

Application Equipment Module

Installation guide

Information is subject to change without notice. Northern Telecom reserves the right to make changes in

design or components as progress in engineering and manufacturing may warrant.

Copyright Northern Telecom 1991, 1992, 1993

All rights reserved.

Meridian 1 and SL-1 are trademarks of Northern Telecom. UNIX is a trademark of AT&T. Motorola is a

trademark of the Motorola Corporation. MVME products are trademarked by the Motorola Corporation.

Publication number: 553-3201-200

Document Status: Standard 3.0

Date: April 1993

Application Equipment Module

Installation guide

Meridian 1

Application Equipment Module

Installation guide

Information is subject to change without notice. Northern Telecom reserves the right to make changes in

design or components as progress in engineering and manufacturing may warrant.

Copyright Northern Telecom 1991, 1992, 1993

All rights reserved.

Meridian 1 and SL-1 are trademarks of Northern Telecom. UNIX is a trademark of AT&T. Motorola is a

trademark of the Motorola Corporation. MVME products are trademarked by the Motorola Corporation.

Publication number: 553-3201-200

Document Status: Standard 3.0

Date: April 1993

Application Equipment Module

Installation guide

Meridian 1

Application Equipment Module

Installation guide

Information is subject to change without notice. Northern Telecom reserves the right to make changes in

design or components as progress in engineering and manufacturing may warrant.

Copyright Northern Telecom 1991, 1992, 1993

All rights reserved.

Meridian 1 and SL-1 are trademarks of Northern Telecom. UNIX is a trademark of AT&T. Motorola is a

trademark of the Motorola Corporation. MVME products are trademarked by the Motorola Corporation.

Application Equipment Module

Installation guide

i

Contents

Overview 1

AEM components 2

Stand-alone components 3

Pedestal 3

Top cap 3

Temperature requirements 4

Equipment handling precautions 5

Installing a stand-alone AEM 7

Unpack and level the AEM column 7

Power connections (ac) 9

Power connections (dc) 13

Alarm connections 22

Alarm connections with Meridian 1 systems 22

Alarm connections with ST or RT systems 25

ST system with a QCA136 cabinet 26

ST system with QCA136 and QCA137 cabinets 28

RT system with a QCA147 cabinet 31

RT system with QCA147 and QCA137 cabinets 33

RT system with QCA147 and two QCA137 cabinets 36

Alarm connections with NT or XT systems 39

Adding an AEM to a column 43

Adding an AEM to the base of a column 46

Adding an AEM between two other modules 47

Adding an AEM to the top of a column 48

Application Equipment Module

Installation guide

i

Contents

Overview 1

AEM components 2

Stand-alone components 3

Pedestal 3

Top cap 3

Temperature requirements 4

Equipment handling precautions 5

Installing a stand-alone AEM 7

Unpack and level the AEM column 7

Power connections (ac) 9

Power connections (dc) 13

Alarm connections 22

Alarm connections with Meridian 1 systems 22

Alarm connections with ST or RT systems 25

ST system with a QCA136 cabinet 26

ST system with QCA136 and QCA137 cabinets 28

RT system with a QCA147 cabinet 31

RT system with QCA147 and QCA137 cabinets 33

RT system with QCA147 and two QCA137 cabinets 36

Alarm connections with NT or XT systems 39

Adding an AEM to a column 43

Adding an AEM to the base of a column 46

Adding an AEM between two other modules 47

Adding an AEM to the top of a column 48

Application Equipment Module

Installation guide

i

Contents

Overview 1

AEM components 2

Stand-alone components 3

Pedestal 3

Top cap 3

Temperature requirements 4

Equipment handling precautions 5

Installing a stand-alone AEM 7

Unpack and level the AEM column 7

Power connections (ac) 9

Power connections (dc) 13

Alarm connections 22

Alarm connections with Meridian 1 systems 22

Alarm connections with ST or RT systems 25

ST system with a QCA136 cabinet 26

ST system with QCA136 and QCA137 cabinets 28

RT system with a QCA147 cabinet 31

RT system with QCA147 and QCA137 cabinets 33

RT system with QCA147 and two QCA137 cabinets 36

Alarm connections with NT or XT systems 39

Adding an AEM to a column 43

Adding an AEM to the base of a column 46

Adding an AEM between two other modules 47

Adding an AEM to the top of a column 48

Application Equipment Module

Installation guide

i

Contents

Overview 1

AEM components 2

Stand-alone components 3

Pedestal 3

Top cap 3

Temperature requirements 4

Equipment handling precautions 5

Installing a stand-alone AEM 7

Unpack and level the AEM column 7

Power connections (ac) 9

Power connections (dc) 13

Alarm connections 22

Alarm connections with Meridian 1 systems 22

Alarm connections with ST or RT systems 25

ST system with a QCA136 cabinet 26

ST system with QCA136 and QCA137 cabinets 28

RT system with a QCA147 cabinet 31

RT system with QCA147 and QCA137 cabinets 33

RT system with QCA147 and two QCA137 cabinets 36

Alarm connections with NT or XT systems 39

Adding an AEM to a column 43

Adding an AEM to the base of a column 46

Adding an AEM between two other modules 47

Adding an AEM to the top of a column 48

ii Contents

553-3201-200 Standard 1.0 April 1993

Removing an AEM 53

Ordering 55

Ordering information 55

Component failure rates 56

Glossary 57

Index 59

List of figures

Figure 1 AEM with Application Modules-front view 2

Figure 2 Static discharge points 6

Figure 3 Locking latches on the AEM 8

Figure 4 Pedestal grill 8

Figure 5 PDU connections 10

Figure 6 Meridian 1/AEM column daisy chain connection

11

Figure 7 AEM Logic return connection-LRTN/GND

common connection for stand-alone column 12

Figure 8 AEM Logic return connection-LRTN isolated

star connection for a multi-column row 12

Figure 9 Direct wiring connection-Meridian 1 to AEM 15

Figure 10 Backplane cover 16

Figure 11 Pedestal to NT6D82 connections 19

Figure 12 Pedestal to QBL12 or QCA13 connections 20

Figure 13 Pedestal to QBL15 connections 21

Figure 14 Alarm connections to ST with a QCA136 cabinet

27

Figure 15 Alarm connections to ST with QCA136 and

QCA137 cabinets 30

Figure 16 Alarm connections to RT with a QCA147 cabinet

32

Figure 17 Alarm connections to RT with QCA147 and

QCA137 cabinets 35

Figure 18 Alarm connections to RT with QCA147 and two

QCA137 cabinets 38

Figure 19 NT8D22 System Monitor connections to a

QPC84 Power Monitor 41

Figure 20 NT8D22 System Monitor connections to a

QPC173 Power Monitor 42

ii Contents

553-3201-200 Standard 1.0 April 1993

Removing an AEM 53

Ordering 55

Ordering information 55

Component failure rates 56

Glossary 57

Index 59

List of figures

Figure 1 AEM with Application Modules-front view 2

Figure 2 Static discharge points 6

Figure 3 Locking latches on the AEM 8

Figure 4 Pedestal grill 8

Figure 5 PDU connections 10

Figure 6 Meridian 1/AEM column daisy chain connection

11

Figure 7 AEM Logic return connection-LRTN/GND

common connection for stand-alone column 12

Figure 8 AEM Logic return connection-LRTN isolated

star connection for a multi-column row 12

Figure 9 Direct wiring connection-Meridian 1 to AEM 15

Figure 10 Backplane cover 16

Figure 11 Pedestal to NT6D82 connections 19

Figure 12 Pedestal to QBL12 or QCA13 connections 20

Figure 13 Pedestal to QBL15 connections 21

Figure 14 Alarm connections to ST with a QCA136 cabinet

27

Figure 15 Alarm connections to ST with QCA136 and

QCA137 cabinets 30

Figure 16 Alarm connections to RT with a QCA147 cabinet

32

Figure 17 Alarm connections to RT with QCA147 and

QCA137 cabinets 35

Figure 18 Alarm connections to RT with QCA147 and two

QCA137 cabinets 38

Figure 19 NT8D22 System Monitor connections to a

QPC84 Power Monitor 41

Figure 20 NT8D22 System Monitor connections to a

QPC173 Power Monitor 42

ii Contents

553-3201-200 Standard 1.0 April 1993

Removing an AEM 53

Ordering 55

Ordering information 55

Component failure rates 56

Glossary 57

Index 59

List of figures

Figure 1 AEM with Application Modules-front view 2

Figure 2 Static discharge points 6

Figure 3 Locking latches on the AEM 8

Figure 4 Pedestal grill 8

Figure 5 PDU connections 10

Figure 6 Meridian 1/AEM column daisy chain connection

11

Figure 7 AEM Logic return connection-LRTN/GND

common connection for stand-alone column 12

Figure 8 AEM Logic return connection-LRTN isolated

star connection for a multi-column row 12

Figure 9 Direct wiring connection-Meridian 1 to AEM 15

Figure 10 Backplane cover 16

Figure 11 Pedestal to NT6D82 connections 19

Figure 12 Pedestal to QBL12 or QCA13 connections 20

Figure 13 Pedestal to QBL15 connections 21

Figure 14 Alarm connections to ST with a QCA136 cabinet

27

Figure 15 Alarm connections to ST with QCA136 and

QCA137 cabinets 30

Figure 16 Alarm connections to RT with a QCA147 cabinet

32

Figure 17 Alarm connections to RT with QCA147 and

QCA137 cabinets 35

Figure 18 Alarm connections to RT with QCA147 and two

QCA137 cabinets 38

Figure 19 NT8D22 System Monitor connections to a

QPC84 Power Monitor 41

Figure 20 NT8D22 System Monitor connections to a

QPC173 Power Monitor 42

ii Contents

553-3201-200 Standard 1.0 April 1993

Removing an AEM 53

Ordering 55

Ordering information 55

Component failure rates 56

Glossary 57

Index 59

List of figures

Figure 1 AEM with Application Modules-front view 2

Figure 2 Static discharge points 6

Figure 3 Locking latches on the AEM 8

Figure 4 Pedestal grill 8

Figure 5 PDU connections 10

Figure 6 Meridian 1/AEM column daisy chain connection

11

Figure 7 AEM Logic return connection-LRTN/GND

common connection for stand-alone column 12

Figure 8 AEM Logic return connection-LRTN isolated

star connection for a multi-column row 12

Figure 9 Direct wiring connection-Meridian 1 to AEM 15

Figure 10 Backplane cover 16

Figure 11 Pedestal to NT6D82 connections 19

Figure 12 Pedestal to QBL12 or QCA13 connections 20

Figure 13 Pedestal to QBL15 connections 21

Figure 14 Alarm connections to ST with a QCA136 cabinet

27

Figure 15 Alarm connections to ST with QCA136 and

QCA137 cabinets 30

Figure 16 Alarm connections to RT with a QCA147 cabinet

32

Figure 17 Alarm connections to RT with QCA147 and

QCA137 cabinets 35

Figure 18 Alarm connections to RT with QCA147 and two

QCA137 cabinets 38

Figure 19 NT8D22 System Monitor connections to a

QPC84 Power Monitor 41

Figure 20 NT8D22 System Monitor connections to a

QPC173 Power Monitor 42

Contents iii

Application Equipment Module

Installation guide

Figure 21 Module-to-module power and system monitor

connections 44

Figure 22 Module mounting bolts 45

Figure 23 Module positioning guides 45

Figure 24 Module power harness power connector 48

Figure 25 System monitor cable at connector J2 48

Figure 26 Removing the air exhaust grill 49

Figure 27 Cable well for wiring 50

Figure 28 Alignment tab on connector 51

Figure 29 Top cap assembly 52

List of procedures

Procedure 1 Power connections (ac) 9

Procedure 2 Power connections (dc) 15

Procedure 3 Alarm connections 22

Procedure 4 ST system with QCA136 cabinet connections 26

Procedure 5 ST system with QCA137 cabinet connections 28

Procedure 6 RT system with QCA147 cabinet connections 31

Procedure 7 ST system with QCA147 and QCA137 cabinet

connections 33

Procedure 8 RT system with QCA147 and two QCA137

cabinet connections 36

Procedure 9 NT or XT system with QPC84 or QPC173 cabinet

connections 39

Procedure 10 Adding an AEM to the base of a column 46

Procedure 11 Adding an AEM between two other modules 47

Procedure 12 Add an AEM to the top of a column 48

List of tables

Table 1 Pedestal wire gauge requirements with two

30-amp 48 V dc feeds (see Note 1) 14

Table 2 NT8D22 switch settings (set as slave) for

operation with Meridian 1 22

Table 3 SW2 positions 3 - 8-unit number for the slave

24

Table 4 ST/RT alarm connection hardware requirements

25

Table 5 NT8D22 switch settings (set as master) for

operation with ST 26

Table 6 NT8D22 switch settings (set as master) for

operation with ST 28

Contents iii

Application Equipment Module

Installation guide

Figure 21 Module-to-module power and system monitor

connections 44

Figure 22 Module mounting bolts 45

Figure 23 Module positioning guides 45

Figure 24 Module power harness power connector 48

Figure 25 System monitor cable at connector J2 48

Figure 26 Removing the air exhaust grill 49

Figure 27 Cable well for wiring 50

Figure 28 Alignment tab on connector 51

Figure 29 Top cap assembly 52

List of procedures

Procedure 1 Power connections (ac) 9

Procedure 2 Power connections (dc) 15

Procedure 3 Alarm connections 22

Procedure 4 ST system with QCA136 cabinet connections 26

Procedure 5 ST system with QCA137 cabinet connections 28

Procedure 6 RT system with QCA147 cabinet connections 31

Procedure 7 ST system with QCA147 and QCA137 cabinet

connections 33

Procedure 8 RT system with QCA147 and two QCA137

cabinet connections 36

Procedure 9 NT or XT system with QPC84 or QPC173 cabinet

connections 39

Procedure 10 Adding an AEM to the base of a column 46

Procedure 11 Adding an AEM between two other modules 47

Procedure 12 Add an AEM to the top of a column 48

List of tables

Table 1 Pedestal wire gauge requirements with two

30-amp 48 V dc feeds (see Note 1) 14

Table 2 NT8D22 switch settings (set as slave) for

operation with Meridian 1 22

Table 3 SW2 positions 3 - 8-unit number for the slave

24

Table 4 ST/RT alarm connection hardware requirements

25

Table 5 NT8D22 switch settings (set as master) for

operation with ST 26

Table 6 NT8D22 switch settings (set as master) for

operation with ST 28

Contents iii

Application Equipment Module

Installation guide

Figure 21 Module-to-module power and system monitor

connections 44

Figure 22 Module mounting bolts 45

Figure 23 Module positioning guides 45

Figure 24 Module power harness power connector 48

Figure 25 System monitor cable at connector J2 48

Figure 26 Removing the air exhaust grill 49

Figure 27 Cable well for wiring 50

Figure 28 Alignment tab on connector 51

Figure 29 Top cap assembly 52

List of procedures

Procedure 1 Power connections (ac) 9

Procedure 2 Power connections (dc) 15

Procedure 3 Alarm connections 22

Procedure 4 ST system with QCA136 cabinet connections 26

Procedure 5 ST system with QCA137 cabinet connections 28

Procedure 6 RT system with QCA147 cabinet connections 31

Procedure 7 ST system with QCA147 and QCA137 cabinet

connections 33

Procedure 8 RT system with QCA147 and two QCA137

cabinet connections 36

Procedure 9 NT or XT system with QPC84 or QPC173 cabinet

connections 39

Procedure 10 Adding an AEM to the base of a column 46

Procedure 11 Adding an AEM between two other modules 47

Procedure 12 Add an AEM to the top of a column 48

List of tables

Table 1 Pedestal wire gauge requirements with two

30-amp 48 V dc feeds (see Note 1) 14

Table 2 NT8D22 switch settings (set as slave) for

operation with Meridian 1 22

Table 3 SW2 positions 3 - 8-unit number for the slave

24

Table 4 ST/RT alarm connection hardware requirements

25

Table 5 NT8D22 switch settings (set as master) for

operation with ST 26

Table 6 NT8D22 switch settings (set as master) for

operation with ST 28

Contents iii

Application Equipment Module

Installation guide

Figure 21 Module-to-module power and system monitor

connections 44

Figure 22 Module mounting bolts 45

Figure 23 Module positioning guides 45

Figure 24 Module power harness power connector 48

Figure 25 System monitor cable at connector J2 48

Figure 26 Removing the air exhaust grill 49

Figure 27 Cable well for wiring 50

Figure 28 Alignment tab on connector 51

Figure 29 Top cap assembly 52

List of procedures

Procedure 1 Power connections (ac) 9

Procedure 2 Power connections (dc) 15

Procedure 3 Alarm connections 22

Procedure 4 ST system with QCA136 cabinet connections 26

Procedure 5 ST system with QCA137 cabinet connections 28

Procedure 6 RT system with QCA147 cabinet connections 31

Procedure 7 ST system with QCA147 and QCA137 cabinet

connections 33

Procedure 8 RT system with QCA147 and two QCA137

cabinet connections 36

Procedure 9 NT or XT system with QPC84 or QPC173 cabinet

connections 39

Procedure 10 Adding an AEM to the base of a column 46

Procedure 11 Adding an AEM between two other modules 47

Procedure 12 Add an AEM to the top of a column 48

List of tables

Table 1 Pedestal wire gauge requirements with two

30-amp 48 V dc feeds (see Note 1) 14

Table 2 NT8D22 switch settings (set as slave) for

operation with Meridian 1 22

Table 3 SW2 positions 3 - 8-unit number for the slave

24

Table 4 ST/RT alarm connection hardware requirements

25

Table 5 NT8D22 switch settings (set as master) for

operation with ST 26

Table 6 NT8D22 switch settings (set as master) for

operation with ST 28

iv Contents

553-3201-200 Standard 1.0 April 1993

Table 7 NT8D22 switch settings (set as master) for

operation with RT 31

Table 8 NT8D22 switch settings (set as master) for

operation with RT 33

Table 9 NT8D22 switch settings (set as master) for

operation with RT 36

Table 10 NT8D22 switch settings (set as master) for

operation with NT or XT 39

Table 11 Field-replaceable items 55

Table 12 Component failure rates 56

iv Contents

553-3201-200 Standard 1.0 April 1993

Table 7 NT8D22 switch settings (set as master) for

operation with RT 31

Table 8 NT8D22 switch settings (set as master) for

operation with RT 33

Table 9 NT8D22 switch settings (set as master) for

operation with RT 36

Table 10 NT8D22 switch settings (set as master) for

operation with NT or XT 39

Table 11 Field-replaceable items 55

Table 12 Component failure rates 56

iv Contents

553-3201-200 Standard 1.0 April 1993

Table 7 NT8D22 switch settings (set as master) for

operation with RT 31

Table 8 NT8D22 switch settings (set as master) for

operation with RT 33

Table 9 NT8D22 switch settings (set as master) for

operation with RT 36

Table 10 NT8D22 switch settings (set as master) for

operation with NT or XT 39

Table 11 Field-replaceable items 55

Table 12 Component failure rates 56

iv Contents

553-3201-200 Standard 1.0 April 1993

Table 7 NT8D22 switch settings (set as master) for

operation with RT 31

Table 8 NT8D22 switch settings (set as master) for

operation with RT 33

Table 9 NT8D22 switch settings (set as master) for

operation with RT 36

Table 10 NT8D22 switch settings (set as master) for

operation with NT or XT 39

Table 11 Field-replaceable items 55

Table 12 Component failure rates 56

Application Equipment Module

Installation guide

1

Overview

Application Module hardware is based on Meridian 1 modular packaging.

The basic unit of the modular package is the Universal Equipment Module

(UEM), which is a modular, self-contained hardware cabinet that houses a

card cage with a power supply, backplane, circuit cards, and other basic

equipment. When the UEM is equipped, it generally supports a system

function and becomes a specific type of module, such as a CPU Module or

Intelligent Peripheral Equipment (IPE) Module.

The term “Meridian 1” is used throughout this document, and refers to

Meridian 1 and “Meridian 1-ready” systems (such as Meridian SL-1 style

cabinets that have been upgraded). See Applications Module overview

guide (553-3201-110) for further information on Application Module

requirements.

In addition, the UEM houses the card cage that supports the Application

Equipment Module (AEM). When this card cage is installed, the UEM

functionally becomes an AEM. There are two versions of the AEM:

•NT7D18AA for ac-powered systems

•NT7D18AB for dc-powered systems

Application Modules, such as the Meridian Link Module, are housed in the

AEM. Each AEM can accommodate up to two Application Modules. (If

only one Application Module is installed, a blank panel covers the rest of

the AEM to channel air flow for cooling.)

An AEM with a standard Meridian 1 pedestal and top cap can be

configured as a stand-alone column. In this configuration, the AEM can

interface with:

•Meridian 1 system options 11, 21, 51, 61 or 71.

Application Equipment Module

Installation guide

1

Overview

Application Module hardware is based on Meridian 1 modular packaging.

The basic unit of the modular package is the Universal Equipment Module

(UEM), which is a modular, self-contained hardware cabinet that houses a

card cage with a power supply, backplane, circuit cards, and other basic

equipment. When the UEM is equipped, it generally supports a system

function and becomes a specific type of module, such as a CPU Module or

Intelligent Peripheral Equipment (IPE) Module.

The term “Meridian 1” is used throughout this document, and refers to

Meridian 1 and “Meridian 1-ready” systems (such as Meridian SL-1 style

cabinets that have been upgraded). See Applications Module overview

guide (553-3201-110) for further information on Application Module

requirements.

In addition, the UEM houses the card cage that supports the Application

Equipment Module (AEM). When this card cage is installed, the UEM

functionally becomes an AEM. There are two versions of the AEM:

•NT7D18AA for ac-powered systems

•NT7D18AB for dc-powered systems

Application Modules, such as the Meridian Link Module, are housed in the

AEM. Each AEM can accommodate up to two Application Modules. (If

only one Application Module is installed, a blank panel covers the rest of

the AEM to channel air flow for cooling.)

An AEM with a standard Meridian 1 pedestal and top cap can be

configured as a stand-alone column. In this configuration, the AEM can

interface with:

•Meridian 1 system options 11, 21, 51, 61 or 71.

Application Equipment Module

Installation guide

1

Overview

Application Module hardware is based on Meridian 1 modular packaging.

The basic unit of the modular package is the Universal Equipment Module

(UEM), which is a modular, self-contained hardware cabinet that houses a

card cage with a power supply, backplane, circuit cards, and other basic

equipment. When the UEM is equipped, it generally supports a system

function and becomes a specific type of module, such as a CPU Module or

Intelligent Peripheral Equipment (IPE) Module.

The term “Meridian 1” is used throughout this document, and refers to

Meridian 1 and “Meridian 1-ready” systems (such as Meridian SL-1 style

cabinets that have been upgraded). See Applications Module overview

guide (553-3201-110) for further information on Application Module

requirements.

In addition, the UEM houses the card cage that supports the Application

Equipment Module (AEM). When this card cage is installed, the UEM

functionally becomes an AEM. There are two versions of the AEM:

•NT7D18AA for ac-powered systems

•NT7D18AB for dc-powered systems

Application Modules, such as the Meridian Link Module, are housed in the

AEM. Each AEM can accommodate up to two Application Modules. (If

only one Application Module is installed, a blank panel covers the rest of

the AEM to channel air flow for cooling.)

An AEM with a standard Meridian 1 pedestal and top cap can be

configured as a stand-alone column. In this configuration, the AEM can

interface with:

•Meridian 1 system options 11, 21, 51, 61 or 71.

Application Equipment Module

Installation guide

1

Overview

Application Module hardware is based on Meridian 1 modular packaging.

The basic unit of the modular package is the Universal Equipment Module

(UEM), which is a modular, self-contained hardware cabinet that houses a

card cage with a power supply, backplane, circuit cards, and other basic

equipment. When the UEM is equipped, it generally supports a system

function and becomes a specific type of module, such as a CPU Module or

Intelligent Peripheral Equipment (IPE) Module.

The term “Meridian 1” is used throughout this document, and refers to

Meridian 1 and “Meridian 1-ready” systems (such as Meridian SL-1 style

cabinets that have been upgraded). See Applications Module overview

guide (553-3201-110) for further information on Application Module

requirements.

In addition, the UEM houses the card cage that supports the Application

Equipment Module (AEM). When this card cage is installed, the UEM

functionally becomes an AEM. There are two versions of the AEM:

•NT7D18AA for ac-powered systems

•NT7D18AB for dc-powered systems

Application Modules, such as the Meridian Link Module, are housed in the

AEM. Each AEM can accommodate up to two Application Modules. (If

only one Application Module is installed, a blank panel covers the rest of

the AEM to channel air flow for cooling.)

An AEM with a standard Meridian 1 pedestal and top cap can be

configured as a stand-alone column. In this configuration, the AEM can

interface with:

•Meridian 1 system options 11, 21, 51, 61 or 71.

2Overview

553-3201-200 Standard 1.0 April 1993

•Meridian SL-1 systems (upgraded) capable of operating on Generic

X11 Release 16, or later, software.

An individual AEM can be placed in a column with other Meridian 1

modules in system options 21, 51, 61 or 71. This document explains how to

install a stand-alone AEM and add an AEM to a Meridian 1 column.

AEM components

The AEM is equipped with a Module Power Distribution Unit (MPDU) on

the left (looking at the front of the AEM).

The MPDU provides two circuit breakers (see Figure 1). The top breaker

controls power to the left Application Module (the one closer to the

MPDU). The bottom breaker controls power to the second Application

Module (on the right of the AEM).

Figure 1xxx

AEM with Application Modules-front view

APPLICATION EQUIPMENT

Module Power

Distribution Unit

M

V

M

E

1

4

7

S

A

*

M

V

M

E

1

4

7

S

A

*

Left-side Application

Module Right-side Application

Module

Breaker for left-

side module

Breaker for

right-side

module

*Could also be

an MVME167

card.

2Overview

553-3201-200 Standard 1.0 April 1993

•Meridian SL-1 systems (upgraded) capable of operating on Generic

X11 Release 16, or later, software.

An individual AEM can be placed in a column with other Meridian 1

modules in system options 21, 51, 61 or 71. This document explains how to

install a stand-alone AEM and add an AEM to a Meridian 1 column.

AEM components

The AEM is equipped with a Module Power Distribution Unit (MPDU) on

the left (looking at the front of the AEM).

The MPDU provides two circuit breakers (see Figure 1). The top breaker

controls power to the left Application Module (the one closer to the

MPDU). The bottom breaker controls power to the second Application

Module (on the right of the AEM).

Figure 1xxx

AEM with Application Modules-front view

APPLICATION EQUIPMENT

Module Power

Distribution Unit

M

V

M

E

1

4

7

S

A

*

M

V

M

E

1

4

7

S

A

*

Left-side Application

Module Right-side Application

Module

Breaker for left-

side module

Breaker for

right-side

module

*Could also be

an MVME167

card.

2Overview

553-3201-200 Standard 1.0 April 1993

•Meridian SL-1 systems (upgraded) capable of operating on Generic

X11 Release 16, or later, software.

An individual AEM can be placed in a column with other Meridian 1

modules in system options 21, 51, 61 or 71. This document explains how to

install a stand-alone AEM and add an AEM to a Meridian 1 column.

AEM components

The AEM is equipped with a Module Power Distribution Unit (MPDU) on

the left (looking at the front of the AEM).

The MPDU provides two circuit breakers (see Figure 1). The top breaker

controls power to the left Application Module (the one closer to the

MPDU). The bottom breaker controls power to the second Application

Module (on the right of the AEM).

Figure 1xxx

AEM with Application Modules-front view

APPLICATION EQUIPMENT

Module Power

Distribution Unit

M

V

M

E

1

4

7

S

A

*

M

V

M

E

1

4

7

S

A

*

Left-side Application

Module Right-side Application

Module

Breaker for left-

side module

Breaker for

right-side

module

*Could also be

an MVME167

card.

2Overview

553-3201-200 Standard 1.0 April 1993

•Meridian SL-1 systems (upgraded) capable of operating on Generic

X11 Release 16, or later, software.

An individual AEM can be placed in a column with other Meridian 1

modules in system options 21, 51, 61 or 71. This document explains how to

install a stand-alone AEM and add an AEM to a Meridian 1 column.

AEM components

The AEM is equipped with a Module Power Distribution Unit (MPDU) on

the left (looking at the front of the AEM).

The MPDU provides two circuit breakers (see Figure 1). The top breaker

controls power to the left Application Module (the one closer to the

MPDU). The bottom breaker controls power to the second Application

Module (on the right of the AEM).

Figure 1xxx

AEM with Application Modules-front view

APPLICATION EQUIPMENT

Module Power

Distribution Unit

M

V

M

E

1

4

7

S

A

*

M

V

M

E

1

4

7

S

A

*

Left-side Application

Module Right-side Application

Module

Breaker for left-

side module

Breaker for

right-side

module

*Could also be

an MVME167

card.

Overview 3

Application Equipment Module

Installation guide

Stand-alone components

A stand-alone configuration consists of a pedestal, an AEM, and a top cap.

Pedestal

The pedestal houses a blower unit, an air filter, and the Power Distribution

Unit (PDU). The PDU, which distributes power to the entire column,

contains the field wiring terminal block, the main circuit breaker (or

breakers) for the column, and a slot that houses the system monitor.

The pedestal weighs 13.6 kg (30 lbs) when empty, and the dimensions are:

•812 mm (32 in.) wide

•660 mm (26 in.) deep

•254 mm (10 in.) high

There are two versions of the pedestal:

•NT8D27 for ac-powered systems

•NT7D09 for dc-powered systems

Top cap

The top cap provides airflow exits, input/output (I/O) cable entry and exit,

and overhead cable-rack mounting. Thermal sensor assemblies for the

column are attached to a perforated panel on top of the highest module in

the column, under the top cap.

The top cap weighs 3.6 kg (8 lbs) and the dimensions are:

•812 mm (32 in.) wide

•558 mm (22 in.) deep

•101 mm (4 in.) high

There are two versions of the top cap:

NT7D00AA for ac-powered systems

NT7D00BA for dc-powered systems

Overview 3

Application Equipment Module

Installation guide

Stand-alone components

A stand-alone configuration consists of a pedestal, an AEM, and a top cap.

Pedestal

The pedestal houses a blower unit, an air filter, and the Power Distribution

Unit (PDU). The PDU, which distributes power to the entire column,

contains the field wiring terminal block, the main circuit breaker (or

breakers) for the column, and a slot that houses the system monitor.

The pedestal weighs 13.6 kg (30 lbs) when empty, and the dimensions are:

•812 mm (32 in.) wide

•660 mm (26 in.) deep

•254 mm (10 in.) high

There are two versions of the pedestal:

•NT8D27 for ac-powered systems

•NT7D09 for dc-powered systems

Top cap

The top cap provides airflow exits, input/output (I/O) cable entry and exit,

and overhead cable-rack mounting. Thermal sensor assemblies for the

column are attached to a perforated panel on top of the highest module in

the column, under the top cap.

The top cap weighs 3.6 kg (8 lbs) and the dimensions are:

•812 mm (32 in.) wide

•558 mm (22 in.) deep

•101 mm (4 in.) high

There are two versions of the top cap:

NT7D00AA for ac-powered systems

NT7D00BA for dc-powered systems

Overview 3

Application Equipment Module

Installation guide

Stand-alone components

A stand-alone configuration consists of a pedestal, an AEM, and a top cap.

Pedestal

The pedestal houses a blower unit, an air filter, and the Power Distribution

Unit (PDU). The PDU, which distributes power to the entire column,

contains the field wiring terminal block, the main circuit breaker (or

breakers) for the column, and a slot that houses the system monitor.

The pedestal weighs 13.6 kg (30 lbs) when empty, and the dimensions are:

•812 mm (32 in.) wide

•660 mm (26 in.) deep

•254 mm (10 in.) high

There are two versions of the pedestal:

•NT8D27 for ac-powered systems

•NT7D09 for dc-powered systems

Top cap

The top cap provides airflow exits, input/output (I/O) cable entry and exit,

and overhead cable-rack mounting. Thermal sensor assemblies for the

column are attached to a perforated panel on top of the highest module in

the column, under the top cap.

The top cap weighs 3.6 kg (8 lbs) and the dimensions are:

•812 mm (32 in.) wide

•558 mm (22 in.) deep

•101 mm (4 in.) high

There are two versions of the top cap:

NT7D00AA for ac-powered systems

NT7D00BA for dc-powered systems

Overview 3

Application Equipment Module

Installation guide

Stand-alone components

A stand-alone configuration consists of a pedestal, an AEM, and a top cap.

Pedestal

The pedestal houses a blower unit, an air filter, and the Power Distribution

Unit (PDU). The PDU, which distributes power to the entire column,

contains the field wiring terminal block, the main circuit breaker (or

breakers) for the column, and a slot that houses the system monitor.

The pedestal weighs 13.6 kg (30 lbs) when empty, and the dimensions are:

•812 mm (32 in.) wide

•660 mm (26 in.) deep

•254 mm (10 in.) high

There are two versions of the pedestal:

•NT8D27 for ac-powered systems

•NT7D09 for dc-powered systems

Top cap

The top cap provides airflow exits, input/output (I/O) cable entry and exit,

and overhead cable-rack mounting. Thermal sensor assemblies for the

column are attached to a perforated panel on top of the highest module in

the column, under the top cap.

The top cap weighs 3.6 kg (8 lbs) and the dimensions are:

•812 mm (32 in.) wide

•558 mm (22 in.) deep

•101 mm (4 in.) high

There are two versions of the top cap:

NT7D00AA for ac-powered systems

NT7D00BA for dc-powered systems

4Overview

553-3201-200 Standard 1.0 April 1993

Temperature requirements

The recommended ambient temperature differs depending in which tier that

the AEM is placed. The following is the maximum ambient temperature for

each operating tier:

•1st tier: 35 degrees C (95 degrees F)

•2nd tier: 30 degrees C (86 degrees F)

•3rd tier: 25 degrees C (77 degrees F)

•4th tier: 20 degrees C (68 degrees F)

The recommended ambient temperature range for an AEM is:

•10 to 35 degrees C (50-95 degrees F)

The maximum allowable ambient temperature is:

•45 degrees C (113 degrees F)

CAUTION

Equipment failure

If room temperature remains outside the

recommended operating temperature for 72 hours,

the disk or tape drive can fail to operate.

If the room temperature frequently drops below or

goes above the recommended operating

temperature, even though it does so for less than

72 hours each time, the same failure may occur.

4Overview

553-3201-200 Standard 1.0 April 1993

Temperature requirements

The recommended ambient temperature differs depending in which tier that

the AEM is placed. The following is the maximum ambient temperature for

each operating tier:

•1st tier: 35 degrees C (95 degrees F)

•2nd tier: 30 degrees C (86 degrees F)

•3rd tier: 25 degrees C (77 degrees F)

•4th tier: 20 degrees C (68 degrees F)

The recommended ambient temperature range for an AEM is:

•10 to 35 degrees C (50-95 degrees F)

The maximum allowable ambient temperature is:

•45 degrees C (113 degrees F)

CAUTION

Equipment failure

If room temperature remains outside the

recommended operating temperature for 72 hours,

the disk or tape drive can fail to operate.

If the room temperature frequently drops below or

goes above the recommended operating

temperature, even though it does so for less than

72 hours each time, the same failure may occur.

4Overview

553-3201-200 Standard 1.0 April 1993

Temperature requirements

The recommended ambient temperature differs depending in which tier that

the AEM is placed. The following is the maximum ambient temperature for

each operating tier:

•1st tier: 35 degrees C (95 degrees F)

•2nd tier: 30 degrees C (86 degrees F)

•3rd tier: 25 degrees C (77 degrees F)

•4th tier: 20 degrees C (68 degrees F)

The recommended ambient temperature range for an AEM is:

•10 to 35 degrees C (50-95 degrees F)

The maximum allowable ambient temperature is:

•45 degrees C (113 degrees F)

CAUTION

Equipment failure

If room temperature remains outside the

recommended operating temperature for 72 hours,

the disk or tape drive can fail to operate.

If the room temperature frequently drops below or

goes above the recommended operating

temperature, even though it does so for less than

72 hours each time, the same failure may occur.

4Overview

553-3201-200 Standard 1.0 April 1993

Temperature requirements

The recommended ambient temperature differs depending in which tier that

the AEM is placed. The following is the maximum ambient temperature for

each operating tier:

•1st tier: 35 degrees C (95 degrees F)

•2nd tier: 30 degrees C (86 degrees F)

•3rd tier: 25 degrees C (77 degrees F)

•4th tier: 20 degrees C (68 degrees F)

The recommended ambient temperature range for an AEM is:

•10 to 35 degrees C (50-95 degrees F)

The maximum allowable ambient temperature is:

•45 degrees C (113 degrees F)

CAUTION

Equipment failure

If room temperature remains outside the

recommended operating temperature for 72 hours,

the disk or tape drive can fail to operate.

If the room temperature frequently drops below or

goes above the recommended operating

temperature, even though it does so for less than

72 hours each time, the same failure may occur.

Overview 5

Application Equipment Module

Installation guide

Equipment handling precautions

To avoid personal injury and equipment damage, read the following

guidelines before handling equipment.

DANGER

Risk of personal injury

A fully loaded module weighs approximately 58.9

kg. (130 lbs). Get help when moving modules.

Use the following guidelines to handle circuit cards:

•Do not unpack or handle cards near electric motors, transformers, or

similar machinery.

•Handle cards by the card stiffeners and edges only. Do not touch the

contacts or components.

•Set cards on a protective antistatic bag. If an antistatic bag is not

available, hand-hold the card, or set it, unseated, in a card cage.

•Store cards in protective packing. Do not stack cards on top of each

other unless they are packaged.

Figure 2 shows connection points for the wrist strap and the metal strips

that you can touch.

Overview 5

Application Equipment Module

Installation guide

Equipment handling precautions

To avoid personal injury and equipment damage, read the following

guidelines before handling equipment.

DANGER

Risk of personal injury

A fully loaded module weighs approximately 58.9

kg. (130 lbs). Get help when moving modules.

Use the following guidelines to handle circuit cards:

•Do not unpack or handle cards near electric motors, transformers, or

similar machinery.

•Handle cards by the card stiffeners and edges only. Do not touch the

contacts or components.

•Set cards on a protective antistatic bag. If an antistatic bag is not

available, hand-hold the card, or set it, unseated, in a card cage.

•Store cards in protective packing. Do not stack cards on top of each

other unless they are packaged.

Figure 2 shows connection points for the wrist strap and the metal strips

that you can touch.

Overview 5

Application Equipment Module

Installation guide

Equipment handling precautions

To avoid personal injury and equipment damage, read the following

guidelines before handling equipment.

DANGER

Risk of personal injury

A fully loaded module weighs approximately 58.9

kg. (130 lbs). Get help when moving modules.

Use the following guidelines to handle circuit cards:

•Do not unpack or handle cards near electric motors, transformers, or

similar machinery.

•Handle cards by the card stiffeners and edges only. Do not touch the

contacts or components.

•Set cards on a protective antistatic bag. If an antistatic bag is not

available, hand-hold the card, or set it, unseated, in a card cage.

•Store cards in protective packing. Do not stack cards on top of each

other unless they are packaged.

Figure 2 shows connection points for the wrist strap and the metal strips

that you can touch.

Overview 5

Application Equipment Module

Installation guide

Equipment handling precautions

To avoid personal injury and equipment damage, read the following

guidelines before handling equipment.

DANGER

Risk of personal injury

A fully loaded module weighs approximately 58.9

kg. (130 lbs). Get help when moving modules.

Use the following guidelines to handle circuit cards:

•Do not unpack or handle cards near electric motors, transformers, or

similar machinery.

•Handle cards by the card stiffeners and edges only. Do not touch the

contacts or components.

•Set cards on a protective antistatic bag. If an antistatic bag is not

available, hand-hold the card, or set it, unseated, in a card cage.

•Store cards in protective packing. Do not stack cards on top of each

other unless they are packaged.

Figure 2 shows connection points for the wrist strap and the metal strips

that you can touch.

6Overview

553-3201-200 Standard 1.0 April 1993

CAUTION

Equipment damage

To avoid damage from static discharge, wear an

antistatic wrist strap when you work on AEM

equipment. If a wrist strap is not available,

regularly touch one of the bare metal strips in the

AEM.

Figure 2xxx

Static discharge points

Wrist strap

connection point Bare metal strip

Wrist strap

connection point Bare metal strip

Power supply slot

Module

front

Module

rear

6Overview

553-3201-200 Standard 1.0 April 1993

CAUTION

Equipment damage

To avoid damage from static discharge, wear an

antistatic wrist strap when you work on AEM

equipment. If a wrist strap is not available,

regularly touch one of the bare metal strips in the

AEM.

Figure 2xxx

Static discharge points

Wrist strap

connection point Bare metal strip

Wrist strap

connection point Bare metal strip

Power supply slot

Module

front

Module

rear

6Overview

553-3201-200 Standard 1.0 April 1993

CAUTION

Equipment damage

To avoid damage from static discharge, wear an

antistatic wrist strap when you work on AEM

equipment. If a wrist strap is not available,

regularly touch one of the bare metal strips in the

AEM.

Figure 2xxx

Static discharge points

Wrist strap

connection point Bare metal strip

Wrist strap

connection point Bare metal strip

Power supply slot

Module

front

Module

rear

6Overview

553-3201-200 Standard 1.0 April 1993

CAUTION

Equipment damage

To avoid damage from static discharge, wear an

antistatic wrist strap when you work on AEM

equipment. If a wrist strap is not available,

regularly touch one of the bare metal strips in the

AEM.

Figure 2xxx

Static discharge points

Wrist strap

connection point Bare metal strip

Wrist strap

connection point Bare metal strip

Power supply slot

Module

front

Module

rear

Application Equipment Module

Installation guide

7

Installing a stand-alone AEM

For proper installation, perform the steps in the following procedures in the

order given.

Unpack and level the AEM column

1Remove the AEM column from the shipping pallet; follow the unpacking

instructions that come with the packaging material.

2Remove the front and rear covers from the AEM:

a. Turn the two locking latches (see Figure 3) clockwise with a

standard screwdriver.

b. Push the latches toward the center of the cover and pull the cover

towards you while lifting it away from the module.

c. Set the covers aside until the installation is complete.

WARNING

Risk of equipment damage

Module covers are not hinged; do not let go of the

cover. Lift the cover away from the module and set

it out of your work area.

3Remove the front and rear grills from the pedestal (see Figure 4). Set

the grills aside until the installation is complete.

4Inspect all equipment for physical damage; report any to your supplier.

5Adjust the feet on the pedestal to level the column (turn the leveling foot

clockwise to raise it).

Note 1:

You must leave at least 12.7 mm (1/2 in.) between the floor and

the bottom of the pedestal for air flow required by the cooling unit.

Application Equipment Module

Installation guide

7

Installing a stand-alone AEM

For proper installation, perform the steps in the following procedures in the

order given.

Unpack and level the AEM column

1Remove the AEM column from the shipping pallet; follow the unpacking

instructions that come with the packaging material.

2Remove the front and rear covers from the AEM:

a. Turn the two locking latches (see Figure 3) clockwise with a

standard screwdriver.

b. Push the latches toward the center of the cover and pull the cover

towards you while lifting it away from the module.

c. Set the covers aside until the installation is complete.

WARNING

Risk of equipment damage

Module covers are not hinged; do not let go of the

cover. Lift the cover away from the module and set

it out of your work area.

3Remove the front and rear grills from the pedestal (see Figure 4). Set

the grills aside until the installation is complete.

4Inspect all equipment for physical damage; report any to your supplier.

5Adjust the feet on the pedestal to level the column (turn the leveling foot

clockwise to raise it).

Note 1:

You must leave at least 12.7 mm (1/2 in.) between the floor and

the bottom of the pedestal for air flow required by the cooling unit.

Application Equipment Module

Installation guide

7

Installing a stand-alone AEM

For proper installation, perform the steps in the following procedures in the

order given.

Unpack and level the AEM column

1Remove the AEM column from the shipping pallet; follow the unpacking

instructions that come with the packaging material.

2Remove the front and rear covers from the AEM:

a. Turn the two locking latches (see Figure 3) clockwise with a

standard screwdriver.

b. Push the latches toward the center of the cover and pull the cover

towards you while lifting it away from the module.

c. Set the covers aside until the installation is complete.

WARNING

Risk of equipment damage

Module covers are not hinged; do not let go of the

cover. Lift the cover away from the module and set

it out of your work area.

3Remove the front and rear grills from the pedestal (see Figure 4). Set

the grills aside until the installation is complete.

4Inspect all equipment for physical damage; report any to your supplier.

5Adjust the feet on the pedestal to level the column (turn the leveling foot

clockwise to raise it).

Note 1:

You must leave at least 12.7 mm (1/2 in.) between the floor and

the bottom of the pedestal for air flow required by the cooling unit.

Application Equipment Module

Installation guide

7

Installing a stand-alone AEM

For proper installation, perform the steps in the following procedures in the

order given.

Unpack and level the AEM column

1Remove the AEM column from the shipping pallet; follow the unpacking

instructions that come with the packaging material.

2Remove the front and rear covers from the AEM:

a. Turn the two locking latches (see Figure 3) clockwise with a

standard screwdriver.

b. Push the latches toward the center of the cover and pull the cover

towards you while lifting it away from the module.

c. Set the covers aside until the installation is complete.

WARNING

Risk of equipment damage

Module covers are not hinged; do not let go of the

cover. Lift the cover away from the module and set

it out of your work area.

3Remove the front and rear grills from the pedestal (see Figure 4). Set

the grills aside until the installation is complete.

4Inspect all equipment for physical damage; report any to your supplier.

5Adjust the feet on the pedestal to level the column (turn the leveling foot

clockwise to raise it).

Note 1:

You must leave at least 12.7 mm (1/2 in.) between the floor and

the bottom of the pedestal for air flow required by the cooling unit.

8Installing a stand-alone AEM

553-3201-200 Standard 1.0 April 1993

Note 2:

If the column is to be bolted to the floor for earthquake bracing,

follow the procedure for earthquake bracing in

System installation

procedures

(553-3001-210).

6Go to the procedure for “Power connections (ac)” or “Power

connections (dc)” as appropriate to connect ground and power wiring.

Figure 3xxx

Locking latches on the AEM

Push

to

open

Latch unlocked

Latch locked

Figure 4xxx

Pedestal grill

8Installing a stand-alone AEM

553-3201-200 Standard 1.0 April 1993

Note 2:

If the column is to be bolted to the floor for earthquake bracing,

follow the procedure for earthquake bracing in

System installation

procedures

(553-3001-210).

6Go to the procedure for “Power connections (ac)” or “Power

connections (dc)” as appropriate to connect ground and power wiring.

Figure 3xxx

Locking latches on the AEM

Push

to

open

Latch unlocked

Latch locked

Figure 4xxx

Pedestal grill

8Installing a stand-alone AEM

553-3201-200 Standard 1.0 April 1993

Note 2:

If the column is to be bolted to the floor for earthquake bracing,

follow the procedure for earthquake bracing in

System installation

procedures

(553-3001-210).

6Go to the procedure for “Power connections (ac)” or “Power

connections (dc)” as appropriate to connect ground and power wiring.

Figure 3xxx

Locking latches on the AEM

Push

to

open

Latch unlocked

Latch locked

Figure 4xxx

Pedestal grill

8Installing a stand-alone AEM

553-3201-200 Standard 1.0 April 1993

Note 2:

If the column is to be bolted to the floor for earthquake bracing,

follow the procedure for earthquake bracing in

System installation

procedures

(553-3001-210).

6Go to the procedure for “Power connections (ac)” or “Power

connections (dc)” as appropriate to connect ground and power wiring.

Figure 3xxx

Locking latches on the AEM

Push

to

open

Latch unlocked

Latch locked

Figure 4xxx

Pedestal grill

Installing a stand-alone AEM 9

Application Equipment Module

Installation guide

Power connections (ac)

One IG-L6-30 or L6-30 receptacle must be within 2.4 m (8 ft) of the

pedestal. Instead of using the power plug provided, you can hard-wire the

PDU to the power source. In this case, you should use #10 AWG

conductors routed through 3/4-inch conduit. Connect the leads to the L1,

L2, and GND terminations on the field wiring terminal block on the PDU.

Use a separate safety ground. The safety ground must be #6 AWG or larger

and must connect the pedestal to the service panel ground bus. Depending

on the distances between columns and the service panel, you may run

safety ground wiring independently from the AEM column to the service

panel, or you may daisy-chain the safety ground wiring between the AEM

column and the Meridian 1.

DANGER

Risk of equipment damage

Failure to follow grounding procedures can result in

an unsafe or faulty system.

Procedure 1xxx

Power connections (ac)

1Make sure the power cord is disconnected from the power source.

2Measure the resistance between the ground pin on the power plug and

a ground lug on the rear of the pedestal.

See Figure 5. The resistance should be zero ohms. If the resistance is

greater than .5 ohms, check the power cord connections.

Installing a stand-alone AEM 9

Application Equipment Module

Installation guide

Power connections (ac)

One IG-L6-30 or L6-30 receptacle must be within 2.4 m (8 ft) of the

pedestal. Instead of using the power plug provided, you can hard-wire the

PDU to the power source. In this case, you should use #10 AWG

conductors routed through 3/4-inch conduit. Connect the leads to the L1,

L2, and GND terminations on the field wiring terminal block on the PDU.

Use a separate safety ground. The safety ground must be #6 AWG or larger

and must connect the pedestal to the service panel ground bus. Depending

on the distances between columns and the service panel, you may run

safety ground wiring independently from the AEM column to the service

panel, or you may daisy-chain the safety ground wiring between the AEM

column and the Meridian 1.

DANGER

Risk of equipment damage

Failure to follow grounding procedures can result in

an unsafe or faulty system.

Procedure 1xxx

Power connections (ac)

1Make sure the power cord is disconnected from the power source.

2Measure the resistance between the ground pin on the power plug and

a ground lug on the rear of the pedestal.

See Figure 5. The resistance should be zero ohms. If the resistance is

greater than .5 ohms, check the power cord connections.

Installing a stand-alone AEM 9

Application Equipment Module

Installation guide

Power connections (ac)

One IG-L6-30 or L6-30 receptacle must be within 2.4 m (8 ft) of the

pedestal. Instead of using the power plug provided, you can hard-wire the

PDU to the power source. In this case, you should use #10 AWG

conductors routed through 3/4-inch conduit. Connect the leads to the L1,

L2, and GND terminations on the field wiring terminal block on the PDU.

Use a separate safety ground. The safety ground must be #6 AWG or larger

and must connect the pedestal to the service panel ground bus. Depending

on the distances between columns and the service panel, you may run

safety ground wiring independently from the AEM column to the service

panel, or you may daisy-chain the safety ground wiring between the AEM

column and the Meridian 1.

DANGER

Risk of equipment damage

Failure to follow grounding procedures can result in

an unsafe or faulty system.

Procedure 1xxx

Power connections (ac)

1Make sure the power cord is disconnected from the power source.

2Measure the resistance between the ground pin on the power plug and

a ground lug on the rear of the pedestal.

See Figure 5. The resistance should be zero ohms. If the resistance is

greater than .5 ohms, check the power cord connections.

Installing a stand-alone AEM 9

Application Equipment Module

Installation guide

Power connections (ac)

One IG-L6-30 or L6-30 receptacle must be within 2.4 m (8 ft) of the

pedestal. Instead of using the power plug provided, you can hard-wire the

PDU to the power source. In this case, you should use #10 AWG

conductors routed through 3/4-inch conduit. Connect the leads to the L1,

L2, and GND terminations on the field wiring terminal block on the PDU.

Use a separate safety ground. The safety ground must be #6 AWG or larger

and must connect the pedestal to the service panel ground bus. Depending

on the distances between columns and the service panel, you may run

safety ground wiring independently from the AEM column to the service

panel, or you may daisy-chain the safety ground wiring between the AEM

column and the Meridian 1.

DANGER

Risk of equipment damage

Failure to follow grounding procedures can result in

an unsafe or faulty system.

Procedure 1xxx

Power connections (ac)

1Make sure the power cord is disconnected from the power source.

2Measure the resistance between the ground pin on the power plug and

a ground lug on the rear of the pedestal.

See Figure 5. The resistance should be zero ohms. If the resistance is

greater than .5 ohms, check the power cord connections.

10 Installing a stand-alone AEM

553-3201-200 Standard 1.0 April 1993

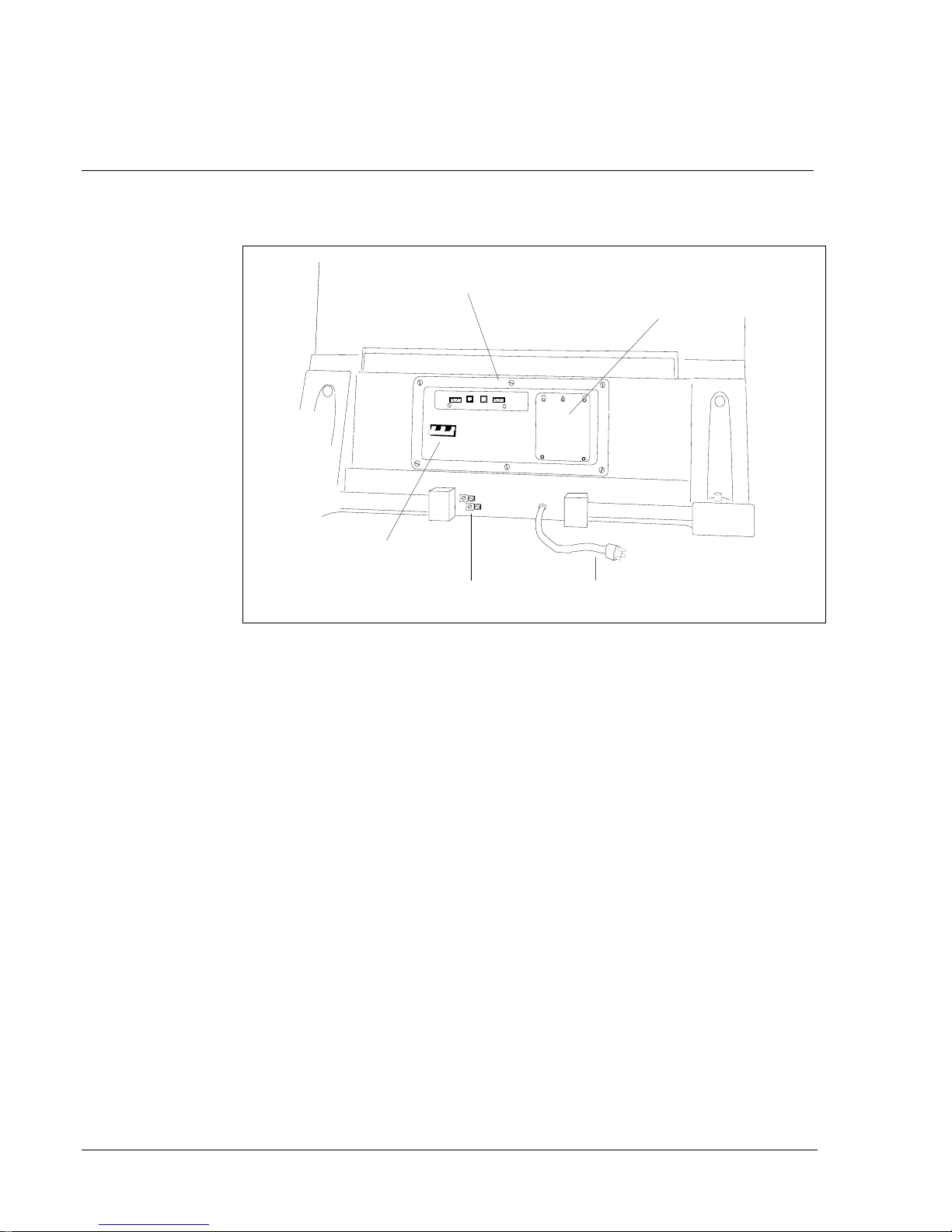

Figure 5xxx

PDU connections

J3 J6 J5 J4

Wiring access plate

Power Distribution Unit

Main circuit

breaker Ground lugs AC line cord

3Connect the safety ground wire.

Use insulated ground wire for system grounding.

For a direct connection, connect a #6 AWG wire from the ground

source in the service panel to a ground lug on the pedestal of the AEM

column.

For a daisy-chain connection, connect a #6 AWG wire from a ground

lug on the closest Meridian 1 column or cabinet to a ground lug on the

pedestal of the AEM column.

10 Installing a stand-alone AEM

553-3201-200 Standard 1.0 April 1993

Figure 5xxx

PDU connections

J3 J6 J5 J4

Wiring access plate

Power Distribution Unit

Main circuit

breaker Ground lugs AC line cord

3Connect the safety ground wire.

Use insulated ground wire for system grounding.

For a direct connection, connect a #6 AWG wire from the ground

source in the service panel to a ground lug on the pedestal of the AEM

column.

For a daisy-chain connection, connect a #6 AWG wire from a ground

lug on the closest Meridian 1 column or cabinet to a ground lug on the

pedestal of the AEM column.

10 Installing a stand-alone AEM

553-3201-200 Standard 1.0 April 1993

Figure 5xxx

PDU connections

J3 J6 J5 J4

Wiring access plate

Power Distribution Unit

Main circuit

breaker Ground lugs AC line cord

3Connect the safety ground wire.

Use insulated ground wire for system grounding.

For a direct connection, connect a #6 AWG wire from the ground

source in the service panel to a ground lug on the pedestal of the AEM

column.

For a daisy-chain connection, connect a #6 AWG wire from a ground

lug on the closest Meridian 1 column or cabinet to a ground lug on the

pedestal of the AEM column.

10 Installing a stand-alone AEM

553-3201-200 Standard 1.0 April 1993

Figure 5xxx

PDU connections

J3 J6 J5 J4

Wiring access plate

Power Distribution Unit

Main circuit

breaker Ground lugs AC line cord

3Connect the safety ground wire.

Use insulated ground wire for system grounding.

For a direct connection, connect a #6 AWG wire from the ground

source in the service panel to a ground lug on the pedestal of the AEM

column.

For a daisy-chain connection, connect a #6 AWG wire from a ground

lug on the closest Meridian 1 column or cabinet to a ground lug on the

pedestal of the AEM column.

Installing a stand-alone AEM 11

Application Equipment Module

Installation guide

Figure 6xxx

Meridian 1/AEM column daisy chain connection

From ground source To ground lug of

next column From last column

to power plant

4Measure the resistance between the ground pin on the power plug and

the ground terminal on the power outlet.

The resistance should be zero ohms. If the resistance is greater than .5

ohms, check the power outlet ground and safety ground connections.

5Remove the field wiring access plate on the PDU.

6Connect logic return wiring.

For a stand-alone column, make sure the logic return wiring, a 3-inch

shorting strap, #10 AWG or larger, connects the LRTN and GND

terminals on the field wiring block (see Figure 7).

For a multi-column row, connect a #8 AWG wire from the Logic Return

Equalizer (LRE) (used with the Meridian 1) to LRTN on the field wiring

block (see Figure 8).

7Replace the field wiring access plate on the PDU.

8Go to the appropriate procedure in “Alarm connections” to configure

and connect the NT8D22 System Monitor in the AEM column.

Installing a stand-alone AEM 11

Application Equipment Module

Installation guide

Figure 6xxx

Meridian 1/AEM column daisy chain connection

From ground source To ground lug of

next column From last column

to power plant

4Measure the resistance between the ground pin on the power plug and

the ground terminal on the power outlet.

The resistance should be zero ohms. If the resistance is greater than .5

ohms, check the power outlet ground and safety ground connections.

5Remove the field wiring access plate on the PDU.

6Connect logic return wiring.

For a stand-alone column, make sure the logic return wiring, a 3-inch

shorting strap, #10 AWG or larger, connects the LRTN and GND

terminals on the field wiring block (see Figure 7).

For a multi-column row, connect a #8 AWG wire from the Logic Return

Equalizer (LRE) (used with the Meridian 1) to LRTN on the field wiring

block (see Figure 8).

7Replace the field wiring access plate on the PDU.

8Go to the appropriate procedure in “Alarm connections” to configure

and connect the NT8D22 System Monitor in the AEM column.

Installing a stand-alone AEM 11

Application Equipment Module

Installation guide

Figure 6xxx

Meridian 1/AEM column daisy chain connection

From ground source To ground lug of

next column From last column

to power plant

4Measure the resistance between the ground pin on the power plug and

the ground terminal on the power outlet.

The resistance should be zero ohms. If the resistance is greater than .5

ohms, check the power outlet ground and safety ground connections.

5Remove the field wiring access plate on the PDU.

6Connect logic return wiring.

For a stand-alone column, make sure the logic return wiring, a 3-inch

shorting strap, #10 AWG or larger, connects the LRTN and GND

terminals on the field wiring block (see Figure 7).

For a multi-column row, connect a #8 AWG wire from the Logic Return

Equalizer (LRE) (used with the Meridian 1) to LRTN on the field wiring

block (see Figure 8).

7Replace the field wiring access plate on the PDU.

8Go to the appropriate procedure in “Alarm connections” to configure

and connect the NT8D22 System Monitor in the AEM column.

Installing a stand-alone AEM 11

Application Equipment Module

Installation guide

Figure 6xxx

Meridian 1/AEM column daisy chain connection

From ground source To ground lug of

next column From last column

to power plant

4Measure the resistance between the ground pin on the power plug and

the ground terminal on the power outlet.

The resistance should be zero ohms. If the resistance is greater than .5

ohms, check the power outlet ground and safety ground connections.

5Remove the field wiring access plate on the PDU.

6Connect logic return wiring.

For a stand-alone column, make sure the logic return wiring, a 3-inch

shorting strap, #10 AWG or larger, connects the LRTN and GND

terminals on the field wiring block (see Figure 7).

For a multi-column row, connect a #8 AWG wire from the Logic Return

Equalizer (LRE) (used with the Meridian 1) to LRTN on the field wiring

block (see Figure 8).

7Replace the field wiring access plate on the PDU.

8Go to the appropriate procedure in “Alarm connections” to configure

and connect the NT8D22 System Monitor in the AEM column.

12 Installing a stand-alone AEM

553-3201-200 Standard 1.0 April 1993

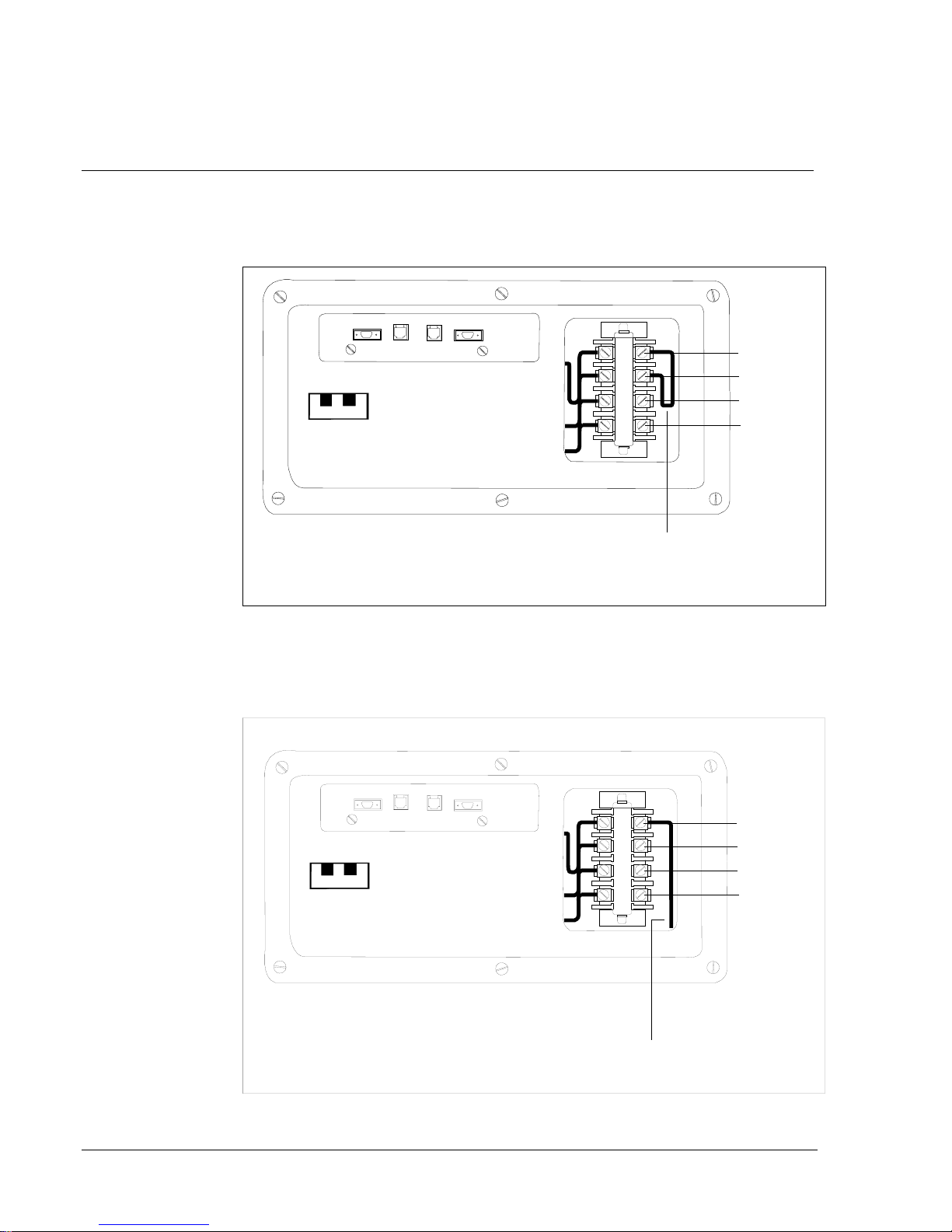

Figure 7xxx

AEM Logic return connection-LRTN/GND common connection for

stand-alone column

J3 J6 J5 J4

Three-inch

Shorting strap

(#10 AWG or larger)

LRTN

GND

L2

L1

Power distribution unit

Figure 8xxx

AEM Logic return connection-LRTN isolated star connection for a

multi-column row

J3 J6 J5 J4 LRTN

GND

L2

L1

To LRE

Power distribution unit

12 Installing a stand-alone AEM

553-3201-200 Standard 1.0 April 1993

Figure 7xxx

AEM Logic return connection-LRTN/GND common connection for

stand-alone column

J3 J6 J5 J4

Three-inch

Shorting strap

(#10 AWG or larger)

LRTN

GND

L2

L1

Power distribution unit

Figure 8xxx

AEM Logic return connection-LRTN isolated star connection for a

multi-column row

J3 J6 J5 J4 LRTN

GND

L2

L1

To LRE

Power distribution unit

12 Installing a stand-alone AEM

553-3201-200 Standard 1.0 April 1993

Figure 7xxx

AEM Logic return connection-LRTN/GND common connection for

stand-alone column

J3 J6 J5 J4

Three-inch

Shorting strap

(#10 AWG or larger)

LRTN

GND

L2

L1

Power distribution unit

Figure 8xxx

AEM Logic return connection-LRTN isolated star connection for a

multi-column row

J3 J6 J5 J4 LRTN

GND

L2

L1

To LRE

Power distribution unit

12 Installing a stand-alone AEM

553-3201-200 Standard 1.0 April 1993

Figure 7xxx

AEM Logic return connection-LRTN/GND common connection for

stand-alone column

J3 J6 J5 J4

Three-inch

Shorting strap

(#10 AWG or larger)

LRTN

GND

L2

L1

Power distribution unit

Figure 8xxx

AEM Logic return connection-LRTN isolated star connection for a

multi-column row

J3 J6 J5 J4 LRTN

GND

L2

L1

To LRE

Power distribution unit

Installing a stand-alone AEM 13

Application Equipment Module

Installation guide

Power connections (dc)

A stand-alone AEM column can be connected to the dc power plant used

with the Meridian 1 system.

Depending on the distances between columns and the service panel, you

may run safety ground wiring independently from the AEM column to the

service panel, or you may daisy-chain the safety ground wiring between the

AEM column and the Meridian 1.

WARNING

Risk of equipment damage

Failure to follow grounding procedures can result in

an unsafe or faulty system.

You must run all wiring (except cables to the system monitor) from the

external power equipment to the pedestal through flexible metallic conduit.

You may route a 3/4-inch conduit through four holes in the top or bottom of

the pedestal. The 3/4-inch conduit can contain a maximum of nine #10

AWG wires or five #8 AWG.

A maximum loop drop of two volts is allowed between the pedestal, or a

junction box, and the external power equipment. See Table 1 for allowable

wire sizes. See Power engineering (553-3001-152) for detailed

information on calculating wire size.

Installing a stand-alone AEM 13

Application Equipment Module

Installation guide

Power connections (dc)

A stand-alone AEM column can be connected to the dc power plant used

with the Meridian 1 system.

Depending on the distances between columns and the service panel, you

may run safety ground wiring independently from the AEM column to the

service panel, or you may daisy-chain the safety ground wiring between the

AEM column and the Meridian 1.

WARNING

Risk of equipment damage

Failure to follow grounding procedures can result in

an unsafe or faulty system.

You must run all wiring (except cables to the system monitor) from the

external power equipment to the pedestal through flexible metallic conduit.

You may route a 3/4-inch conduit through four holes in the top or bottom of

the pedestal. The 3/4-inch conduit can contain a maximum of nine #10

AWG wires or five #8 AWG.

A maximum loop drop of two volts is allowed between the pedestal, or a

junction box, and the external power equipment. See Table 1 for allowable

wire sizes. See Power engineering (553-3001-152) for detailed

information on calculating wire size.

Installing a stand-alone AEM 13

Application Equipment Module

Installation guide

Power connections (dc)

A stand-alone AEM column can be connected to the dc power plant used

with the Meridian 1 system.

Depending on the distances between columns and the service panel, you

may run safety ground wiring independently from the AEM column to the

service panel, or you may daisy-chain the safety ground wiring between the

AEM column and the Meridian 1.

WARNING

Risk of equipment damage

Failure to follow grounding procedures can result in

an unsafe or faulty system.

You must run all wiring (except cables to the system monitor) from the

external power equipment to the pedestal through flexible metallic conduit.

You may route a 3/4-inch conduit through four holes in the top or bottom of

the pedestal. The 3/4-inch conduit can contain a maximum of nine #10

AWG wires or five #8 AWG.

A maximum loop drop of two volts is allowed between the pedestal, or a

junction box, and the external power equipment. See Table 1 for allowable

wire sizes. See Power engineering (553-3001-152) for detailed

information on calculating wire size.

Installing a stand-alone AEM 13

Application Equipment Module

Installation guide

Power connections (dc)

A stand-alone AEM column can be connected to the dc power plant used

with the Meridian 1 system.

Depending on the distances between columns and the service panel, you

may run safety ground wiring independently from the AEM column to the

service panel, or you may daisy-chain the safety ground wiring between the

AEM column and the Meridian 1.

WARNING

Risk of equipment damage

Failure to follow grounding procedures can result in

an unsafe or faulty system.

You must run all wiring (except cables to the system monitor) from the

external power equipment to the pedestal through flexible metallic conduit.

You may route a 3/4-inch conduit through four holes in the top or bottom of

the pedestal. The 3/4-inch conduit can contain a maximum of nine #10

AWG wires or five #8 AWG.

A maximum loop drop of two volts is allowed between the pedestal, or a

junction box, and the external power equipment. See Table 1 for allowable

wire sizes. See Power engineering (553-3001-152) for detailed

information on calculating wire size.

14 Installing a stand-alone AEM

553-3201-200 Standard 1.0 April 1993

Table 1xxx

Pedestal wire gauge requirements with two 30-amp 48 V dc feeds (see Note 1)

Length Single

conduit

#8 AWG

Dual conduit

#6 AWG

(Note 2)

Junction box

(single #4 AWG)

(Note 3)

Junction box

(double #4 AWG)

(Note 4)

0 - 3 m (10 ft) Yes Yes Yes Yes

0 - 6 m (20 ft) Yes Yes Yes Yes