Nortrac 296025 User manual

1

Owner’s Manual

Instructions for Installation/Set-up, Operation, Servicing, & Storage

Portable Outdoor Use-Only, Power Take-Off (PTO) Chipper

Make sure you completely read and understand this manual before using the chipper for the first time. If

you have any questions, contact your retail or rental dealer or NorTrac Customer Service at 1-800-521-

0438 WARNING

READ and UNDERSTAND this manual completely before using the chipper!Failure to properly set

up, operate, and maintain this chipper could result in serious injury or death to the operator or bystanders. In

addition, PTO shaft can become airborne and cause severe injury if improperly secured.

In particular, be aware of the following hazards:

Failure to properly mount and secure the chipper to the tractor may cause the unit to flip violently during

use, which could cause severe injury to the operator or bystanders, or damage to surrounding objects.

Never operate the chipper without proper PTO guarding, including a freely rotating shaft guard. Clothing or

hair can become rapidly entangled in unguarded rotating PTO shaft or connections, resulting in serious

injury or death.

Make sure PTO driveline shaft is securely locked at both ends. An unlocked PTO shaft can whip or become

dangerously airborne.

Keep hands and feet away from inlet and discharge openings.

Do not allow children under the age of 18 or untrained adults to operate.

Wear eye protection and other personal protection against flying debris.

Do not attempt to perform adjustments, declog or clean unit while engine is running.

Make sure no children or bystanders are within 100’ (feet) of chipping operation.

Protect cars, windows and other objects within 100’ from flying debris.

Be aware of potential for carbon monoxide (CO) poisoning.

Avoid using in slippery, muddy, wet or icy conditions where falls may occur.

These and other hazards in the manual and summarized at the end under “Important Safety

Information.”

STOP!

ASSEMBLY REQUIRED: This product requires assembly before use. Some of the components in this unit

are heavy and cannot be lifted by one person safely. Please plan on assembling this product when another person

can be available to help out. See “Assembly Instructions” section for instructions.

INSPECT COMPONENTS: Closely inspect to make sure no components are missing or damaged.

See the “Receiving and Transporting” section for instructions on whom to contact to report missing or

damaged parts. Any Questions, Comments, Problems, or Parts Orders

Call your dealer or NorTrac Customer Service 1-800-521-0438

MODEL NUMBER: 296025

SERIAL NUMBER: _____________

M296025D

Hazard Signal Word Definitions

2

Table of Contents

3

Part I. Introduction

About Your Chipper............................................................................................................................4

Safety Labels Locations......................................................................................................................5

Receiving & Transporting:

Initial Inspection ..........................................................................................................................7

Assembly Instructions..................................................................................................................8

Connecting To Your Tractor........................................................................................................9

Moving Instructions.....................................................................................................................12

Part II. Operation

Operation:

1. Pre-start Check List & Procedures...........................................................................................13

2. Starting/Stopping .....................................................................................................................14

3. Feeding Material/Clearing Jam................................................................................................15

4. Storing the Chipper..................................................................................................................16

Part III. Maintenance and Repair

Maintenance (To be done by owner or Rental Dealer).......................................................................17

1. Chipping Knife........................................................................................................................19

2. Belt and Sheave Care ..............................................................................................................22

3. Maintenance Schedule.............................................................................................................25

4. Bolt Torque Chart....................................................................................................................26

Specifications.........................................................................................................................................27

Machine Component Identification..............................................................................................28

Parts Explosion ....................................................................................................................................30

Part IV: Summary of Important Safety Information

Summary of Important Safety Information.........................................................................................33

Limited Warranty Policy..................................................................................................................36

About Your Chipper

4

Owner/Operator/Renter Training

Read and follow all instructions and safety precautions presented throughout this manual. A summary

of important safety information can be found at the end of the manual. Keep this manual for reference

and review. If the owner of this unit is different than the operator, give a copy of this manual to any

operator. Keep in mind that the operator or user is responsible for accidents or hazards occurring to

other people, their property, and themselves.

Rental Companies

Check the storage tube on the cutter guard side (beneath hopper) to make sure the chipper manual is

inside. All persons to whom you rent/loan this chipper must have access to this manual. Advise all

persons who will operate the machine to read it. You should also provide personal instruction on how

to safely operate the chipper and remain available to answer any questions a renter/borrower might

have. If videos are available, have renter watch training video.

Product Suitability

Your chipper is designed to only chip wood. A chipper knife is mounted on a revolving flywheel and

converts branches fed into the chipper hopper into “chips”. Make sure you completely read and

understand this manual before using the chipper for the first time.

Before using, the user shall determine the suitability of this product for the job it will be used for. The

user assumes liability for any non-intended or misuse of the product.

As is common with all manufacturers, NorTrac is constantly improving its products. The specifications

outlined herein, while believed to be accurate at publication, are subject to change without prior notice

or obligation. Do not modify or alter this chipper. The purchaser and/or user shall assume the potential

liability for any modification and/or alterations of this equipment from its original design and

manufacture.

Contact your rental or retail dealer or NorTrac Customer Service at 1-800-521-0438 for any questions

about the appropriate use of this chipper or about optional accessories.

Warranty Registration

Please fill out and submit the warranty registration card so that we may contact you with updated

information regarding product literature, replacement parts, or safety information.

Safety Label Locations

5

The following safety labels appear on your chipper. These are warnings and instructions

particularly important for proper safety and functionality. Other warnings and instructions also

appear throughout this manual. Reading and understanding these labels below will expedite your

safe use of the product. The labels on the machine will then serve to further remind you of

important safety and operation procedures.

WARNING: Replace Missing Labels

ALWAYS make sure safety labels are in place and in good condition. If a safety label is missing

or not legible, order new labels.

To order

Replacement

Safety Labels,

call NorTrac

Customer Service at

1-800-521-0438

Safety Label Locations

6

Part #

Ref #

Description

Qty

796191

2

Infeed Hazard, Danger

2

3

General Precautions and Operation

2

796192

1

Flying Debris, Warning

2

4

Amputation Hazard, Discharge Chute

1

5

Belt Entanglement, Warning

1

6

Amputation Hazard, Guard

2

7

PTO Hazard, Danger

1

786689

8

Spiral

2

799952

9

Spark-Strike Warning

1

1

3

4

2

6

5

7

8

9

Receiving & Transporting

7

Initial Inspection

You should inspect the chipper immediately after taking possession and before use.

See the “Machine Component Identification” section of this manual for a diagram of the chipper and all

its components.

If you have missing components, contact your retail or rental company or NorTrac Customer Service at

1-800-521-0438.

Fastener Bag

Contents

5/16" NYLOC NUT

QTY: 28

PART# 82020

5/16" x 3/4"

CARRIAGE BOLT

QTY: 4

PART# 82088

5/16" x .625"

CARRAIGE BOLT

QTY: 18

PART# 82425

5/16" USS FLAT

WASHER

QTY: 12

PART# 82021

5/16" x 1" BOLT

QTY: 6

PART# 82091

Receiving & Transporting

8

Hopper

hood

Cutter

housing

5/16"nyloc

nut

5/16" flat

washer

5/16" x

1" bolt

Assembly Instructions

1. Attach Shields

to Top Hopper

1. Using (4) 5/16" x 3/4" carriage

bolts and (4) 5/16" nyloc nuts,

assemble in order shown.

2. Torque to 11 ft./lbs.

3. Assemble

Hopper Sides

1. Attach hopper right side to

hopper bottom, using (5)

5/16" x 0.625" bolts and (5)

5/16" nyloc nuts making sure

the flange on the hopper

bottom is in the inside.

2. Repeat with hopper left side

to hopper bottom.

3. Install hopper top and shields

to left and right hopper sides

using (8) 5/16" x 0.625" bolts

and (8) 5/16" nyloc nuts.

Make sure hopper top flanges

are in the inside.

4. Torque to 11 ft./lbs.

5. Attach Hopper

to Chipper

Note: Two people are required –one to hold the hopper and one to fasten.

1. Assemble hopper to cutter housing using

(6) 5/16" x 1" bolts, (12) 5/16" flat

washers, and (6) 5/16" nyloc nuts.

Torque to 11 ft./lbs.

Clear vinyl shield

Plastic shield

Shield

backer plate

Hopper top

5/16"

nyloc

nut

5/16" x 3/4" carriage bolt

Right hopper side

Hopper left side

Hopper bottom

5/16" nyloc nut

5/16" x 0.625"

bolt

Hopper top & shields

Flanges

Hopper right side

Note: Carriage bolt

heads are inside the

hopper, nyloc nuts

are outside the

hopper.

Receiving & Transporting

9

Connecting to your Tractor

WARNING

The chipper must be correctly mounted and then attached to the tractor 3-point hitch for safe operation.

Follow the instructions below for safely mounting and connecting the chipper.

1. Read instructions

Review your tractor manual or check with your dealer for instructions

and safety information about how to properly connect the chipper to your

tractor’s 3-pt hitch and PTO shaft.

Ensuring a correct hook-up to your tractor is your responsibility.

2. Tractor turned off

& parking brake

engaged

Turn off the tractor and engage the parking brake before attaching the

chipper.

3. Attach to tractor

3-point hitch links

Attach chipper to tractor’s 3-point hitch links.

a. Connect the tractor’s lower link to the lower hitch studs of the chipper.

Secure with lynch pins.

b. Connect the tractor’s upper link to the upper hitch pin of the chipper.

Secure with lynch pin.

Upper hitch pin

Tractor's upper link

Lynch pin

Lynch pin

Tractor's lower links

Lynch pin

Lower hitch stud

Receiving & Transporting

10

WARNING

An improperly attached chipper could become dislodged during transportation

or operation, which could result in serious injury to the operator or bystanders.

Do not drive the tractor or operate the chipper until you are sure the chipper is

properly attached and hitch pins are fully engaged.

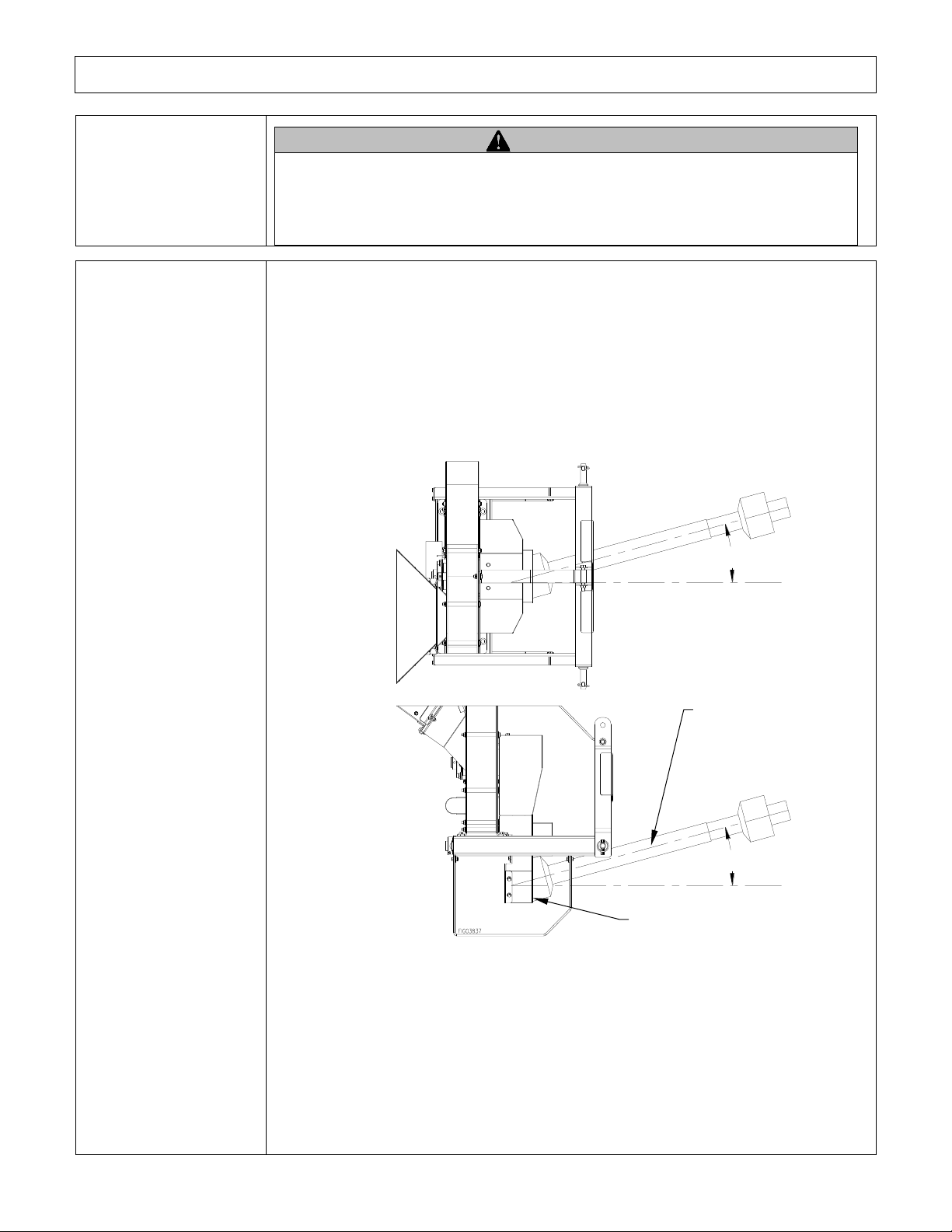

Attach PTO

driveline shaft

Connect the PTO driveline shaft to the tractor:

1. Align the tractor and chipper to minimize the driveline angle in both the

horizontal and vertical planes; it should be as near to a direct line in all

directions as possible. The angle should never exceed 25°in any direction.

Note: Proper alignment will increase the life of the power takeoff shaft,

reduce wear on the bearings of the PTO and chipper, and reduce

vibration.

2. Ensure that the tractor PTO is disengaged and the tractor is turned OFF.

3. One half of the PTO driveline is already attached to the chipper's input

shaft.

4. Slide the other half of the PTO driveline into the half connected to the

chipper.

5. Connect the other end to the tractor PTO stub. Pull back on collar and slide

coupler onto 6-tooth spline PTO stub. Push collar forward to lock onto

PTO stub. Pull on driveline to ensure proper connection.

Top View

Side View

Max. 25°

Max. 25°

Driveline

Set screws

Receiving & Transporting

11

WARNING

Make sure PTO driveline shaft is securely locked at both ends. Unlocked

PTO shafts can whip or become dangerously airborne.

Secure driveline

guard, check shields

& attach safety

chains

1. A driveline GUARD must ALWAYS be used with the driveline shaft.

Secure the driveline guard according to manufacturer's instructions.

2. Make sure the tractor and chipper shields are in place at both ends of the

driveline shaft:

On the tractor where the driveline connects to the PTO stub.

On the chipper where the driveline connects to the input shaft.

3. Secure PTO safety chains to a stationary part of the chipper frame and

tractor to prevent guards from turning.

WARNING

Never operate the chipper without proper PTO guarding, including a freely

rotating shaft guard as well as tractor and chipper shields at both ends.

Clothing or hair can become rapidly entangled in unguarded rotating PTO

shaft or connections, resulting in serious injury or death.

Safety chains

Receiving & Transporting

12

Moving Instructions:

WARNING

Serious injury can occur if the tractor on which the chipper is mounted is driven unsafely.

1. Drive to desired

location

Drive tractor and chipper carefully to desired work site.

Important safety instructions:

Read tractor instructions. Review safety instructions in your tractor

manual with regard to driving with 3-point hitch mounted equipment

attached.

Securely attached. Be sure chipper is securely attached before transporting.

Make sure chipper is raised as to not contact the ground or objects on the

ground. Damage can occur if chipper is dragged on the ground

Added length. Be aware of the added length of the chipper.

Never operate the machine at high transport speeds on hard or slippery

surfaces.

Reduced road stability. Be aware that heavy, 3-point hitch mounted

equipment can reduce road stability, regardless of the amount of front-end

counterweight added. Drivers should take extra caution when driving with

the chipper attached. Reduce your speed and take extra caution during turns

or while driving on rough or sloped terrain.

On public roads. If transporting the chipper on a public road, make sure to

comply with all local, state, and federal requirements.

Exercise extreme caution when operating on or crossing gravel drives,

walks or roads. Stay alert for hidden hazards or traffic.

No riding or cargo on chipper. Never ride or transport cargo on the

chipper.

Unattended. Turn off the tractor before leaving the chipper unattended.

Under the influence. Never transport or operate this chipper while under the

influence of alcohol, drugs, or medication.

2. Engage parking

brake

Make sure the tractor’s parking brake is engaged before operating the chipper.

WARNING

If the parking brake is not engaged, the tractor could roll while you are

operating the chipper. Personal injury could result. Always engage the parking

brake before leaving the tractor while the chipper is attached.

Operation

13

1. Pre-start Check List & Procedures

WARNING: High Energy Machine

This is a high-powered machine. It has moving parts operating with high energy and at high speeds.

Safe procedures must be used to avert serious injury or death. Unsafe operation will create serious

hazards for you, as well as anyone else in the nearby area.

Each time you get ready for a chipping session and before starting the engine you should follow these

items:

Wear Personal Protection

Establish Safe Working Area

Remove Hazardous Chipping Materials

Only Work During Daylight

Wear Personal

Protection

Use approved protective clothing and approved protective equipment when

using the machine.

Wear ANSI-approved and OSHA-compliant safety glasses with side

shields and a hard hat.

Use of earplugs or another hearing protection device if working within

15-20 feet of the running chipper for longer than a few minutes. Hearing

can be damaged from prolonged close-range exposure to the type of

noise produced by this chipper.

Wear long pants to protect legs from flying debris.

Wear gloves with no cuffs.

Never wear jewelry or loose-fitting clothing when starting or operating

the chipper or any mechanical device. Loose or dangling apparel,

jewelry or hair can become entangled in moving parts.

Establish Safe

Working Area

Layout a safe working area that best fits your project and/or situation by:

Using safety tools such as

barricade signs, safety cones and

caution tape.

Determining placement of

equipment and brush pile (i.e. on

or off the street) that will

minimize interference with auto

traffic.

Keeping children, pets and

onlookers at a safe distance.

Operation

14

Remove Hazardous

Chipping Materials

Thoroughly inspect the area where you will be working and remove all

foreign objects.

Look for rope, wire, etc. and remove these objects before chipping.

(Inserting these objects into the chipper could damage the machine and/or

cause injury)

Work During

Daylight Hours

Use the machine only in daylight or in well-lit conditions. Never operate the

chipper after dark.

2. Starting the Chipper

For detailed engine operation and maintenance information, always refer to the specific

tractor’s Owner’s Manual.

1. Engage parking

brake

Secure chipper from unintended movement—make sure the tractor’s

parking brake is engaged before operating the chipper.

WARNING: If the parking brake is not engaged, the tractor could roll

while you are operating the chipper. Personal injury could result.

2. Lower chipper

to level ground

The driveline angle should never exceed 25°.

Warm-Up Checks

Slowly bring the PTO speed up.

Listen for any unusual metal to metal sounds as chipper wheel is rotating.

Listen for any belt squealing indicating belt needs to be tightened or

replaced

(Unusual sounds may mean a need for repair or cleaning out foreign

material stuck in chipper. STOP engine and refer to “Maintenance and

Repairs” section of this manual)

If you don’t hear any unusual sounds, slowly bring PTO speed up to 540

rpm.

Normal Operation

Always operate the PTO at 540 rpm. Proper chipping requires 540

revolutions per minute.

3. Stopping the Tractor

Move throttle slowly to decrease engine speed until RPM is at its minimum.

Turn off PTO.

Turn tractor OFF.

Chipper knife will continue to rotate for a short time.

Operation

15

4. Feeding Material/ Clearing Jam

Feeding Material

DANGER: Amputation Hazard

Never place your hands, feet or any part of your body in the chipper hopper, discharge opening, or near any

moving part while the machine is running. If a feeding problem should occur, shut the machine down and

see Maintenance and Repair” section to address the problem.

WARNING: Feed brush from the side of the chute

Never stand directly in front of hopper opening. This will reduce the risk of you being caught and

dragged into the machine.

WARNING: Flying Debris Hazard

Stones, chips, and debris can cause serious injury or property damage. Debris can fly 100 ft in any direction

out of the chute and bounce off objects and hit operator, bystanders or breakable objects.

Chipping

The chipper is designed to accept wood only.

Feed branches in butt end first to keep the chipper from getting jammed and to reduce the

kickback of material.

Let go of the material once placed in the hopper.

Use a push stick to help feed small pieces and brush through the chipper. Keep your distance

from the machine’s moving parts. Do not push material into the chute with your hands or feet,

pitch fork, etc. Lay shorter pieces on top of longer branches when feeding them through the

machine.

Do not force material into the chipper. If the machine does not chip well, the chipper knife may

need to be sharpened or replaced, or the belts may need to be replaced or tightened.

Overloading the chipper hopper will cause the rotor speed to decrease. If you hear the engine

RPM decreasing, stop feeding material into the hopper until the material already in the machine is

chipped and the engine has returned to full speed.

Never allow an accumulation of processed material to build up in the discharge area as this will

prevent proper discharge and can result in kickback from the chipper hopper.

After striking a foreign object, stop the tractor, wait for all moving parts to come to a complete

stop, and disconnect the driveline from the tractor's PTO shaft. Thoroughly inspect the machine

for any damage, repair the damage before restarting and operating the machine.

If the machine should start to vibrate abnormally, stop the tractor, wait for all moving parts to

come to a complete stop, disconnect the driveline from the tractor's PTO shaft, and check

immediately for the cause. Vibration is generally a warning sign for trouble.

Clearing Jam

WARNING: Shut Off Engine to Clear Jam

Before attempting to unclog debris or clear a jam:

1. Shut off engine.

2. Wait for all rotating parts to come to a complete stop.

3. Disconnect PTO shaft from tractor and wait 5 minutes before servicing.

Operation

16

7. Storing the Chipper

Storage Procedures

Clean the chipper.

Inspect for worn or damaged parts.

Choose a covered storage location.

Storage Procedures

Clean chipper

Clean any dirt, debris and other foreign matter from the machine, discharge

chute and hopper.

Inspect chipper

Inspect the machine for worn or damaged parts and tighten any nuts or

screws that may have become loose.

Choose a storage

location

Store the chipper in a location that is:

Clean and dry.

Away from extreme high or low temperatures.

Covered for extra protection

1. Remove belt guard,

discharge chute and belt

guard side access plate.

2. Wearing gloves and safety

glasses; use a piece of wood

to push/pull clogged

material up and out of the

cutter housing.

3. Reinstall belt guard,

discharge chute and belt

guard side access plate.

Torque fasteners according

to torque chart before

operating.

Discharge chute

Flywheel

housing

Belt guard side access

plate

Belt guard

Maintenance and Repair

17

WARNING

ALWAYS shut off the tractor, make sure flywheel comes to a complete stop, and disconnect the

drive shaft before cleaning, adjusting, or servicing the chipper. Make sure all guards and shields

are replaced before using.

Maintenance safety

rules

Read and follow these safety rules whenever you will be servicing the

chipper:

Turn off chipper. Always turn off chipper, wait for all parts to come to

a complete stop, and disconnect PTO shaft from tractor before opening.

Replace guards/shields. Make sure all guards and shields are replaced

after servicing the chipper.

Repair. Major service, including the installation or replacement of

parts, should be performed only by a qualified service technician.

Obtain factory approved parts from NORTRAC at 1-800-521-0438.

Replacement parts. If a part needs replacement, only use factory

approved repair parts. Replacement parts that do not meet specifications

may result in a safety hazard or poor operation of the chipper and will

void the warranty.

After servicing. Make sure all tools and wrenches have been removed.

Start tractor and run chipper at low RPM. Listen for any metal against

metal noise or squealing noises from belts. If you should hear any

foreign noise stop engine and solve problems. Re-start and slowly bring

PTO to 540 RPM and run for 10 minutes to assure that repair was

successful.

Checking and

adjusting belt

tension

Drive Belts: Check and adjust according to pages 22-24.

Lubrication

Your chipper was greased at the factory. The operator needs to lubricate the

chipper main bearings periodically. Bearings should be greased weekly or

every 10 hours of use.

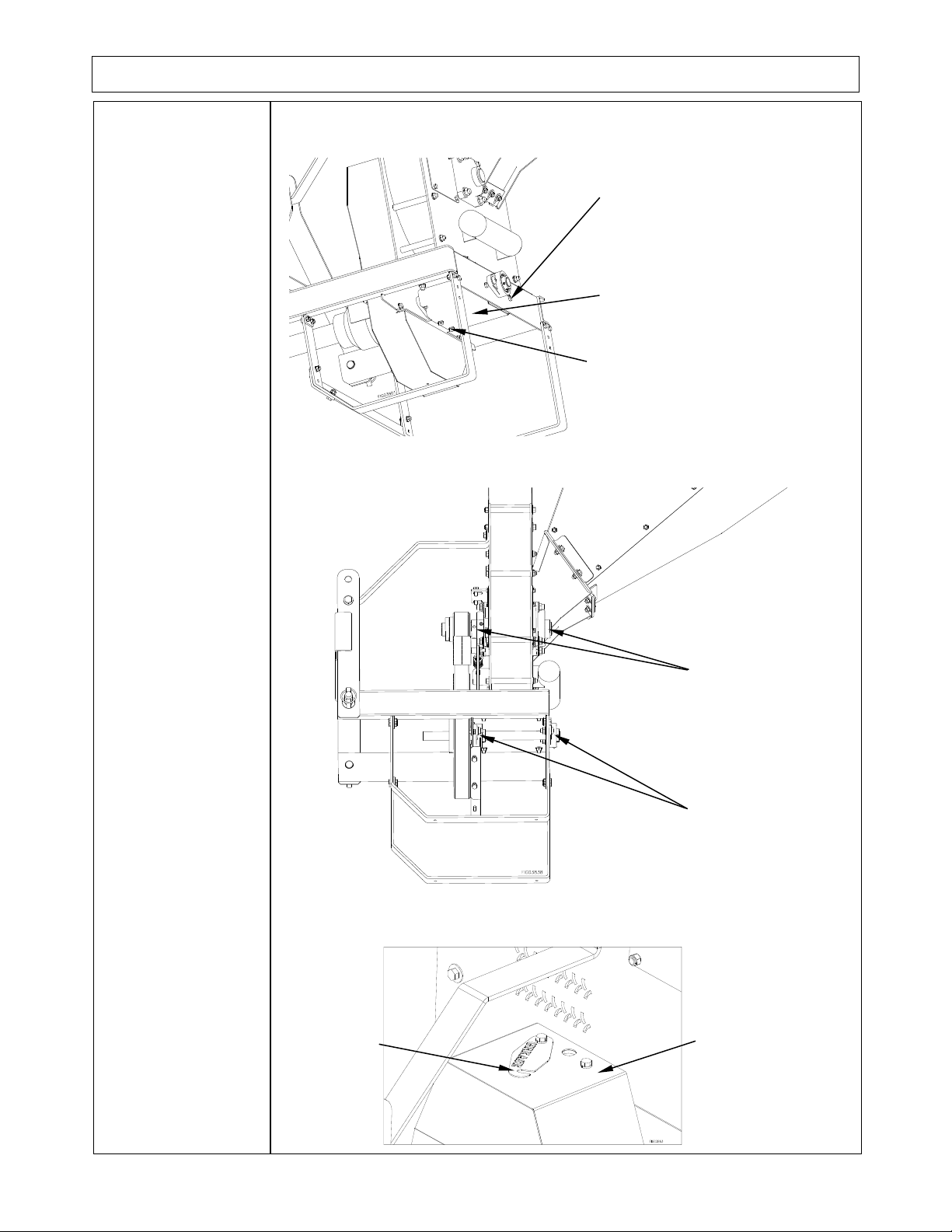

There are two chipper main bearings (in the front and rear) and two drive

shaft bearings (on the front and underneath).

Maintenance and Repair

18

To access drive shaft bearings, remove drive shaft guard. See pg. 19 for belt

guard removal instructions.

Note: Do not over grease. Too much grease will damage bearing seals.

Use EP-2 lithium base grease for bearings.

To access belt guard side main bearing's grease zerk, remove grease patch

plate attached to top of belt guard.

Main

bearings

Drive

bearings

Grease patch

plate

Belt guard

(2) 5/16"-18 x 3/4" bolt

(2) 5/16" flat washers

(2) 5/16" nyloc nuts

(2) 5/16"-18 x 1/2" bolt

(2) 5/16" split washers

Drive shaft guard

Maintenance and Repair

19

1. Chipping Knife

The blade (or knife) is called the flywheel blade. It is mounted on the large spinning wheel which

drives the blade (knife) past the incoming material at a high rate of speed and causes the “chipping”

action. Routine inspection of the chipper blade for sharpness will ensure the chipper is operating at

full efficiency. Operating with a worn or damaged knife or blade will cause extreme stress and

vibration to the machine and make chipping difficult for the operator.

While the chipper knife is made from the highest grade of chipper knife steel, which is heat treated

and ground to a very sharp edge, its life is relative to what is chipped. It may dull the first day or

last for months. The life span depends on the amount of dirt and rocks that enter the chipper.

Sometimes trees will have nails or wire embedded into the surface.

The knife should be checked for damage before each use. It should be turned or changed as

necessary.

A dull knife can:

Cause excessive fuel consumption.

Cause unnecessary stress and strain on the machine.

Produce poor quality chips.

Reduce production rate slowing the feed rate.

Actually wear further and faster.

To check, turn or change the chipper wheel knife you will have to remove the access plates.

Removing Belt Guard and Access Plates

Remove Belt

Guard

Remove (6) 5/16-18 x 3/4" bolts and (6) 5/16" split lock washers from the

top and toward the bottom of the belt guard.

Remove (4) 5/16-18 x 1/2" bolts and (4) 5/16" split lock washers from

underneath the frame.

5/16" x 3/4" bolts

5/16" split lock washers

5/16" x 1/2" bolts

Maintenance and Repair

20

Remove Access

Plates

Remove (8) 1/4"-20 x 1/2" screws and (8) 1/4" split lock washers.

Removing the Chipper Knife

Removing Knife

CAUTION

Wear gloves while changing the knife.

1. Clamp the flywheel to the wall of the cutter housing via the infeed side

access panel.

2. To remove knife, hold bolt heads stationary with 3/8” hex wrench and

loosen nuts with a ratchet and deep socket.

3. Clean knife and knife pocket on flywheel.

4. Sharpen, turn; or if it has nicks or damage, replace the knife.

5. Install all (4) knife bolts, washers and nuts before tightening. Hold bolt

heads stationary with 3/8” hex wrench and tighten nuts to 44 ft./lbs.

Infeed side access plate

1/4" x 1/2" screws

1/4" split lock washers

Belt guard side

access plate

Clamp

Cutter

housing

Flywheel

Table of contents