3

SAFETY INSTRUCTIONS FOR FORESTRY SKIDDING WINCHES

1. Work safely!

The relevant health and safety regulations and the operating instructions must be

complied with!

2. Operation and maintenance of the cable winch may only be entrusted to suitable and

reliable persons over 18 years of age who are familiar with this type of work.

3. Wear personal safety equipment (helmet, safety shoes, protective gloves)!

4. Working alone is only permissible if there is a radio emergency call system!

5. The cable winch must be checked before use, but at least once every working day, to

make sure that it is in perfect operating condition (safety guard, dead-man’s circuit,

overload protection, brake function). Any faults must be remedied professionally

6. The winch drive must be turned off when malfunctions are being remedied or repairs

and maintenance are being carried out. It is not enough to disengage the winch drive.

The drive motor of the skidder must be turned off.

7. The safety devices on the winch must not be disabled.

8. Only use load suspension devices, e.g. lifting hooks, choker cables, chains, pulleys

and straps that are suitable for the pulling power of the winch.

9. Only use stress-relieved cables of sufficient strength for pulling as per the

specifications on the cable winch’s name plate and the operating instructions. The

breaking load of the choker and skidding chains must be twice the pulling power

specified on the winch for the first turn.

10. Damaged cables and chains must be replaced promptly.

11. Do not use cables that are too long. When the cable is fully wound, the flange rings

must still project beyond the top turn by at least one and a half times the diameter of

the cable.

12. Before starting the skidding winch, the machine operator must satisfy himself that no

one is in danger.

13. The winch operator must make sure that at least two turns of the cable remain on the

drum under load except in a hazardous situation (adjust overrun brake correctly)!

14. Only wind the cable in under load (unwind cable completely and wind in evenly at

least once a day and more often if necessary)

15. The winch must only be operated from a safe position where the winch

operator is not at risk from the winch itself, the load, the cable or the hitches.

The driver’s cab of the skidder can be regarded as a safe position if there is an

adequate safety guard between the winch and the driver’s seat.

The winch operator must be provided with appropriate protection when

operating the winch from outside the driver’s cab.

The skidder itself might be used as protection or the operator might stand at a

safe distance from the skidder behind a tree, for example.

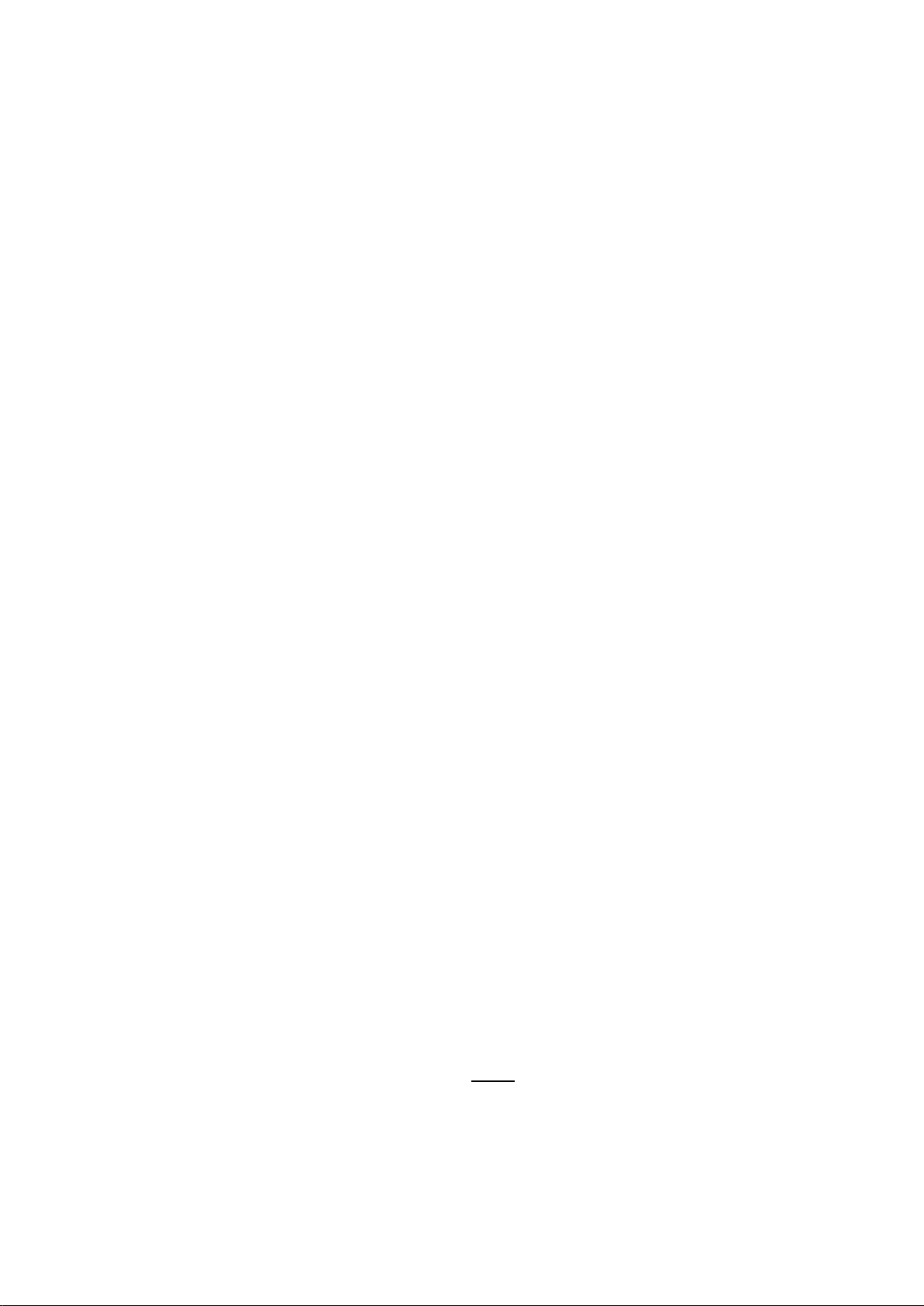

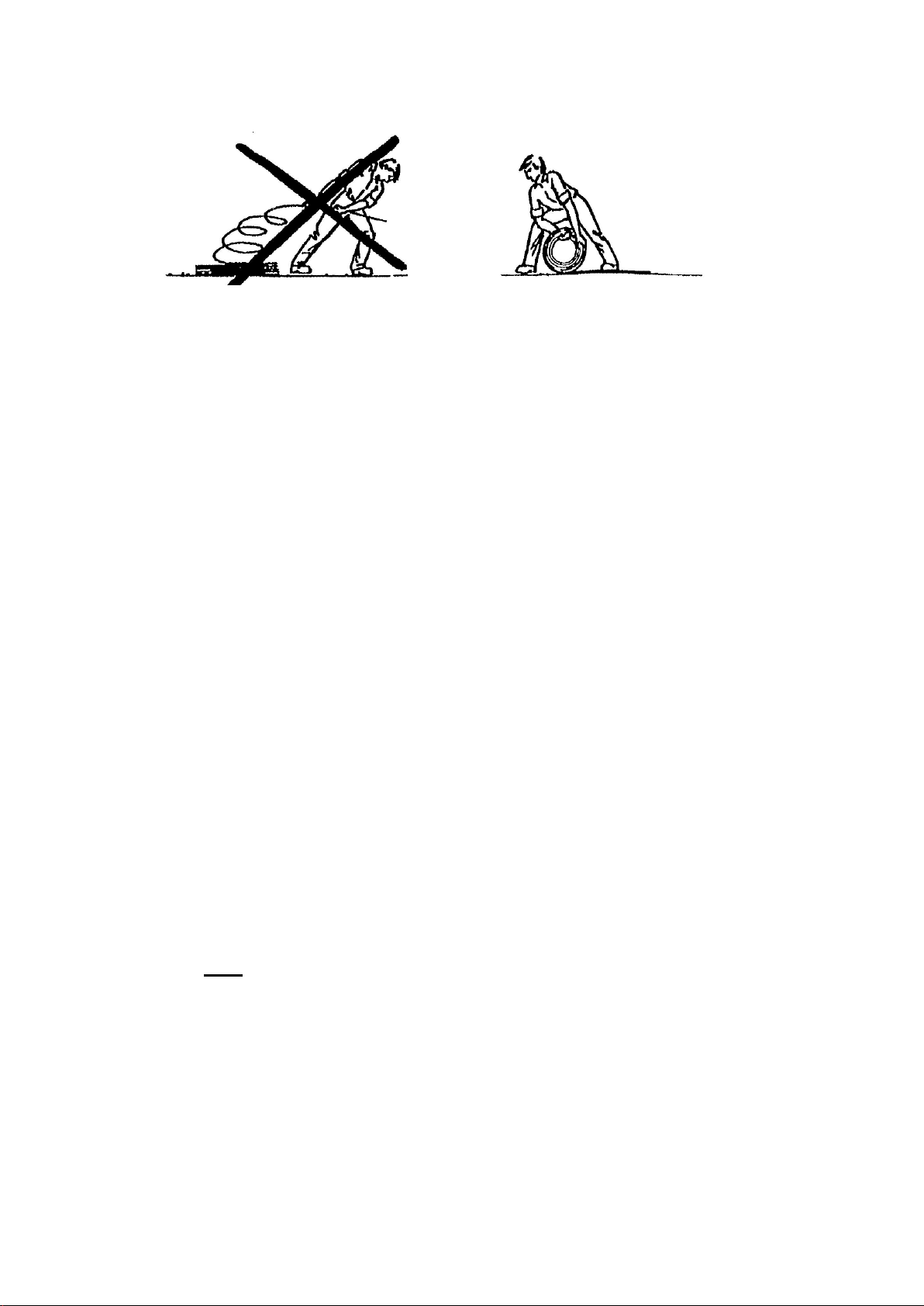

If radio-controlled winch operation requires the winch operator to accompany the log,

he must stay close to the hitching.

Long logs can be accompanied at the side, next to the hitching, while log sections can

be accompanied from diagonally behind the load, see figure 1.

16. From his position the winch operator must be able to keep the skidding load under

observation at all times; otherwise arrangements must be made to have the path of