10

Safety Instructions

If the maximum permissible wind

speed has been exceeded, tempera-

tures are outside the scope of applica-

tion or after any extraordinary event

has taken place such as a fire or earth-

quake, the functionality and load-bear-

ing capacity of all safety components

as well as the supporting structure are

to be checked.

Safety components:

Visual checks are to be carried out

by authorised personnel at regular

intervals.

Before any climbing or assembly, a

functionality check is carried out by

qualified personnel.

If parts need to be replaced, only

PERI original components may be

used.

Repairs are only allowed to be car-

ried out by PERI qualified personnel.

In the case of overloading or recur-

rent damage, stop work operations

on and under the platforms, deter-

mine the cause and rectify.

Supporting structure:

A visual inspection is to be carried

out by authorised personnel before

initial use.

Only PERI original components are

to be used for repairs or replace-

ment.

In the case of overloading or recur-

rent damage, stop work operations

on and under the platforms, deter-

mine the cause and rectify.

Other components:

Repairs are carried out by authorised

personnel and the contractor/site

management is to be informed.

Determine the cause of any damage

that occurs on a recurring basis and

rectify.

Persons are not allowed to remain un-

der suspended loads. If work under

suspended loads cannot be avoided,

determine and apply all appropriate

measures. Avoid entering the area be-

tween suspended loads and the build-

ing.

Site personnel are forbidden to remain

in areas below where assembly work is

being carried out unless the area of risk

has been provided with sufficient pro-

tection against falling, overturning, slid-

ing or rolling objects and masses. The

area of risk is to be cordoned off.

Maintenance and repairs

The system components are to be in-

spected before each use to ensure that

they are in perfect condition and func-

tion correctly. Only materials in perfect

condition are to be used.

The units are to be inspected for signs

of damage at regular intervals by au-

thorised personnel. Dirt which affects

the functionality is to be removed im-

mediately. Damaged components are

to be inspected, removed and re-

placed.

System-Specific

Assembly work

The contractor must ensure that the

user has the appropriate and sufficient

number of tools, lifting equipment and

slings, suitable and sufficient space for

assembly and storage, as well as ade-

quate crane capacity at his disposal.

There is always the possibility of un-

foreseen risks arising during assembly

work. The level of risk is to be estimat-

ed according to each individual case

and, if necessary, measures are to be

taken to avoid or at least to minimise

the risk.

If anti-fall protection cannot be used or

has to be removed due to operational

reasons, safety equipment must be in-

stalled in its place in order to prevent or

arrest falls from any height. If the use

of fall arrest equipment is deemed to

be inappropriate, personal protection

equipment (PPE) can be used if suita-

ble fixing points are available.

Use a guide rope to ensure that assem-

bly units suspended from the crane are

fully under control when being moved.

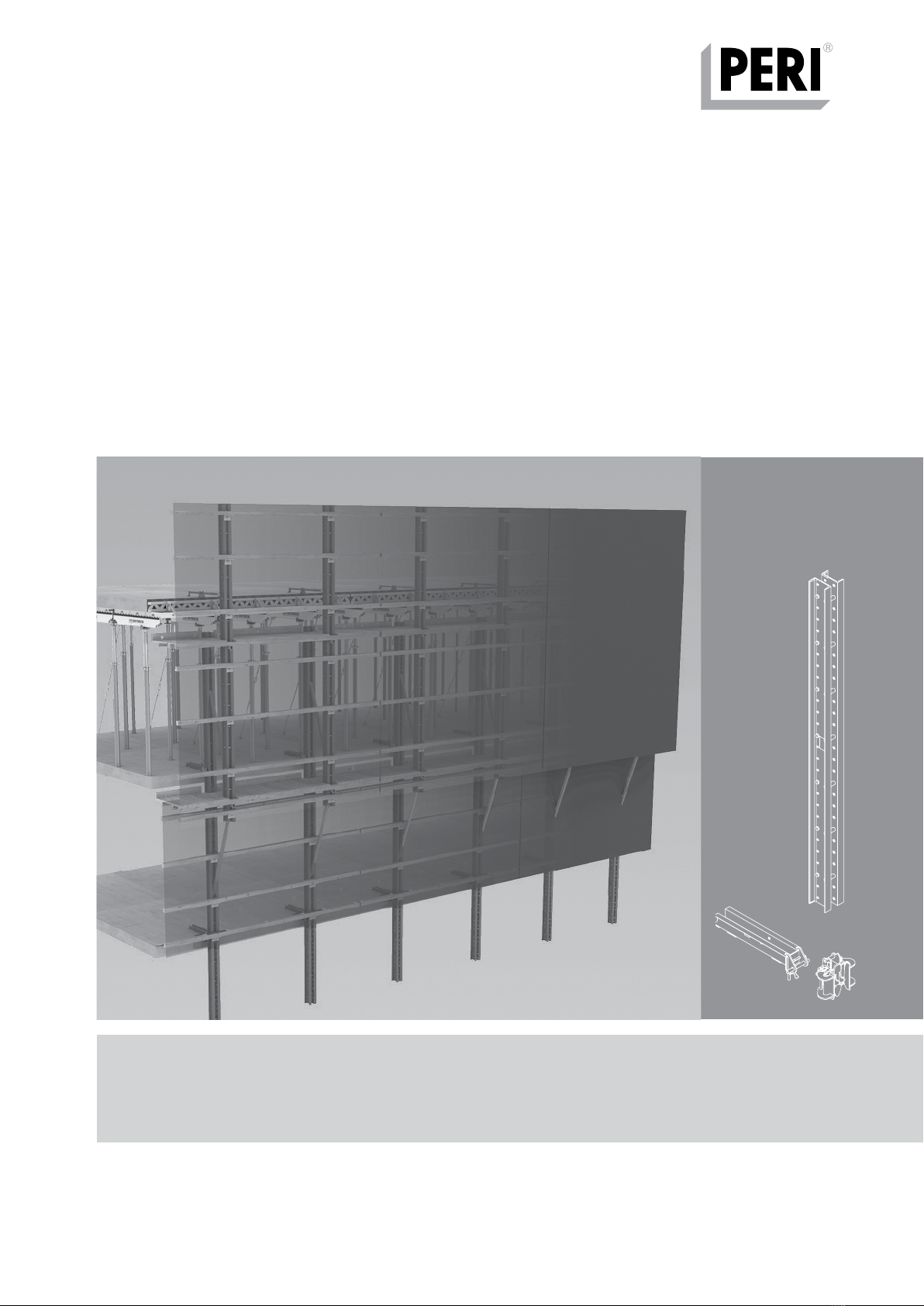

RCS P Climbing Protection Panel

Instructions for Assembly and Use – Standard Configuration