Au3Tech SC1000 User manual

SC1000 Fiber Laser Cutting

CNC System User’s Manual

WUHAN AU3TECH TRADING CO., LTD

Version:V1.00

2017/3/27

Copyright © WUHAN AU3TECH TRADING CO., LTD

2

SC1000 Fiber Laser Cutting CNC System User’s Manual Version:V1.00

2017 年3月27 日

Preface

Introduction

This archive mainly describes about the interface, functions and operations of the fiber laser cutting

CNC system software (We call it: SC1000). And if you want to know more about installation and

debugging, please reference to Fiber Laser Cutting CNC System Quick Setup. Before you use it and

its relevant equipment, please read it carefully which can help you use it more conveniently. And since

our product are keeping updating, so this manual cannot fully match in all aspects with the product, hope

you can understand.

Readers

This manual mainly for those people below:

Installation / debugging engineer

Maintenance engineer

Operator

The meaning of symbols

Symbol

Meaning

Forbidden

It means high potential risk, if can’t avoid, which can result in seriously damaging

to equipment or even hurting people.

Alarm

It means medium or low potential risk, if can’t avoid, which can result in slightly

or moderately damaging to equipment or hurting people.

Attention

It means potential risk, if ignore this manual, which can result in damaging the

equipment, losing all the data or some unpredictable results.

Tips

It means can help you solve some problem or save your time.

Explanation

It means additional information, which emphasizes and supplements the main

part of manual.

Modification record

Modification record accumulates each updated descriptions of this archive. The newest updated

archive includes all the updated contents of the old version.

Copyright © WUHAN AU3TECH TRADING CO., LTD

3

SC1000 Fiber Laser Cutting CNC System User’s Manual Version:V1.00

2017 年3月27 日

Version V1.00(2017-5)

Copyright © WUHAN AU3TECH TRADING CO., LTD

4

SC1000 Fiber Laser Cutting CNC System User’s Manual Version:V1.00

2017 年3月27 日

Content

Preface...........................................................................................................................................2

Introduction .................................................................................................................................2

Readers ......................................................................................................................................2

The meaning of symbols .............................................................................................................2

Modification record......................................................................................................................2

1 Introductions................................................................................................................................6

1.1 Introduction of products.........................................................................................................6

1.2 UI and descriptions................................................................................................................6

2 0perations....................................................................................................................................9

2.1 Quick actions.........................................................................................................................9

2.1.1 Operation flowchart.........................................................................................................9

2.1.2 Graphic importing/drawing ..............................................................................................9

2.1.3 Graphic processing.........................................................................................................9

2.1.4 Cutting tracts.................................................................................................................11

2.1.5 Cutting process setting..................................................................................................12

2.1.6 Checking before cutting ................................................................................................13

2.1.7 Cutting ..........................................................................................................................14

3 Functions...................................................................................................................................17

3.1 Tittle bar..............................................................................................................................17

3.2 Tool option...........................................................................................................................17

3.2.1 Start..............................................................................................................................17

3.2.2 Draw.............................................................................................................................19

3.2.3 System analysis............................................................................................................29

3.2.4 Advanced......................................................................................................................32

3.3 View section........................................................................................................................39

3.4 Running control option.........................................................................................................40

3.4.1 Running control.............................................................................................................40

3.4.2 Running parameters......................................................................................................42

3.5 Message bar........................................................................................................................43

Copyright © WUHAN AU3TECH TRADING CO., LTD

5

SC1000 Fiber Laser Cutting CNC System User’s Manual Version:V1.00

2017 年3月27 日

3.6 Layer parameters option......................................................................................................44

3.7 Status bar............................................................................................................................47

4 Warning and exceptions handling ..............................................................................................48

4.1 System alarm and descriptions............................................................................................48

4.2 Normal exceptions and handling..........................................................................................50

4.2.1 System communication exceptions...............................................................................50

4.2.2 Reposition exceptions...................................................................................................52

4.2.3 Pulse equivalent setting ................................................................................................53

4.2.4 Fly-cutting debugging....................................................................................................53

Copyright © WUHAN AU3TECH TRADING CO., LTD

6

SC1000 Fiber Laser Cutting CNC System User’s Manual Version:V1.00

2017 年3月27 日

1Introductions

1.1 Introduction of products

SC1000 is a flat fiber laser cutting CNC system software which includes graphic drawing and editing,

cutting process dealing, cutting process controlling, system monitoring, components monitoring and

debugging, and so on.

Features:

1) Operations are simple but functions are powerful.

Developed based on RIBBON framework, software is not only beautiful but also easy to operate.

UI design is more humanize, which is easier to use without training.

With powerful CAM functions based onAUTOCAD design, support graphic import, graphic drawing,

graphic editing, and graphic transformation, graphic optimized and so on.

Intelligent capturing, which makes drawing more convenient and accurate.

Unique properties option design, which helps user to design the cutting graphic more easily.

Support various sort methods, auto sort can recognize the film inside or outside the graphic to make

sure the path planning optimized.

Powerful lead line function, support various ways to lead line, auto added suitable lead line based

on graphic nested relations. Support check/revise interfered lead line by one click.

2) Complete cutting process, debugging easily

Support all kinds of cutting process: Section drill, gradual drill, 3 stages drill, cutting with film, fix

height cutting, and predrill and so on.

Support laser’s power/frequency adjusted with speed, to decrease or avoid the problem of firing

corners when cutting carbon steel.

Support multilayer cutting or marking, and other sorts of processing ways.

Support micro-joint, gap, over-cutting, bridge, kerf-compensation and so on.

Powerful material database, which can save all sorts of material cutting process.

Support complex functions: Edge seeking, fly-cutting and so on.

Support breakdown position tracking/forward/backward and so on.

3) Rea-time alarm, stable and reliable.

Support running error measurement, it can check the error between running orbit and graphic error.

Real-time alarming the status of capacitive height controller, laser, gas and other equipment, make

sure the security during cutting.

More than 50 different kinds of alarms, to secure the equipment in whole aspect, avoid user’s wrong

operation.

1.2 UI and descriptions

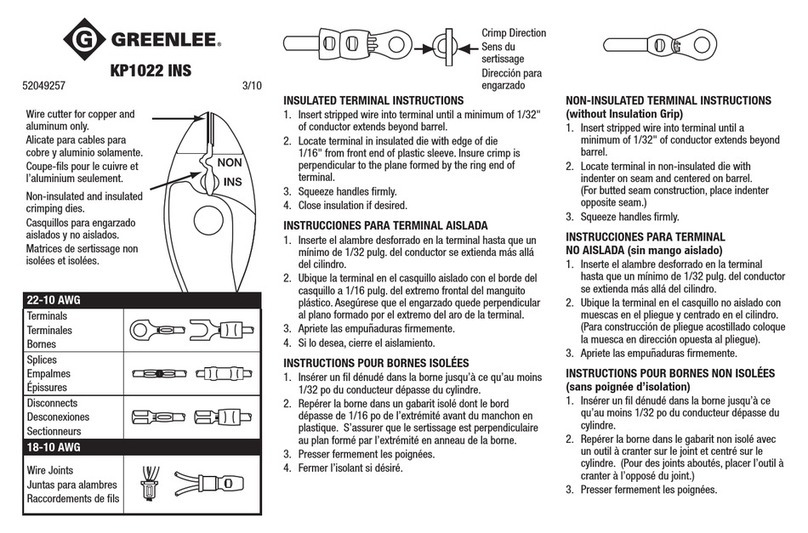

Graphic 1-1 UI

Copyright © WUHAN AU3TECH TRADING CO., LTD

7

SC1000 Fiber Laser Cutting CNC System User’s Manual Version:V1.00

2017 年3月27 日

UI design is very clear, from up to down: title option, tool option, alarm option, view option, running

control option, message bar, graphic parameters option, and status bar. The functions of each section

shows as below:

Name

Functions

Remark

Tittle bar

Display software’s name and version number.

Tool option

Mainly collects the tools needed for software

operation, it has four submenu:

START/DRAW/SYSTEM

ANALYSIS/ADVANCED. User can do graphic

drawing, graphic editing, graphic

transformation, adding lead line, monitoring

running status, configuration machine tool.

Alarm bar

Display the current system alarm.

Alarm will be displayed in

pop-up window, and once

the alarm is cleared, the

pop-up window will be

gone.

View section

Graphic drawing/displaying section, machine

tool’s width displaying section. (机床幅面显示

区).

Running control

option

Run all kinds of cutting actions through

software.

Message bar

Display the current running status in scrolling.

Layer properties

Set up layer properties such as layer process,

Copyright © WUHAN AU3TECH TRADING CO., LTD

8

SC1000 Fiber Laser Cutting CNC System User’s Manual Version:V1.00

2017 年3月27 日

option

graphic transformation and so on.

Running status

Display the running status, running location,

cutting speed and so on.

Copyright © WUHAN AU3TECH TRADING CO., LTD

9

SC1000 Fiber Laser Cutting CNC System User’s Manual Version:V1.00

2017 年3月27 日

20perations

2.1 Quick actions

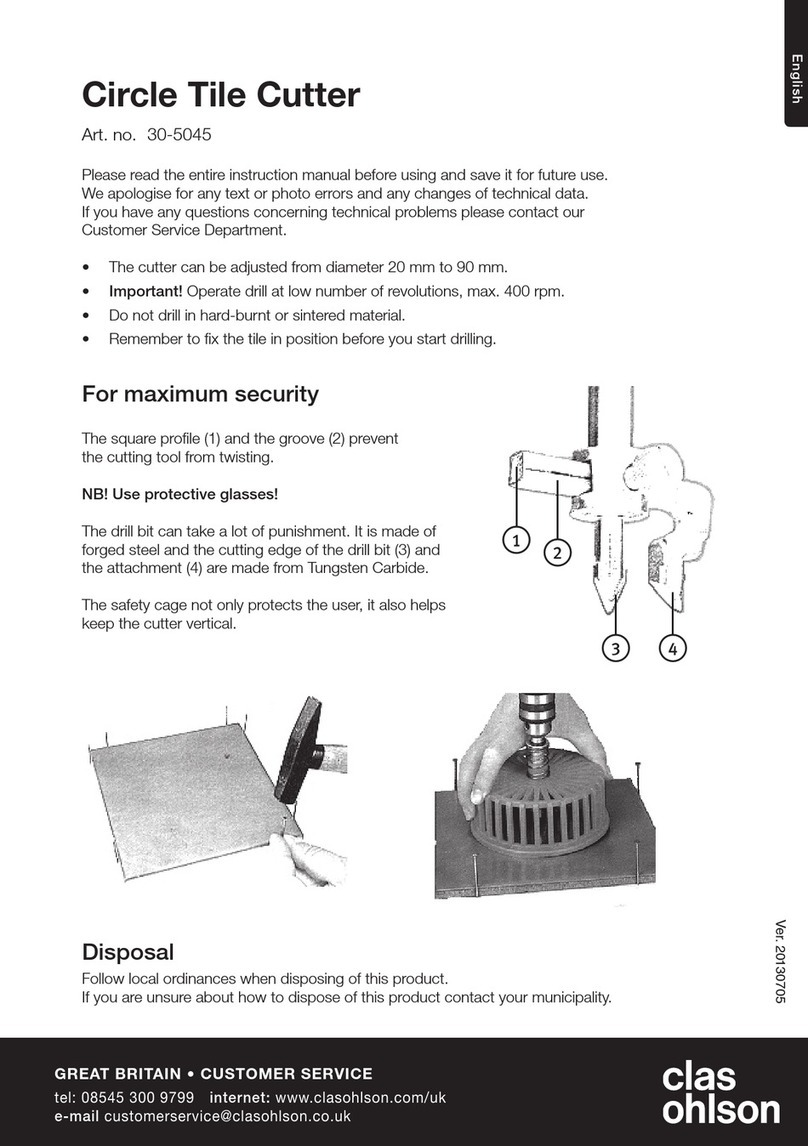

2.1.1 Operation flowchart

2.1.2 Graphic importing/drawing

After start the software, user can import the file according to his needs or he can draw it by the

drawing tool in the software.

Choose “START”—>“Open”, import the cutting file.

Choose “New”can build a new view section, user can draw any parts he need when cutting.

2.1.3 Graphic processing

Before importing the cutting file, user can set up all the conditions he needs, including whether to

auto remove minimal graphics, or whether to auto remove duplicate lines and so on.

Choose “ADVANCED”—>“Options”, select the options as below:

Graphic

import/drawing Graphic dealing Path planning

Cutting process

setting

Checking before

cutting

Cutting

Copyright © WUHAN AU3TECH TRADING CO., LTD

10

SC1000 Fiber Laser Cutting CNC System User’s Manual Version:V1.00

2017 年3月27 日

After importing/ newly building the file, user can revise the file if they need.

1、Choose in tool option “DRAW”,select suitable tool to revise the graphic: Zoom in/out in proportion,

rotate, mirror, align, array, group, nest, merge, split, smooth, unload, chamfer, chamfer R,

refactor, fill circle.

2、Or use graphic transformation to adjust the graphics.

Copyright © WUHAN AU3TECH TRADING CO., LTD

11

SC1000 Fiber Laser Cutting CNC System User’s Manual Version:V1.00

2017 年3月27 日

Tips

User can quickly revise the selected graphics in its coordinate, size, alignment point, and cutting

sort and so on in property option. It’s also very convenient for user to adjust the graphics using these

tools.

Layer parameters can be used to revise the parameters of the selected graphic: uncut, short no-lift,

unfollow, direct, section drill, gradual drill, fix height drill, with film, keep gas on, and so on.

User can set chamfer R for rectangle.

2.1.4 Cutting tracts

After adjusting the cutting graphic, then comes path planning, including the lead line setting,

micro-joint, gap, home ref, path start, reverse, inside, outside.

Copyright © WUHAN AU3TECH TRADING CO., LTD

12

SC1000 Fiber Laser Cutting CNC System User’s Manual Version:V1.00

2017 年3月27 日

Tips

Support auto/manual adding lead line, and checking the interfered lead line.

Support various sort methods, please select by clicking “Sort”. Auto-recognize the film

inside/outside the graphic when sorting.

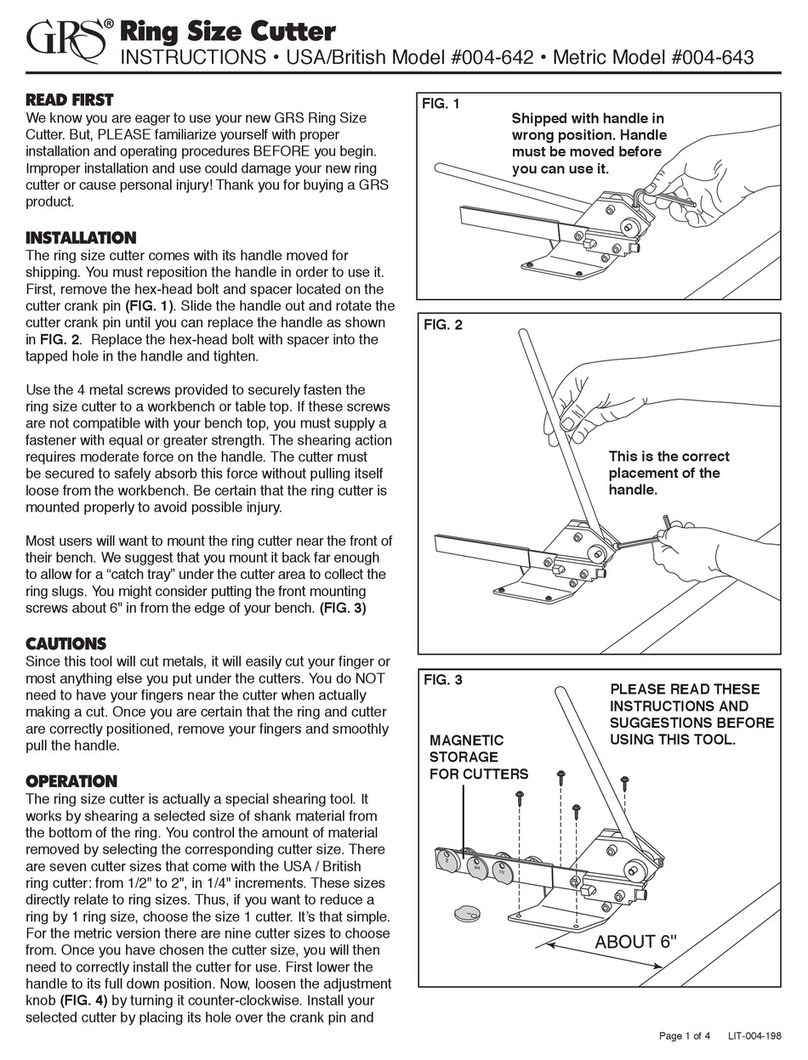

2.1.5 Cutting process setting

After checking the path planning, please set up the cutting process. SC1000 supports multi-layers: 1

background layer, 10 cutting layers. And the parameters of each layer can be set up separately

according to user’s needs. Click the “Layer X” in the graphic properties to set up the layer parameters,

as below:

Copyright © WUHAN AU3TECH TRADING CO., LTD

13

SC1000 Fiber Laser Cutting CNC System User’s Manual Version:V1.00

2017 年3月27 日

User can set up different parameters to achieve the best situation of cutting: cutting ways, cutting

speed, cutting power, gas type/pressure, up height and so on.

2.1.6 Checking before cutting

Before you really start cutting, please check the cutting graphics and path planning to make sure

everything has been settled properly.

1) Please check the cutting graphic in these aspects: Size, lead line, sort, unclosed curve, minimal

graphic, similar graphic.

2) SC1000 can measure the size of the graphic and check lead line ,

it can also auto-remove the interfered lead line. It shows the unclosed graphic. You can

choose unclosed curve/minimal graphic/similar graphic in “Select”.

3) Please check the path planning in these aspects: Cutting frame, running tracks and so on by

Copyright © WUHAN AU3TECH TRADING CO., LTD

14

SC1000 Fiber Laser Cutting CNC System User’s Manual Version:V1.00

2017 年3月27 日

setting parameters in running control option.

4) Click “Edge seek”,SC1000 will order the machine to run along the graphic frame, so user can

check whether if the workpiece is inside the frame or not so that user can adjust the place of the

graphic/workpiece.

5) Click “Sim”, SC1000 will auto-simulate the cutting track, and the simulation speed can be adjusted.

2.1.7 Cutting

The running control must be done on the real machine. So the motion control card must

communicate with SC1000 normally, or the relevant buttons will turn gray and can’t be selected.

Copyright © WUHAN AU3TECH TRADING CO., LTD

15

SC1000 Fiber Laser Cutting CNC System User’s Manual Version:V1.00

2017 年3月27 日

The meaning of each button shows as below:

Name

Functions

Remark

Start

Start cutting.

Continue after

pause

User can continue the cutting process after

pause cutting.

After start

Pause

Pause cutting, SC1000 will reserve the

current cutting information.

Stop

Stop cutting.

Dry Cut

Cutting without laser.

If user wants Z axis to follow when

dry cut, please select “Enable

Follow When Dry Cut” in “Run

Parameters”.

Frame

Cutting the frame of the selected graphic

Make sure the cutting graphic is

Copyright © WUHAN AU3TECH TRADING CO., LTD

16

SC1000 Fiber Laser Cutting CNC System User’s Manual Version:V1.00

2017 年3月27 日

without laser.

inside the workpiece.

Sim

Simulate the cutting process without laser.

BreakPt

SC1000 will auto locate the breakpoint

after pause/stop.

Backward

SC1000 will go backward some distance

after pause/locate the breakpoint.

User can set up the backward

speed/distance.

Forward

SC1000 will go forward some distance

after pause/locate the breakpoint.

User can set up the forward

speed/distance.

Loop

Mainly to cut the same graphic repeatedly.

User can set up the time and

spacing distance

Copyright © WUHAN AU3TECH TRADING CO., LTD

17

SC1000 Fiber Laser Cutting CNC System User’s Manual Version:V1.00

2017 年3月27 日

3Functions

3.1 Tittle bar

Tittle bar shows SC1000’s logo and the version. User can check whether the version is the newest

one, and if not, please download on our website: www.au3tech.com

3.2 Tool option

3.2.1 Start

3.2.1.1 File

There are five functions in file part: “New”, “Open”, “Import”, “Save”, “Save as”.

1) :Build a new view section, the former graphic will be covered and SC1000 will ask the user

whether if to save the old graphic or not to avoid false operation and lose all the graphics in the old

view section.

2) :Open a new graphic, and the former graphic on the view section will be covered by the

graphic user just opened.

3) :Import a graphic user already has, and the former graphics on the view section will be

covered by the graphics user just opened.

4) : Save the graphics on the view section.

5) : Save the graphics on the view section in “.chf” or “.dxf” / at anywhere you want on the

computer. User can also choose to export to sheets.

Copyright © WUHAN AU3TECH TRADING CO., LTD

18

SC1000 Fiber Laser Cutting CNC System User’s Manual Version:V1.00

2017 年3月27 日

Tips

Click the dropdown menu of “Open” to check the file list recently opened, and user can easily find

the file he opened before.

3.2.1.2 Initialization

The initialization part collects all the functions user will be use at the beginning when all the

equipment power on: “Go origin”, “Edge seek”, “Cancel edge seek”, “Clear warning”.

1) :After Z axis go back to origin, X axis and Y axis go back to origin of machine at the same

time (default). Or user can choose “Only Z follower” (only Z axis go origin), “Only X” (only X

axis go origin), “Only Y” (only Y axis go origin).

Attention

Before axis go origin, please make sure the parameters of direction/type/speed and other

parameters have already been set. Make sure “Go origin” button works properly and no obstacles

on the workpiece sheet. Or it can possibly result in damaging to machine or even hurting people.

2) :According to the real place of the workpiece sheet to revise the coordinate of SC1000, so

that user can make sure the cutting graphics are inside the workpiece sheet without moving the

sheet. Click the “Edge seek” button, UI shows as below:

Copyright © WUHAN AU3TECH TRADING CO., LTD

19

SC1000 Fiber Laser Cutting CNC System User’s Manual Version:V1.00

2017 年3月27 日

User can use the red light of laser from cutting head to seek one point along the edge of X axis and

mark “P1”. Then move to another point along the edge of X axis and mark “P2”. After SC1000

auto-calculate the rotation angle, it’ll revise the coordinate accordingly. Click the “OK” button, then “Edge

seek” is over successfully.

“Cancel edge seek”: after finish edge seek, the coordinate will rotate accordingly. And if you want

SC1000 go back to the original coordinate, just click “Cancel edge seek”.

3) :System alarm has two different kinds of alarms: auto-clear warning and manual clear

warning. For example, “Servo alarm” is manual clear warning, after clear all the problems of servo

equipment, user can only clear the warning of SC1000 by clicking “Clear warning” button so that to

make sure the safety of user and the equipment.

3.2.1.3 Help

1) :Click “Help”, user can check SC1000 user’s manual.

2) :Click “About” to check the information of version.

3.2.2 Draw

“View”collects all the functions related to graphic editing/path planning, user can easily design the

cutting graphics and process he needs.

3.2.2.1 View

Icon

Name

Function

Contour Select

User can select one/all graphics.

Vertex Edit

User can edit the vertex of the selected graphic.

View Move

User can move the view section by pressing the Mouse left.

Copyright © WUHAN AU3TECH TRADING CO., LTD

20

SC1000 Fiber Laser Cutting CNC System User’s Manual Version:V1.00

2017 年3月27 日

Zoom in

User can zoom in the graphic in the view section.

Zoom out

User can zoom out the graphic in the view section.

Zoom Reset

User can restore the size of the graphic in view section to the original

size.

Revoke

Revoke the latest operation.

Redo

Redo the latest operation.

Select

User can choose “Select All”, “Invert Selection”, “Select unclosed

curve”, “Select graphics smaller than”, “Select similar curve”.

Show box for

graphics

User can click here to show the box of graphic on view section.

Show unclosed

curve as red

User can click here to show unclosed curve as red.

Show index

User can click here to show index.

Show path start

User can click here to show path start.

Show path direction

User can click here to show path direction.

Show move path

User can click here to show move path.

3.2.2.2 Draw

“Draw” part collects all the functions related to drawing, which based on AUTOCAD, user can

easily design any graphic he want.

1) :Draw line. Click Mouse Right to finish the current drawing by selecting “End Draw”.

2) :Draw circle/circular arc/ellipse. User can choose “Point Circle”, “Point Arc”, “Scan

Arc”, and “Ellipse”through dropdown menu.

3) :Draw rectangle/rounded rectangle/polygon/star through dropdown menu.

4) :Input text. Support various ways of typing text, and user can set up the parameters of text,

Other manuals for SC1000

1

Table of contents

Other Au3Tech Cutter manuals