nosstec 4126 User manual

Bending Roll Machine 4126

Operating instructiOns

4126 English, rev 4 3

Table of conTenTs

Main components ............................................................4

Operation .....................................................................5

Safety..........................................................................7

Service and maintenance .................................................. 12

Machine plates and stickers ............................................... 13

Dismantling the bending roll machine.................................... 14

Contact information................................................. See back

Note: We reserve the right to alter specifications without prior notice.

For copyright reasons all reproduction and copying of the texts, tables and illustrations within this manual is

prohibited without written permission from Nosstec AB.

Operating instructiOns 4126

42012-12- 06

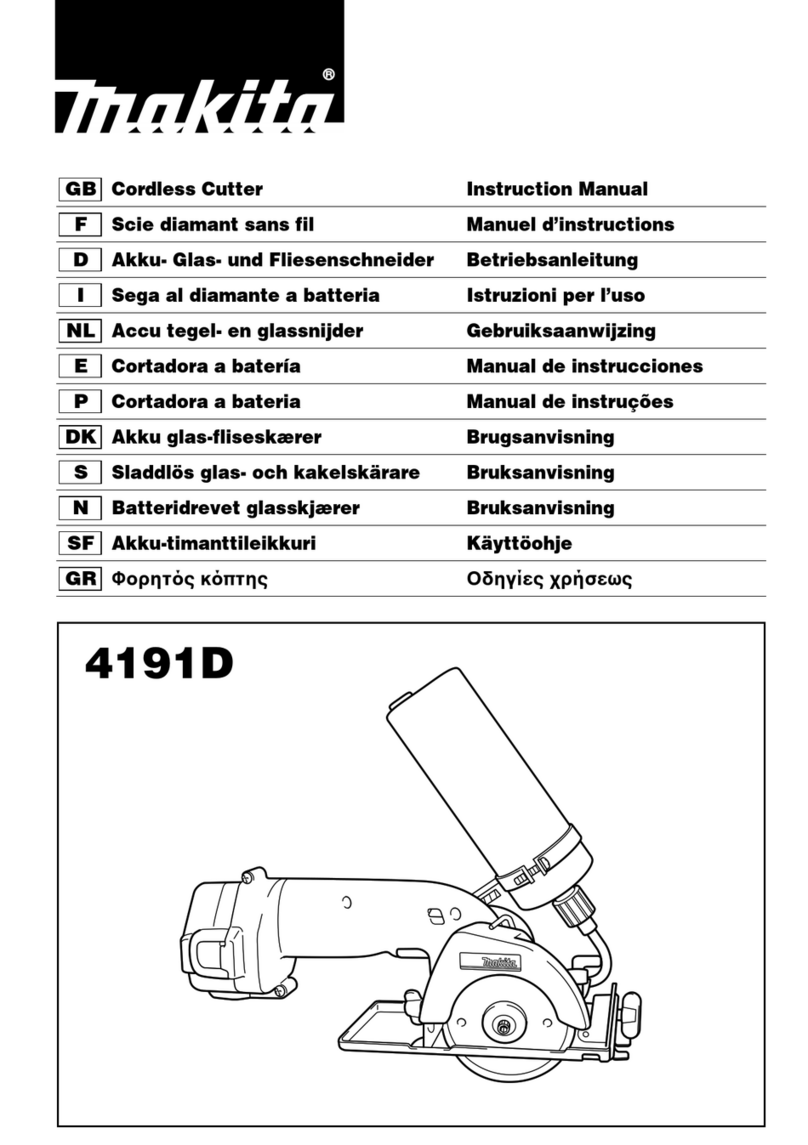

Hand wheel for

lower roll

Top roll

Lower roll

Bending roll

Hand wheel for

bending roll

Cone bending

setting

Pull-out sleeve

for top roll

Handle

Main coMponenTs

Front side

Back side

Disclaimer: The machine pictured on this page is not necessarily representative of the actual product

as delivered. Differences in sizes, options and/or accessories may or may not be pictured here.

4126 English, rev 4 5

operaTion

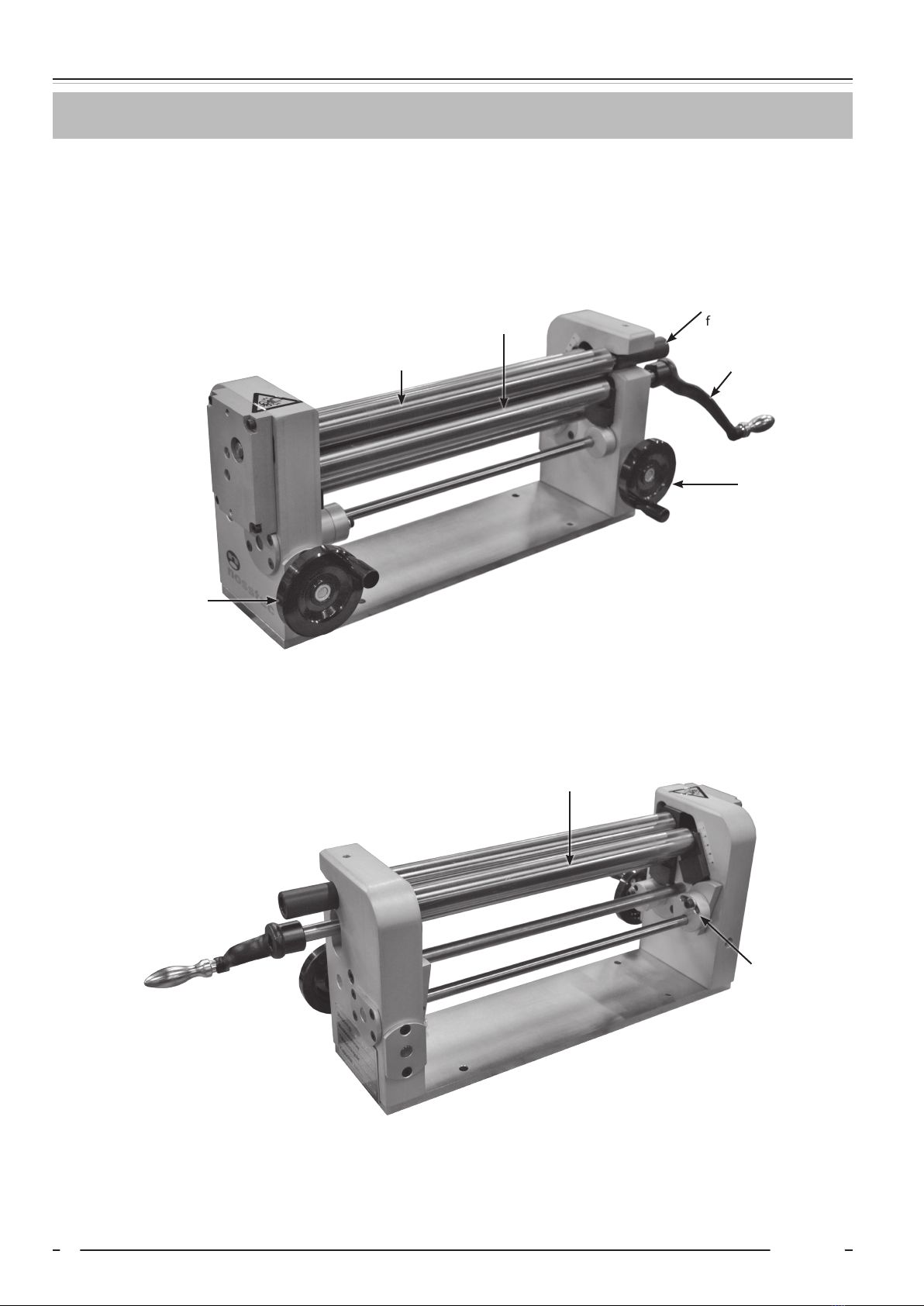

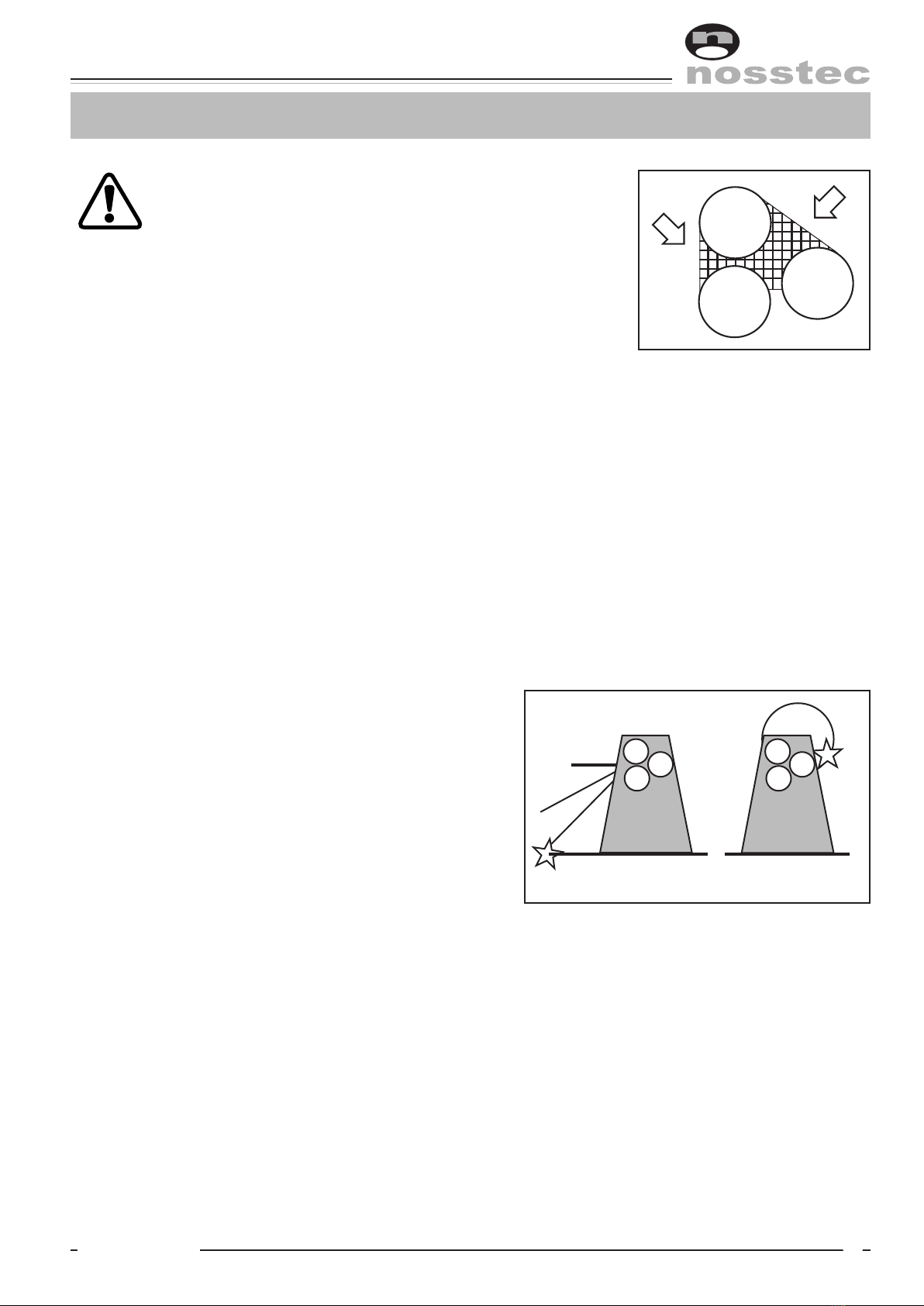

Prebending

In order to avoid a flat part at the beginning of the workpiece, it should be prebent first. As the rolls are

asymmetrically mounted the prebending is carried out as per the drawing.

Fig. 1 The workpiece is introduced from the back of the machine and clamped between the upper

and lower rolls. By raising the bending roll the workpiece is bent to the required diameter.

Fig. 2 The prebent workpiece is introduced from the front and clamped between the upper and lower

rolls.

Fig. 3 The bending is carried out in one operation.

Bending

At the maximum operating length and the maximum sheet thickness tubes down to about 1,5 times the

diameter of the upper roll can be formed and for thinner sheets down to about 1,2 times the diameter of

the roll.

When bending steel sheet or stainless steel the maximum thickness capacity of the machine will be

reduced to about ⁄ compared to mild carbon steel sheet.

Adjustment of rolls

Introduce the workpiece between the upper and lower rolls and fasten it by raising the lower roll by

means of the handwheel on the left hand side of the machine.

In order to get the required bending diameter, the bending roll should by adjusted by means of the

handwheel of the right hand side of the machine.

Operating instructiOns 4126

62012-12- 06

operaTion

Removal of workpiece

The finished workpiece is removed from the machine as follows:

• Pull out the sleeve of the upper roll on the right hand side.

• Swing out the released roll.

• Remove the workpiece.

• Swing back the upper roll to its initial position and push back the

sleeve.

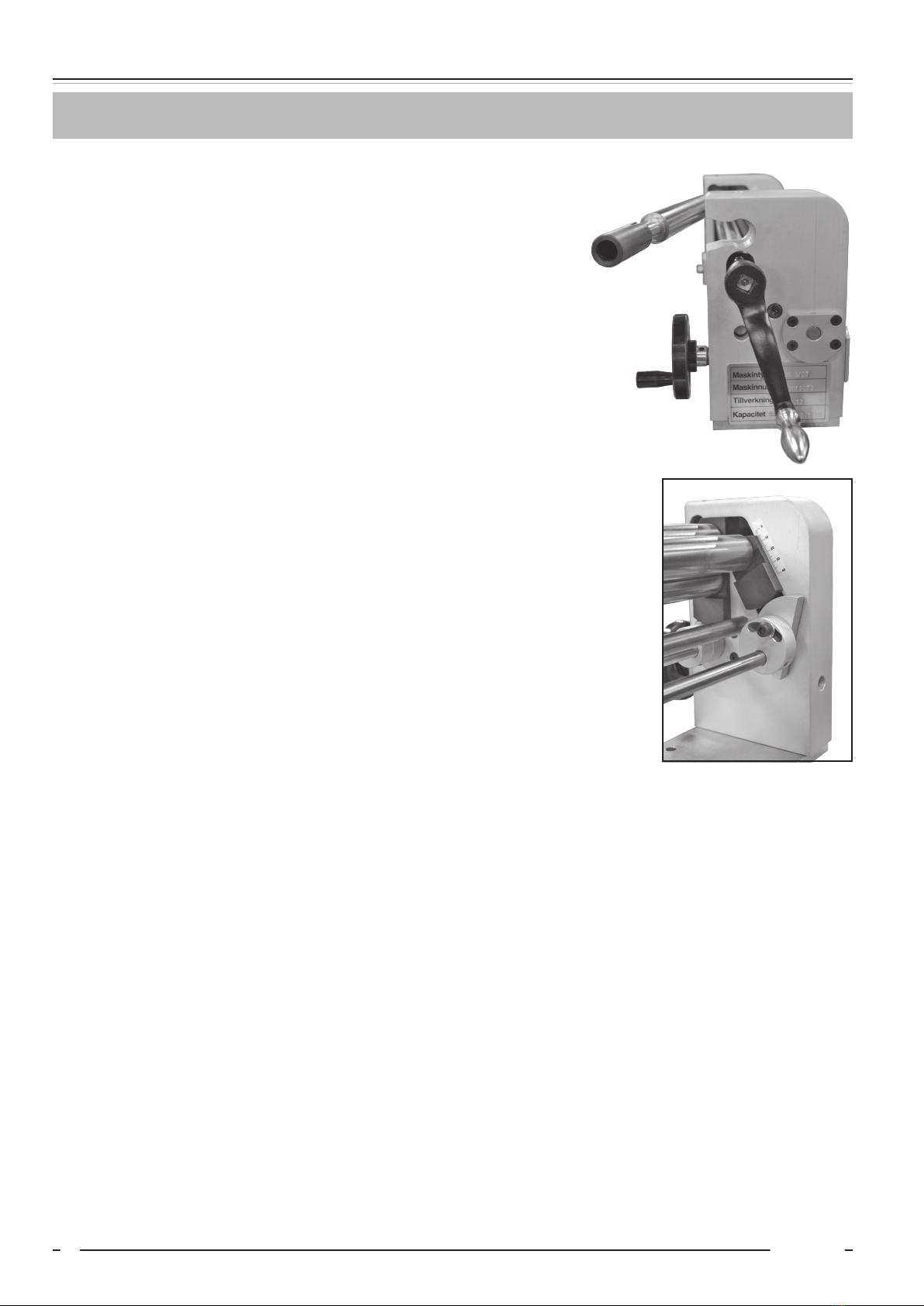

Cone bending

In order to facilitate cone bending, the bending roll can be set diagonally

as follows:

• Loosen the internal hexagon screw on the left hand side of the

bending roll.

• Adjust the cam so that the required diagonal setting is obtained.

• Tighten the screw.

To reset, see “Parallel adjustment of rolls”.

Parallel adjustment of rolls

The parallelism of the lower- and bending rolls in relation to the upper roll is set by pressing the roll in

question towards the upper roll. Loosen the internal hexagon screw and turn the handle as much as pos-

sible. Set the released cam for the horizontal position and tighten the internal hexagon screw.

4126 English, rev 4 7

safeTy

General

This machine is designed with a view to eliminating personal injuries provided that the instructions in

this manual are being followed.

Only authorized and trained staff is allowed to use the machine. Read the whole instruction manual and

make sure that you understand the contents before the machine is taken into use. It is important that

you read the safety instructions below.

Safety instructions in connection with the installation

In order to prevent tensions in the machine it should be bolted to a solid workbench or onto

optional stand bolted safely to the floor.

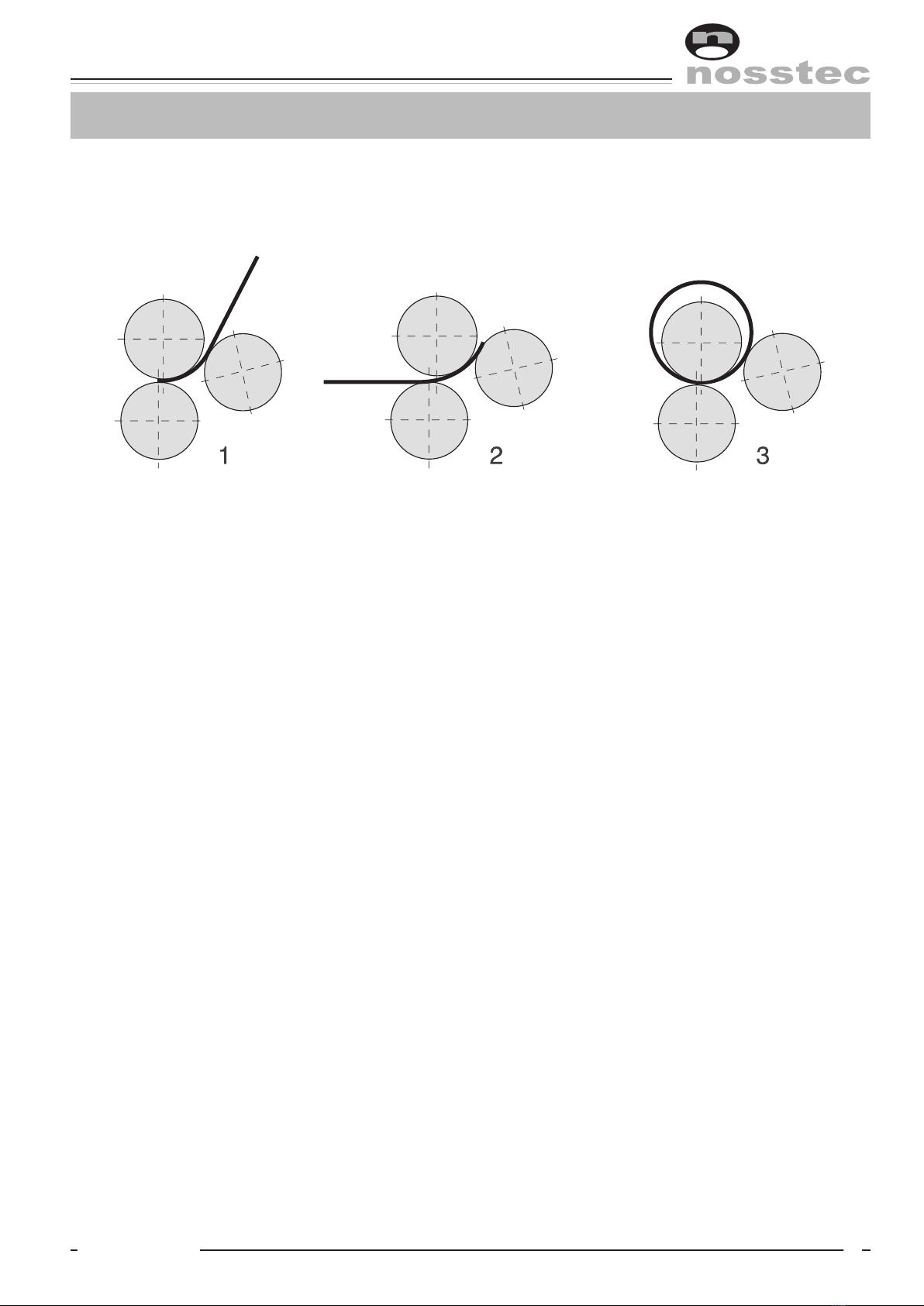

Lifting instructions

This machine must be lifted by truck as long as it is

packed in a crate or a wooden case. When lifting it

from the packing to the permanent working site an

approved lifting device type travelling crane must be

used. Instructions for lifting be means of travelling

crane:

1. Check that the top roll is in the locked position.

2. Put a lifting sling around the rolls as per figure.

3. Lift carefully at the same time as you check that the

rolls are pressed together.

Regarding weights, see machine plate on the machine.

Operating instructiOns 4126

82012-12- 06

safeTy

Application

Never use the machine for material which is outside the capacity range of the machine. Check

the machine plate for more information.

Before the machine is operated the following steps must be taken:

Check that all safety devices function and that they are not damaged. Also check that moveable parts are

not exposed to obstacles e.g. owing to incorrectly mounted guards or parts. Broken parts or safety com-

ponents must be changed by authorized staff. Contact Nosstec in case spare parts are needed. The ma-

chine has a 24 month applicable warranty from date of delivery. The warranty is only applicable as long

as original spare parts are used.

Check that the environment around the machine is suitable

• Do not expose the machine to rain.

• Do not use the machine in wet or damp premises.

• Check that the lighting of the premises is satisfactory.

• The floor must be clean, dry and free from oil and grease spots.

• Never use easily inflammable material close to the machine.

• Dirty working sites increase the risk of accidents.

Avoid unstable working positions

Check that the operator always has a secure and stable working position.

Do not keep tools on the machine

Remove all tools from the machine before it is operated.

All repairs must be carried out by authorized staff

The machine has been made according to valid safety rules. All repairs must be carried out by

trained and qualified staff. Only original spares must be used.

Note: If the repairs also involve dismantling of the machine, this must be carried out

according to the enclosed dismantling instruction. This instruction must not be kept

together with the machine.

4126 English, rev 4 9

safeTy

Danger zone

In connection with production work check that no part

of the body comes too close to the infeed side of the

clamping rolls of the machine (see figure).

Note: The infeed side may vary owing to the direction

of rotation of the rolls.

Keep the instruction manual of the machine in a safe place.

The instruction manual contains important information that besides the safety information also give im-

portant information regarding operation, service, maintenance etc.

Modification of the machine

All conversion, modification or change of this machine is strictly forbidden with the exception of

• Original spare parts

• Optional equipment supplied by the manufacturer.

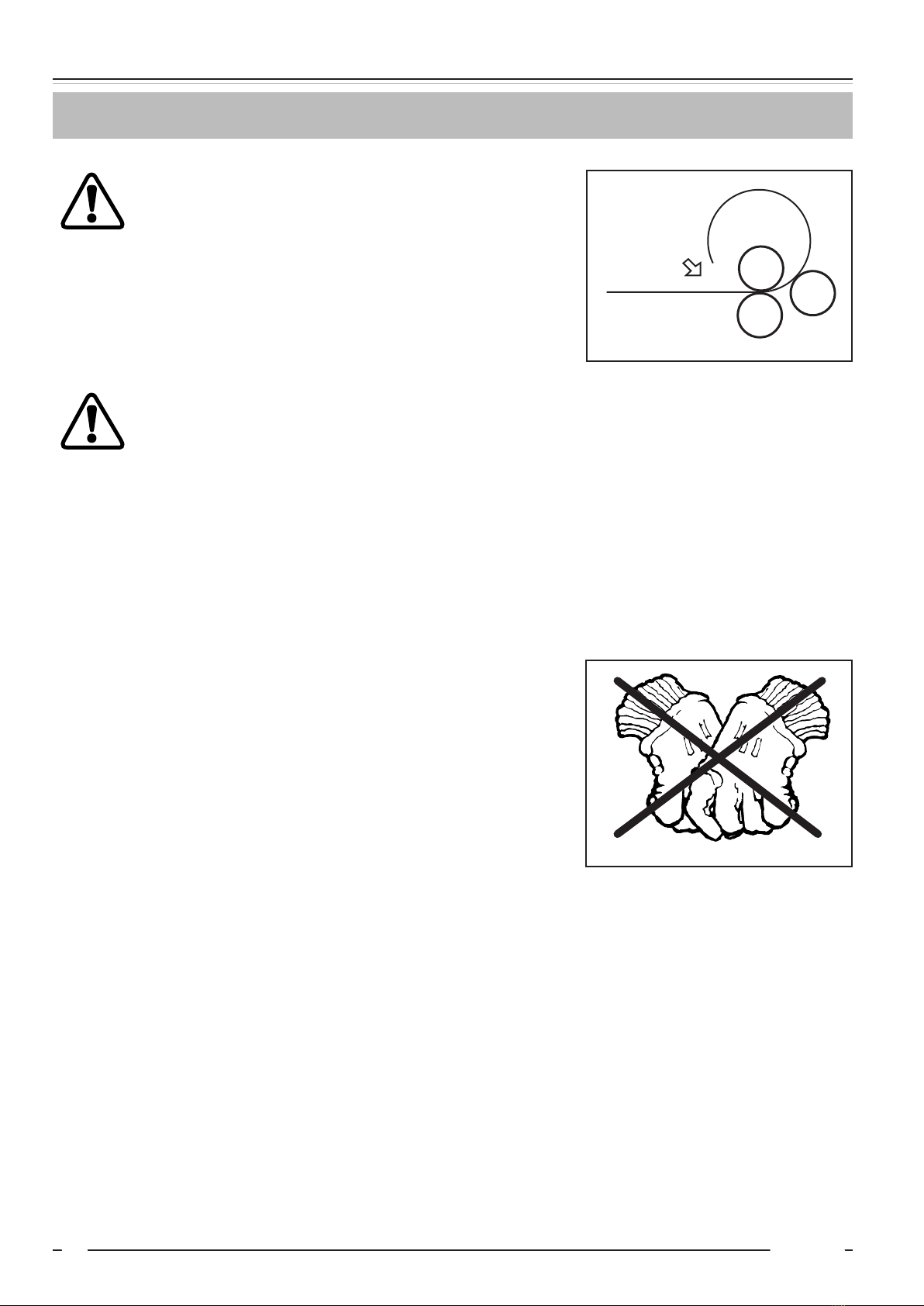

Falling workpieces

Be careful when working with heavy workpieces so

that they do not fall down by mistake when the grip

loosens between the upper and lower rolls (see figu-

re). If necessary use a support table, travelling crane

or some other lifting device.

Operating instructiOns 4126

10 2012-12- 06

safeTy

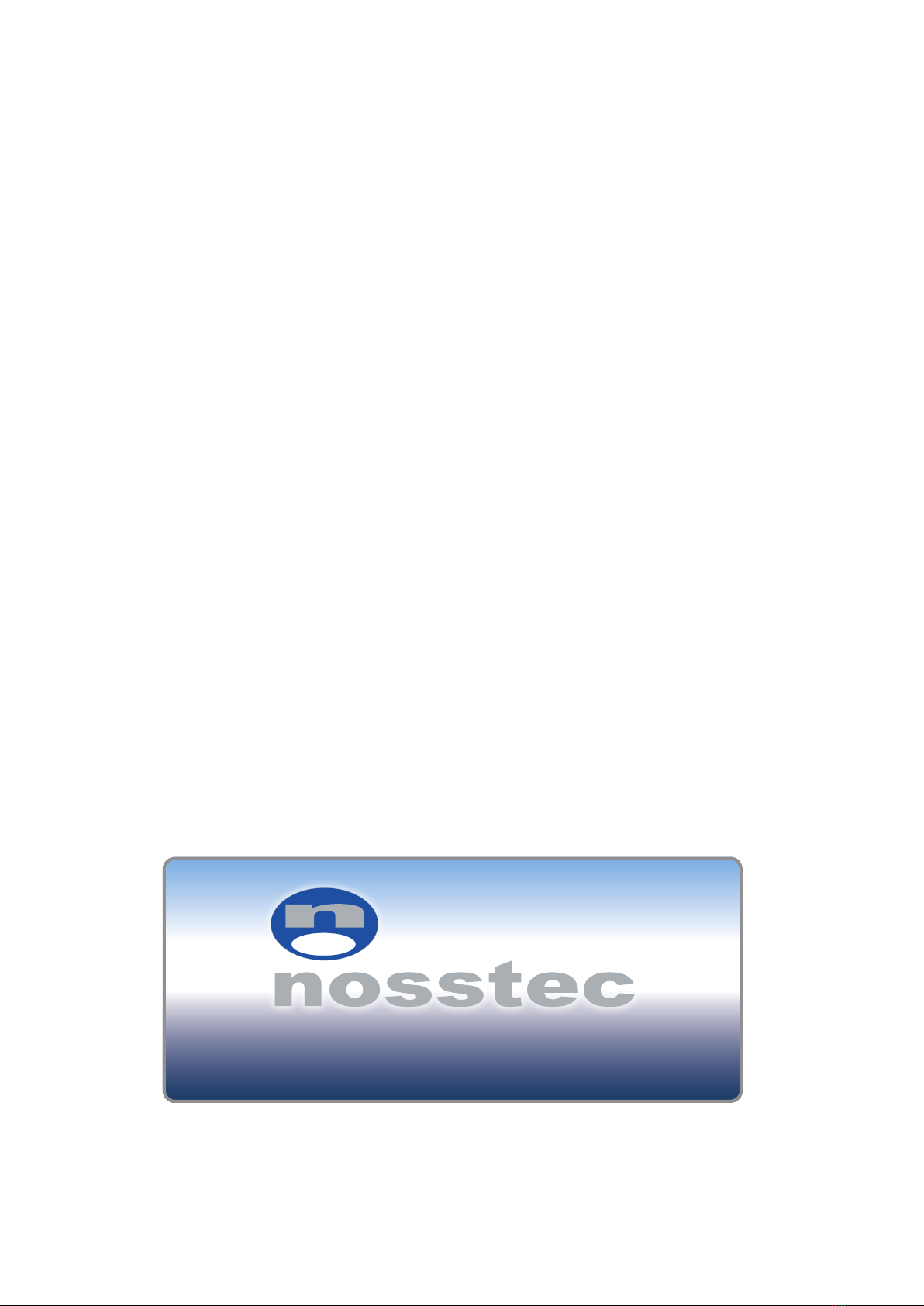

Pinching risk of the workpiece

Note that there is a pinching risk between the ends

of the workpiece, see figure.

Gearing protection

All machine transmissions are completely covered by fixed protections.

Note! The machine must not be run if one of these protections has been removed.

Service and maintenance

Before service and maintenance are carried out on the machine you must have had instructions from

your foreman. You must also read and understand this instruction manual. If the machine must be dis-

mantled, completely or partly, contact your foreman.

Protective clothing

Important! Never use gloves when bending, as this consider-

ably increases the risk of getting pinched between the rolls.

For other handling of the workpieces use gloves. The operator

must not carry belts, rings or necklaces.

Working shoes with steel inserts must be used.

Loose hanging clothes must not be used.

If the operator has long hair, this must not hang loose.

Deburring of the workpiece

Burrs and sharp edges must be removed from the workpiece before bending.

Pinching risk

4126 English, rev 4 11

safeTy

Safety in general

The chapters describing the safety devices are based on the assumption that the machine is used in the

manner described in this instruction manual, that the operator has got the necessary information regard-

ing the safety of the machine as well as the special risks involved with this type of machine.

If the machine is not used in the proper way, the manufacturer cannot be held responsible for personal

injuries or material damages, which may be the result. Also check the following:

• Take all necessary safety precautions when loading, setting, changing spare parts, cleaning, repairing

and servicing so that the exposed person cannot start the machine.

• Do not disconnect the safety devices of the machine.

• Do not remove any part of the machine belonging to the safety devices.

• Always check that all safety devices have been remounted after repair work etc.

Operating instructiOns 4126

12 2012-12- 06

service and MainTenance

Installation

The machine must be placed on firm ground e.g. cemented floor or similar. The ground must be level in

order to avoid tensions in the machine when fixing it to the floor.

Maintenance

The 4126 machine is lifetime lubricated and must not be relubricated under normal circumstances.

4126 English, rev 4 13

Type

Capacity

Weight Kg

Machine no.

Machine plaTes and sTickers

Aluminium plate, blue anodized text.

Operating instructiOns 4126

14 2012-12- 06

disManTling The bending roll Machine

Dismantling

If necessary, disassemble the machine very carefully and note how the parts were mounted. Please note

that only original spare parts from Nosstec are recommended for a fault free function.

www.nosstec.se

Nosstec AB • Kristineholmsvägen 12, 441 39 Alingsås, SWEDEN

Tel: +46 (0)512 298 85 • Fax: +46 (0)512 298 89 • E-mail: info@nosstec.se

For copyright reasons all reproduction and copying of the texts, tables and illustrations

within this manual is prohibited without written permission from Nosstec AB.

Table of contents

Other nosstec Cutter manuals

Popular Cutter manuals by other brands

BE Ag & Industrial

BE Ag & Industrial BE-RC Series Operations & parts manual

Makita

Makita CA5000 instruction manual

Nova Technology International, LLC

Nova Technology International, LLC RX-200 user manual

Land Pride

Land Pride RCFM4014 Operator's manual

Rubi

Rubi TX Series instruction manual

Nothern Industrial tools

Nothern Industrial tools 1555811 owner's manual