nosstec 4135 User manual

Bending Roll Machine 4135

Operating instructiOns

4135 English, rev 3 3

Table of conTenTs

Main components ............................................................4

Operation .....................................................................5

Safety..........................................................................6

Service and maintenance .................................................. 11

Lubrication / Grease chart ................................................. 12

Technical data .............................................................. 13

Machine plates and stickers ............................................... 14

Dismantling of bending roll machine ..................................... 15

Spare parts.................................................................. 16

Declaration of conformity.................................................. 18

Contact information.................................................See back

Note: We reserve the right to alter specifications without prior notice.

For copyright reasons all reproduction and copying of the texts, tables and illustrations within this manual is

prohibited without written permission from Nosstec AB.

Operating instructiOns 4135

42013-05-23

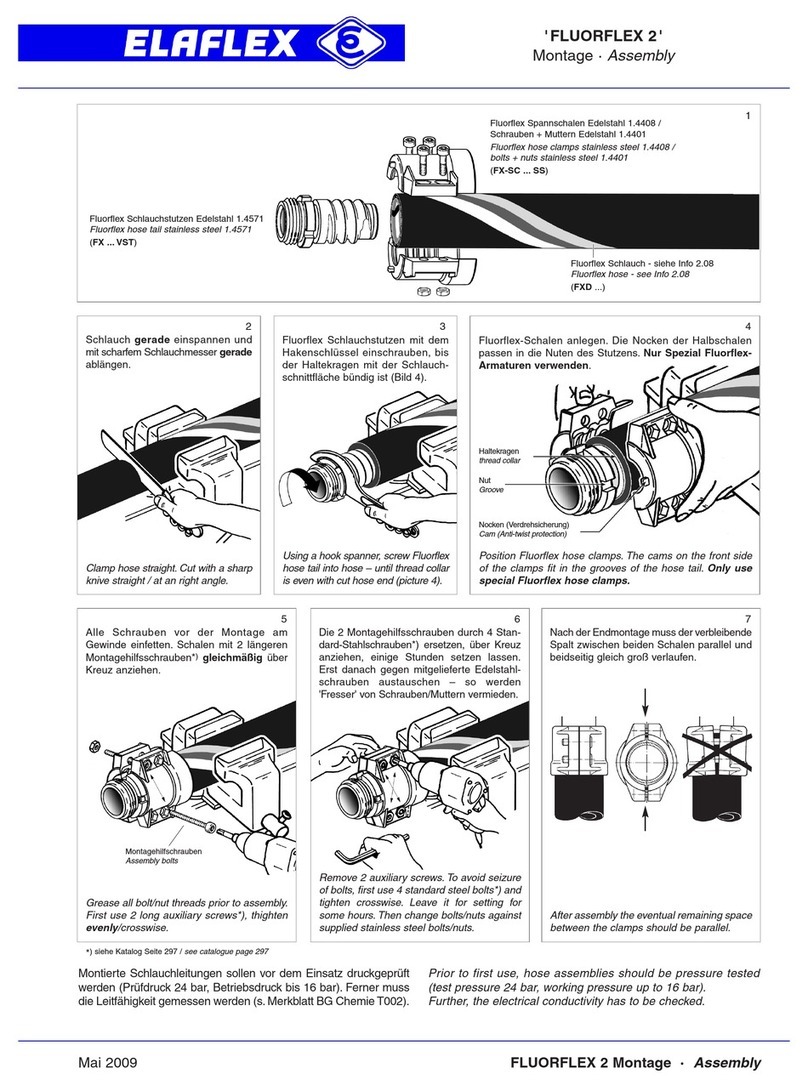

Stand, power

operated side

Motor with

gear box

Emergency

stop

Safety equipment

Top roll Lower roll

Stand, slip

collar side

Pull-out sleeve

Hand wheel for

lower roll

Lever for

bending roll

Main coMponenTs

Front side

Foot switch

Disclaimer: The machine pictured on this page is not necessarily representative of the actual product

as delivered. Differences in sizes, options and/or accessories may or may not be pictured here.

4135 English, rev 3 5

operaTion

Prebending

In order to give the workpiece a

symmetrically round shape, it is

necessary to prebend the part of the

workpiece, which should be bent first.

This must be made from the back

of the machine and with the rolls

rotating in the opposite direction (see

picture 1 in the figure on the right).

Bending

Place the bending roll in the required position.

Introduce the prebent workpiece between the upper and lower rolls and use the bending roll as a back

gauge.

Turn the hand wheel of the lower roll so that the workpiece is clamped between the rolls. Bend the sheet

(check that the sheet runs above the bending roll as per figure above).

Adjust the bending roll and repeat the operation until the workpiece has got the desired shape. Swing

out the top roll and remove the workpiece. Swing back the top roll into its initial position.

At the maximum operating length and sheet thickness tubes down to 1.5x the diameter of the top roll

can be bent and for thinner material down to 1.2x the diameter of the roll.

When bending steel sheet or stainless steel the capacity of the machine will be reduced to about ⁄

compared to mild carbon steel sheet.

Cone (taper) bending

In order to facilitate cone bending the bending roll can be set diagonally as follows:

The bending roll can be set diagonally in both ends by loosening the screw of the cam disk and adjust

the handle upwards or downwards. When the desired inclination of the roll has been obtained, retighten

the screw of the cam disk

Note: Do not forget to reset the parallelism of the rolls after completed cone bending.

Operating instructiOns 4135

62013-05-23

safeTy

General

This bending roll machine is designed with a view to eliminating personal injuries provided that the in-

structions in this manual are being followed.

Only authorized and trained staff is allowed to use the machine. Read the whole instruction manual and

make sure that you understand the contents before the machine is taken into use. It is important that

you read the safety instructions below.

Safety instructions in connection with the installation

The machine must be bolted to the floor with 4 pcs expansion shell bolts diameter 16 mm.

Electrical installation of the machine must be carried out by authorized staff.

Lifting instructions

This machine must be lifted by truck as long as it is

packed in a crate or a wooden case. When lifting it

from the packing to the permanent working site an ap-

proved lifting device type travelling crane must be used.

Instructions for lifting be means of travelling crane:

1. Check that the top roll is in the locked position.

2. Set lower and bending roll in upper position.

3. Put a lifting sling around the rolls as per figure.

4. Lift carefully at the same time as you check that the

rolls are pressed together.

Regarding weights: see technical data

Dangerous area

The dangerous area of the machine is

described in the figure.

This area shall in an appropriate way be

marked in the floor.

A person staying in the dangerous area

will henceforth be called “exposed per-

son” and the user of the machine the

“operator”.

Operator,

prebending

Operator

1,5 m

1,5 m 1,5 m

1,5 m

4135 English, rev 3 7

safeTy

Application

Never use the machine for material which is outside the capacity range of the machine. Check

the machine plate and the section “Technical data”.

Before the machine is operated the following steps must be taken:

Check that all safety devices function and that they are not damaged. Also check that moveable parts

are not exposed to obstacles e.g. owing to incorrectly mounted guards or parts. Broken parts or safety

components must be changed by authorized staff. Contact Nosstec in case spare parts are needed. The

machine has a 24 month applicable warranty from date of delivery.

Check that the environment around the machine is suitable.

• Do not expose the machine to rain.

• Do not use the machine in wet or damp premises.

• Check that the lighting of the premises is satisfactory.

• The floor must be clean, dry and free from oil and grease spots.

• Never use easily inflammable material close to the machine.

• Dirty working sites increase the risk of accidents.

Position of top roll

The top roll must never be in the swung-out position when the machine is in operation.

Avoid unstable working positions

Check that the operator always has a secure and stable working position. When prebending the opera-

tor must stand on the reverse side of the machine.

Do not keep tools on the machine

Remove all tools from the machine before it is operated.

All repairs must be carried out by authorized staff

The machine and its electrical equipment has been made according to valid safety rules. All

repairs must be carried out by trained and qualified staff. Only original spares must be used.

Note: If the repairs also involve dismantling of the machine, this must be carried out

according to the enclosed dismantling instruction. This instruction must not be kept

together with the machine.

Operating instructiOns 4135

82013-05-23

safeTy

Cut the power

Cut the current before touching live parts. This is done either by disconnecting the main

switch of the machine or by disconnecting the voltage of the electrical cabinet.

Note: Do not put the main switch or the safety switch of the machine out of operation.

Danger zone

In connection with production work check that no part

of the body comes too close to the infeed side of the

clamping rolls of the machine (see figure).

Note: The infeed side may vary owing to the direction

of rotation of the rolls.

Keep the instruction manual of the machine in a safe place.

The instruction manual contains important information that besides the safety information also give

important information regarding operation, service, maintenance etc.

Modification of the machine

All conversion, modification or change of this machine is strictly forbidden with the exception of

• Original spare parts

• Optional equipment supplied by the manufacturer.

Airborne noise

The following noise level has been measured at the operator’s place:

Equivalent noise level Leq, idle running 66 dB(A)

Equivalent noise level Leq, operation 68 dB(A)

Falling workpieces

Be careful when working with heavy workpieces so

that they do not fall down by mistake when the grip

loosens between the upper and lower rolls (see figu-

re). If necessary use a support table, travelling crane

or some other lifting device.

4135 English, rev 3 9

safeTy

Pinching risk of the workpiece

Note that there is a pinching risk between the ends

of the workpiece, see figure.

Emergency stop

This machine is equipped with two emergency stop functions, i.e. one emergency stop on the electrical

cabinet and one emergency wire running around the machine at foot height. This together with the fact

that the machine is equipped with brake motor enables the machine to stop instantaneously in case of

injury or risk of injury no matter where you are around the machine.

Service and maintenance

Before service and maintenance are carried out on the machine you must have had instructions from

your foreman. You must also read and understand this instruction manual. Disconnect the main switch

before the service job begins. If the machine must be dismantled, completely or partly, contact your

foreman.

Protective clothing

Important! Never use gloves when bending, as this consider-

ably increases the risk of getting pinched between the rolls.

For other handling of the workpieces use gloves. The operator

must not carry belts, rings or necklaces.

Working shoes with steel inserts must be used.

Loose hanging clothes must not be used.

If the operator has long hair, this must not hang loose.

Deburring of the workpiece

Burrs and sharp edges must be removed from the workpiece before bending.

Jamming

If for some reason the machine stops while

bending a workpiece, proceed as follows:

• Crank down the bottom roll and possibly also the bending roll.

• Remove the workpiece. Identify the trouble reason. If the motor protection is released,

wait for some minutes before it is reset. The machine is then ready for use again.

• If the trouble is mechanical or electrical: Cut the current and contact the supervisor.

Pinching risk

Operating instructiOns 4135

10 2013-05-23

safeTy

Regular checking

Daily check the function of the foot switch as well as the condition of the electric cable of the foot switch.

Also check that the emergency stop works. Carry also out the regular service, which is described in the

chapter Service and Maintenance in the instruction manual.

Safety in general

The chapters describing the safety devices are based on the assumption that the machine is used in the

manner described in this instruction manual, that the operator has got the necessary information regard-

ing the safety of the machine as well as the special risks involved with this type of machine.

If the machine is not used in the proper way, the manufacturer cannot be held responsible for personal

injuries or material damages, which may be the result. Also check the following:

• Take all necessary safety precautions when loading, setting, changing spare parts, cleaning, repairing

and servicing so that the exposed person cannot start the machine.

• Do not disconnect the safety devices of the machine.

• Do not remove any part of the machine belonging to the safety devices.

• Always check that all safety devices have been remounted after repair work etc.

4135 English, rev 3 11

service and MainTenance

Installation

The machine must be placed on firm ground e.g. cemented floor. The ground must be level in order to

avoid tensions in the machine when fixing it to the floor.

Check that the motor is branched to the right voltage. Also check the direction of rotation. Plates with

“Forward” and “Reverse” are mounted on the protection cover of the foot switch.

If the machine is equipped with motor powered setting of the bending roll and/or the lower roll also

check the voltage and oil level here.

Maintenance

The machine is delivered with greased bearings for about 200 hours’ continuous duty. After this period it

should be lubricated with ball bearing grease of good quality, e.g. Esso Multi purpose grease H or equiv-

alent. All rolls and worm gears are mounted on needle and ball bearings and therefore recommended

grease should be used. Guides for the roll bearing box as well as sleeves for the upper roll and cone

bending device to be lubricated when required. Grease lubs, see grease chart.

The gearbox is lifetime lubricated and doesn’t need any regular inspection. Should there be any leakage,

please check oil level and refill if necessary.

Daily check

• Brake function of the motor

• All emergency stop functions

Parallelism of the rolls

Check that all rolls are parallel. If adjustment is necessary proceed as follows:

Between upper and lower rolls:

• Crank up the lower roll to its highest position.

• Loosen the two nuts blocking the wedge on the transmission side.

• Adjust by means of the wedge until the distance between the upper and lower rolls are the same in

both ends

• Lock the wedge by means of the nuts.

Between upper and bending rolls:

• Press the bending roll by means of the lever up to its highest position.

• Loosen the screw of the cam disk.

• Adjust until the distance between the upper and bending rolls is the same at both ends.

• Retighten the screw against the cam disk .

Operating instructiOns 4135

12 2013-05-23

lubricaTion / Grease charT

Lubrication points

There are in total 8 lubrication points:

1. 1 grease nipple in each bearing

housing.

2. 1 grease nipple in the gear housing.

3. 1 grease nipple on the back side of each

stand, level with the axle.

4. 1 grease nipple in the guide of the

sleeve.

See images for locations of

the lubrication points.

1

1

1

4

3

1

3

2

4135 English, rev 3 13

Technical daTa

Serial No ...............................................................................

Type .....................................................................................

Rolling speed ......................................................................... m/min

Max. sheet thickness (at 400 N/mm2).......................................... mm

Operating length .................................................................... mm

Total net weight ..................................................................... kg

Weight of rolls

Top and lower rolls.............................................................. kg/m

Bending roll ....................................................................... kg/m

Total dimensions: length × width × height .................................. mm

Working height ...................................................................... mm

Motor rating .......................................................................... kW

Voltage ................................................................................. V

Feeding motor:

Brand .............................................................................

Type..............................................................................

..................................................................................... V

..................................................................................... kW

Diameter of rolls, top and lower rolls .......................................... mm

Diameter of roll, bending roll .................................................... mm

Optional equipment:

Hardened and ground rolls

Frequency inverter

Digital readout

Deviation from the normal execution:

Operating instructiOns 4135

14 2013-05-23

Machine plaTes and sTickers

Nosstec AB

Järnvägsgatan 19

465 30 Nossebro

SWEDEN

Productionyear:

Type:

Capacity:

Weight:

Serial No:

kg

mm

Current:

Voltage:

Phase:

Frequency:

Aluminium plate, blue anodized.

REVERSE FORWARD

Blue background, white text Blue background, white text

MAIN SWITCH MUST BE

DISCONNECTED FOR ALL

TYPES OF SERVICE AND

MAINTENANCE

O N LY T R A I N E D

STAFF MAY HANDLE

THIS MACHINE

NEVER RUN THE MACHINE

WITH THE TOP ROLL IN

SWINg-OUT POSITION

White and yellow background,

black text

White and yellow background,

black text

White and yellow background,

black text

Yellow background,

black text

Yellow background,

black text

Yellow background,

black text

Yellow background,

black text

4135 English, rev 3 15

disManTlinG of bendinG roll Machine

This instruction is made in order to support trained staff when repairing

with a view to minimizing the risk of personal injuries and damage to

the machine.

To enable dismantling of the machine in a safe way, the job must be car-

ried out by at least two trained mechanics.

This dismantling instruction must not be kept together with the machi-

ne. The proper holder is the supervisor and/or service staff.

Procedure:

1. Loosen the 3 bolts attaching the gear housing.

2. Pull the worm gear motor out of the worm gear box.

3. Loosen the four bolts and remove the cover.

4. Dismount the two gears.

5. Swing out the top roll and pull it out of the worm gear box.

6. Dismount the tube bar at the front bottom stand and place a suita-

ble support under the front of the tube bar.

7. Loosen the two nuts on the stand.

8. Loosen the nuts and dismount the wedge.

9. Dismount the shaft.

10. Secure the bending roll and the lower roll by means of lifting straps

and travelling crane.

11. Pull out the stand and remove the shaft.

12. Release the bending roll from the lifting strap and remove it from

the stand.

13. Repeat the same procedure with the lower roll.

Note: Handle the loose parts carefully and check that all pieces

removed also are mounted in their right places, but in the re-

verse order.

1

3

3

4

7

8

810

11

2

Operating instructiOns 4135

16 2013-05-23

spare parTs

4135 English, rev 3 17

spare parTs

Svenska English Deutsch Francais

1 1 Snäckväxel Worm gear Schneckengetriebe Engrenage à vis sans n

2 4 Skruv Screw Schraube Vis

3 1 Lock för växelhus Cover for gearbox Abdeckung für Getriebe Couvercle de boîte de vitesses

4:01 1 Kugghjul Gear Zahnrad Roue dentée

4:02 1 Kugghjul Gear Zahnrad Roue dentée

5 1 Växelhus Gearbox Getriebegehäuse Boîte de vitesse

6 1 Kil Wedge Keil Coin

7 1 Övervals Top roll Oberwalze Rouleau supérieur

8 1 Hylsa med styrning Sleeve with guide Buchse mit Führung Douille avec guide

9 1 Ändbricka End washer Endplatte Disque

10 1 Spännstift Roll pin Spannstift Goupille de serrage

11 1 Skruv Screw Schraube Vis

12 4 Skruv Screw Schraube Vis

13 1 Lagerhus Bearing housing Lagergehäuse Boîte de palier

14 1 Kil Wedge Keil Coin

15 8 Smörjnippel Grease nipple Schmiernippel Graisseur

16 1 Böjvals Bending roll Biegewalze Rouleau arriére

17 1 Undervals Lower roll Unterwalze Rouleau inférieur

18 1 Styrning Guide Führungen Guide

19 1 Smörjnippel Grease nipple Schmiernippel Graisseur

20 1 Lagerhus Bearing housing Lagergehäuse Boîte de palier

21 1 Lagerhus Bearing housing Lagergehäuse Boîte de palier

22 1 Kil Wedge Keil Coin

23 6 Mutter Nut Mutter Ecrou

24 1 Axel Axle Achse Axe

25 1 Ok Support Stütze Support

26 1 Lagerhus Bearing housing Lagergehäuse Boîte de palier

27 1 Kil Wedge Keil Coin

28 1 Mutter Nut Mutter Ecrou

29 1 Stoppskruv Stop screw Stellschraube Vis d’arrêt

30 1 Excenter Eccentric Exzenter Excentrique

31 1 Axel Axle Achse Axe

32 1 Spännstift Roll pin Spannstift Goupille de serrage

33 1 Skruv Screw Schraube Vis

34 1 Bricka Washer Scheibe Rondelle

35 1 Kamskiva Cam Kamscheibe Disque à came

36 1 Handtag Handle Gri Poignée

37 1 Fjäder Spring Feder Ressort

38 1 Bricka Washer Scheibe Rondelle

39 1 Skruv Screw Schraube Vis

40 1 Spärr Lock Verriegelungsgri Poignée de verrouillage

41 1 Kuggsegment Cog segment Zahnsegment Segment denté

42 1 Skruv Screw Schraube Vis

43 2 Flänsmutter Flange nut Flanschmutter Écrou à embase

44 1 Skruv Screw Schraube Vis

45 2 Skruv Screw Schraube Vis

46 1 Spännstift Roll pin Spannstift Goupille de serrage

47 1 Ratt Wheel Handrad Volant

48 2 Gavel underdel Side, lower Giebel, unten Bâti partie inférieure

49 8 Bricka Washer Scheibe Rondelle

50 8 Skruv Screw Schraube Vis

51 1 Rörstag Pipe strut Rohrstrebe Support tubulaire

52 1 Gavel utsvängbar sida Side, openable side Giebel, Nebentüren Bâti côté pivotant

53 1 Motor Motor Motor Moteur

54 2 Stag Strut Strebe Support

55 1 Skruv Screw Schraube Vis

56 1 Mutter Nut Mutter Ecrou

57 1 Gavel transmissionssida Side, transmission side Giebel, Transmissionseite Bâti côté de transmission

58 1 Axelsäkring Axle lock Achssperre Arrêt d’axe

59 4 Mutter Nut Mutter Ecrou

60 2 Skruv Screw Schraube Vis

61 4 Skruv Screw Schraube Vis

62 1 Fläns Flange Flansch Bride

63 1 Fläns Flange Flansch Bride

64 2 Klammer Clip Klammer Crampon

65 2 Skruv Screw Schraube Vis

Operating instructiOns 4135

18 2013-05-23

declaraTion of conforMiTy

Declaration of conformity

as per the EC Machinery Directive 98/37 EG, Annex II A.

Manufacturer: Nossebro Mekaniska Verkstad AB

SE 465 30 NOSSEBRO +46 512 298 80

Distributor: Nosstec AB

SE 465 30 NOSSEBRO +46 512 298 85

herewith declare that:

Machine: ..............................................................

Type

..............................................................

Serial No

is manufactured in conformity with:

– The Council Directive of 2006/42/EG

– EMC Directive 2004/108/EG

– Low voltage directive 2009/96/EG

............................... ..........................................

Place and date Signature, Managing Director

www.nosstec.se

Nosstec AB • Kristineholmsvägen 12, 441 39 Alingsås, SWEDEN

Tel: +46 (0)512 298 85 • Fax: +46 (0)512 298 89 • E-mail: info@nosstec.se

For copyright reasons all reproduction and copying of the texts, tables and illustrations

within this manual is prohibited without written permission from Nosstec AB.

Table of contents