RX-200 Touchscreens

10

18

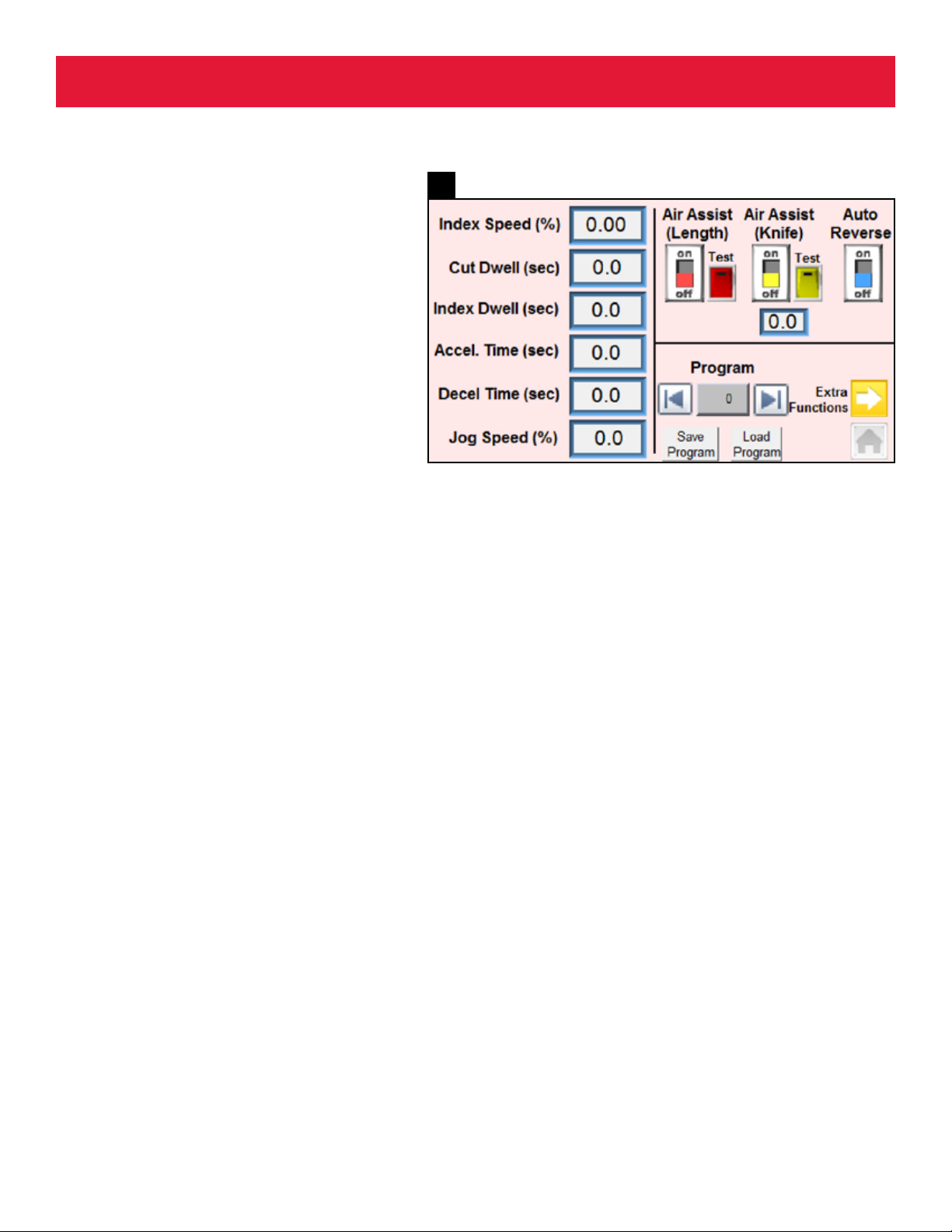

ADVANCED SETTINGS SCREEN

The Advanced Setting screen (PHOTO 18) is used for

changing dwell settings, motor ramp and jog speeds,

air assist settings (when equipped), motor auto

reverse, and program saving. The Advanced Settings

Screen contains the following elements and function

descriptions:

Index Speed (%): Sets the maximum length motor

speed in percent (1% - 100%).

Cut Dwell (sec): Sets the cutting dwell time (in

seconds) for cutting through the material. Light

materials require less time than heavy materials.

Index Dwell (sec): Sets the dwell time (in seconds)

between from the end of the cut cycle to the

measuring of the next length. This setting allows a

melted end to cool.

Accel. Time (sec): Sets the time (in seconds) for the

motor to accelerate to full speed. A longer Accel Time

will allow the length motor to accelerate more slowly

and minimize roller slip, to improve length accuracy,

especially on heavy rolls or with elastic materials.

Decel. Time (sec): Sets the time (in seconds) for the

motor to decelerate before cutting. A longer Decel

Time will minimize material overfeed of heavy or stiff

materials.

Jog Speed (%): Sets the motor speed when the JOG

button is pressed on the main screen.

Air Assist (Length): (red switch & test button) An

optional function that uses compressed air to assist

the measuring of very lightweight and imsy materials.

When equipped with an air assist valve the air nozzle

will emit a blast of air through the knife to prevent

jamming and sticking of the material. Pressing the red

Test button will momentarily activate the air assist

valve.

Air Assist (Knife): (yellow switch & test button) An optional

function that uses compressed air to assist the removal of cut

material from the knife or anvil. When equipped with an air assist

valve the air nozzle will emit a blast of air off the knife. This

function has a dwell time setting below the yellow switch. Pressing

the yellow Test button will momentarily activate the air assist valve.

Auto Reverse: (blue switch) When activated, this function will

cause the feed roller to reverse briey before measuring. This allows

the motor to remove material that might have adhered to the anvil.

If the machine experiences jamming in the knife area, turn this

function on.

Program: (with left and right arrows) Program (recipe) settings

may be saved by pressing the gray Save Program button. To run a

previously saved program (recipe), toggle to the program number

using the arrows and press Load Program. Programs are saved by

number only. For detailed instructions, see the Appendix.

Home: (gray house) - Press the home button to return to the main

screen.

Extra Functions: (yellow arrow) advances to the Additional

Functions Screen