SuperNova2 – Disassembly

STEPS DESCRIPTION IMAGE

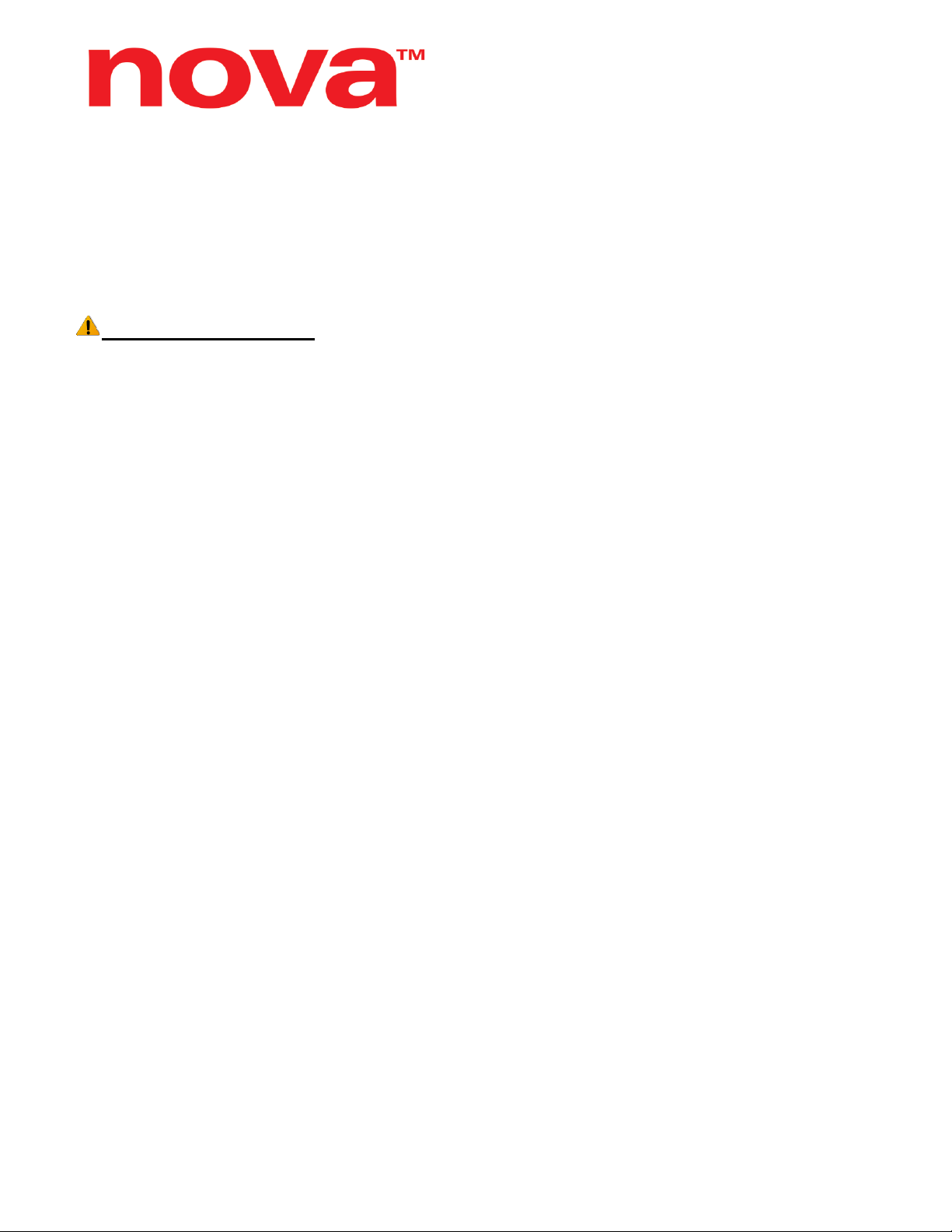

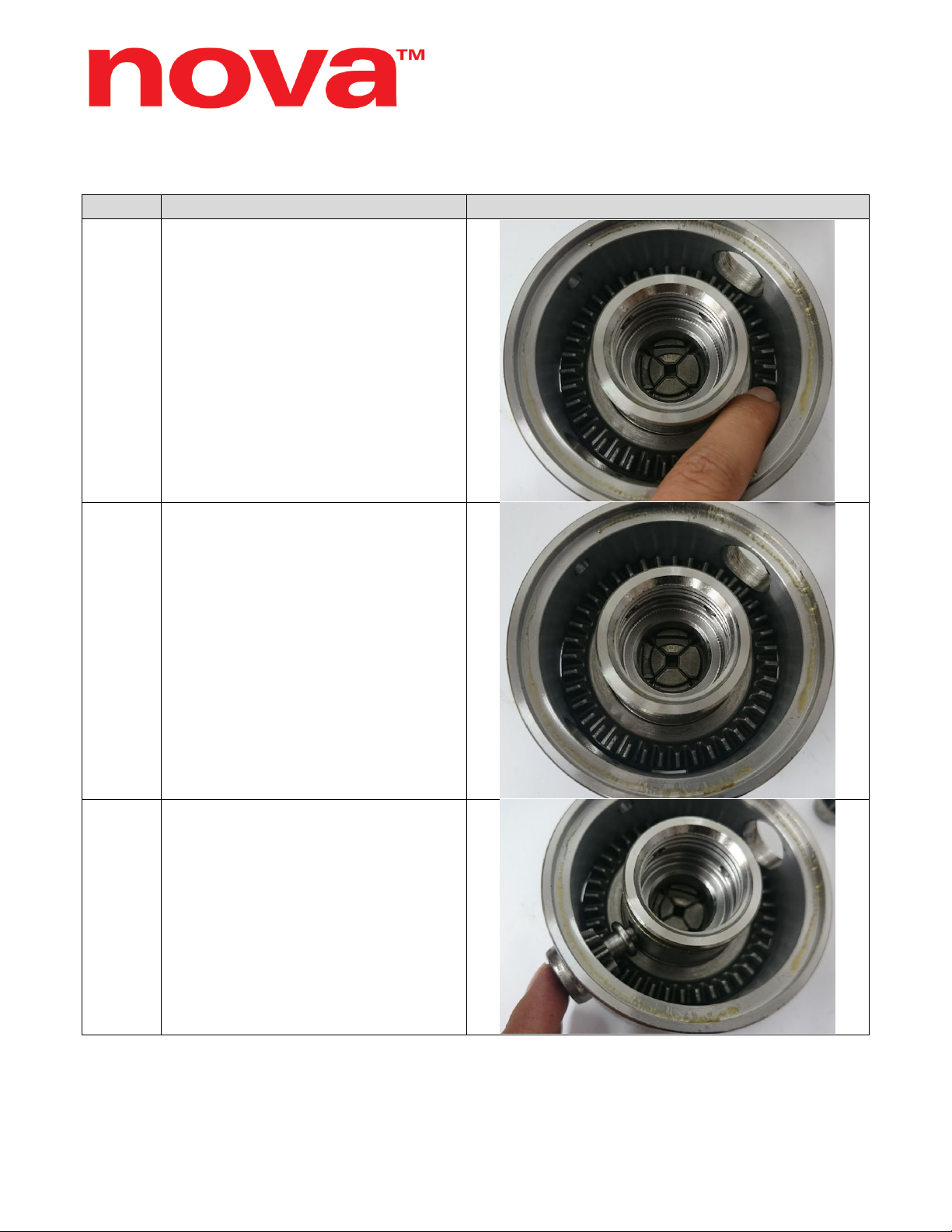

3.

Once retaining ring is removed, the

backing plate can be removed from

chuck body.

Option 1: When removing the

backing plate, use two flat-head

screw drivers to lift it straight out from

the chuck body.

Option 2: Or thread an insert into the

chuck (if chuck is an Insert type – not

direct thread) and use a soft mallet to

give it a sharp impact. This would

release the backing plate from the

chuck body.

NOTE: This step might be tricky as

the backing plate can be stuck onto

the chuck body with old lubricants.

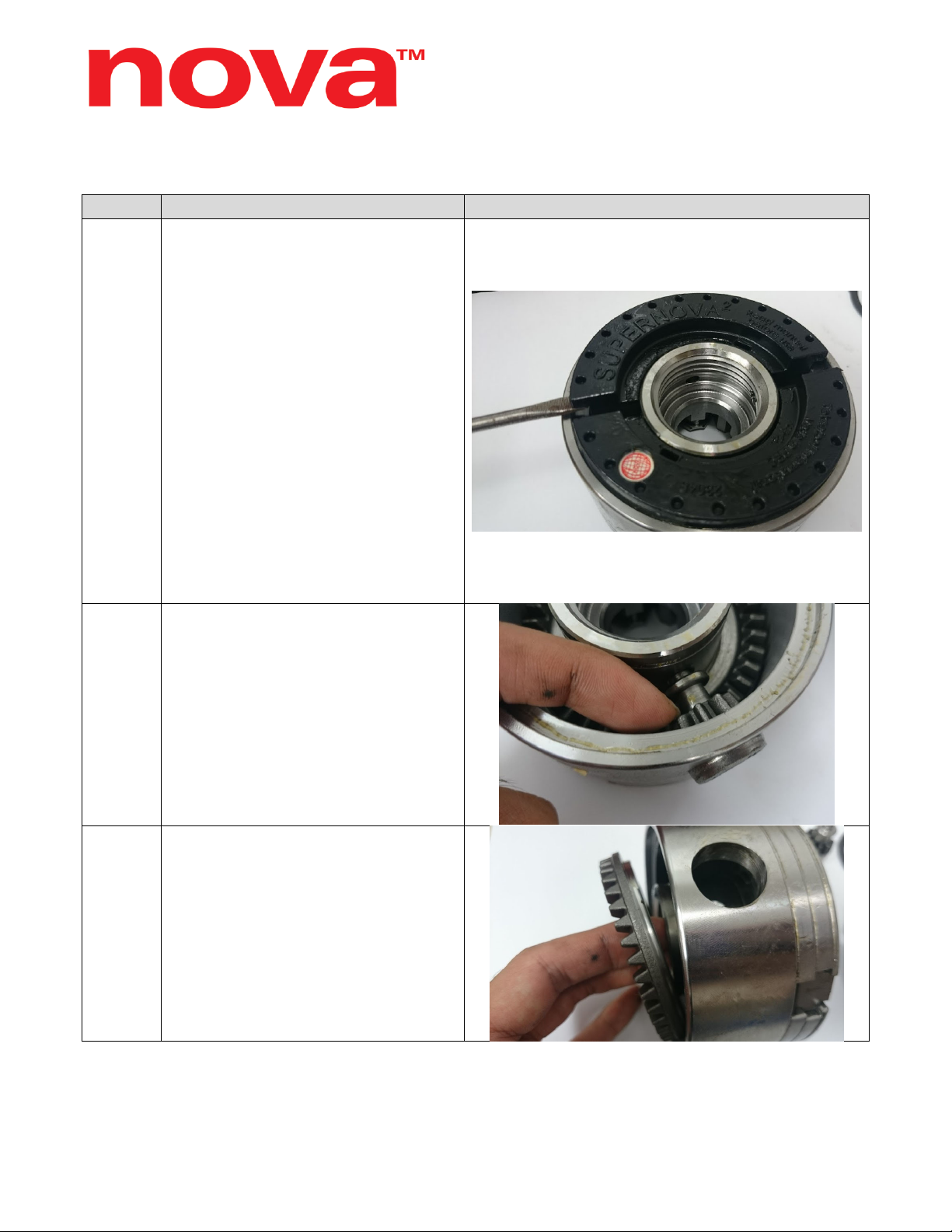

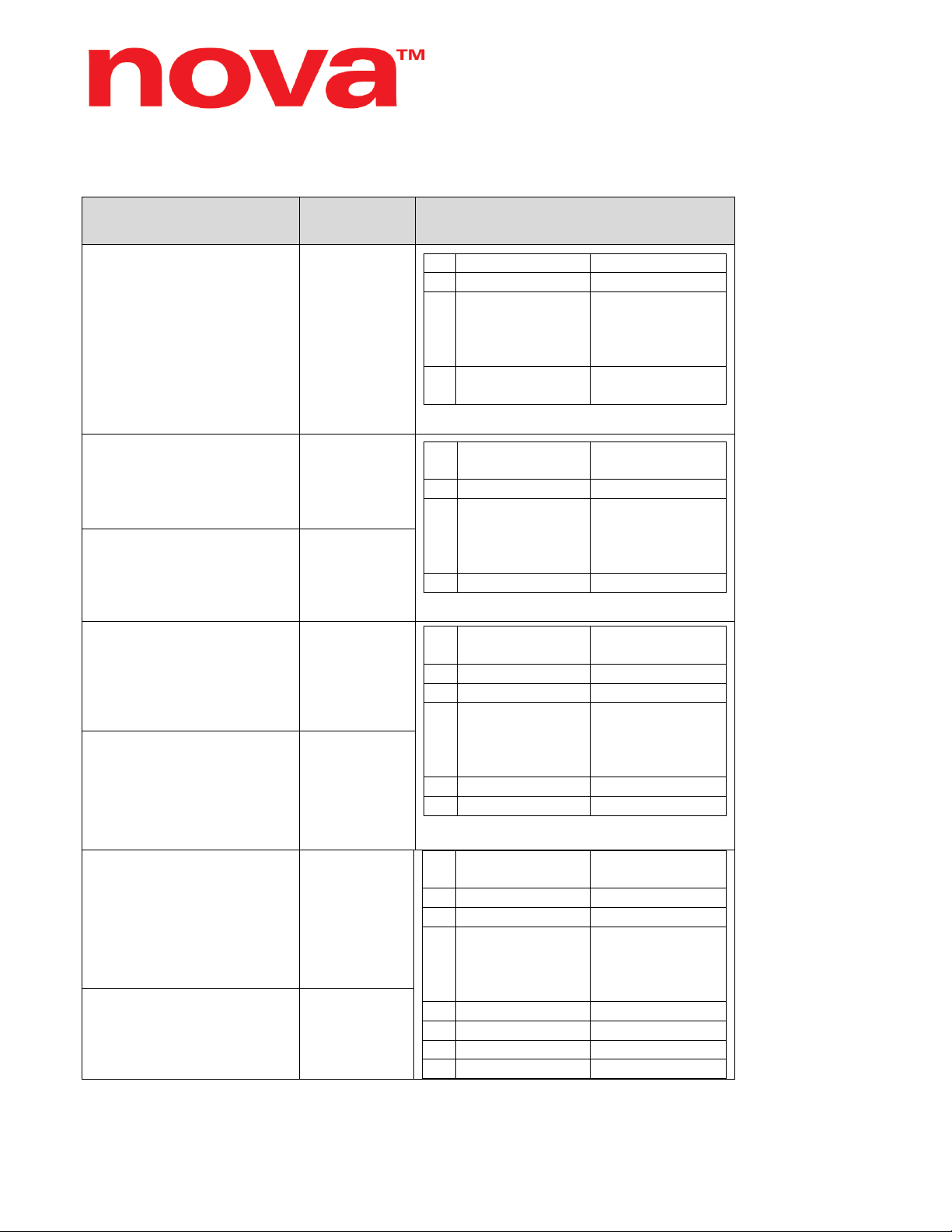

4.

Remove the pinion gears by pushing

them outwards.

This may require a bit of force as dirt

can get caught in the gaps.

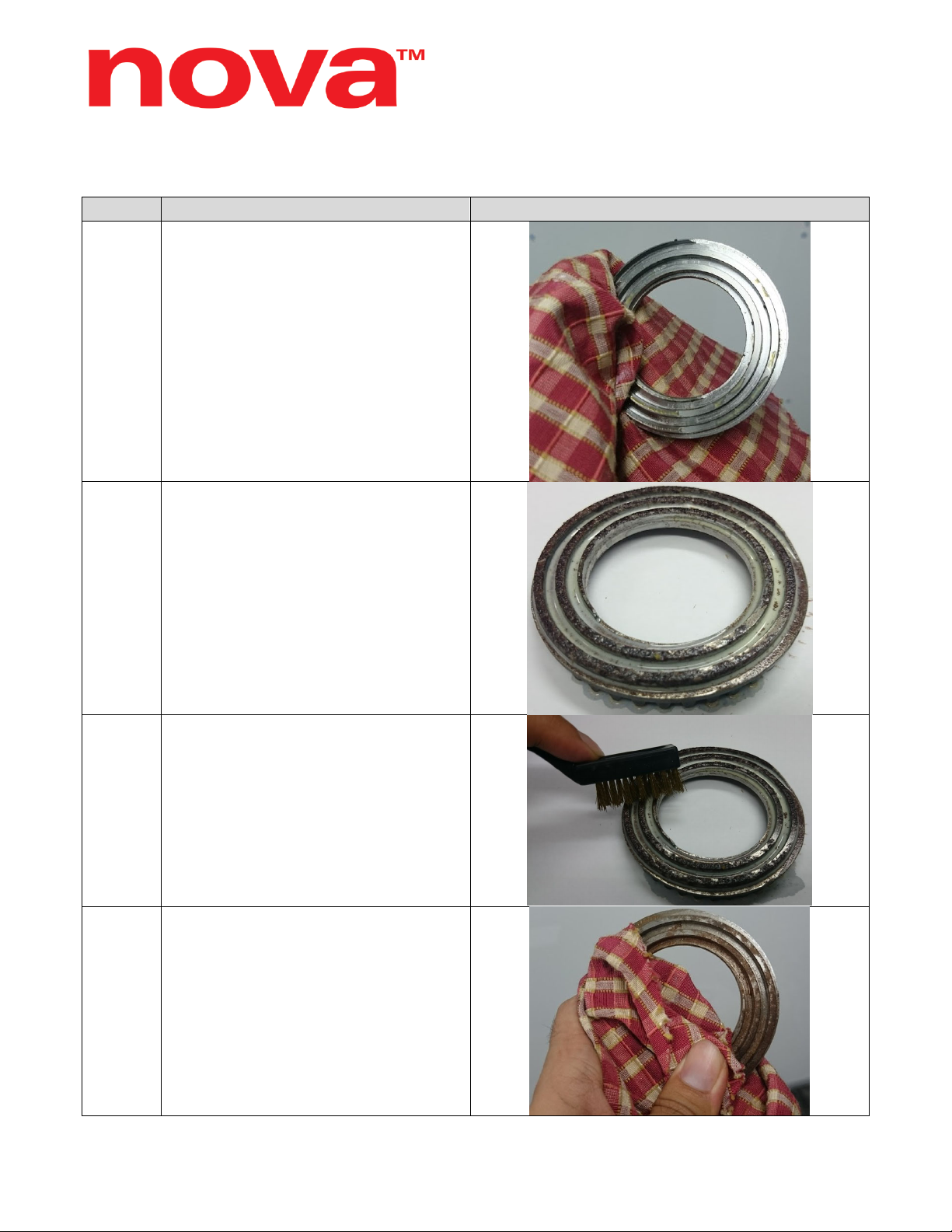

5.

Remove the scroll ring from the

chuck body. This should just slide out

but, if stuck, might need a bit of

tapping.

Continues to next page…

p.13