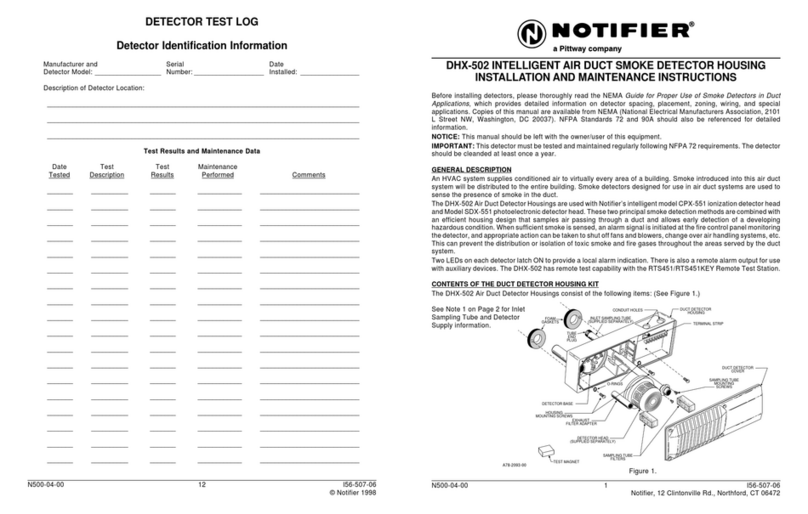

N500-59-00 2 I56-1250-05R

HPX-751 is not designed to operate in explosive envi-

ronments.

Wiring Instructions

All wiring must be installed in compliance with the National

Electrical Code, applicable local codes, and any special

requirements of the Authority Having Jurisdiction. Proper

wire gauges should be used. The installation wires should

be color-coded to limit wiring mistakes and ease system

troubleshooting. Improper connections will prevent a sys-

tem from responding properly in the event of a re.

Remove power from the communication line before

installing detectors.

All wiring must conform to applicable local codes, ordi-

nances, and regulations.

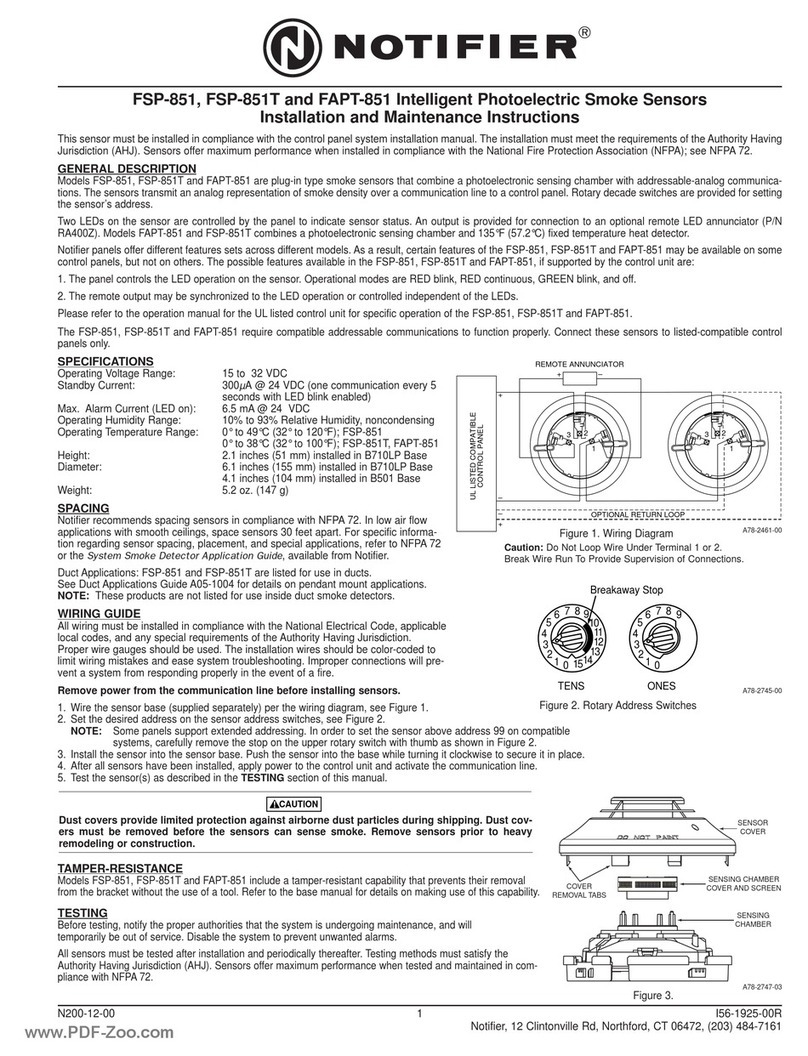

1. Wire the sensor base per the wiring diagram, please

see Figure 1.

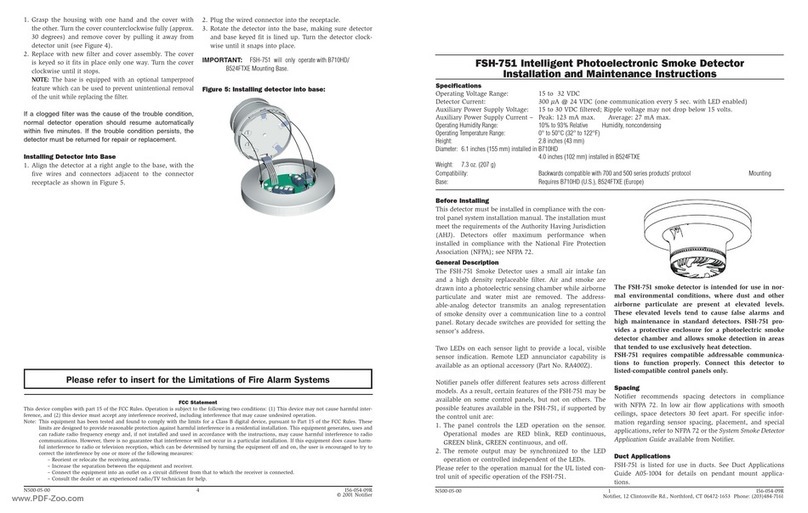

2. Set the desired address on the sensor address switch-

es, please see Figure 2.

3. Insert 5-wire connector on mounting base into 5-pin

connector on the unit. Install the detector into the sen-

sor base. Push the detector into the base while turning

it clockwise to secure it in place. (Please see Figure 5

and INSTALLING DETECTOR INTO BASE on page 4

for specic directions.

4. After all detectors have been installed, turn on the aux-

iliary power supply, then apply power to the control unit

and activate the communication line.

5. Test the detector(s) as described in the TESTING sec-

tion of this manual.

Dust cover must be removed before the detector can

sense smoke.

Testing

Before testing, notify the proper authorities that the system

is undergoing maintenance, and will temporarily be out of

service. Disable the system to prevent unwanted alarms.

All detectors must be tested after installation and periodi-

cally thereafter. Testing methods must satisfy the Authority

Having Jurisdiction (AHJ). Detectors offer maximum per-

formance when tested and maintained in compliance with

NFPA 72.

The sensor can be tested in the following ways:

A.

Functional: Magnet Test (P/N M02-04-01 or M02-09-

00)

This detector can be functionally tested with a test mag-

net. The test magnet electronically simulates smoke in

the sensing chamber, testing the detector electronics

and connections to the control panel.

1. Hold the test magnet in the magnet test area as

shown in Figure 3.

2. The detector should alarm the panel. Two LEDs on

the detector are controlled by the panel to indicate

sensor status. Coded signals, transmitted from the

panel, can cause the LEDs to blink, latch on, or latch

off. Refer to the control panel technical document-

ation for detector LED status operation and expected

delay to alarm.

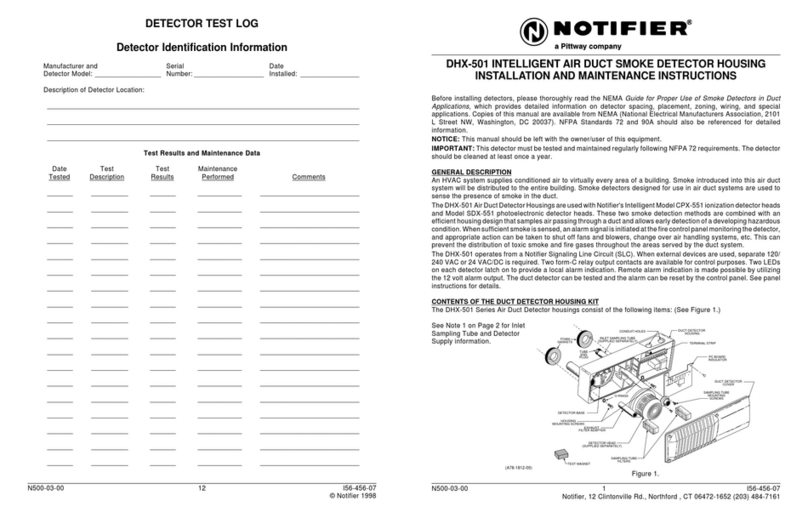

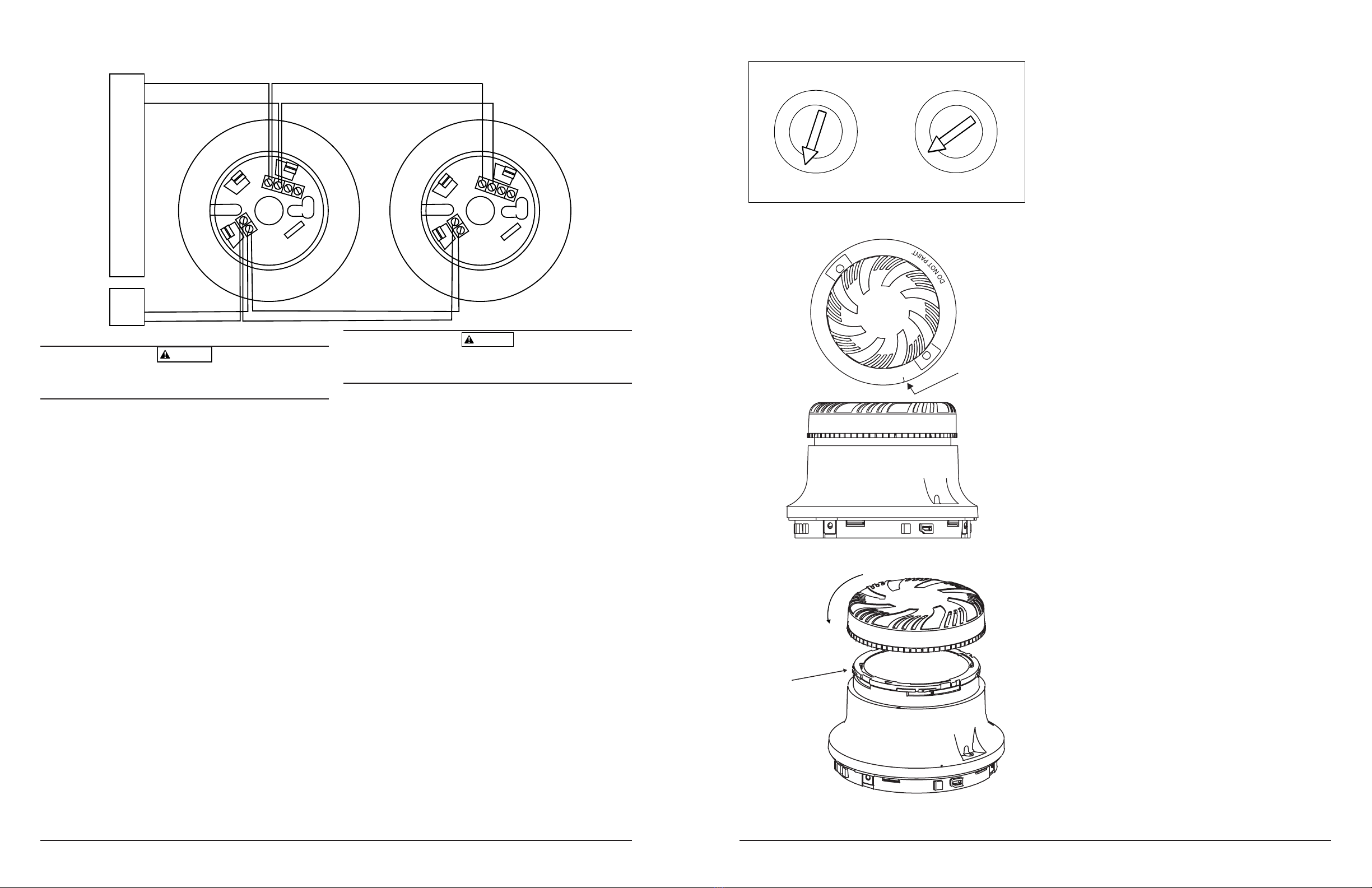

Figure 1. Wiring diagram:

NOTIFIER CONTROL PANEL

AUX.

POWER

SUPPLY

+

+

–

–

AUX+

AUX–

AUX+

AUX–

2(–) 3(RA) 4(S)

1(+)

1(+)

2(–) 3(RA) 4(S)

N500-59-00 3 I56-1250-05R

A78-2460-00

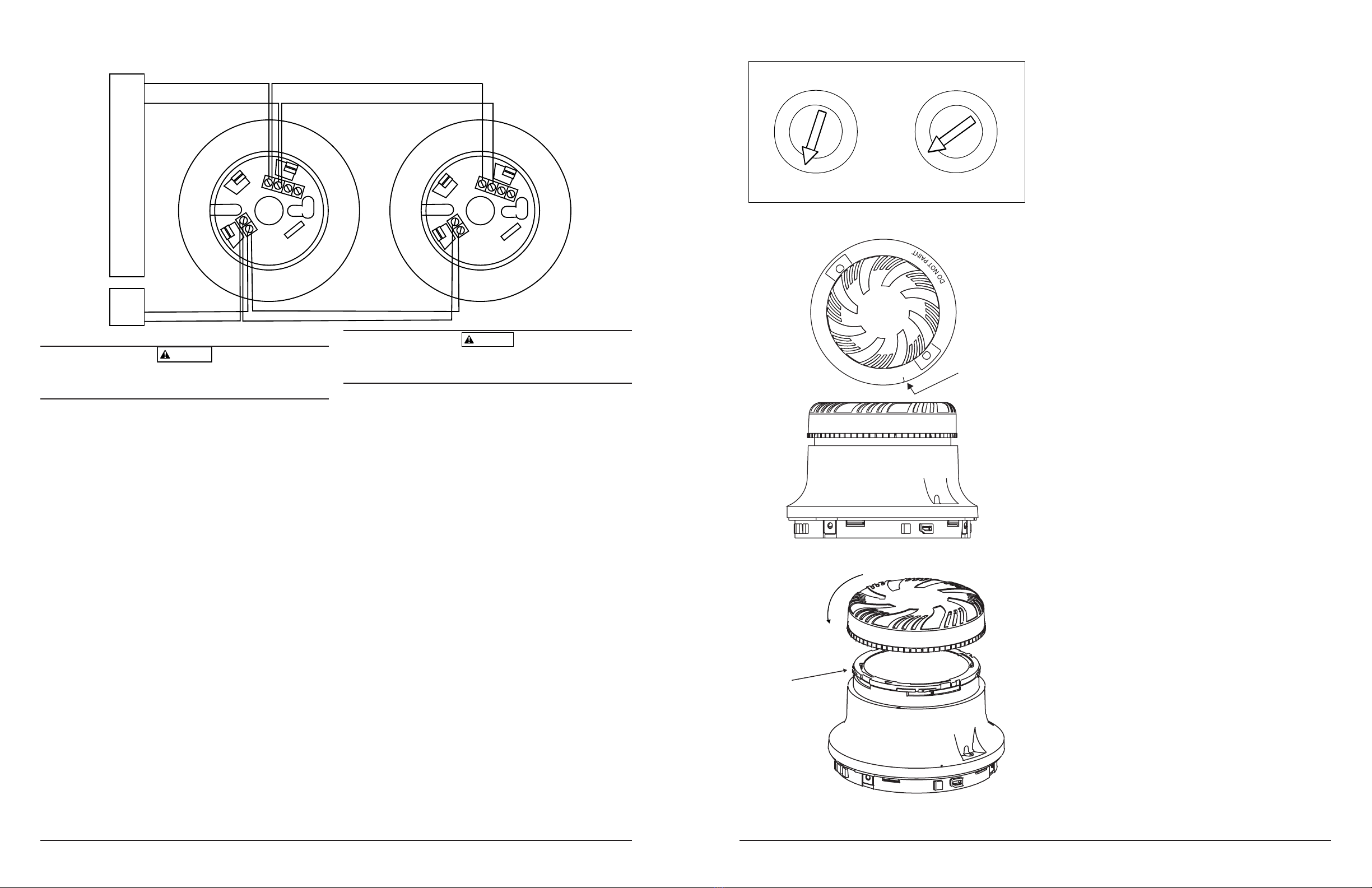

Figure 2. Rotary decade address switches:

Figure 3. Test magnet position:

Figure 4. Replacing the lter cover:

B. Smoke Entry: Aerosol Generator

Aerosol generators for smoke entry testing are available

from a number of third party manufacturers (e.g., Gem-

ini Scientic). Following the manufacturer’s instructions,

apply aerosol until the panel alarms.

A detector that fails any of these tests should be retested.

If the detector still fails any test, have its lter replaced

(see instructions below) and retested. Finally, if the de-

tector continues to fail after replacing the lter, it must be

returned for repair or replacement.

When testing is complete, restore the system to normal

operation and notify the proper authorities that the system

is back in operation.

Cleaning

The unique design of the HPX-751 eliminates the need for

typical detector cleaning. The only maintenance necessary

is replacing the lter, which is signaled by a trouble con-

dition at the panel (see below).

The HPX-751 smoke detector has been designed to max-

imize the amount of time before maintenance is required.

The detector utilizes a replaceable lter that may become

clogged over time. The detector monitors itself to insure

that the lter has not become clogged. Because environ-

mental conditions can vary signicantly, the amount of time

before maintenance could vary signicantly as well. To fully

understand the maintenance requirements of the HPX-751

in its installed location, it is recommended that the following

test program be conducted.

1. Install the HPX-751 detector in the desired location.

2. Connect the detector to the re alarm control panel.

3. Maintain a record for at least 90 days of any mainte-

nance performed on or required by the detector.

4. At the end of the test period, use the record to develop

and schedule maintenance. The HPX-751 should be

serviced at regular intervals to insure that the re alarm

system provides continuous protection.

Replacing the Filter

IMPORTANT:

When the lter becomes too clogged to draw ade-

quate air into the unit, power is automatically cut

from the detector, sending a trouble signal to the

re control panel. After 5 minutes, power is re-

stored to the detector for 72 hours. After 72 hours,

power is cut again and the detector will remain off-

line until the lter is replaced.

Note: The unit has two lters. The replaceable lter is in-

side the cover. A permanent lter is mounted to the unit.

Alignment marks are

provided on the cap

and top of the perma-

nent lter.

Caution: Do Not Loop Wire Under Terminal 1 or 2.

Break Wire To Provide Supervision of Connections.

Cover is keyed to

fit into 4 matching

size slots.

www.PDF-Zoo.com