Siemens Building Technologies / HVAC Products 74 319 0312 0 a 19.08.2002 1/28

74 319 0312 0

G2488

en Installation Instructions Energy Manager / Heating Controller RVP540

RVP550

Installation

Place of installation

•In a dry room, e.g. the boiler room

•Installation choices:

- Control panel (in the panel front, on the inner wall, or

on a DIN rail)

- Control cabinet

- Sloping front of a control desk

•Permissible ambient temperature: 0...50 °C

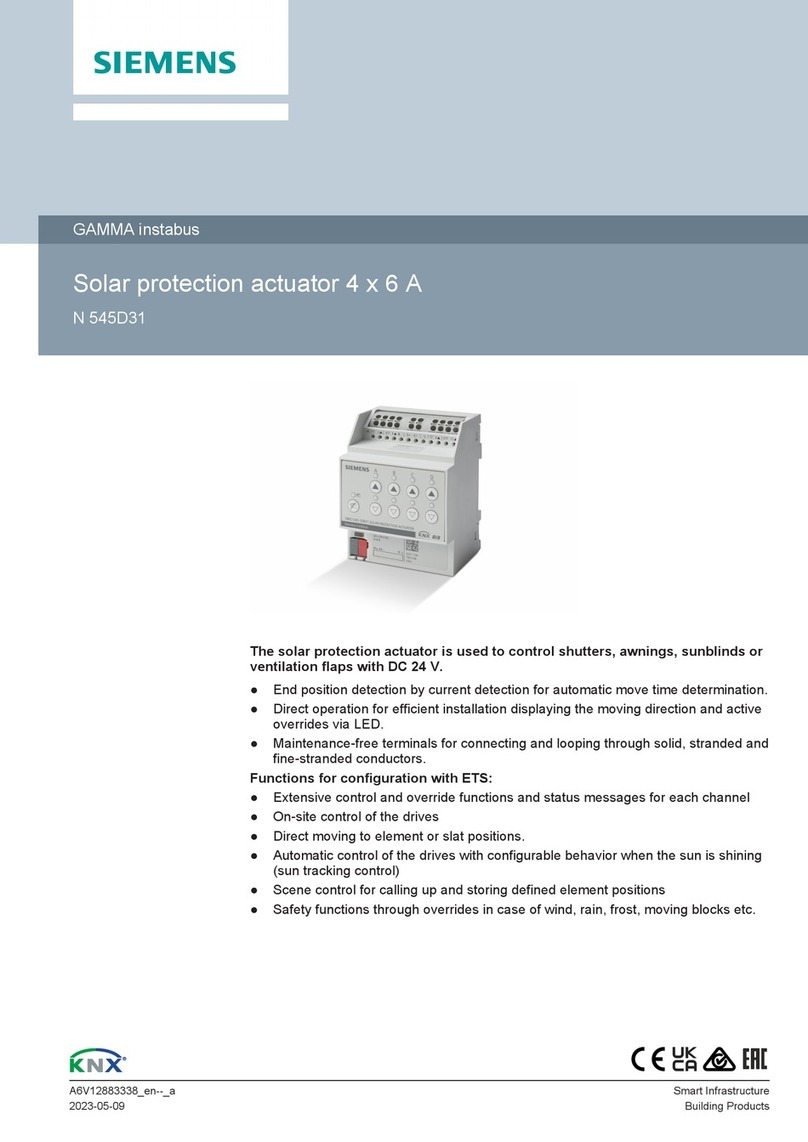

Electrical installation

•The local regulations for electrical installations must

be complied with

•Cable strain relief must be ensured

•Cables from the controller to the actuators and

pumps carry mains voltage

•Sensor cables should not be run parallel to mains car-

rying cables

•To protect the solar collector sensor from voltage

surges (caused by lightning for example), the separately

available conduit box for overvoltage protection

(AGS2S.200/109) should be installed

Permissible cable lengths

•For all sensors, thermostats and external contacts:

Copper cable 0.6 mm dia. max. 20 m

Copper cable 1.0 mm2max. 80 m

Copper cable 1.5 mm2max. 120 m

•For room units:

Copper cable 0.25 mm2max. 25 m

Copper cable 0.5 mm2max. 50 m

•For the data bus:

0.75...2.5 mm2according to Data Sheets

N2030E and N2032E

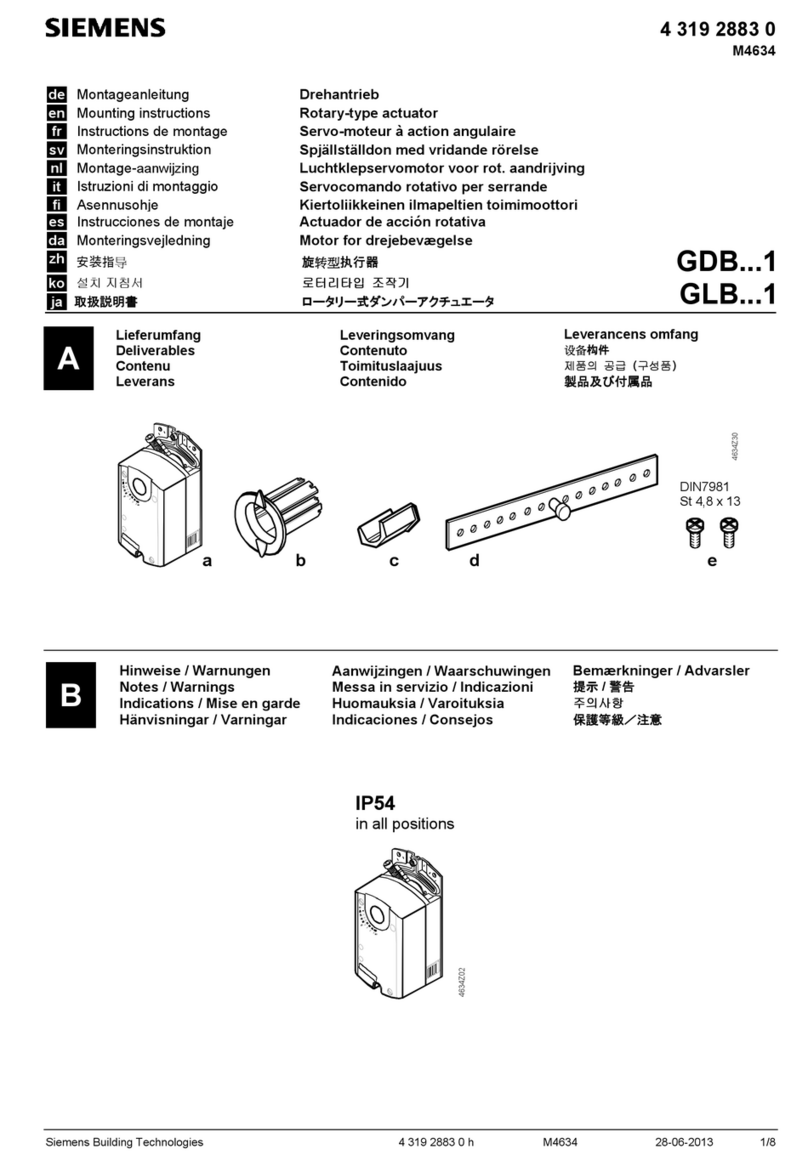

Mounting and wiring the base

Wall mounting

1. Separate base from the controller.

2. Hold base against the wall. Marking TOP must be at

the top!

3. Mark fixing holes on the wall.

4. Drill holes.

5. If required, knock out holes on the base for the cable

entry glands.

6. Screw base to the wall.

7. Wire up the base.

DIN rail mounting

1. Fit rail.

2. Separate base from the controller.

3. If required, knock out holes on the base for the cable

entry glands.

4. Fit base to the rail. Marking TOP must be at the top!

5. If required, secure the base (depending on the type of

rail).

6. Wire up the base.

Flush panel mounting

•Panel cutout required: 92 x 138 mm

•Maximum thickness: 3 mm

1. Separate base from the controller.

2. If required, knock out holes on the base for the cable

entry glands.

3. Insert base in the panel cutout from behind until stop

is reached. Marking TOP must be at the top!

4. Push lateral tongues behind the front panel (refer to

illustration below).

2462Z06

Wrong Correct

Place tongues on both sides correctly – they may not be

located inside the cutout!

5. Wire up the base. Make sure the cable lengths are

such that there is sufficient space to open the control

panel door.

Commissioning

Preparatory checks

1. DO NOT switch on power yet.

2. Check wiring according to the plant connection diagram.

3. Ensure correct position and location of the levers by

turning the fixing screws (refer to illustration on the lat-

eral wall of the unit).

2522Z13

4. Insert controller in the base until stop is reached.

Marking TOP must be at the top!

5. Tighten fixing screws alternately.

6. Check the motorized valves: See if

−they are correctly installed (observe direction of flow

as indicated on the valve body)

−the manual lever is disengaged.

7. Note with underfloor and ceiling heating systems:

The limit thermostat must be correctly adjusted. During

the functional test, the flow temperature may not ex-

ceed the maximum permissible level (usually 55 °C). If

it does, proceed immediately as follows:

- Either close the valve manually, or

- Switch off the pump, or

- Close the pump isolating valve