Novalynx 255-704-B User manual

DOC 255-704-B UM 20210419

255-704-B

User Manual

255-704-B Evaporation Logger

255-704-B Evaporation Logger

with

255-100 Analog Output Evaporation Gauge

Phone (530) 823-7185

NovaLynx Corporation

255-704-B Page 2 April 2021

Receiving and Unpacking

Carefully unpack all components and compare to the packing list. Notify NovaLynx Corporation

immediately concerning any discrepancy. Inspect equipment to detect any damage that may have

occurred during shipment. In the event of damage, any claim for loss must be filed immediately with

the carrier by the consignee. Damages to equipment sent via Parcel Post or UPS require the consignee

to contact NovaLynx Corporation for instructions.

Returns

If equipment is to be returned to the factory for any reason, call NovaLynx between 8:00 a.m. and 4:00

p.m. Pacific Time to request a Return Authorization Number (RA#). Include with the returned

equipment a description of the problem and the name, address, and daytime phone number of the

sender. Carefully pack the equipment to prevent damage or additional damage during the return

shipment. Call NovaLynx for packing instructions in the case of delicate or sensitive items. If packing

facilities are not available take the equipment to the nearest Post Office, UPS, or other freight service

and obtain assistance with the packaging. Please write the RA# on the outside of the box.

Warranty

NovaLynx Corporation warrants that its products are free from defects in material and workmanship

under normal use and service for a period of one year from the date of shipment from the factory.

NovaLynx Corporation's obligations under this warranty are limited to, at NovaLynx's option: (i)

replacing; or (ii) repairing; any product determined to be defective. In no case shall NovaLynx

Corporation's liability exceed product's original purchase price. This warranty does not apply to any

equipment that has been repaired or altered, except by NovaLynx Corporation, or that has been

subjected to misuse, negligence, or accident. It is expressly agreed that this warranty will be in lieu of

all warranties of fitness and in lieu of the warranty of merchantability.

Address

NovaLynx Corporation

431 Crown Point Circle, Suite 120

Grass Valley, CA 95945-9531 USA

Phone: (530) 823-7185

Email: nova@novalynx.com

Website: www.novalynx.com

Copyright © 1988-2021 by NovaLynx Corporation

NovaLynx Corporation

255-704-B Page 3 April 2021

CONTENTS

1 FORWARD ....................................................................................................................................................................... 4

2 INTRODUCTION ............................................................................................................................................................... 4

3 SPECIFICATIONS .............................................................................................................................................................. 4

4 COMPUTER SYSTEM REQUIREMENTS ............................................................................................................................. 5

5 INSTALLATION ................................................................................................................................................................. 5

5.1 Connections ............................................................................................................................................................ 5

5.2 Float and Chain Installation .................................................................................................................................... 6

5.3 Software Installation ............................................................................................................................................... 6

5.4 Logger Settings ........................................................................................................................................................ 8

5.5 Offset Calibration (optional) ................................................................................................................................. 11

5.6 Field Calibration (optional) ................................................................................................................................... 11

6 OPERATION ................................................................................................................................................................... 12

6.1 Start Logging ......................................................................................................................................................... 12

6.2 Upload Data .......................................................................................................................................................... 13

6.3 Water Level Management .................................................................................................................................... 14

7 MAINTENANCE .............................................................................................................................................................. 14

8 BATTERY REPLACEMENT ............................................................................................................................................... 15

9 TEMPERATURE SENSORS (optional) .............................................................................................................................. 15

10 EVAPORATION GAUGE CALIBRATION CHECKUP ....................................................................................................... 16

NovaLynx Corporation

255-704-B Page 4 April 2021

1 FORWARD

Thank you for purchasing NovaLynx products. NovaLynx has been designing and manufacturing

weather instruments since 1988. NovaLynx represents several well-known brands of quality

manufacturers, including Gill Instruments, RM Young, Kipp & Zonen, and Vaisala. It is our hope that our

products will meet all your monitoring requirements.

2 INTRODUCTION

The 255-704-B Evaporation Logger is designed to record the output of an analog evaporation gauge

(NovaLynx 255-100). The logger displays the current water level in the evaporation pan, along with

logging status, battery status, and memory consumption. The logger stores up to 1.9 million

measurements with 16-bit resolution.

The logger is protected by a waterproof enclosure that is strapped to the outside of the evaporation

gauge. The clear cover on the enclosure must be removed and a USB cable connected in order to read

data out of the logger. The PC or Mac compatible software manages the logger and includes graphing

and export functions.

Optional air and water temperature sensors can be connected to the logger to record temperature

readings along with the pan water level. The logger calculates minimum, maximum, average, and

standard deviation statistics.

3 SPECIFICATIONS

NovaLynx Corporation

255-704-B Page 5 April 2021

4 COMPUTER SYSTEM REQUIREMENTS

PC: Windows 10, 8, 7, XP

Mac: OSX Ver 10.11.x,10.10.x, 10.9.x

Java Runtime Environment (JRE): 1.7.0_17 and above (32-bit or 64-bit on Windows)

Software required: 195-BHW-KIT (Includes Software on CD and 6' USB Cable)

5 INSTALLATION

The 255-704-B Evaporation Logger and 255-100 Analog Output Evaporation Gauge are often ordered

together. When ordered at the same time, the logger is mounted on the gauge and pre-wired, saving

time for the installer.

Retrofitting the logger to an existing evaporation gauge is straightforward. The

enclosure is fitted with a large band clamp, which must be opened and passed around

the body of the evaporation gauge (photo). Adjust the height so that the logger does

not interfere with the cover of the gauge, and tighten the band.

5.1 Connections

Route the cable from the evaporation gauge into the cord grip on the bottom of the

logger enclosure and tighten the cord grip. Connect the wires to the terminal strip

provided, matching the color of the wires to the colors painted on the terminal strip.

255-100 ANALOG OUTPUT

EVAPORATION GAUGE

Top Terminal

255-704-B EVAPORATION

DATA LOGGER

USB Connector

RED (+Vreg)

WHITE (Signal)

BLACK (Gnd)

1

2

3

DWG 890-0086-02

Counter-

weight

Float Float Touching Bottom

of Evaporation Gauge

30°

White

Pointer

11:00 o'clock

NovaLynx Corporation

255-704-B Page 6 April 2021

5.2 Float and Chain Installation

The 255-100 Analog Output Evaporation Gauge measures water level in the evaporation pan by means

of a float and chain that turns a precision potentiometer housed at the top of the gauge. The sprocket

and chain must be synchronized so that the full range of the potentiometer is utilized without entering

the electrical dead band of the potentiometer.

Install the evaporation gauge according to the instructions in the user manual. Connect the gauge to

the evaporation pan but do not fill the pan with water. Level the gauge. Remove the four screws that

hold the evaporation gauge cover to the body and set the cover aside.

IMPORTANT: Be careful when removing the packing material not to hit the sprocket, because that

might damage the potentiometer. Do not attempt to remove the float from the body of the sensor.

Chain Installation Using the Pointer

1. Make sure the gauge is empty of water.

2. Turn the sprocket until the white pointer is at the

11:00 o'clock position (30 degrees to left).

3. Lift the chain until all the slack is taken up, but the

float is still resting on the bottom of the gauge. Drape

the chain over the sprocket so that the float is on the

right and the counterweight is on the left.

5.3 Software Installation

HOBOware software is required to operate the logger. The software and user manual are on the CD

provided with NovaLynx 195-BHW-KIT. The kit includes a USB cable. If your computer does not have a

CD drive, download the software and user manual here:

https://www.onsetcomp.com/products/software/hoboware/

https://www.onsetcomp.com/files/manual_pdfs/12730-AD%20HOBOware%20User%27s%20Guide.pdf

Install HOBOware_Free_Setup.exe onto the computer before connecting to the logger.

The first time HOBOware runs, the Setup Assistant feature will open to allow the following selections:

(If the Setup Assistant window does not appear, select File / Preferences / to open the HOBOware

Preferences window, then click the Setup Assistant button.)

Device Type ~ Select USB devices.

Unit System ~ Select US (inches) or SI (millimeters).

Data Assistant ~ Select Linear Scaling Assistant.

Counter-

weight

Float

Float Touching Bottom

of Evaporation Gauge

DWG 880-0002-02

30°

White Pointer

11:00 o'clock

NovaLynx Corporation

255-704-B Page 7 April 2021

Connect the logger to the computer:

1. Loosen the screws at the four corners of the clear plastic cover on the enclosure and remove

the cover.

2. The logger is magnetically attached to a metal plate fastened to the back of the enclosure. To

access the USB connector which is on the right side of the logger, pull gently on the plastic tab

protruding from the right side of the logger.

3. Connect the USB cable to the mini USB input port on the logger. Connect the other end of the

cable to the computer.

4. Look at the status ribbon at the bottom of the HOBOware program

window (below). At first, the status will indicate "No devices

connected". Within a minute, the status should update and show "1

device connected". If the logger is not detected, make sure the logger

is powered (the battery indicator is in the upper right corner of the

LCD screen). Disconnect/reconnect the USB cable.

Status Ribbon

Software Navigation:

The commonly used functions are associated with program icons. The same functions are accessible

using the drop-down menus above the icons. View the Help dropdown menu for information on using

HOBOware.

Program Icons

Launch device

Readout device

Device status

Stop device

Select device

Set default unit system

NovaLynx Corporation

255-704-B Page 8 April 2021

5.4 Logger Settings

Click the "Launch device" icon to retrieve the logger settings.

The 255-704-B Evaporation Logger has been pre-programmed to read Channel #1 as water level in the

evaporation pan. The logger will be programmed either in inches or millimeters, depending on the

order specification. The example below is in inches.

5. Please verify the settings on your logger.

6. Click the button marked "Scaling (1)…".

7. The Data Assistants window will open (screenshot, next page).

NovaLynx Corporation

255-704-B Page 9 April 2021

8. Make sure the "Ev Pan Level" series is highlighted, then click "Edit"

9. The Linear Scaling Assistant window will open. Please verify the settings on your logger.

NOTE: The generic calibration shown above does not take into account the amount of water required

to raise the float off the bottom of the gauge. If desired, an offset can be applied or a field calibration

can be performed to scale the logger to actual water depth (Section 5.5 or 5.6).

NovaLynx Corporation

255-704-B Page 10 April 2021

10. After you have verified the settings, click "Cancel" (or "Update" if changes were made) to exit

from the Linear Scaling Assistant window. Click "Done" on the Data Assistants page to close it.

Click "Cancel" to close the "Launch Logger" window.

11. Click the "Device status" icon to open the Status window (below). Note the battery level and

memory used, to ensure there is enough power and memory available for your next logging

session.

12. Set the Screen Refresh Interval to one second. You will see the evaporation gauge readings

presented in two ways:

Number 1 Voltage is the pan level expressed in volts.

Number 5 Ev Pan Level is the calibrated pan level, expressed in inches or millimeters.

Click "OK" or "X" to close the window.

NovaLynx Corporation

255-704-B Page 11 April 2021

5.5 Offset Calibration (optional)

The generic calibration (Section 5.4) does not take into account the amount of water required to lift the

float off the bottom of the gauge. Since evaporation is the DIFFERENCE between readings (typically

measured once every 24 hours), it isn't necessary to adjust the offset. However, to match the readings

to the actual water level, add the offset to each scaled measurement in the Linear Scaling Assistant.

The amount of water required to lift the float is about 1.7 inches (varies from unit to unit). To find the

actual offset for a particular unit, measure the water level in the evaporation pan (using a tape

measure) and subtract the logger's reading at that level.

1. Measure the water depth and calculate the offset:

Example: 8.00" Measured Depth – 6.30" Logger Reading = 1.7" Offset

2. Add the offset to the generic calibration values:

Value 1 Scaled: 0 + 1.7" Offset = 1.70000

Value 2 Scaled: 9.444 + 1.7" Offset = 11.14400

3. Program the new calibrations into the Linear Scaling Assistant.

5.6 Field Calibration (optional)

A two-point field calibration is easy to do provided there is an accurate way to measure the water

depth in the evaporation pan. The depth can be measured with a tape measure, ruler, hook gauge, or

by adding known amounts of water.

Connect a computer to the logger, run HOBOware, then open the Status window. In the Current

Readings section, set the Screen Refresh Interval to 1 second.

Use the calibration chart below to record your measurements:

Raw Scaled

Units: Volts Inches

Value 1: 0.00000 1.70000 (1.7" offset added)

Value 2: 2.50000 11.14400 (1.7" offset added)

NovaLynx Corporation

255-704-B Page 12 April 2021

Raw Scaled

Units:

Volts inch / mm

Value 1:

Value 2:

1. Value 1:

a. Fill the evaporation pan with approximately 5 inches of water. Allow the water to settle.

b. Observe the Number 1 Voltage measurement shown in the Current Readings window.

Record the voltage.

c. As accurately as possible, measure the depth of water in the pan. Record the level.

2. Value 2:

a. Add water to the evaporation pan until the water is approximately 8 inches deep. Allow

the water to settle.

b. Record the Number 1 Voltage measurement.

c. As accurately as possible, measure the depth of water in the pan. Record the level.

3. Close the Status window.

4. Open the Launch Logger window and navigate to the Linear Scaling Assistant window

(Section 5.4). Enter your measurements in place of the generic parameters.

5. Click "Update" to save your measurements.

6. Return to the Status screen and compare the calibrated result (Number 5 Ev Pan Level) with the

Value 2 depth measurement. They should be very close, provided the water level has not

changed.

6 OPERATION

6.1 Start Logging

Connect your computer to the logger (Section 5.3). Click the "Launch device" icon to open the logger

setup window. When ready, click the "Start" button (lower right) to start logging. The LCD display will

now show the current position of the potentiometer expressed in inches (or millimeters). Look at the

lower left corner of the LCD display and verify that the logger is "LOGGING". Disconnect the USB cable.

NovaLynx Corporation

255-704-B Page 13 April 2021

Replace the logger in the enclosure. Magnets on the back of the logger hold it in place. Press upward on

the plug that connects the evaporation gauge signal to the logger (occasionally the signal connector gets

dislodged when the logger is moved to access the USB port). Make a note of the time and date the

logger was started, along with the initial reading.

6.2 Upload Data

Connect your computer to the logger (Section 5.3). Click the "Readout device" icon. Select a file

location and filename, then click "Save". Once the file is saved the "Plot Setup" screen will open. Select

the elements you want to display in graphical and tabular form, then click "Plot".

LEFT: Plot Setup screen showing the Ev Pan Level check

box selected. The logger has three spare channels which

can be used for monitoring temperature or other

analog parameters. These channels can be selected to

plot on the same graph as the evaporation pan level, or

the file can be re-opened and selected sensors can be

plotted together.

BELOW: The current log file is shown in tabular form

and as a graph. The data can be exported (.csv format).

Refer to the HOBOware manual for additional features,

or click the Help drop-down box.

NovaLynx Corporation

255-704-B Page 14 April 2021

6.3 Water Level Management

The logger can operate for long periods of time un-attended due to its very large memory capacity.

However, other factors must be considered to ensure the evaporation station is operating properly. A

regular maintenance period should be scheduled to inspect the evaporation pan, water replacement

system, and operation of the logger and evaporation gauge.

Evaporated water must be replaced. Ideally, the water level should be maintained from 7 to 8 inches

deep (175 to 200 mm) in the evaporation pan. In practice, keeping the level between 5 and 8 inches

deep (125 to 200 mm) is adequate. Do not overfill because the potentiometer may enter the dead band

where the readings would be "floating", resulting in meaningless data.

Water replacement can be accomplished by means of a NovaLynx 255-620-A Automatic Refill System,

if a water source is available. Otherwise the station will need to be visited often enough to keep the

water level within acceptable limits.

Upload the data regularly and process the data. Water that is added either manally or automatically

must be deducted from the evaporation totals. Water added by precipitation should also be deducted.

7 MAINTENANCE

At regular intervals, inspect the following:

Check under the evaporation pan for leaks.

Inspect the pipe between the pan and the analog evaporation gauge for leaks.

Make sure the automatic refill system shuts off completely between refills.

If the optional offset calibration (Section 5.5) was performed when the logger was installed,

compare the reading on the logger with the actual water level (use a measuring stick).

Note: If the offset calibration was not done the measurements will not agree because the

generic calibration does not include an offset for the amount of water required to cause the

float to lift off the bottom of the pan.

Read the logger memory using a computer. Check the data to ensure the logger is recording

data properly.

From the HOBOware icon menu, select "Device status" and verify the battery is good and the

memory is not too full. Replace the two AAA batteries if needed (Section 8).

Be sure to "Start" the logger before disconnecting.

Disconnect the USB cable.

Install the logger in the enclosure.

Make sure the sensor cable on the bottom of the logger is plugged in all the way and the

display is showing the correct water level.

Verify the logger is LOGGING and the display updates every 15 seconds.

NovaLynx Corporation

255-704-B Page 15 April 2021

8 BATTERY REPLACEMENT

WARNING: Keep all batteries away from small children. Dispose of used batteries properly.

IMPORTANT: When the batteries are removed all programming

in the logger is lost and the display will go blank UNLESS you

provide power to the logger while the batteries are being

changed.

FIRST: Connect the USB cable from your logger to a computer,

USB wall charger, or USB output battery pack.

1. Open the battery door on the back of the logger.

2. Remove any old batteries.

3. Insert two new batteries observing polarity.

4. Reinsert the battery door and snap it back into place.

The two AAA 1.5V batteries should provide you with 7 to 9

months of continuous use.

Note: A desiccant pack may be inside the logger box. It can be replaced or retreated as needed.

9 TEMPERATURE SENSORS (OPTIONAL)

The NovaLynx 210-TMC/20 Water or Air Temperature Sensor (sold separately) connects directly to the

logger, and includes 20' (6 m) of cable. The sensor can be submerged in the evaporation pan to

monitor the water temperature, or mounted in the NovaLynx 380-280 Solar Radiation Shield for

monitoring ambient air temperature.

To add sensors, connect them to available input channels and enable the channels. Open the "Launch

Logger" window and select the check boxes on the left. Select the TMCx-HD sensor from a drop-down

list (this step calibrates the channel). Type in a unique name for each sensor.

NovaLynx Corporation

255-704-B Page 16 April 2021

10 EVAPORATION GAUGE CALIBRATION CHECKUP

The 255-704-B Evaporation Logger can be used to check the accuracy of the potentiometer as part of a

regular maintenance cycle. At a minimum, the operation of the potentiometer should be checked at

the beginning of a monitoring season. The following procedure applies to the logger when it is

calibrated to the generic factory settings.

Disassembly

1. Remove the four screws holding the evaporation gauge cover and lift the cover off.

2. Remove the chain from the sprocket by lifting the counterweight. Drape the counterweight and

chain over the outside of the gauge. Do not attempt to remove the float.

3. Rotate the sprocket by hand to verify that it turns freely 360° without binding. It should spin freely

when given a small push.

255-704-B EVAPORATION

DATA LOGGER

USB Connector

DWG 890-0060-04

White Stripe

Testing with Evaporation Data Logger

Setup

1. Note that one ridge on the sprocket face has been painted with a white stripe. The other ridges are

not painted and are spaced 60° around the face of the sprocket. The back side of the sprocket has

similar ridges but none are painted.

2. Verify that the logger is displaying the position of the sprocket. Rotate the sprocket a little and note

the change in reading. Remember, the display updates only once every 15 seconds. Be patient.

NovaLynx Corporation

255-704-B Page 17 April 2021

Procedure

1. Adjust the position of the sprocket until the display reads 9.00"

or 228.6 mm. The white stripe on the front of the sprocket

should be at approximately 1 o'clock position as viewed from the

front.

2. While looking at the back of the sprocket, use a sticky-note as a

pointer and apply it to the top of the evaporation gauge housing,

aligning one corner to point at a rib on the back side of the

sprocket.

3. Enter the measured value as the starting point in the table (next

page). View from Back of Sprocket

4. Rotate the sprocket 60° counter-clockwise to the next ridge and record the measured value.

5. Continue recording measurements in 60° increments.

6. Compare the actual readings with the expected readings at each measured point, and determine

the Pass/Fail status.

Remedial Steps

If the white stripe is not between 12:00 and 1:00 o'clock at the starting point (9.00" or 228.6 mm),

the sprocket may have slipped on the shaft and be out of position.

If the readings on the display are progressively worse the farther the sprocket is turned, the

potentiometer may be out of specification, or there is added resistance in the circuit. Check all

connections.

If successive readings are non-linear then the potentiometer may need to be replaced.

The measured depth of water and the display will not agree when calibrated to the generic settings,

because the amount of water required to raise the float is not accounted for. This is acceptable since

the amount of evaporation is relative (i.e. the difference of two readings). If desired, an offset can be

applied or a field calibration can be performed to scale the logger (Section 5.5 or 5.6).

Reassembly

Replace the chain (Section 5.2). Replace the cover on the evaporation gauge.

inches millimeters inches millimeters

9.00" Starting point 9.000 228.6 ±0.074 ±1.9

Rotated 60° 7.333 186.2 ±0.074 ±1.9

Rotated 120° 5.666 143.9 ±0.074 ±1.9

Rotated 180° 4.000 101.6 ±0.074 ±1.9

Sprocket Position

Expected Value

Measured Value

Acceptable Limit

Pass Fail

White Pointer

DWG 880-0002-01

60°

Sticky Note

Table of contents

Popular Data Logger manuals by other brands

MadgeTech

MadgeTech Logicbus Temp1000Ex Product user guide

ADLINK Technology

ADLINK Technology DAQ-2010 user guide

Triplett

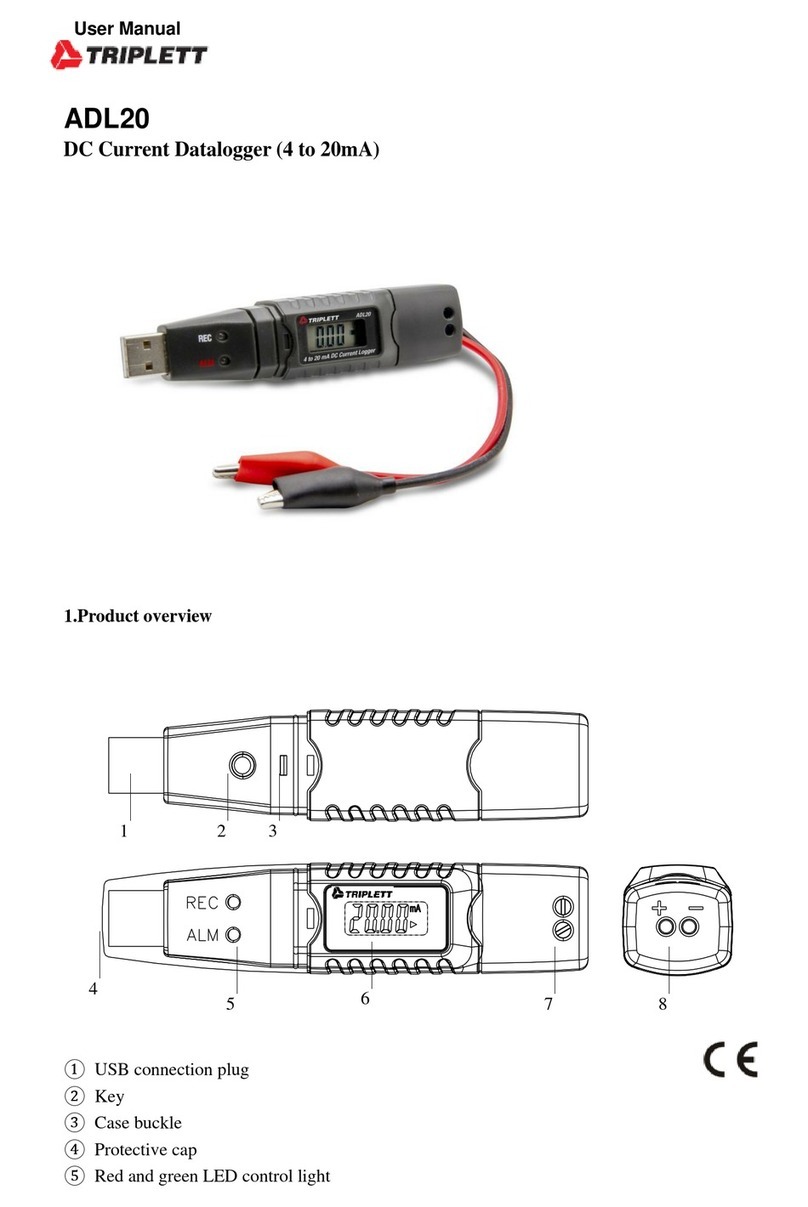

Triplett ADL20 user manual

MadgeTech

MadgeTech TEMP1000EX user guide

Neptune Technology

Neptune Technology MRXV4E Getting started guide

LogTag Recorders

LogTag Recorders UTRID-16 Product user guide