Novatech Instruments 409C User manual

NOVATECH INSTRUMENTS 1 Rev 0, 409C Manual

INSTRUMENTS

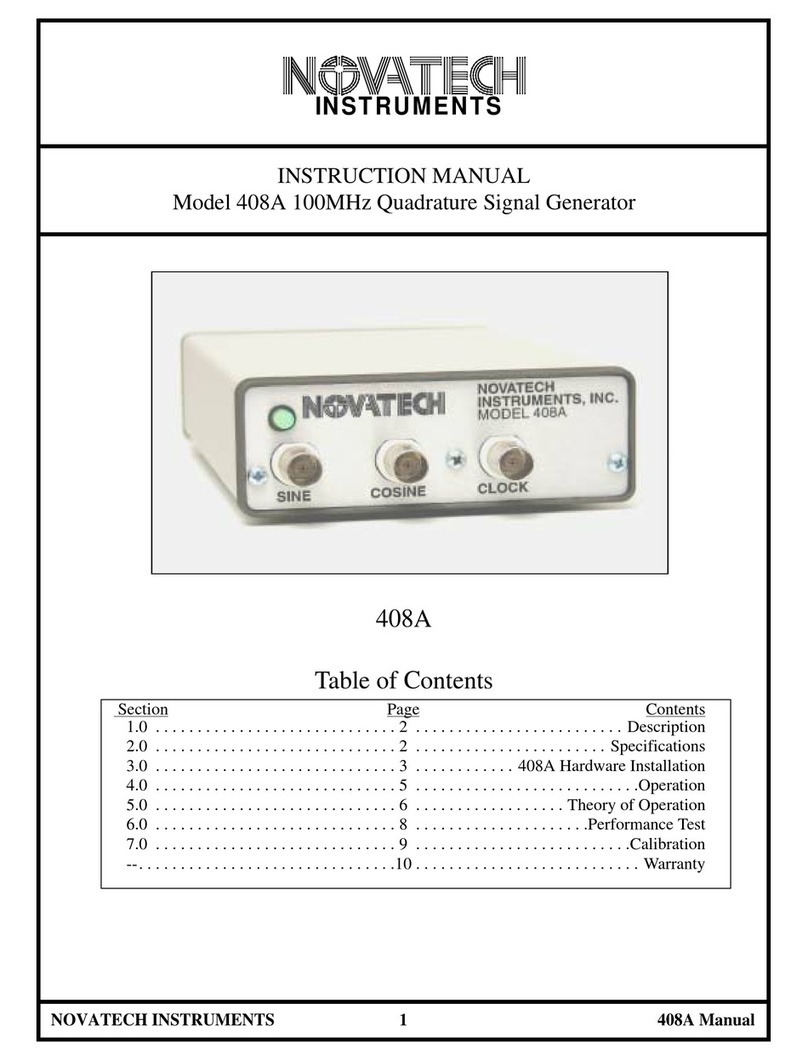

INSTRUCTION MANUAL

Model 409C, 171 MHz, 4-Channel Signal Generator

Model 409C

Table of Contents

Section Page Contents

1 2 Description

2 2 Specifications

3 3 Hardware Installation

4 4 Operating Instructions

4 5 & 6 Tables 2 & 3, Serial Commands

5 8 Theory of Operation

6 9 Performance Test

7 10 Calibration

8 11 Option /R

9 11 Option –AC

12 Warranty

NOVATECH INSTRUMENTS 2 Rev 0, 409C Manual

NOTE:

This manual applies to Model 409C with Firmware ver-

sion 0.3 or later.

1.0 DESCRIPTION

1.1 The Model 409C is a four-channel Direct Digital

Synthesized (DDS) Signal Generator in a small table top

case with USB serial control. The 409C provides four

independent, phase-synchronous sine wave output sig-

nals, which can be set from 0.0 Hz (DC) to 171 MHz in

0.1 Hz steps

1.2 A Table feature enables users to store frequency,

phase, amplitude and dwell time. The 409C can then run

through the table automatically or step through it on

command from the serial port or from an external hard-

ware trigger.

1.3 The 409C has a rear panel 14-pin header connector

(J8) that enables the user to synchronize output updates

using external hardware triggering.

1.4 The –AC option provides two rear panel mounted

SMA connectors that can also be used to trigger and syn-

chronize 409C output updates using external hardware

triggering.

1.5 The /R option adds a rear panel BNC connector that

accepts an external 10MHz reference input. This option

phase locks the internal master oscillator to the external

reference, with no binary round-offer errors. When this

feature is used the accuracy and stability of the output

are equal to those of the reference.

.

2.0 SPECIFICATIONS

2.1 OUTPUTS

TYPES: Four independently programmable, phase syn-

chronous, sine wave outputs.

IMPEDANCE: 50Ω.

RANGE: 0.0 Hz to 171 MHz in 0.1 Hz steps (Sine out,

int. clock).

SINE AMPLITUDE: Programmable from 0.000 to 1.000

Vpp into 50Ω.

PHASE: Programmable from 0 to 359.99 degrees.

FLATNESS: ±3dB from 1 kHz to 150 MHz referenced

to amplitude at 35 MHz, full scale.

2.2 TABLE

Stores up to 14,250 rows containing frequency, phase,

amplitude, row number and a dwell time in non-volatile

memory. Each row can contain data for up to four out-

put channels.

2.3 CONTROL

Output frequencies (32-bits), amplitudes (10-bits) and

phases (14-bits) are controlled by sending commands

from the USB serial port or by executing rows saved in

the 409C table. All outputs and other settings can be

saved in non-volatile memory.

2.4 FREQUENCY ACCURACY AND STABILITY

Accuracy: <±1.5ppm at 10 to 40oC. Stable to an addi-

tional ±1ppm per year, 18 to 28oC. (Internal Clock)

2.5 EXTERNAL REFERENCE (/R OPTION): Exter-

nal Reference must be 10 MHz, ±5ppm. Automatically

detected. Internal clock is locked to and tracks this value.

Level must be 0.2 to 0.5 Vrms, sine or square wave,

50Ω.

2.6 SPECTRAL PURITY

(Typ. 50Ω load, Internal Freerunning Clock, full-scale

output)

Phase Noise: <-120dBc, 10 kHz offset, 10 MHz out.

Spurious:

<-60dBc below 10 MHz (typ. 300MHz span)

<-60dBc below 40 MHz

<-55dBc below 80 MHz

<-50dBc below 160 MHz

409C Rear Panel

NOVATECH INSTRUMENTS 3 Rev 0, 409C Manual

Harmonic:

<-65dBc below 1 MHz

<-55dBc below 20 MHz

<-45dBc below 80 MHz

<-35dBc below 160 MHz

(channel-channel isolation: <-60dBc)

2.7 POWER REQUIREMENTS

+4.5 to +5.5 VDC < 1 Amp. AC adapter provided.

2.8 SIZE

39mm H, 107mm W, 172mm L, not including connect-

ors.

2.9 CONNECTORS

BNC for Sine Outputs. USB 2.0 Type B female for USB

Serial Control. 2.5mm center positive power receptacle

for +5 volts input. 14 pin header for logic I/O.

2.10 LOGIC I/O (J8 AND –AC OPTION)

Voh >=2.4V and Vol <=0.4V when series terminated.

Output Rise and fall times <100ns.

2.11 OPTIONS

OPTION /R: Adds rear mounted BNC connector to

accept external 10MHz clock input.

OPTION -AC: Provides SMA connectors on the rear

panel for IOUD and TS signals. The SMA connectors

serve the same function as pins on the rear mounted J8

header connector. The J8 connector is a standard feature

on the 409C.

3.0 HARDWARE INSTALLATION

3.1 Power Connection. The input power is applied

through a 2.5mm center-positive power connector on the

rear panel. A solid green light on the front panel LED

indicates power is on.

3.2 Power Supply. The quality of your power supply

affects the performance of the 409C. The supply should

be free of ripple and noise (<50mV). Even though exten-

sive filtering is used internal to the 409C, a quiet and

well regulated power supply will ensure optimum perfor-

mance. The supplied AC-adapter has been tested for

proper operation.

3.3 USB Serial Interface Installation. The 409C is con-

trolled from a computer that must have a USB driver

made by Silicon Labs. This driver can be found at

https://www.silabs.com/developers/usb-to-uart-bridge-

vcp-drivers. A Silicon Labs VCPdriver for Microsoft

windows is included on the USB memory stick that

comes with the 409C. To install this driver select the

CP210xVCPInstaller… application that matches you

computer and run it.

Connect the 409C to your computer using the provided

cable. The USB Type A connector on the cable plugs

into your computer and the USB Type B connector plugs

into the 409C. After the 409C is connected to a comput-

er with the Silicon Labs USB driver installed, the com-

puter will automatically create a virtual COM port.

3.5 Virtual COM Port Settings. The Default settings

for the 409C COM port are 115.2 kBaud, 8 bits, 1 stop

bit, no parity and no hardware flow control.

NOTE:

The SOF8_409C windows application is included with

the 409C. This program has a “COM Port” menu where

you can view the available COM ports and select the

COM port that is connected to your 409C. The

SOF8_409C software automatically sets your selected

COM port to the 409C default COM port settings.

3.7 Serial Commands. Commands are not case sensi-

tive and must end with any combination of Carriage Re-

turn (CR), Line Feed (LF) or CRLF. A response code is

returned after sending a command. See Table 1 for a list

of the response codes and Tables 2 and 3 for a list of the

serial commands.

3.8 Query Command. The Q command returns the pre-

sent state of the 409C non-volatile parameters. See Ta-

bles 2 and 3 for an explanation of the values returned by

the Q command.

Q

F0=4.0000000 P0=0.00 V0=1.000

F1=10.0000000 P1=0.00 V1=1.000

F2=10.0000000 P2=0.00 V2=1.000

F3=10.0000000 P3=0.00 V3=1.000

VS=1 M=N I=A TSCALE=1

TRNG=00000 - 14249

TS input: Disabled

Firmware version: 0.3

OK

NOVATECH INSTRUMENTS 4 Rev 0, 409C Manual

3.9 Connector J8. The J8 header connector provides

access to the IOUD and TS signals. It is mounted on the

rear panel. The pin numbers from left to right when fac-

ing the rear panel are 13, 11, 9, 7, 5, 3, 1 (top) and 14,

12, 10, 8, 6, 4, 2 (bottom). +TS is on pin 1 and +IOUD

is on pin 3. The other odd number pins are not used. All

bottom row, even numbered pins are grounded. A plug

compatible, six inch long, 14-pin ribbon cable is includ-

ed.

3.9 Rack Mounting. An optional 1U rack adapter is

available for mounting up to four 409C into a rack panel.

4.0 OPERATING INSTRUCTIONS

4.1 Apply Power

Plug the 5Vdc connector from the AC Power Adapter

into the rear panel connector labeled 5V.

After power is applied, the 409C takes approximately

500ms to initialize. Commands sent during this time will

be ignored or may cause erroneous operation. After all

the power is applied and all signal cables and serial com-

munication cables are installed and operating , send the

409C the “R” (Reset) command .

4.2 Warmup. Specifications are met within approxi-

mately 15 minutes of power up.

4.3 Commands. After the 409C has been installed in the

customer application system, all that is required for oper-

ation is to send the appropriate serial commands as

shown in Tables 2 and 3 on pages 5 and 6.

4.4 Response Codes. The user host computer software

must properly format the serial commands. Incorrect for-

matting will result in a response error code being re-

turned. See Table 1 for a list of response error codes.

4.5 Echo. For maximum interface speed, it is suggested

that Echoing be disabled by using the “E d” command.

This will allow the host to send characters at a faster rate.

Even when Echo is disabled, the 409B will respond with

an “OK” for a correctly received data command.

4.6 Baud Rate. A special command, “Kb x”, is availa-

ble if you wish to set a baud rate that is different from

the default of 115.2KBaud. The value set by this com-

mand is volatile and not saved in EEPROM. Upon pow-

er up, reset or clear, the 409B defaults to 115.2KBaud.

The available “Kb x” commands are:

KB 0 sets baud rate to 9600

KB 1 sets baud rate to 19200

KB 2 sets baud rate to 38400

KB 3 sets baud rate to 57600

KB 4 sets baud rate to 115200 (default)

KB 5 sets baud rate to 230400

KB 6 sets baud rate to 460800

4.7 Phase Alignment. Phase relationships are main-

tained by appropriate use of the “M” and “I” commands.

The “M” command has special modes “M a” and “M n”.

“M a” means automatically clear phase at the end of each

command. This will clear the phase register each time

any command is performed. This is important when all

outputs must be phase aligned. However, it will cause a

phase jump in the output.

Error Code Meaning

OK Good Command Received

?0 Unrecognized Command

?1 Invalid Frequency

?4 Invalid Phase

?6 Invalid Parameter

?7 Invalid Amplitude

?8 Invalid Baud Rate

?A Invalid Amplitude

?C Invalid Channel Number

?D Invalid Dwell Time

?E Empty Row in Acve Range

?F Invalid Frequency

?M Invalid Parameter

?N Invalid Table Row Number

?P Invalid Phase

?R Table is Running

?T Invalid Table Command

?V Invalid Calibraon Value

?W Invalid Acve Row Range

Table 1 Response and Error Codes

NOVATECH INSTRUMENTS 5 Rev 0, 409C Manual

Serial Command Function

Fn xxx.xxxxxxx Set Frequency of output “n” in MHz to nearest 0.1Hz. n=0, 1, 2 or 3. Decimal point not re-

quired. 0.00 sets a channel to DC. Maximum setting: 171.1276031 MHz. Single tone mode.

Pn xxx.xx Set Relative Phase of output “n” in degrees. n=0,1,2 or 3. xxx.xx = 0.00 to 359.99. Single

tone mode.

Vn x.xxx Set the Amplitude of output channel “n”. n=0,1,2 or 3. The amplitude indicates the signal

level in Vpp when driving a 50 ohm load. Maximum amplitude setting is x = 1.000 . The

default amplitude is set to the maximum. If the amplitude scale factor is not 1, the Vn com-

mand specifies the output amplitude before the amplitude scale factor is applied.

Vs n Set the output Amplitude Scale Factor. n=1 for full scale, n=2 for one half scale, n=4 for one

quarter scale and n=8 for one eighth scale. All channels are scaled equally

E x Serial Echo control. x=D for Echo Disable, x=E for Echo Enable

R Reset. This command resets the 409C to the same state as after power-up or cycling power,

except the baud rate remains unchanged (cycling power will reset the baud rate to

115.2KBaud).

CLR Clear. This command resets all factory default values except for the values stored in table

memory. Use the TCLEAR command to reset the table to an empty state.

S Save. Saves Frequency, Amplitude, Amplitude Scale Factor, Relative Phase, Phase Reset

Mode, Update Mode, Active Table Range, Table Dwell Scaling and Echo settings to flash

memory. Does not save the Table Rows. Use TSAVE to save Table Rows. Saved values will

be the default settings upon next power up or reset. Use the “CLR” command to return to fac-

tory default values.

Q Returns the current values of the non-volatile settings and the firmware version.

M x Phase Mode. x=n means the phase will not be reset with every update. This is the default

mode. x=A means the phase will be reset on every update. x=S will force a manual update

on all phases.

I x I/O Update (IOUD). If x=a, then an IOUD update pulse is automatically sent at the end of

each serial command. This is the default. If x=m, then an IOUD update pulse must be sent

manually. If x=p then a manual IOUD update pulse is sent. If x= e, then the IOUD is

changed from an output to an input. If x=s, then external TS inputs are enabled. If x=d the

external TS inputs are disabled.

Table 2: Serial Commands (Not Case Sensive)

NOVATECH INSTRUMENTS 6 Rev 0, 409C Manual

Serial Table Functions (A bracket set […] indicates optional parameters)

T r d c f p a [c f p a]

[c f p a] [c f p a]

T Command. Enters a row into the table. Where r=row, d=dwell, c=channel, f=frequency,

p=phase and a=amplitude. One channel set consisting of ‘c f p a’ values is required. Up to

three additional channel sets as indicated by [...] is optional. The entire T command must be

on one line.

D x y Display Table. Reads and displays the table values from row x to row y.

TRNG x y Table Range Command. Makes a range of rows in the table Active. The TRUN and

TONCE commands only operate on the Active rows. The active rows start at row x and in-

clude all rows up to and including row y. Default is the entire table from row 0 to 14249. The

parameters x and y are saved using the ‘S’ command.

TRUN [x y] Run Table Command. Saves all table rows to flash memory if they have been entered but

not saved and starts the table continuously looping through the active table rows. If the op-

tional x and y parameters are entered then the table will loop from row x to row y. Also sets

the IOUD signal to an output and disables the TS hardware inputs.

TONCE [x y] Run Table Once Command. Saves all table rows that have been entered but not saved and

causes the table to run once through the active table rows. If the optional x and y parameters

are entered then the table will run once from row x to row y. Also sets the IOUD signal to an

output and disables TS hardware inputs.

TSTOP Stops the table from running. The state of the channels will be the sames as they were when

the table was stopped.

TS [x] Table Step Command. Causes the table to move to the next active row. Does not save table

data in RAM to flash memory. You must use the TSAVE command to save to RAM. If the

optional ’x’ parameter is included it causes the table to go to row x.

TSAVE Save to Flash Command. The T Command creates table data in RAM memory. The

TSAVE command saves this RAM table data to flash memory. The table only operates on

data that is in flash memory.

TCLEAR Clear Table Command. Resets all table rows in the table flash memory to the empty state.

TSCALE x Dwell Scaling Command. ‘x’ can be 1 or 4. x=1 is the default and sets the maximum dwell

time to 8191.875 microseconds. If x=4 then all the dwell times are multiplied by 4 and the

maximum dwell time becomes (4 x 8191.875 = 32.7675) milliseconds. Parameter ’x’ is

saved using the ‘S’ command.

Table 3: Serial Commands For Table (Not Case Sensive)

NOVATECH INSTRUMENTS 7 Rev 0, 409C Manual

4.8 Phase Synchronous. The “M n” command turns off

the automatic clearing of the phase register. This is the

default mode. In this mode, the phase register is left in-

tact when a command is performed. Use this mode if you

want frequency changes to remain phase synchronous,

with no phase discontinuities.

4.9 Command Execution. Further control of phase rela-

tionships and timing of command execution can be exer-

cised by using the “I x” commands. The default mode is

automatic (x=a) in which a command is parsed and exe-

cuted immediately following the end of the serial input

sequence. In manual mode (x=m), an update pulse will

not be sent to the DDS chip automatically. This is useful

when it is important to change all the outputs to new val-

ues simultaneously. Use external triggering or the “I p”

command to cause a manual update. Sending “I x”

where x=e, x=s or x=d controls the function of the IOUD

and TS control logic. (See Section 9)

4.10 Amplitude Matching. For applications which re-

quire precise amplitude matching between the channels,

the recommended method is to use the “Vn x.xxx” com-

mand to adjust the channels to match.

4.11 Table Mode. The Model 409C contains Flash

memory capable of storing up to 14249 rows of data in a

table format. Each row can specify the frequency, phase

and amplitude of each channel in any combination of

channels. Any channels that are not specified in a row

will not change when the row is run. The row also stores

a dwell time that specifies how long the channel settings

specified by the row are held before stepping to the next

row. The dwell time is only used when running the ta-

ble. To run the table send a TRUN [x y] or TONCE [x

y] command. You can also manually step through the

table using the TS [x] command. The table mode ena-

bles you to update the 409C outputs very quickly since

running the table eliminates the need to communicate

over the USB port every time you send a frequency,

phase and/or amplitude command.

4.12 Dwell Time. When running the table, one row is in

dwell mode at the same time the next row is being loaded

into the AD9959 registers. To allow time for this load-

ing there is a minimum dwell time requirement that is a

function of the size of the following row. This limit is as

follows:

13 microseconds when next row has 1 channel

19 microseconds when next row has 2 channels

25 microseconds when next row has 3 channels

31 microseconds when next row has 4 channels

The resolution and range of the dwell time is controlled

by the TSCALE command. TSCALE can be set to 1 or

4. TSCALE = 1 is the default and sets the allowable

range from the minimum above to 8191.875 microsec-

onds. Setting TSCALE = 4 multiplies all existing dwell

times by 4 and makes the allowable range the minimum

to 32.7675 milliseconds.

4.13 Table Data Entry. The T command along with the

TSAVE command are used to enter data into the 409C

Table. An example T command for entering one output

channel is as follows:

T 1 100 0 10 180 0.8

In this example the row number is 1, the dwell time is

100 microseconds, there is one output channel setting

and it is channel 0 which is set to 10MHz, 180 degrees

phase and 0.8Vpp amplitude. Channels 1, 2 and 3 will

not be changed. There must be a space separating each

parameter and any channel included must contain fre-

quency, phase and amplitude values. All T commands

must be on a single line and end with a carriage return

line feed. T commands store the data in RAM. The row

data must be in Flash memory to operate as a table. The

TSAVE command, the TRUN [x y] command and the

TONCE [x y] command will each move any rows that

are in RAM memory to table flash memory.

Another Example T command:

T 500 31 0 10 180 0.8 1 11 270 0.9 2 12 359.99 0.955 3

13 90 1

This example enters four output channels in row number

500 with a dwell time of 31 microseconds. Row 500 sets

output channels 0,1,2 and 3 to frequencies 10,11,12 and

13MHz. The phases are set to 180, 270, 359.99 and 90

degrees and the amplitudes are set to 0.8, 0.9, 0.955 and

1vpp.

NOVATECH INSTRUMENTS 8 Rev 0, 409C Manual

4.14 Display Table Contents. The D x y command will

return the contents of the table from row x to row y. If

there is no data in these rows or if some rows have no

data then the D x y command will return “xxxx Empty

Row”, where xxxx is the row number, for the rows with

no data.

4.15 Active Rows. The TRNG x y command makes the

table rows from row x to row y the Active Rows. The

TRUN [x y] command with no optional [x y] parameters

causes the 409C to loop through all the active rows con-

tinuously until a TSTOP command is received. The

TONCE [x y] command with no optional [x y] parame-

ters will run the active rows one time. If you send

TRUN [x y] or TONCE [x y] and include the optional x

and y parameters then the active rows are from row x to

row y and the 409C will step through the table from x to

y continuously (TRNG) or one time (TONCE).

4,16 Single Stepping the Table. The TS [x] command

can be used to execute any single row in the table as des-

ignated by the x row parameter. Note that the TS [x]

command does not move table data from RAM memory

to flash table memory so you may need to use the

TSAVE command before using the TS [x] command.

Also, you cannot use the TS [x] command if the table is

running. If you execute the TS command without includ-

ing the optional x parameter, then the manual steps will

start at the beginning of the active row as set by the

TRNG command. Once you manually step to the end of

the active rows, the next TS command will take you back

to the first active row.

4.24 Table Synchronization with External Events.

For precision timing application it is recommended that

external table synchronization be used. This involves

triggering table operations using customer supplied ex-

ternal hardware. See Section 9 for detailed instructions.

5.0 THEORY OF OPERATION

5.1 Block Diagram. Please refer to the Simplified Sys-

tem Block Diagram in Figure 1 on the next page for the

following discussion.

5.2 System Clock. The 409C master clock oscillator

generates a frequency of 28.633,115,306666667 MHz.

This is fed to the AD9959 where it is multiplied by 15 to

produce a System Clock Frequency of 429.4967296

MHz.

5.2 DDS Frequency Generation. At every cycle of the

409C System Clock, the AD9959 integrated circuit in-

crements the phase of an internal register by a phase val-

ue calculated from the frequency command sent to the

AD9959. The AD9959 converts this phase value to a

sinusoidal amplitude level and then sets the values of the

on-chip 10-bit digital-to-analog converters. The analog

signals from these converters are filtered by differential

7th-order elliptical low pass filters, amplified and sent to

the 409C output connectors.

5.4 Maximum Frequency. The 409C theoretical output

frequency is limited to a maximum of 1/2 the system

clock frequency. While it is possible to generate an out-

put near 50% of the system clock, the distortion would

be unacceptable. Therefore, the 409C frequency output is

limited to 40% of the 429 MHz system clock frequency

by 7th-order elliptical low pass analog filters. This out-

put limit is 171 MHz.

5.5 Lock to 10MHz Reference. When option /R is add-

ed to the 409C and an external 10MHz reference is con-

nected to the 409C rear panel, the Master clock is phase

locked to the external 10MHz reference signal and the

accuracy of the Master clock is then equal to the accura-

cy of the external reference.

NOVATECH INSTRUMENTS 9 Rev 0, 409C Manual

6.0 PERFORMANCE TEST

6.1 Setup. Power up the 409C and connect your host

controller. Maintain the 409C in a stable environment of

18-28oC.

NOTE:

Allow the 409C to warm up for at least 15 minutes and

verify there is a steady green light on the front panel

LED before performing any measurements. For best re-

sults, the 409C should be verified in its installed environ-

ment.

6.2 Test Equipment. See Table 4 on the next page for a

list of recommended test equipment to perform the fol-

lowing measurements.

6.3 Verify Frequency Accuracy. Set the output sequen-

tially to each value in Table 5. Connect the recommend-

ed frequency counter set to 50Ω termination and 1 Hz

resolution. Verify the limits show in Table 5. Test all

channels to verify functionality of all outputs. If you do

not use an external reference for the frequency counter,

be sure to add the error of your counter to the tolerance.

6.4 Verify Amplitude. Set the frequency of the 409C to

10MHz. Connect the 409C to the oscilloscope set for

50Ω termination. Verify a reading of 1Vpp ±0.25Vpp on

all four outputs.

6.5 Verify Amplitude Control. Leave the output fre-

quency set to 10MHz. Send the command “Vn 0.5” to

each channel, where “n” is the channel number being

tested. Verify that the amplitude on each channel de-

creases by one-half. Send the “R” command to reset the

levels before performing the next tests.

6.6 Verify Output Flatness. Set the 409C outputs to

35MHz and observe the output amplitudes. Change the

409C frequencies to the values of Table 5 on each chan-

nel. Verify that the amplitude reading remains within

±3dB (x1.414 to x0.707) of the value at 35MHz. (Limit

upper frequency to 150 MHz.)

6.7 Return the 409C to normal operation and default val-

ues by sending the “CLR” command.

6.8 This concludes the performance test of the 409C.

10MHz

NOVATECH INSTRUMENTS 10 Rev 0, 409C Manual

7.0 CALIBRATION

7.1 The 409C has one adjustable component: Y2 fre-

quency. Y2 is located on top of the master oscillator (see

photo). Calibration should be performed only if the 409C

fails the performance test or if the unit has been repaired.

Routine adjustments are not recommended nor generally

required. This procedure assumes that the 409C has

failed the performance test or has been repaired.

WARNING:

Calibration of the Model 409C requires that the case be

opened. Calibration should be performed only by quali-

fied personnel. The internal components are static sensi-

tive.

7.2 Remove the two phillips head screws on the rear

panel. Tip the rear panel away from the instrument and

slide the top cover off. Be careful not to unduly flex the

connecting wires.

7.3 The adjustments shown are set to one half the fre-

quency accuracy specification value.

NOTE:

Allow the 409C to warm up for at least 15 minutes before

performing any adjustments. For optimum performance

the 409C should be calibrated in an environment similar

to its installation.

NOTE:

If your unit has the /R option installed, the oscillator ad-

justment is the same, except the oscillator location has

moved to the adapter board.

7.4 Frequency Adjust, Y2. Set the output of the 409C to

10.0000000 MHz using the command “F0 10.0000000”.

Connect output of channel 0 to your frequency counter

set for 50 Ω termination. Adjust Y2 using a non-metallic

adjustment tool for 10.000000 MHz, ±7.5 Hz.

Item Minimum

Specification

Recommended

Oscilloscope 300 MHz

50Ω

Tektronix TDS3032B

50Ω

Terminaon

50Ω +1%

Frequency

Counter 180 MHz HP53132A

Counter Time

Base

10 MHz

<+0.1 ppm

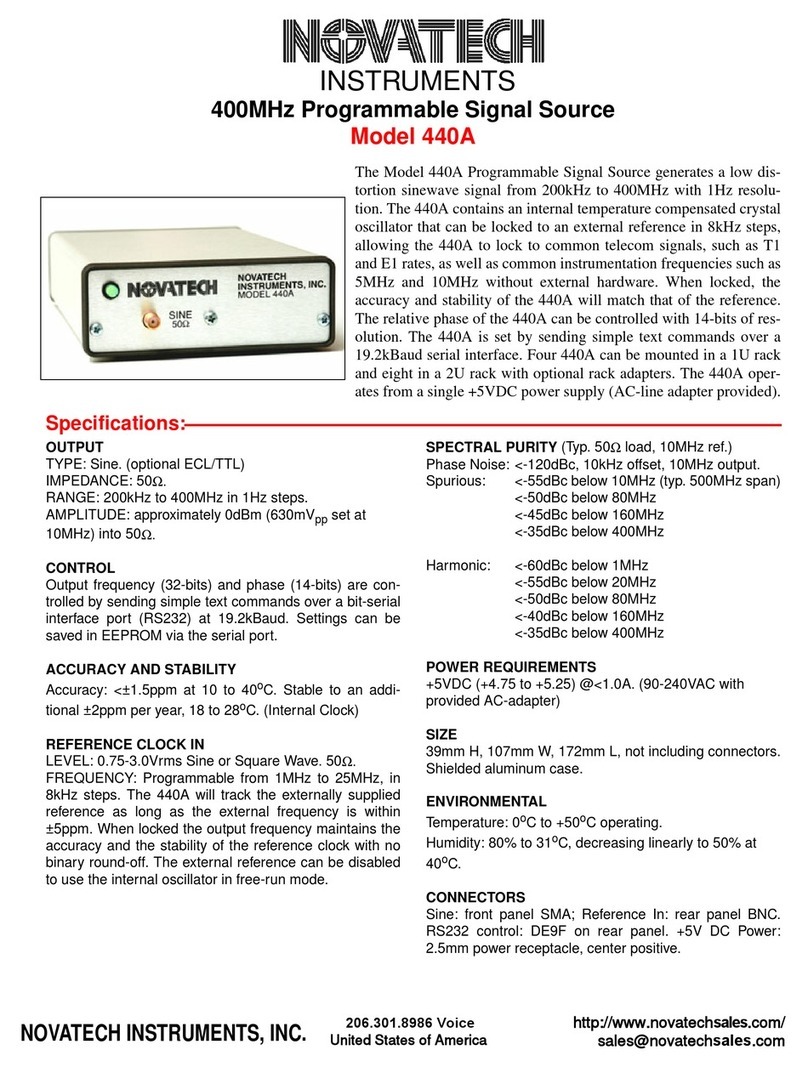

Novatech Instruments

Model 2960AR

External Clock 400 MHz Novatech Instruments

Model 440A

Table 4: Recommended Test Equipment

Frequency Tolerance

100 kHz + 0.15 Hz +1 LSD

1 MHz +1.5 Hz +1 LSD

10 MHz +15 Hz +1 LSD

30 MHz +45 Hz +1 LSD

50 MHz +75 Hz +1 LSD

100 MHz +150 Hz +1 LSD

170 MHz +255 Hz +1 LSD

Table 5: Frequency Test Points

NOVATECH INSTRUMENTS 11 Rev 0, 409C Manual

8.0 OPTION /R:

LOCK TO 10MHz REFERENCE

8.1 The /R option consists of a small circuit board that is

mounted inside the 409C. It provides locking and track-

ing circuitry to phase lock the internal master oscillator

to an external 10MHz reference.

8.2 A 10MHz reference must be connected to the rear

panel BNC connector labeled 10MHz input. See para-

graph 2.5 for the required specs of this signal. The

10MHz input signal is automatically detected and, if

within a lock range of approximately ±5ppm, it is locked

to and tracked by a narrow-band phase lock loop.

8.3 If an input signal is not detected, the unit will default

to the internal free-running oscillator and perform identi-

cally to a 409C without the /R option.

8.4 The front panel LED will display four conditions:

Steady Green: unit is locked to a stable external

reference or is using the internal free

running master clock.

Blinking Green: unit is stabilizing to a free

running condition. This occurs upon

powerup or if the reference is removed.

Steady Red: unit detects an external input, but

cannot lock to it.

Blinking Red: unit has detected a 10MHz

external signal and is attempting to

lock. This will occur if the 409C had

previously been free running.

8.5 When changing the reference mode, the phase lock

loop may take several minutes to stabilize to the final

resolution of the 409C. Changing from a blinking LED

to a stable LED indicates that the process is completing,

but you should verify the outputs.

.

9.0 EXTERNAL TIMING CONTROL

USING J8 & OPTION –AC.

9.1 Description. Option –AC adds two rear mounted

SMA connectors, labeled IOUD and TS, that can be used

for triggering and synchronizing 409C outputs. These

signals are in parallel with the IOUD and TS pins on the

rear mounted header connector J8. The logic levels for

these pins are 0V for logic 0 and 3.3V for logic 1.

9.2 IOUD Output vs Input. By default, the IOUD sig-

nal is an output indicating that the microcontroller has

triggered an update. The “I e” command changes IOUD

from an output to an input and requires that an external

trigger pulse IOUD high to update the 409C outputs.

9.3 IOUD Used as Output. The IOUD signal is pulled

down internally to ground. When the 409C microcon-

troller updates the 409C, it pulses IOUD high. The actu-

al trigger happens on the rising edge of this signal and

this rising edge can be read by the users hardware.

9.4 TS Input. The TS input connector is disabled by

default. It can be enabled using the IS command. When

enabled it functions just like the “TS” serial command.

If a table is not running and the TS input is enabled, then

applying a trigger signal to the TS connector will step

through the active rows of the table. The TS input is

pulled down inside the 409C. Pulsing the TS input high,

will trigger the update on the positive edge of the pulse.

An edge occurring sooner than the minimum dwell time

will be ignored.

9.5 External Triggering when IOUD is an Input.

The AD9959 DDS ASIC must be preloaded with a new

set of values prior to applying an external IOUD trigger.

Preloading is done with the TS command or by applying

a trigger signal to the TS connector. Once preloaded, the

409C can be triggered to update all outputs by applying a

trigger pulse to the IOUD connector. The trigger signal

must pulse IOUD high, the update will happen on the

rising edge.

9.6 More Precise Timing with External Triggering.

Using external triggering enables the user to take control

of exactly when the outputs are updated. This avoids the

uncertainty regarding the exact amount of time the pro-

cessor will take to move data from Table Flash to the

AD9959 DDS ASIC registers. While the user must still

allow upwards of 10 microseconds for this data to move,

the timing of the trigger update is decoupled from this

time uncertainty. Thus, this method enables the user to

more easily synchronize updates with external events.

External triggering can be used with the table and it can

also be used without the table when the user is sending

serial commands.

NOVATECH INSTRUMENTS 12 Rev 0, 409C Manual

WARRANTY

NOVATECH INSTRUMENTS warrants that all instruments it manufactures are free from defects in

material and workmanship and agrees to replace or repair any instrument found defective during a period of one

year from date of shipment to original purchaser.

This warranty is limited to replacing or repairing defective instruments that have been returned by

purchaser, at the purchaser's expense, to NOVATECH INSTRUMENTS and that have not been subjected to mis-

use, neglect, improper installation, repair alteration or accident. NOVATECH INSTRUMENTS shall have the

sole right to final determination regarding the existence and cause of a defect.

This warranty is in lieu of any other warranty, either expressed or implied, including but not limited to

any warranty of merchantability or fitness for a particular purpose. In no event shall seller be liable for

collateral or consequential damages. Some states do not allow limitations or exclusion of consequential

damages so this limitation may not apply to you.

All instruments manufactured by NOVATECH INSTRUMENTS should be inspected as soon as they are re-

ceived by the purchaser. If an instrument is damaged in shipment the purchaser should immediately file a claim

with the transportation company. Any instrument returned to NOVATECH INSTRUMENTS should be shipped

in its original shipping container or other rigid container and supported with adequate shock absorbing material.

This warranty constitutes the full understanding between NOVATECH INSTRUMENTS and the

purchaser and no agreement extending or modifying it will be binding on NOVATECH INSTRUMENTS unless

made in writing and signed by an authorized official of NOVATECH INSTRUMENTS.

NOVATECH INSTRUMENTS

United States of America

206.301.8986 Voice

http://www.novatechsales.com/

Table of contents

Other Novatech Instruments Portable Generator manuals