Northern Tool + Equipment M11571GNEA User manual

Owner’s Manual

Instructions for Assembly, Testing, Operation,

Servicing, & Storage

Log Splitter: Outdoor hydraulic powered machine that

splits wood logs.

WARNING

READ and UNDERSTAND this manual completely before using log splitter.

All operators of this equipment must read and completely understand all safety information, operating instructions,

maintenance and storage instructions. Failure to properly operate and maintain the log splitter could result in serious

injury to the operator or bystanders from moving parts that can crush or cut, flying objects, burns, fire or explosion,

escaping high pressure hydraulic fluid, or carbon monoxide poisoning. In particular, be aware of the following

hazards: Crush and Cut Hazards

Moving parts can crush and cut hands and fingers. Keep hands clear of endplates, wedge, and logs while splitting.

High Pressure Hydraulic Fluid Hazards

High fluid pressures and temperatures are developed in hydraulic log splitters. Hydraulic fluid escaping through

even a pin-size hold opening can puncture skin and cause severe blood poisoning. Inspect hydraulic system

regularly for possible leaks. Never check for leaks with your hand while the system is pressurized. Seek medical

attention immediately if injured by escaping fluid. Fire Hazards

• If your log splitter is intended for use near any ignitable forest, brush, or grassy covered land, the engine exhaust

should be equipped with a spark arrestor.

• Keep a fire extinguisher with you, rated for ordinary combustibles and flammable liquids.

STOP!

ASSEMBLY REQUIRED: This product requires assembly before use. See “Assembly” section for instructions.

INSPECT COMPONENTS. Closely inspect upon receipt to make sure no components are missing or damaged. See

“Assembly” section for instructions on whom to contact to report missing or damaged parts.

ADD ENGINE OIL and HYDRAULIC OIL BEFORE USING: This product is shipped without engine oil or

hydraulic oil. DO NOT start log splitter before adding both oils. See “Assembly” and “Initial Unpacking & Set-

up” sections for detailed instructions.

Any Questions, Comments, Problems or Parts Orders

Call Product Support 1-866-443-2576

ITEM NUMBER: 11571GNE

SERIAL NUMBER: _______________

M11571GNEA

Hazard Signal Word Definitions

2

Table of Contents

3

About Your Log Splitter...........................................................................................................4

Safety Label Locations.............................................................................................................5

Machine Components Identification ........................................................................................6

Initial Set-up.............................................................................................................................7

Moving & Towing to the Job Site............................................................................................9

Before Each Use:

Step One: Inspection/Maintenance.................................................................................11

Step Two: Fueling ..........................................................................................................13

Step Three: Work site Selection & Set-up.....................................................................14

Splitting Operation ...................................................................................................................15

Storage......................................................................................................................................20

Periodic Maintenance...............................................................................................................21

Troubleshooting........................................................................................................................22

Specifications............................................................................................................................23

Parts Breakdown – Exploded View..........................................................................................24

Summary of Important Safety Information for Operation........................................................26

Assembly Instructions ..............................................................................................................31

About Your Log Splitter

4

Thank you for purchasing your log splitter!

About Your Log Splitter

This log splitter is a machine designed to split wood logs using a hydraulically powered moving wedge.

The gasoline-powered engine is used to pressurize the system.

This log splitter model is capable of splitting logs up to 24” long and 16” in diameter

This log splitter is designed to split logs lengthwise with the grain only.

This log splitter model is designed with a unique, timesaving feature -- a double-edged cutting wedge that

is capable of splitting wood on both the extension and retraction strokes of the wedge.

The technical specifications for your log splitter are provided in the “Specifications” section of this

manual.

WARNING

This log splitter uses a high-pressure hydraulic system to generate a very strong

splitting force. Read the manual completely before using the machine to understand

how to safely operate and maintain it.

Follow all safety precautions presented throughout this manual. A summary of important safety

information can be found at the end of the manual.

Contact Product Support at 1-866-443-2576 for any questions about the appropriate

use of this log splitter and/or optional accessories.

Warranty Registration:

Please fill out and submit the warranty registration card so that we may have your contact information for

any future product literature or replacement parts you may need.

Attention: All Rental Companies and Private Owners who

loan this equipment to others!

All persons to whom you rent/loan the log splitter must have access to and read this manual. Keep this

owner’s manual with the splitter at all times and advise all persons who will operate the machine to read

it. You must also provide personal instruction on how to safely operate the splitter and available to

answer any questions a renter/borrower might have.

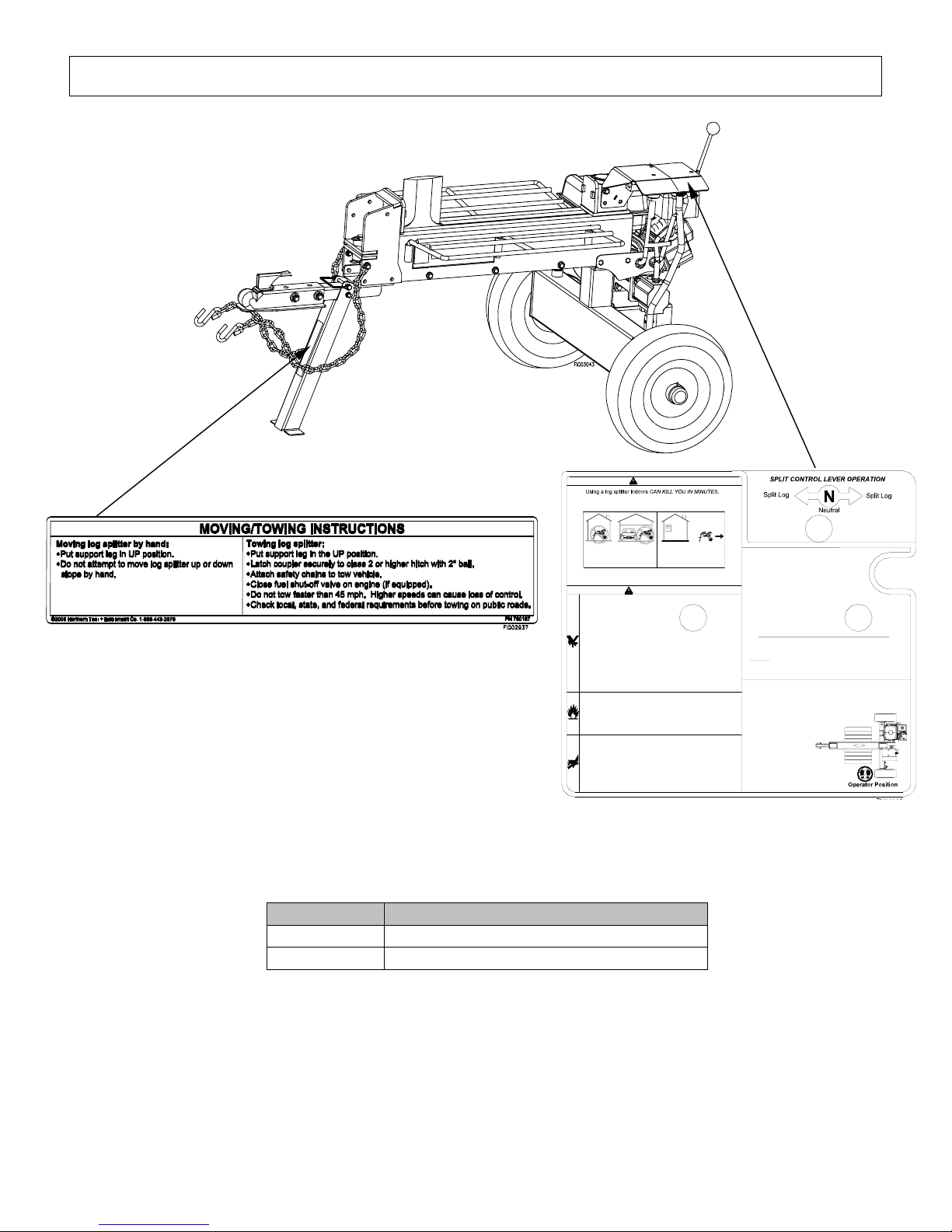

Safety Label Location

5

Part # Description

781831 Splitter Warning / Instructions Decal

780187 Moving/Towing Decal

Always make sure safety labels are in place and in good condition. If a safety label is missing or not

legible, order new labels or unsafe operation could result.

WARNING

Equip engine with a spark arrestor if you will be using near ignitable

forest, brush or grassy covered land.

Keep a fire extinguisher on hand that is rated for ordinary combustibles

and flammable liquids.

High fluid pressures and temperatures are developed in the hydraulic

system.

Hydraulic fluid escaping through even a pin-size hole opening can

puncture skin and cause blood poisoning.

Hot exhaust can ignite dry brush, trees, or grass.

ESCAPING HIGH PRESSURE HYDRAULIC FLUID HAZARD

Log splitter exhaust contains carbon monoxide.

This is a poison you cannot see or smell.

Avoid other log splitter hazards.

READ MANUAL BEFORE USE.

Only use OUTSIDE and

far away from windows,

doors, and vents.

READ the Owner's Manual completely before

operating.

Only one person should operate the log splitter. If an assistant is helping

to load logs, the operator should not actuate controls until the assistant is

at least 10 ft away.

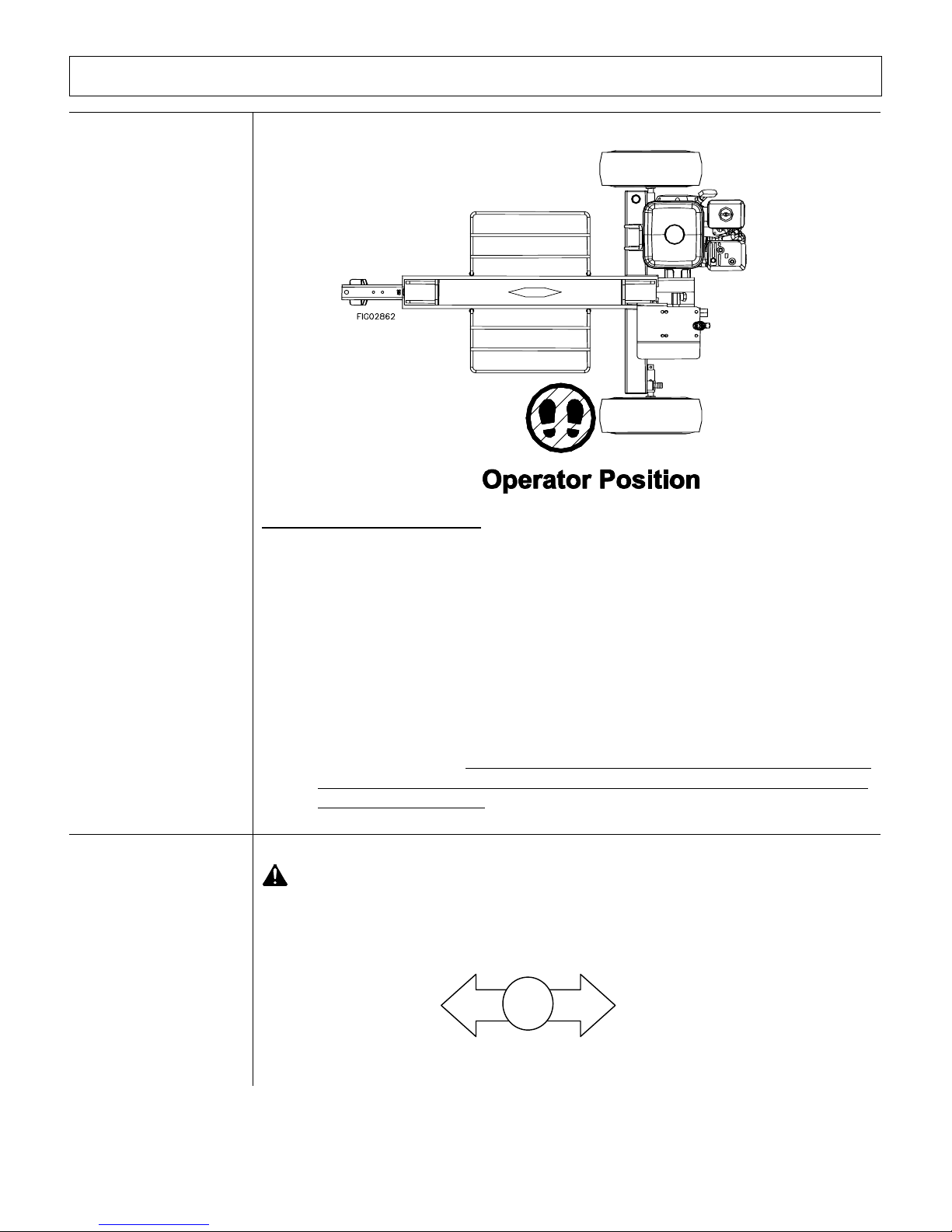

Stay in the designated OPERATOR POSITION while actuating the controls.

Split wood in direction of the grain only.

Hold bark side of logs when loading.

Keep hands away from wedge, endplates, and partly split logs.

Never leave log splitter unattended during operation.

Stay off slopes and slippery surfaces.

See additional safety rules in the Owner's Manual.

Inspect hydraulic system regularly for leaks.

Never check for leaks with your hand while system is pressurized.

Seek medical attention immediately if injured by escaping fluid.

©Northern Tool + Equipment Co. 1-866-443-2576

FIRE HAZARD

NEVER use inside a home

or garage. EVEN IF doors

and windows are open.

- Moving parts can crush and cut.

- Pieces can fly out while splitting.

- Follow safety rules for operatingthe log

splitter or serious injury could result.

DANGER

1. Retract wedge just enough to remove pressure between the log and endplate.

2. Turn engine OFF.

3. Remove stuck log from wedge manually with a pry baror sledgehammer.

Important: Be extremely careful as log pieces may fly off as they separate

from wedge.

Wear safety goggles and make sure bystanders are clear.

4. Do not attempt to resplit a stuck log once it has been removed from wedge.

GENERAL

Stay in the OPERATOR POSITION while actuating controls.

Never actuate controls until the helper is10ft away from log splitter, including

any helpers assisting to load logs.

Wear eye protection, hearing protection, snug fitting gloves,

& safety shoes or heavy boots. No loose or dangling

apparel.

OPERATING INSTRUCTIONS

SPLITTING LOG

Position log on beam, against endplate.

Move split control to extend wedge and split log.

Release split control to stop wedge.

Remove split wood from work area.

SETTING UP

Place log splitter on dry, level ground.

Secure splitter for unintended

movement.

Start engine.

PN 781831

ALWAYS remove the log MANUALLY using this procedure:

If this happens NEVER attempt to remove a stuck log by:

Using the hydraulic Modifying the Adding

force of the splitter splitter attachments

to the splitter

A log can become stuck to the wedge if the wedge becomes

embedded in the log and the log doesn't split and separate.

This can happen if the log is too stringy or tough tosplit

completely.

IF LOG BECOMES STUCK ON WEDGE

Personal injury could result from log or metal

pieces flying out at high speed toward the

operator or bystanders, or the splitter could

become damaged.

Machine Components Identification

6

1.) Log Table. This large log table keeps the log from falling on the ground after splitting. The

log table will keep the log on the beam without operator assistance.

2.) Beam/Cylinder. The hydraulic cylinder has a 4” bore and a 24” stroke, depending on model.

3.) Wedge. The wedge has two tapered edges that allow splitting in both directions. The wedge

features a taper that makes splitting easier.

4.) End Plate. The end plate keeps the log from moving as the wedge moves though the log.

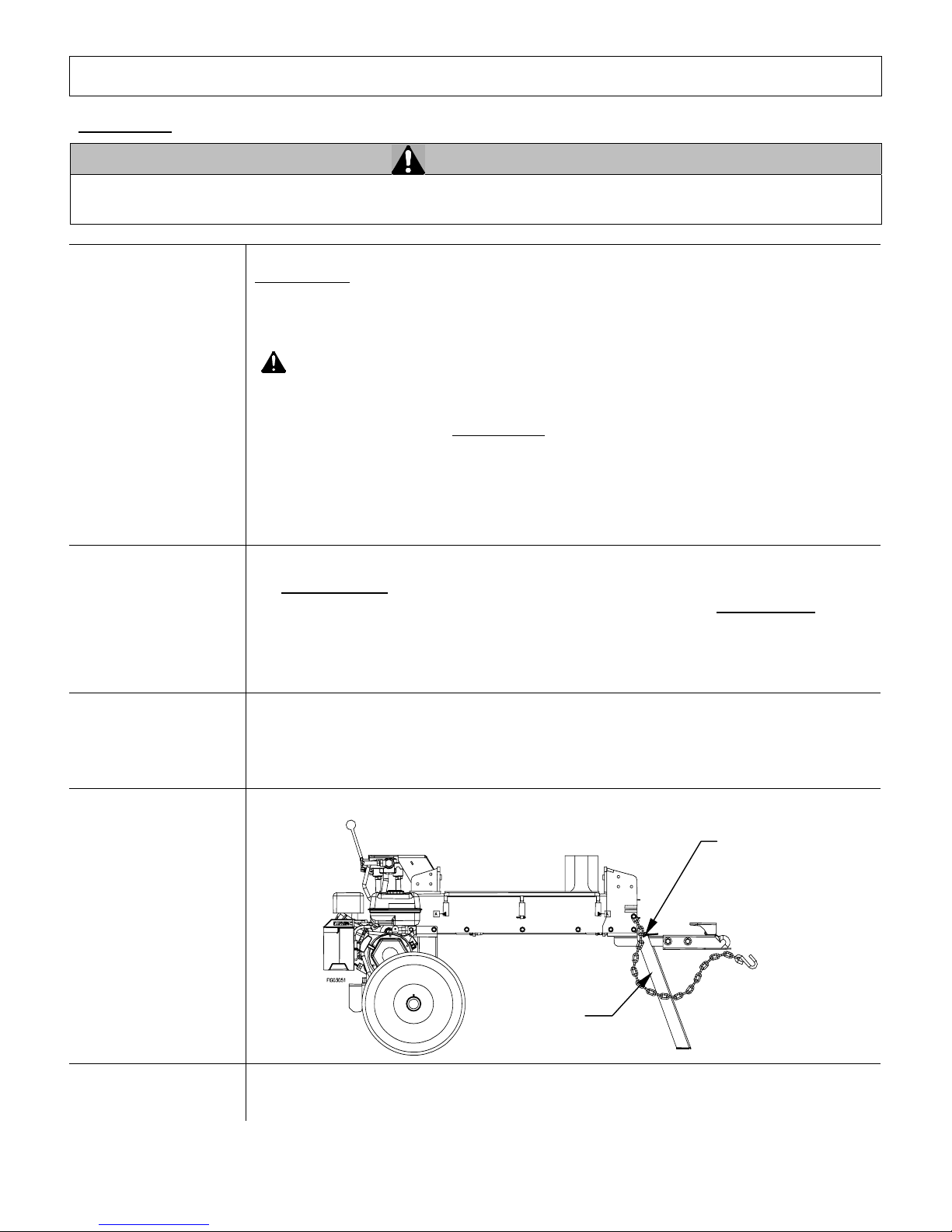

5.) 2” Coupler. Allows the trailer unit to be hooked up to a 2” ball hitch.

6.) Safety Chains. Secures trailer to vehicle in case of accidental disconnection of ball and

coupler.

7.) Leg. The leg supports the log splitter while operating. The leg should be raised while towing

(see Operation Instructions).

8.) Lock. The locking pin locks the log to prevent unintended movement.

9.) Tires. The tires on this log splitter are for high speed towing (max 45mph).

10.) Hydraulic Tank. The hydraulic tank stores the hydraulic oil.

11.) Hydraulic Pump. The hydraulic pump makes the hydraulic oil flow through the system.

12.) Suction Strainer. The suction strainer removes debris from the hydraulic oil before entering

the pump.

13.) Engine. The air-cooled engine powers the hydraulic pump.

14.) Splitter Control Lever. Use the split control lever to move the wedge forward and

backward.

Initial Set-up

7

WARNING

Carefully read and follow all instructions for initial assembly and set-up of

this log splitter.

Failure to properly assemble and set up this equipment could result in serious

injury to the user or bystanders, or cause equipment damage.

Step One:

Assemble log splitter

Assemble your log splitter.

See the “Assembly” section of this manual – It will provide you with detailed instructions

on:

• Inspecting shipped components and whom to contact if anything is missing or

damaged.

• Assembly.

• Testing.

Step Two:

Add oil to engine Add oil to engine.

Using a funnel, add SAE 10W-30 oil up to the FULL mark on the dipstick. (See

engine Owner’s Manual for oil capacity and location of fill cap.)

Step Three:

Add Hydraulic Oil to

Reservoir

1. Remove hydraulic oil dipstick.

2. Refer to the Specifications section for approximate hydraulic oil capacity.

3. Fill reservoir with 10 wt AW32, ASLE H-150, or ISO 32 oil. Use a funnel

4. Replace hydraulic oil dipstick and check that oil level reads full.

5. Start engine and use split control lever to extend and retract wedge 5 (five) times

to remove air from the high pressure lines.

6. With wedge retracted, check oil level again. Fill if necessary.

Note: If the log splitter will be run for long periods of time in outdoor temperatures above

70°F, we recommend changing the hydraulic oil to DEXTRON III.

Step Four:

Check Hydraulic

system

Check the hydraulic system carefully:

1. Visually inspect all hoses, tubing, clamps/fittings, pump, and cylinder for cracks,

fraying, kinks, or other damage.

2. Check all components for oily residue, which may indicate a leak.

Do NOT operate the log splitter if there is any indication of damage or oily residue.

Small leaks in hydraulic lines can cause severe injuries and can also be an indication of

catastrophic failure in the near future. The life of hydraulic hoses may be from a few

months to a few years, depending on use and storage patterns.

WARNING: High fluid pressures and temperatures are developed in hydraulic

log splitters. Hydraulic fluid escaping through a pin hole sized opening can burn or

puncture skin, resulting in wounds that could cause blood poisoning, infection,

disability, gangrene, amputation, or death. Therefore, the following instructions

should be heeded at all times when inspecting or servicing the hydraulic

components of the log splitter:

• Stop the engine, disconnect the spark plug, and move the split control lever

back and forth to relieve pressure before changing or adjusting hydraulic

system components such as hoses, tubing, fittings or other components.

Initial Set-up

8

• NEVER check for leaks with your hand. Leaks can be located by holding a

piece of cardboard or wood (at least two feet long) with your hand at one end

and passing the other end over the suspected area (wear eye protection). Look

for discoloration of the cardboard or wood.

• NEVER adjust the pressure setting of the pump or valve.

• If injured by escaping fluid, no matter how small the wound is, see a doctor at

once. A typical injection injury may be a small puncture wound that does not

look serious. However, severe infection or reaction can result if proper

medical treatment is not administered immediately by a doctor who is familiar

with injection injuries.

WARNING: NEVER remove the hydraulic oil fill cap when the engine is

running or hot. Hot oil can escape causing severe burns. Allow log splitter to

cool completely before removing hydraulic oil fill cap.

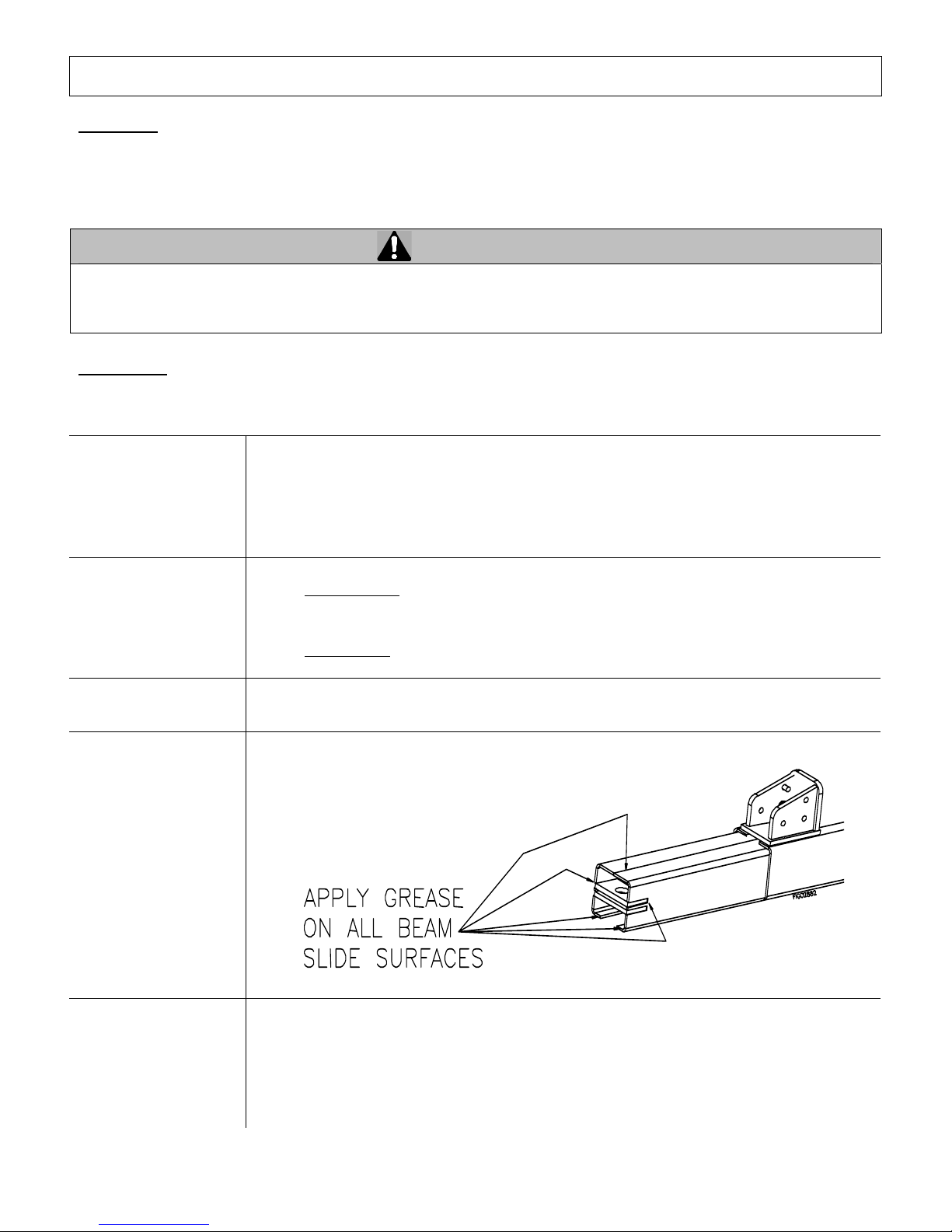

Step Five:

Lubricate slide rail

beam

Lubricate wedge slide.

Extend the wedge slide as shown, and lubricate the surface of it with grease. This will

help prevent wear between the wedge slide and beam.

Moving & Towing to Job Site

9

WARNING

The log splitter is heavy. It can crush and cause serious injury if it rolls out of control or tips over.

Follow the instructions below for safely moving and towing the log splitter.

Moving the log splitter:

1. Engine off IMPORTANT: Ensure log splitter engine is off.

Never move the log splitter with its engine running

2. Fuel valve off Turn fuel valve off to prevent carburetor flooding and reduce the chance of fuel leakage.

3. Swing leg UP Lock the leg in the “UP” position before you move the log splitter anywhere by hand.

4. Move log splitter

to work site or tow

hitch

Move log splitter by hand either directly to chosen work site or to tow hitch for

towing.

(See “Before Each Use” section on selecting a work site)

Important Safety Instructions:

• Hills. Do not move the log splitter up or down hills by hand - use a towing

vehicle.

• No riding. Never allow anyone to sit or ride on the log splitter.

• No cargo. Never transport cargo or wood on the log splitter.

Towing:

1. Read instructions Review towing safety instructions in your vehicle manual.

2. Check tires Make sure tires are fully inflated and in good repair.

See tire sidewall for recommended tire pressure.

WARNING:

●Do not over-inflate tires. Serious injury can occur if tire explodes.

●When seating a bead after repair, do not exceed 30 PSI. Pressures higher than 30 PSI

can cause the tire and wheel to rupture and explode.

Swing leg

Pin Catch

Moving & Towing to Job Site

10

3. Swing leg UP Lock the leg in the “UP” position before you move the log splitter anywhere by hand.

4. Attach to hitch

(2” ball)

Attach Log Splitter to vehicle hitch.

1. Attach log splitter’s coupler to a class 2

or higher hitch with 2” ball (only).

2. Adjust coupler to ball by raising locking

lever and turning lock nut with fingers.

3. Proper adjustment is obtained when

coupler is as tight as possible on ball and

locking lever can still be opened and

closed.

4. Lock lever closed to secure the

attachment. An optional locking pin or

padlock may be inserted in the locking

lever hole for extra security.

5. Attach safety

chains Attach safety chains.

1. Two safety chains must be used while towing.

2. Cross safety chains under the coupler allowing only enough slack for vehicle turns.

6. Tow to desired

location Tow log splitter carefully to desired work site.

(See “Before Each Use” section on selecting an appropriate work site.)

Important safety instructions:

• Speed limit. Never tow this log splitter over 45 mph. Faster speeds may result in

loss of control.

• Added length. Be aware of the added length of the splitter.

• Rough terrain. Drive slowly and take extra caution when traveling over rough

terrain.

• On public roads. If towing on a public road, make sure to comply with all local,

state, and federal towing requirements. It is the sole responsibility of the

purchaser to obtain licensing, trailer lights, safety chains or signage, as needed to

comply.

• Unattended. Turn off the towing vehicle before leaving the splitter unattended.

• Under the influence. Never tow or operate this splitter while under the influence

of alcohol, drugs, or medication.

7. Lock leg down &

unhitch Lock tow bar leg in the DOWN position and unhitch from vehicle.

NEVER operate log splitter while it is attached to the vehicle.

Locking lever

(locked position)

Unlocked

position

Housin

g

Lock nut

Swing leg

Pin Catch

Before Each Use – Inspection / Maintenance

11

Step One: Inspect and maintain log splitter before each use.

If the log splitter has been used previously, it must be inspected and maintained BEFORE EACH SUBSEQUENT

USE.

WARNING

ALWAYS shut off the engine, disconnect the spark plug, and relieve system pressure before inspecting, cleaning,

adjusting, or repairing the splitter. Relieve system pressure by moving the split control lever back and forth several

times.

Important:

If a part needs replacement, only use parts that meet the manufacturer’s specifications. Replacement parts that do

not meet specifications may result in a safety hazard or poor operation of the log splitter.

1. Engine off / relieve

hydraulic pressure Perform all inspections/repairs with the engine off and hydraulic system

pressure relieved.

1. Make sure engine is off and cool.

2. Disconnect the spark plug

3. Relieve all hydraulic system pressure by moving the split control lever back and

forth several times.

2. Remove debris Remove debris from engine, muffler, and moving parts.

1. Engine debris.Debris on a hot engine can be a fire hazard. Clean debris and

chaff from engine cylinder head, cylinder head fins, blower housing rotating

screen, and muffler areas. Avoid contact with hot muffler.

2. Other debris. Debris on moving parts can cause excess wear. Clear debris from

the beam, wedge, and end plates.

3. Fuel tank / lines Check fuel tank and fuel lines for leaks.

Any fuel leak is a fire hazard. Fix any fuel leaks before starting engine.

4. Mechanical parts Check to be sure all nuts and bolts are tight to make sure the log splitter is in safe

working condition.

Extend wedge slide, and apply grease.

5. Hydraulic system Check the hydraulic system carefully:

1. Visually inspect all hoses, tubing, clamps/fittings, pump, and cylinder for cracks,

fraying, kinks, or other damage.

2. Check all components for oily residue, which may indicate a leak.

Before Each Use – Inspection / Maintenance

12

Do NOT operate the log splitter if there is any indication of damage or oily residue.

Small leaks in hydraulic lines can cause severe injuries and can also be an indication of

catastrophic failure in the near future. The life of hydraulic hoses may be from a few

months to a few years, depending on use and storage patterns.

WARNING: High fluid pressures and temperatures are developed in hydraulic

log splitters. Hydraulic fluid escaping through a pin hole sized opening can burn or

puncture skin, resulting in wounds that could cause blood poisoning, infection,

disability, gangrene, amputation, or death. Therefore, the following instructions

should be heeded at all times when inspecting or servicing the hydraulic

components of the log splitter:

• Stop the engine, disconnect the spark plug, and move the split control lever

back and forth to relieve pressure before changing or adjusting hydraulic

system components such as hoses, tubing, fittings or other components.

• NEVER check for leaks with your hand. Leaks can be located by holding a

piece of cardboard or wood (at least two feet long) with your hand at one end

and passing the other end over the suspected area (wear eye protection). Look

for discoloration of the cardboard or wood.

• NEVER adjust the pressure setting of the pump or valve.

• If injured by escaping fluid, no matter how small the wound is, see a doctor at

once. A typical injection injury may be a small puncture wound that does not

look serious. However, severe infection or reaction can result if proper

medical treatment is not administered immediately by a doctor who is familiar

with injection injuries.

6. Hydraulic oil level Check dipstick to make sure hydraulic oil level is to the fill line with cylinder

retracted. Fill as needed.

Note: Fill the tank with 10 wt AW32, ASLE H-150, or ISO 32 hydraulic oil. If the

log splitter will be run for long periods of time in outdoor temperatures above 70°F,

we recommend changing the hydraulic oil to DEXTRON III.

WARNING: NEVER remove the hydraulic oil fill cap when the engine is running or

hot. Hot oil can escape causing severe burns. Allow log splitter to cool completely

before removing hydraulic oil fill cap.

7. Engine Inspect and perform engine maintenance as directed in the engine manual.

8. Spark arrestor

muffler If the engine is equipped with a spark arrester muffler, clean and inspect it regularly

(follow spark arrestor manufacturer’s service instructions). Replace if damaged.

9. Tires Make sure tires are fully inflated and in good repair if you will be towing the

splitter.

See tire sidewall for recommended tire pressure.

WARNING:

• Do not over-inflate tires. Serious injury can occur if tire explodes.

• When seating a bead after repair, do not exceed 30 PSI. Pressures higher than 30

PSI can cause the tire and wheel to rupture and explode.

10. Shields / guards Replace all guards and shields after servicing the log splitter.

Before Each Use – Fueling

13

Step Two: Fueling

WARNING

Gasoline is highly flammable and explosive. You can be burned or seriously injured when

handling fuel. Use extreme care when handling gasoline.

1. Engine off / cool The engine must be off and allowed to cool at least two minutes before adding

fuel.

WARNING: A running engine is hot enough to ignite fuel. Never add fuel

or remove gas cap if engine is running or still hot.

2. Outdoor location Fill fuel tank outdoors – never indoors.

WARNING: Gasoline vapors can ignite if they collect inside an enclosure.

Explosion can result.

3. Remove gas cap Remove engine gas cap.

4. Add gasoline Add gasoline through fill opening from an UL-approved container.

Important Safety Instructions:

• Use approved container. NEVER pump fuel directly into engine at gas

station. Static charge can build and ignite fuel. Use a UL approved fuel

container to transfer gas to the engine.

• Don’t overfill. DO NOT overfill the gas tank. Allow at least 1/2” of empty

space below the fill neck to allow for fuel expansion

• Heat / flames / sparks. Stay away from sources of heat, flame, or sparks

while adding fuel.

5. Spills / splashes Clean up fuel spills /splashes immediately.

1. Move log splitter away from spilled fuel on the ground.

2. Wipe fuel off engine and wait 5 minutes for excess fuel to evaporate before

starting engine.

3. Gas soaked rags are flammable and should be disposed of properly.

4. If gasoline is spilled on your skin or clothes, change clothes and wash skin

immediately.

6. Replace gas cap Replace gas cap securely before starting engine.

7. Gasoline storage Store extra gasoline in a cool, dry place in an UL approved, tightly sealed

container.

Before Each Use – Work Site Selection & Set-Up

14

Step Three: Work site selection and log splitter set-up

WARNING

It is important to select an appropriate work site and properly set up the log splitter in order to minimize the risk of

slips and falls, equipment rolling or tipping over, carbon monoxide poisoning, and accidental fires.

1. Select location Select an appropriate location for operating the log splitter.

Requirements:

1. Dry, level surface with good footing. Stay clear of areas with mud, ice, tall grass,

weeds, or brush.

2. Outdoors, away from air intakes.

DANGER: The running engine gives off carbon monoxide, a poisonous gas that can

kill you. You CANNOT smell it, see it, or taste it.

• ONLY run log splitter OUTDOORS and away from air intakes. NEVER run log

splitter inside homes, garages, sheds, or other buildings or semi-enclosed spaces.

These spaces can trap poisonous gases, EVEN if you run a fan or open windows.

• If you start to feel sick, dizzy, or weak while using the log splitter, shut off the

engine and get to fresh air RIGHT AWAY. See a doctor. You may have carbon

monoxide poisoning.

2. Fire precautions Take the following precautions against fire:

1. IMPORTANT: If your splitter will be used near any unimproved forest, brush,

or grassy covered land, then engine must be equipped with a spark arrestor.

2. Make sure you comply with applicable local, state and federal codes.

3. Keep a fire extinguisher available (classified for both ordinary combustibles &

flammable liquids) as a precautionary measure when operating the log splitter in dry

areas.

3. Position 7’ from

any combustibles

or flammable

liquids

Position splitter at least 7 ft. from combustible objects during operation.

Hot exhaust fumes from splitter engine could cause fire. Also, hydraulic oil leaking or

spraying on hot engine can ignite.

4. Lock leg down Lock leg in the “DOWN” position.

5. Block Wheels Block wheels to prevent unintended movement of the log splitter.

Swing leg

Pin Catch

Splitting Operation

15

WARNING

Before starting the log splitter, review the following instructions and safety information for safe operation.

Failure to follow these rules may result in serious injury to the operator or bystanders from moving parts

that crush, cut, or entangle; from flying objects, burns, fire, falling or tripping; or from carbon monoxide

poisoning.

General safety information

• Read manual. Do not allow anyone to operate the log splitter who has not read the Owner’s Manual or has

not been instructed on the safe use of the splitter. The log splitter owner should instruct all operators in safe

log splitter operation.

• Age restrictions. Never allow anyone under 16 years old to operate the log splitter. Children 16 years and

older must be trained and supervised by a trained adult.

• Intended use. Log splitters should only be used for splitting wood logs, lengthwise with the grain. Do not

use for other purposes as unforeseen hazards may result.

• Modifications. Never modify or alter the log splitter in any way. Modifications can create serious safety

hazards and will void the warranty:

o Attachments. Never add attachments to the splitter, except for authorized accessories supplied by

the manufacturer with instructions for safe installation and use.

o Engine speed. The maximum engine speed is preset at a safe limit. Never attempt to modify the

engine speed setting to run at a higher speed.

o Fuel/exhaust system. NEVER modify or add to the exhaust system, fuel tanks, or fuel lines. Fire

can result.

o Remote control. NEVER attach a rope, cable, or other remote device to the splitting control.

o Splitting wedge. NEVER attempt to change the height or speed of the splitting wedge.

o Pressure setting. NEVER increase the pressure setting of the pump or control valve.

• Safety equipment / controls. Always operate the log splitter with all safety equipment in place and in good

working order, and all controls properly adjusted for safe operation.

• Know how to stop. Be thoroughly familiar with all controls and with the proper use of the equipment.

Know how to stop the log splitter and relieve system pressures quickly if needed.

• Operating speed. Always operate the log splitter at the manufacturer’s recommended speed. The

maximum speed of the engine, pump and wedge are preset within safe limits.

• Daylight only. Only use the log splitter in daylight so you can see what you are doing.

• Smoking / sparks. Never smoke while operating the log splitter, and never operate near sources of sparks

or flames.

• Under the influence. Never operate, or let anyone else operate, the log splitter while under the influence of

alcohol, drugs, or medication.

• Unattended. Never leave the machine unattended while the engine is running.

• Refueling. Never refuel the engine until it has cooled at least two minutes.

• Adjusting / repairing. Always make sure the engine is off before cleaning, repairing or adjusting the

splitter, except as recommended by the manufacturer. In addition, disconnect the spark plug and move all

control handles back and forth to relieve system pressure before changing or adjusting hydraulic system

components such as hoses, tubing, fittings or other components.

• Replace labels. Always make sure safety labels are in place and in good condition. If a safety label is

missing or not legible, order new labels because unsafe operation can result. Call 1-866-443-2576 to order

new safety labels.

Splitting Operation

16

1. Put on protective

clothing / gear Wear the following protective clothing and safety gear.

1) Eye protection. Always wear safety glasses or goggles when operating the machine.

Pieces of log may fly out and serious eye injury can occur

2) Boots. Falling logs can crush feet. Always wear safety shoes or heavy boots when

operating or helping to load logs.

3) Gloves. Wear snug fitting gloves without drawstrings or loose cuffs.

4) Hearing protection. The use of earplugs or other hearing protection device is

recommended. Applications

5) No Loose / dangling apparel. Loose or dangling apparel can become entangled in

moving parts. Never wear jewelry or loose-fitting clothing

2. Lock & block Secure log splitter from unintended movement. Check that:

1) The tow bar leg is locked in the DOWN position.

2) The wheels are blocked.

3. Start engine Start the engine.

See the engine owner’s manual for engine starting instructions.

Note:

a) Make sure the hydraulic oil is above 10oF before starting the engine. Cold

hydraulic oil can damage the hydraulic pump.

b) If outdoor air temperature is below 32oF, allow log splitter to warm up by

extending and returning the wedge several times before splitting wood.

WARNING:

Burns. To avoid burns, stay clear of hot muffler if you are starting a warm engine.

Carbon monoxide. The running engine gives off carbon monoxide, a poisonous

gas that can kill you. You CANNOT smell it, see it, or taste it. If you start to feel

sick, dizzy, or weak while using the log splitter, shut off the engine and get to

fresh air RIGHT AWAY. See a doctor. You may have carbon monoxide

poisoning.

Other exhaust dangers. Engine exhaust, some of its constituents, and certain

vehicle components contain or emit chemicals known to the State of California to

cause cancer, birth defects, or other reproductive harm. Avoid inhalation of

exhaust.

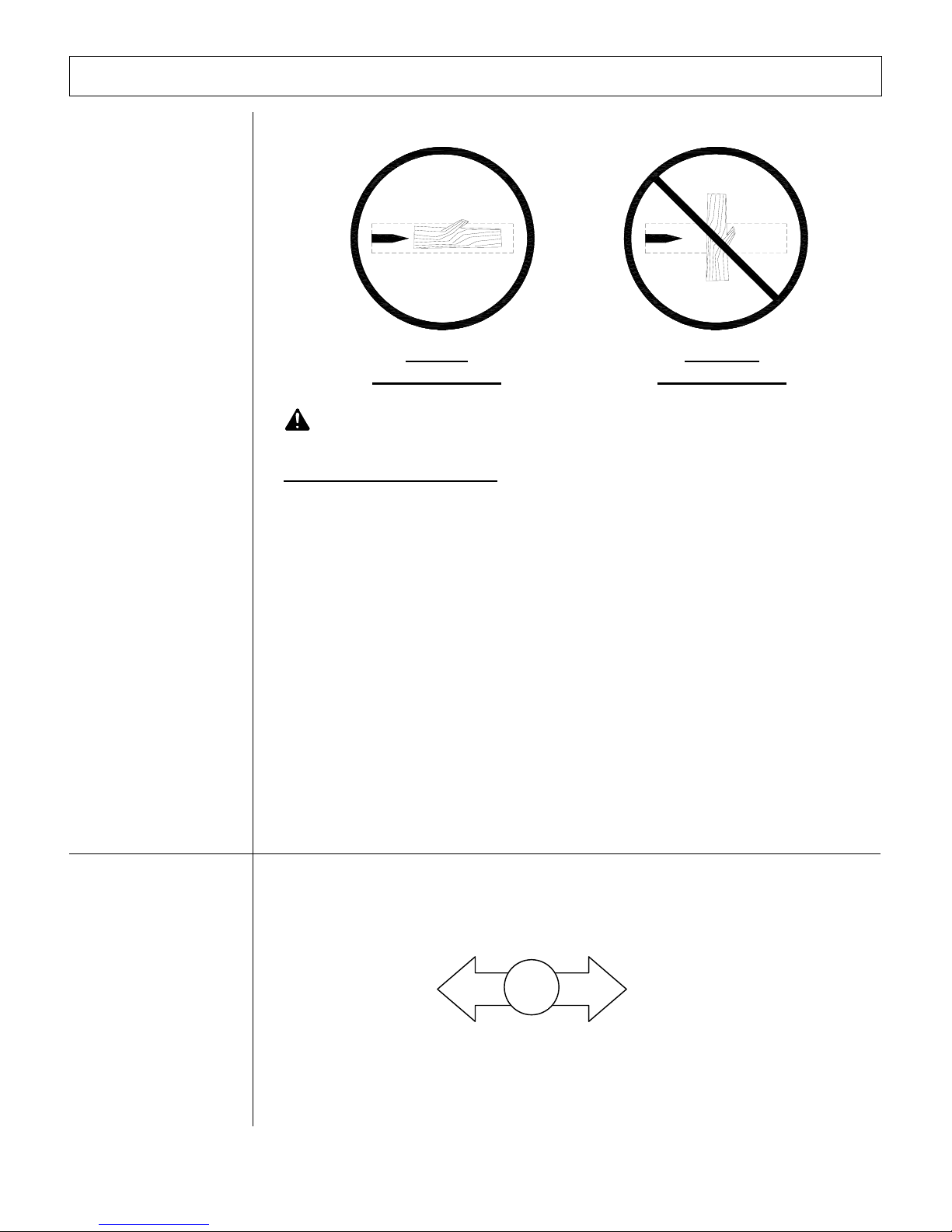

4. Load log Load log onto beam between the wedge and an endplate, cut edge against the

endplate - positioned for a lengthwise cut.

Notes:

a) This log splitter is equipped with a unique double-edged cutting wedge, which is

capable of splitting wood on either the extension or retraction stroke of the

wedge.

b) The log splitter is designed only for cutting lengthwise with the grain, NOT for

cutting across the grain.

c) This log splitter is designed for cutting logs only up to 24” long and 16” in

diameter, lengthwise with the grain only. Larger diameter logs could get stuck on

the wedge and longer logs will not fit on the beam.

Splitting Operation

17

FIG02218

WARNING: ALWAYS keep hands and feet away from the wedge and partially

split logs while loading, operating and unloading the log splitter.

Important safety instructions:

• Hold bark side. Hold the bark side of logs when loading or positioning, never

the ends. Never place your hands or any part of your body between a log and

any part of the log splitter.

• Wedge moving. NEVER load or unload logs while the wedge is moving.

• Straddling / reaching across. Never straddle, reach across, or step over the

beam while the engine is running. You could trip, actuate the controls, and get

seriously injured.

• Unsplit log pile. Do not pile logs to be split in a place that will make you reach

across the log splitter in order to load them.

• Square log ends. Logs that are not cut square can slide out while splitting and

become a safety hazard or cause excessive force to log splitter components. Use

a chainsaw to cut logs square on each end before attempting to split them.

• Single log. Never attempt to split more than one log at a time. Pieces of log can

unexpectedly be thrown from the machine causing serious injury.

• Split along grain. Do not use the log splitter to split logs across the grain.

Doing so will damage the log splitter and could also cause pieces of log to be

thrown, injuring the operator or bystanders

5. Extend wedge Move Split Control Lever toward the end plate to move the wedge and split the log.

Correct

Log Orientation Incorrect

Log Orientation

Split Log Split Log

N

SPLIT CONTROL

Splitting Operation

18

Important safety instructions:

• Operator position. ALWAYS operate the log splitter from the manufacturer’s

indicated OPERATOR POSITION. (See diagram above.) Other positions are

unsafe because they can increase the risk of injury from crushing, cutting, flying

objects, or burns.

• Remove hands. Remove both hands from log before activating the split control

lever.

• Hand activate. Use only your hand to operate the Split Control Lever. Never

use any other body part, or a rope, cable, or other remote device to actuate the

control.

• Second person. Many accidents occur when there is more than one person

involved in loading and operating the log splitter. Only one person should

operate the controls. If a second person is assisting in loading logs, the operator

must NEVER actuate the split control lever until the assistant and all bystanders

are at least 10 feet away. NEVER allow an assistant to hold the log in place

while the operator actuates the Split Control Lever.

6. Stop wedge Release Split Control Lever to stop wedge movement when log is split.

WARNING: Cracks in logs can close quickly and pinch fingers. Keep fingers away

from any cracks that open in partially split logs.

Split Log Split Log

N

SPLIT CONTROL

Splitting Operation

19

7. Important

STUCK LOG

procedure

If a log does not split completely and becomes stuck on the wedge, follow the

instructions below to remove the log.

A log can become stuck to the wedge if the wedge becomes embedded in the log and the

log doesn’t split and separate. This can happen if the log is too stringy or tough to split

completely.

If this happens, follow the directions below.

WARNING: NEVER attempt to remove a stuck log by:

• Using the hydraulic force of the splitter

• Modifying the splitter

• Adding attachments to the splitter

Personal injury could result from log or metal pieces flying out at high speed toward

the operator or bystanders, or the splitter could become damaged.

1. Remove pressure from log by moving wedge away from the endplate.

2. Turn engine OFF.

3. Remove stuck log from the wedge manually with a pry bar or a sledgehammer.

Important: Be extremely careful as log pieces may fly off as they separate

from the wedge. Make sure bystanders are clear and wear safety goggles.

4. Do not attempt to resplit a stuck log once it has been removed from the wedge.

Manually split with an axe or cut with a chainsaw.

8. Remove split

wood Move each log away from log splitter after it is split. Split logs left near the log

splitter are a trip hazard.

9. After use 1. Turn off engine.

2. Remove engine debris.

Debris on a hot engine can be a fire hazard. After the engine is off, clean debris and

chaff from engine cylinder head, cylinder head fins, blower housing rotating screen,

and muffler areas.

WARNING: Avoid contact with hot muffler.

Any Questions, Comments, Problems or Parts Orders

Call Product Support 1-866-443-2576

Storage

20

WARNING

Gasoline vapors can ignite and cause a fire. Select a well-ventilated storage area away from sources of

heat, flame, or sparks.

Follow the instructions below for storing your log splitter between uses:

1. Retract cylinder Retract the wedge completely to the hitch end of the log splitter to keep the rod

protected from corrosion.

2. Cool Allow the machine to cool 5 minutes before storing.

WARNING: A hot engine can be a fire hazard.

3. Wipe with oily rag Wipe the wedge with an oily rag to prevent corrosion.

4. Engine manual Refer to the engine manual for proper engine storage instructions.

CAUTION: Gasoline will oxidize and deteriorate in storage. Old gasoline in the

engine will cause hard starting and leave gum deposits that can clog the fuel

system. Deterioration problems may occur within a few months, or even less if

gasoline was not fresh when you filled the fuel tank.

Short-Term Storage:

1. Consider adding a fuel stabilizer to extend fuel storage life.

2. Leave the fuel valve lever in the OFF position to reduce the possibility of fuel

leakage.

Long Term Storage: (between infrequent uses and at end of season)

Drain the fuel tank and carburetor as instructed in the engine owner’s manual.

Important Safety Instructions:

• Always drain fuel from tank in outdoor, well-ventilated area.

• Stay away from sources of heat, flame, or sparks while handling fuel.

• Clean up fuel spills/splashes immediately.

5. Splitter storage

location Store the log splitter in a location away from corrosive material, sources of heat,

open flames, sparks or pilot lights.

WARNING: Never store log splitter inside where there is a source of heat or an

open flame, spark, or pilot light – such as water heaters, space heaters, furnaces,

clothes dryers, or other gas appliances. Even if the log splitter’s gas tank is empty,

residual gasoline vapors could ignite.

NOTE: Do not store the log splitter near fertilizer or any other corrosive material.

6. Gasoline storage Store gasoline in a cool, dry place in an UL approved, tightly sealed container.

WARNING: Gasoline vapors can ignite if they collect inside an enclosure and

explosion can result.

Table of contents

Other Northern Tool + Equipment Log Splitter manuals

Popular Log Splitter manuals by other brands

The Handy

The Handy THPLS7TP instruction manual

Wallenstein

Wallenstein 3652A300 installation instructions

Boss Industrial

Boss Industrial ED16T21 Owners manual assembly & operating instructions

Zipper Mowers

Zipper Mowers ZI-HS8 manual

Champion Power Equipment

Champion Power Equipment 92251-1 owner's manual

Central Hydraulics

Central Hydraulics 91839 Set up and operating instructions