Primayer PrimeLog User manual

PrimeLog User Manual

Issue 6.1

Mai 2003

Primayer Limited

Primayer House

Parklands Business Park

Denmead

Hampshire

PO7 6XP

Telephone +44 (0) 23 9225 2228 Fax +44 (0) 23 9225 2235

UK Office:

Primayer Limited

Primayer House

Parklands Business Park

Denmead

Hampshire

PO7 6XP

England

Telephone: +44 (0)23 9225 2228 Fax: +44 (0)23 9225 2235

Malaysian Office:

Primayer Sdn Bhd

23 Jalan TPP 6/3,

Taman Perindustrian Puchong,

Section 6,

47100 Puchong,

Selangor DE,

Malaysia

Telephone: +603 8060 5225 Fax: +603 8060 5252

French Office:

Primayer France

1, rue Louis Juttet

69410 CHAMPAGNE AU MONT D’OR

France

Telephone: +33 (0) 4 72 19 10 62 Fax: +33 (0) 4 72 17 70 54

Primayer Limited reserves the right to amend any specification without notice. Primayer Limited will not be

responsible for any consequential damages arising from such changes, or from errors contained in any publication.

Copyright © Primayer Limited 1998, 2002

Windows 95®, Windows 98®, Windows Me®, Windows NT®, Windows 2000® and Windows XP®are registered

trademarks of Microsoft Corporation. All other trademarks are acknowledged.

Document Number: LXD 011/6.1

Table of Contents

PrimeLog User Manual

Contents

1. PrimeLog...............................................................................................................4

1.1. Introduction..........................................................................................................4

1.1.1. Features of logger range..........................................................................4

1.2. PrimeLog Type.....................................................................................................4

1.2.1. Model........................................................................................................4

1.2.2. Main features............................................................................................4

1.2.3. Logging features.......................................................................................4

1.2.4. Flow and pressure logging .......................................................................5

1.2.5. Special features........................................................................................5

1.3. System Description..............................................................................................6

1.3.1. Overview...................................................................................................6

1.3.1.1. Auxiliary battery unit...............................................................................7

1.3.1.2. Auxiliary Battery/Communications adaptor............................................8

1.4. Hardware Connections ........................................................................................9

1.4.1. Sealing......................................................................................................9

1.4.2. Polarisation...............................................................................................9

1.4.3. PrimeLog Input Connections....................................................................9

1.4.3.1. Digital Inputs..........................................................................................9

1.4.3.2. Internal Pressure Transducer ................................................................9

1.4.3.3. Analogue Inputs...................................................................................10

1.4.3.4. Communication Link ............................................................................10

1.4.3.5. Modem Connection..............................................................................10

1.5. Installation and Use...........................................................................................11

1.5.1. Logger Set Up ........................................................................................11

1.5.2. Logger Use.............................................................................................11

1.6. Interfacing..........................................................................................................12

1.6.1. Quadrina Insertion Meters......................................................................12

1.6.1.1. The Quadrina range.............................................................................12

1.6.1.2. Volumetric flow measurement..............................................................12

1.6.1.3. Probe calibration..................................................................................12

1.6.1.4. Logger Configuration ...........................................................................12

1.6.2. Other Flowmeters...................................................................................13

2. Appendices.........................................................................................................14

2.1. Appendix 1: Meter Scaling Tables....................................................................14

2.1.1. Kent Domestic, Helix & Master Meters...................................................14

2.1.2. Schlumberger Domestic & Helix Meters.................................................14

2.1.3. Socam Domestic & Helix Meters............................................................15

2.1.4. Supplementary Notes for Meter Scaling Tables.....................................15

2.1.4.1. Kent Meters:.........................................................................................15

2.1.4.2. Schlumberger meters:..........................................................................15

2.1.4.3. Socam meters:.....................................................................................16

2.2. Appendix 2: Specifications................................................................................17

2.3. Appendix 3: Safety.............................................................................................19

2.3.1. Airfreight Regulations applicable to PrimeLogs......................................19

2.3.1.1. Shipment of loggers in new condition..................................................19

2.3.1.2. Shipment of loggers with discharged batteries....................................19

2.4. Appendix 4: Modem Statutory Notices..............................................................20

PrimeLog

PrimeLog User Manual 4

1 PrimeLog

1.1 Introduction

PrimeLog is a family of advanced submersible dataloggers, designed specifically for

applications in the Water Industry. A typical range of applications includes:

•District, domestic and leakage flow monitoring

•Network analysis

•Pressure monitoring

•PRV monitoring

•Open channel flow

•Reservoir and borehole depth

The range of loggers offers single, two or four data input channels; this manual describes

operation in a general manner, thus some sections may not be applicable to particular loggers.

1.1.1 Features of logger range

Standard (non-modem) Logger 1F 1A 1P 2i 2 4 4i

Telephone (PSTN) Logger 1FM 1PM 2iM 2M 4M

Total number of channels 1 1 1 2 2 4 4

Number of bi-directional flow

channels 1 1 1 2 2

Number of analogue channels (for

transducer, voltage or current input) 1 1 2

Number of internal pressure channels 1 1 2

Pressure / analogue channel

accuracy (%) ±0.1 ±0.5 or

±0.1 ±0.1 ±0.1 ±0.1 ±0.1

1.1.2 Main features

•Single to four channel models

•Submersible to IP68

•Powered for five years (see note below)

•Extremely robust

•Fits in small locations

•Maintainable – can be disassembled

Please Note: The battery packs fitted to PrimeLog dataloggers are designed to last for five

years. This period is derived from calculations based upon one typical usage

regime. Actual datalogger configuration and usage pattern will affect battery

life. Primayer Limited does not guarantee that all batteries will last for the five-

year period.

1.1.3 Logging features

•Measurement range 1 second to 24 hours – independently set per channel

•Cyclic, start-stop, stop when full modes

•Readback of all data, data since last read, or defined data

PrimeLog

PrimeLog User Manual 5

•Large data store – 128K RAM standard (1 year at 15 min

interval) 256K, 512K and 1M options

1.1.4 Flow and pressure logging

•Logs from all flowmeters eg Kent, Meinecke (Socam),

Schlumberger, ABB Kent-Taylor, Quadrina

•Logs bi-directional flow

•Logs directly from combination meters

•Internal or external transducer

•Pressure accuracy options to +0.1% (meets WRC code of

practice for network analysis)

1.1.5 Special features

•One logger accepts many analogue inputs:

pressure and depth sensors 4-20mA voltage (various ranges)

•Loggers power Kent HRP/PU100 pulse units directly

•Logger stores Quadrina calibration data internally: 10 point calibration Velocity

profile and blockage factor

Table of Logger Types

Submersible

1F 1FM 1P 1PM 2i 2iM 2 2M 4 4M

Flow Flow Press. Press. Flow +

Press. Flow +

Press. 2-ch. 2-ch. 4-ch. 4-ch.

Key:

..................Digital input

..................Analogue input

................Internal pressure transducer

..................Internal modem

PrimeLog

PrimeLog User Manual 6

1.2 System Description

Please Note: This manual has been produced to provide information on as many standard

features as possible, but not all configurations can be foreseen nor all uses

anticipated.

Primayer provides a Technical Support service to assist with all matters

relating to the configuration and use of PrimeLogs. Customers are encouraged

to make use of this service. Please use the email address

front of this manual.

1.2.1 Overview

Models in the PrimeLog range of submersible dataloggers are available with one to four input

channels and various options for powering; all models are also available with an internal

pressure transducer. The range of loggers and the facilities provided by each type are shown

in the tables in the previous section, and are described in more detail below.

All loggers are fitted with military-grade connectors and are sealed to IP68. Loggers are

optionally available with an integral PSTN modem for remote programming and data

collection.

PrimeLog (Model 2)

Local communication is by serial connection to a PC or a hand-held Psion Workabout, which

provides a local display for real time measurement as well as inspection of recorded values.

Comprehensive software support is provided by the PC-based PrimeWare host application.

This is a multi-tasking system, running under Windows 95, 98, Me, NT, 2000 or XP, which

handles both local and remote loggers simultaneously. PrimeWare incorporates advanced

graphing and reporting using Wizards, simplifying greatly the presentation of data. The user

PrimeLog

PrimeLog User Manual 7

interface is fully GUI-compliant, providing full drag-and-drop facilities and dockable toolbars.

See the PrimeWare User Manual for more information.

PrimeLog with integral modem (Model 2M)

PrimeLog units are powered by an internal battery with a design life of five years or more,

depending on the nature of use. However, it should be noted that battery life will be affected

significantly by temperature. If the unit is operated continually above 30°C or below 0°C then

battery life will be reduced. All models have the option of an internal PSTN modem powered

by an additional internal battery. These models’ casings have been lengthened to

accommodate the extra cells.

1.2.1.1 Auxiliary battery unit

An auxiliary battery unit containing 6 C-size alkaline cells is available to supply additional

power to digital sensors with heavy current demands. When such a sensor is selected for a

logger (using Logger Setup and the Digital tab options – see the PrimeLog Menu section of

the PrimeWare manual), a warning message is displayed to advise the user of the need to

use the unit. The disposable pack is fully encapsulated to meet IP68 and connects to the

logger through the Comms connector.

Because of the connection method, the auxiliary battery pack is connected to the logger after

programming and has to be disconnected temporarily when communicating with the logger.

This will result in the logger not recording data from the digital sensor during periods of

disconnection.

All battery voltages may be monitored continually and alarms generated if any voltage falls

below the preset threshold – see the Battery Warning Setup section of the PrimeWare User

Manual for more information.

PrimeLog

PrimeLog User Manual 8

1.2.1.2 Auxiliary Battery/Communications adaptor

If it is necessary that logging continues during communication periods, an adaptor is available

which allows the battery pack to be connected continuously whilst providing access to the

comms connector.

PrimeLog

PrimeLog User Manual 9

1.3 Hardware Connections

1.3.1 Sealing

The connectors fitted to PrimeLogs are waterproof only when mated with a matching

connector, or when the captive sealing cap is fitted.

For continued full environmental performance it is essential that the sealing caps are fitted

unless the connector is in use.

Sensors supplied by Primayer are factory-fitted with sealed matching connectors. Connectors

fit with a bayonet (twist-and-click) action of the rotating shell.

Connectors will seal correctly only if foreign matter is excluded from the mating faces. Logger

sensors operate at low levels of current, consequently any penetration of moisture is likely to

cause electrical leakage causing degradation or destruction of data. Contaminated

connectors may be cleaned by scrubbing with a brush using industrial alcohol (methylated

spirits).

It is good practice when connections are made to ensure that the sealing caps are also mated

to each other. This prevents dirt and moisture accumulating in the cap and so being

transferred to the connector.

1.3.2 Polarisation

All PrimeLog connectors are polarised, such that it is impossible to connect the wrong input.

1.3.3 PrimeLog Input Connections

PrimeLog loggers have their connectors identified by logos, which are shown against the

appropriate input below.

IMPORTANT: Due to the operational requirements of depth transducers, it is essential that

the connector is never immersed in or exposed to water. The vent tube from the transducer

sensor is terminated at the connector and must be open to atmosphere to sense pressure in

vented gauge mode. If water is allowed to enter the vent tube then the operation of the sensor

may be impaired or irreparably damaged. This damage is not covered by any warranty.

1.3.3.1 Digital Inputs

Commonly it is only necessary to connect the sensor correctly, as the logger provides the

necessary power. Sensors which require to be powered by an external power source are

discussed in the chapter on Interfacing.

If the logger starts before the sensor is connected, no malfunction will occur but the data up to

the time when the sensor was connected will be zero values.

1.3.3.2 Internal Pressure Transducer

Loggers fitted with an internal pressure transducer have a male quick-release connector

mounted on the logger end cap.

The integral pressure transducer is available in a wide range of sensitivities, from 3 bar to 25

bar. Damage may occur if the transducer is subjected to pressures of more than 150% of its

range. The zero point calibration of the transducer may change if the logger is subjected to

shocks, but this offset can be compensated by calibrating the logger.

(no logo)

PrimeLog

PrimeLog User Manual

10

A hose with male and female connectors is available to connect the logger to the pressure

monitoring point.

Care must be taken to avoid pressure shock when connecting to the transducer, as this can

damage or destroy the sensing diaphragm.

1.3.3.3 Analogue Inputs

Analogue inputs are of two types - general purpose and dedicated integral pressure

transducer.

General analogue inputs may be voltage or current.

Voltage input range is nominally 0 - 21V DC. Voltages outside this range require a special

cable; standard voltage ranges available are 0 - 5V and 0 - 10V.

Current input requires a special cable. This is suitable for 0 - 10mA, 0 - 20mA and 4 - 20mA

ranges.

If the logger starts before the sensor is connected, no malfunction will occur but the data up to

the time when the sensor was connected will be zero values.

1.3.3.4 Communication Link

The communication link is a cable which interfaces directly to a PC serial port or to a Psion

Workabout. Communication is at standard RS-232C levels. Loggers must be configured by

PC or Workabout before use.

The communications socket on submersible loggers is used also for connection of the

Auxiliary Battery Unit.

1.3.3.5 Modem Connection

The modem connection is a direct lead between the logger and the external PSTN linebox.

PrimeLog

PrimeLog User Manual 11

1.4 Installation and Use

Installation of the logger is principally a matter of connecting the cables for the inputs, and for

the modem if fitted.

Sensors supplied by Primayer are factory-fitted with the appropriate connector.

1.4.1 Logger Set Up

The logger is set up by running the support software, or by downloading programming data

from the Psion Workabout.

Refer to the PrimeWare User Manual or to the PrimeLog Psion User Manual, as appropriate.

1.4.2 Logger Use

No routine action is required when the logger is in use. Data may be downloaded at any time

without interrupting the recording of data, either by local connection or by modem if fitted.

PrimeLog

PrimeLog User Manual 12

1.5 Interfacing

1.5.1 Quadrina Insertion Meters

Quadrina insertion meters are probes which are inserted, usually on a temporary basis, into

mains supply pipes, and which measure the local velocity.

1.5.1.1 The Quadrina range

Probes are supplied in two sizes: standard (Probeflo) and miniature (Miniprobe). Each is

available for unidirectional or bi-directional flow. As two options are available for the insertion

tube, there are eight hardware variants. Any variant may be fitted with the MEP or QEP

electronic interface.

The QEP interface requires no power from the logger and so is compatible with all PrimeLog

instruments. Its pulse frequency is linear against velocity

The MEP interface normally requires power from the logger. The PrimeLog submersible

range requires an Auxiliary Battery Unit to be used. The MEP output pulse frequency is non-

linear.

If the MEP interface has been specified to be powered internally, PrimeLogs can be

interfaced directly without auxiliary batteries.

1.5.1.2 Volumetric flow measurement

Volumetric flow must be calculated from the measurement of velocity at one point in this flow.

It is common practice (which will be assumed here) for the measurement point to be set on

the centreline of the pipe, and to assume that flow is symmetrical about this point. There is

the additional complication that the probe forms an obstruction to the flow (blockage factor).

Happily, these problems are minimised by the probe manufacturer, who supplies tables (F

factors) which give the ratio of mean velocity to (measured) centreline velocity allowing for the

blockage of the probe in common sizes of pipe.

1.5.1.3 Probe calibration

Each probe is supplied with a calibration certificate showing the number of pulses produced

per metre of flow. (If this value seems peculiar, consider “...number of pulses produced per

second for each metre per second of flow rate...” - the two figures are identical).

Probes fitted with QEP interfaces have a single-point calibration. For the non-linear MEP

interfaces, calibration figures are supplied for several different velocities. From these values a

mean factor is also calculated, which is convenient to use but which does introduce some

error.

1.5.1.4 Logger Configuration

When the option Quadrina Insertion Probe is selected from the PrimeWare flowmeter menu,

the following information is required:

Probeflo (default) or Miniprobe

Unidirectional (default) or bi-directional

Standard (0.5”) or oversize (0.75”) insertion tube

Pipe diameter

MEP or QEP electronic interface

PrimeLog

PrimeLog User Manual 13

If MEP interface is selected, then there is a choice of either single point or multiple point

calibration. For multi-point calibration, the given values or rate (metres/second) and

corresponding output frequencies (Hz) must be entered from the calibration certificate.

For both interfaces, single point calibration is simply entering the value given on the

calibration certificate.

PrimeWare automatically sets up the logger to calculate the flow rate in litres per second.

Please Note: Quadrina devices must be configured with PrimeWare. They cannot be set up

using a Psion unit.

1.5.2 Other Flowmeters

Interfacing the PrimeLog instruments to other flowmeter sensors requires knowledge of the

powering requirements of these sensors. The following table specifies the power interface:

Powering Standard Sensors

Type Sensor Power

source

1 -

Contact

Closure

Kent PSM/LRP/MSM/PU10

Kent Helix 4000 Reed Switch

Meinecke/Socam K01/K505R/K510/RO2.2/RD022

Schlumberger Model S/Cyble LF/Cyble HF

Datalogger

2 Kent HRP/PU100 Datalogger

3 Kent BPG20

Meinecke/Socam OPTO06/OPTO OD06

Schlumberger TLOS

Auxiliary

unit

4 ABB Kent-Taylor Aquamag/Aquaprobe

ABB Kent-Taylor Magmaster Self-

powered

5 Kent Combination Meter Datalogger

6 Combination Meter - non-Kent Auxiliary

unit

Typical figures for the life of the auxiliary battery unit powering Type 3 sensors are:

Kent BPG20: 94 days

Socam OPTO06: 215 days

Schlumberger TLOS: 9 days

Appendices

PrimeLog User Manual 14

2 Appendices

2.1 Appendix 1: Meter Scaling Tables

2.1.1 Kent Domestic, Helix & Master Meters

Pulse Unit Types

Meter PU10/LRP PU100/HRP

PD100 BPG20 PG100

(4000 Reed) PSM

MSM

TYPE SIZE (mm) FCAL

Helix 2000 40-80 10 1

100-300 100 10

Helix 3000 40-80 10 1

*100 10 1

150 100 10

Master 2000 40-50 1 0.1

80-100 10 1

Helix WP4000 80-125 1 10/100

150-300 10 100/1000

PSM-PS15-

PS20 15-20 0.5 ** 5

PSM-PS25-

PS30 25-30 5 ** 50

PSM-PS40 40 5 ** 5

PSM-LT 15 0.5

MSM-T ALL 1

MSM-RS ALL 10

2.1.2 Schlumberger Domestic & Helix Meters

Pulse Unit Type

CYBLE CYBLE LF

METER S* TLOS HF K=2.5 K=5 K=10 K=25 K=100 K=1000

Type Size (mm) FCAL

Aquadis 15-20 1 0.01 0.1 0.25 0.5 1 2.5 10 100

25-30 10 0.05 1 2.5 5 10 25 100 1000

40 10 0.1 1 2.5 5 10 25 100 1000

P40M All 1 0.01 1 2.5 5 10 25 100 1000

Flowstar M 40 100 1 1 2.5 5 10 25 100 1000

50-100 100 1 10 25 50 100 250 1000 10000

Woltex 50-100 100 1 10 25 50 100 250 1000 10000

150-300 1000 10 100 250 500 1000 2500 10000 100000

400-500 10000 100 1000 2500 5000 10000 25000 100000 1000000

Woltmag V 50-100 100 2 10 25 50 100 250 1000 10000

Appendices

PrimeLog User Manual 15

2.1.3 Socam Domestic & Helix Meters

Pulse Unit Types

METER K510

* K505R R02.2 RD

022 OD 06 OPTO

06

Type Size (mm) FCAL

0.5

510PR Qn 1.5 - 2.5 1

Qn 1 - 1.5 -

2.5 10 0.5

501LM Qn 1 - 1.5 -

2.5 100

1000

510PR

501JM

Qn 3.5 - 6 - 10

Qn 1.5 - 10

5

10

100

1000

5

Cosmos II 50-125

150-300

400-500

100

1000

10000

1

10

100

Cosmos

WPD /

Galaxy

50-125

150-250

300-800

100

1000

10000

1

10

100

2.1.4 Supplementary Notes for Meter Scaling Tables

FCAL = NO. LITRES PER PULSE

2.1.4.1 Kent Meters:

* Some earlier 100mm meters require the following:

FCAL = 100(PU10/LRP) or 10(PU100/HRP). These meters can be distinguished by the

centre pointer dial registration = 1000 litres/rev.

** Applies to 7 digit counters only, the other FCAL’s apply to the 8 digit counters.

Kent combination meters use a Helix 3000 meter as the main meter and a PSM-T as the

secondary meter. Select the appropriate FCAL from the table above for each of the meters.

Master 2000 has been discontinued.

2.1.4.2 Schlumberger meters:

* It should be noted that the ‘S’ pulse unit is factory fitted and that various outputs can be

specified at this time. The individual meter should be checked before selecting the

appropriate FCAL.

Schlumberger combination meters use a Woltex meter as the main meter and a Flowstar as

the secondary meter. Depending on the size mix, select the appropriate FCAL from the table

above for each of the meters.

Appendices

PrimeLog User Manual 16

2.1.4.3 Socam meters:

*The K510 pulse unit is factory fitted and cannot be removed. The FCAL is determined at the

factory and the above table shows the values available. The individual meter should be

checked before selecting the appropriate FCAL.

The K505R is a removable reedswitch with only two FCAL values available.

** It is recommended that the K10 position on the index head be used at all times when using

the R02.2 and RD022 reedswitch as this will give a higher resolution. The two Opto devices

use K=1000 as a pulsed output value.

Appendices

PrimeLog User Manual 17

2.2 Appendix 2: Specifications

Inputs: Single, 2 and 4 channels

Dedicated models:

Single channel flow

Single channel pressure

2-channel flow & pressure

4-channel flow x 2, pressure x 2

General purpose:

2-channel - 1 each analogue & digital

4-channel - 2 each analogue & digital

Digital channels:

Frequency: 0 - 500 Hz max

Bi-directional: YES - 2 pins provided

Conversion: 10 point table

Compatibility: Volt-free contact/open drain FET

Socam / Meinecke RO1.1 / OPTO 06

Kent PU100/HRP/BPG10

Schlumberger DS/S/TLOS

Combination Meters

Electromagnetic Meters - ABB/ Krone /

Fisher Porter

Insertion Meters - Quadrina MEP / QEP,

ABB Aquaprobe

Analogue channels:

Voltage: 100 mV, 0.5 V, 1.0 V, 5.0 V, 10 V

Current: 10 mA, 20 mA, 4 - 20 mA

Pressure: 350 mBar - 20 Bar (3.5 m - 200 m)

Accuracy (20°C): 0.1% or 0.5% of range

Dedicated pressure

channel:

Range: 3 - 25 Bar

Accuracy (20°C): 0.5% of range

Auto Zero: On site (by Psion Workabout)

Outputs:

Alarm: One per channel

Local comms: 19200 baud

Modem comms: 2400 baud (V.22bis)

Local readout: by Psion Workabout

Memory retrieval: All data / data since last read / defined data

Logging:

Types: Count

Modes: Cyclic / start-stop / stop when full

Capacity: 128 Kbytes (approx 1 year at 15

minutes/channel)

Interval: 1 second - 24 hours

Features: Independent logging per channel

Modem: Available on all models

Power:

Appendices

PrimeLog User Manual 18

Lithium battery: Design life 5 years (see note on page 4)

Factory or agent replaceable

(calculation based on 15 minute logging –

more frequent measurement intervals may

reduce battery life.)

Battery options: Alkaline field-replaceable battery

Physical:

Sealing: IP68 - all models

Operational

range: 0°C to 50°C

Dimensions:

Submersible, no

modem: 112 x 59 x 155 mm (except 4 channel

model)

112 x 59 x 178 mm (4 channel model only)

Submersible, with

modem: 112 x 59 x 195 mm (except 4 channel

model)

112 x 59 x 270 mm (4 channel model only)

Appendices

PrimeLog User Manual 19

2.3 Appendix 3: Safety

2.3.1 Airfreight Regulations applicable to PrimeLogs

PrimeLogs are powered by internal C-size Lithium cells, and as such are governed by the

appropriate regulations issued by ICAO and IATA.

The effect of these regulations can be summarised in two parts:

2.3.1.1 Shipment of loggers in new condition

Loggers containing new batteries may be shipped by passenger or freight airline. A

waterproof package must be used; this may be an inner sealed plastic bag. The equipment

must be packed securely so that no movement can occur within the package.

There is no restriction on the number of loggers in any package.

A special warning label (Hazard Label for Class 9 - Miscellaneous Dangerous Goods) must

be affixed to the outside of the package. This label is readily available from packaging

suppliers.

2.3.1.2 Shipment of loggers with discharged batteries

It is expressly forbidden to ship equipment with discharged batteries.

Cells which are discharged or in a condition close to discharge must be removed from

loggers (and subjected to correct disposal) before shipping such loggers by air. Naturally,

loggers which do not contain any batteries are exempt from the requirements quoted above.

NOTE: This summary applies only to batteries contained within the loggers, not to

unmounted batteries for which other sections of the Regulations are applicable.

Table of contents

Other Primayer Data Logger manuals

Popular Data Logger manuals by other brands

Chauvin Arnoux

Chauvin Arnoux C.A 10101 Getting started guide

LogTag

LogTag UTREL30-16 quick start guide

Capetti Elettronica

Capetti Elettronica WSD12-VW user manual

Delta OHM

Delta OHM DO 9847K manual

Intempco

Intempco CX402-T205 manual

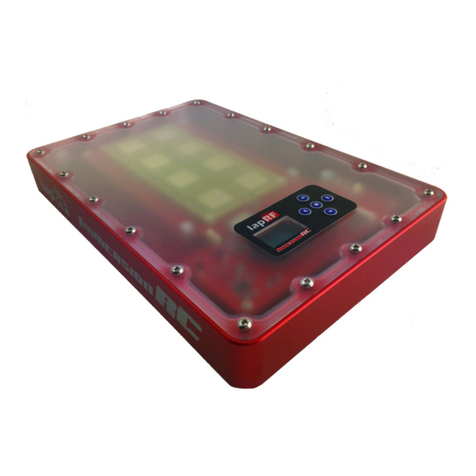

ImmersionRC

ImmersionRC LapRF 8-Way Event Timing Preliminary Operator's Manual