Novax 2020-S System manual

Phone: 64-9-407-5581

Fax: 64-9-407-5582

www.novax.co.nz

P.O. Box 495, Kerikeri

Bay of Islands, New Zealand 0245.

Novax 2020-S

Installation Handbook

Wiring Information Novax Electronic Products Ltd.

World Leaders in taximeters

Novax Electronic Products Ltd.

Dimensions:

- 157mm x 72 mm and Only 16mm deep!

- Slim and light enough to mount by your mirror!

Graphics Display:

- Easy to read, black on white, large FARE window

- Supplementary window for EXTRAS or Distance

- Rate window shows actual $/km. being charged

- Displays labels for each Operate button function

Back illuminated tactile switches:

- Four buttons for simple operation.

- Numeric keypad for account, log-in and menu entries

Features:

- Displays Text messages

- Receipt Printer & MSR.

- Handles Payment Cards

- Log On / Log Off

- Driver Working hours

- Total Mobility compliant

Quirks and the unexpected.

There are a number of factors to watch out for when installing:

1. To drive the Roof Lights, you need to connect the orange wire

(lamp circuit feed) to 12v as well as the brown (meter power) wire. A

suitable fuse should be used in this line.

2. Lamp drives are programmable (a function of the Farekey

program). If they don’t work, they probably haven’t been

programmed!

3. The Novax 1200 series meter utilises a new data structure, which

is not backward compatible with earlier meters (1100 series)!

Farekeys programmed for earlier versions will not be recognised by

1200 series firmware and vice versa!

4. Fare schedules are date-stamped. Meters can be programmed in

advance of the scheduled date. The new rate will remain “pending”

until the date arrives. Check the meter clock/calendar is set

correctly before programming with a farekey.

5. The set-up and calibration features can only be accessed with an

installation-key in place, a “fare-key” will no longer allow access to

perform these tasks, this prevents the possibility of unintentional re

programming the fare schedule.

6. As well as configuration settings, a number of programmable files

control operation. Eg. Modem settings, interface protocol. Failure to

function with other equipment may be related to these files.

7. Printer Power is switched by the meter, it uses the “Hired” O/P. If

this O/P is not programmed, the printer wont be powered!

8. If the clock skips an hour (or looses an hour): The Meter contains

“daylight saving” dates in its calendar file. If an out of date calendar

table has been used the meter will try to catch up and advance (or

retreat). This should be, at worst, a one off, but can be annoying.

It can be prevented by programming the farekey to ignore the clock

calendar, or by making sure the calendar file is current.

Disassembly.

The meter module itself consisting of the circuit board and facia,

and is held in the case only by the sealing screw and collar. With the

screw and collar removed, press the PCB from behind, through the

connector opening in the case. The lower edge of the pcb should

“snap” out of the back-shell case, allowing you to slide the assembly

down, free of the groove which supports the top of the pcb.

It may be necessary to remove the module in order to connect other

devices to the various ports. These ports are labelled; J5, 6 and 7.

J5: Printer port

J6: GPS, Swipe reader

J7: Serial Port 1 - Data Transfers

- Multiple Interfaces

- GPS Receiver port

- Modem Interface port

- Shift & Lease control

- Alarm switch I/P

Optional connections:

GPS receiver, Swipe Reader (J6)

ser. port 1 (J7)

Ser. Port 2 (via J1 only)

Ser. Printer, alarm sw. (J5)

Main Cable.

Black: Meter 0 volts, to Vehicle Ground (J1.12)

Brown: Meter power, to Vehicle battery (J1.11)

White: Speedo signal, to Vehicle speedo system (J1.13)

Orange: Lamp Power, to Vehicle battery (J1.9)

Blue: Power to For Hire light, switched by meter (J1.5)

Purple: Power to Hired light, switched by meter J1.6)

Green: Aux switched o/p 1 Hd.1, Courtesy light (J1.7)

Red: Aux switched o/p 2 Hd.2, Ext. Beep (J1.8)

(Alarm switch I/P, serial ports etc can also be accessed

Via main 20 pin connector (J1)).

Fitting Instructions.

Before attempting to install the meter. Get the position right! Hold

it in the car and find the best possible position. It is light enough

to mount above the mirror, on the mirror or glass mount as well

as conventional dash mount, but keep the following in mind:

1. The meter must be clearly visible to all passengers. LCD

displays can be difficult to read if the viewing angle is too great.

2. Mount the meter where it is not likely to be damaged by

passengers or their luggage. Also keep it away from ashtrays.

3. It must be close enough to be operated from the driver’s seat.

4. The sealing screw must be readily accessible.

5. Routing of the required wiring.

Once the position is known, if necessary, remove the meter

module from the back-shell case and put it aside. The case can

be fastened in place by small flat head screws using the existing

holes, or it can be held in place with suitable adhesive products.

The meter module is secured to the case only by the sealing

screw and collar.

Setup Options.

The Data screen provides information about the meter:

Model, Serial Number, Cab Number, GST number, Date of Manu-

facture and firmware revision. Two sets of registers relating to the

data security provide indelible counters and date stamps which

record each time the meter is programmed with either Fare Sched-

ule or Calibration adjustments.

From the “Data”

screen, access can

be gained to a

“Menu” (button ‘A’ in

“Data mode”) which

allows selection of

various parameters

as shown.

Each entry is PIN pro-

tected with individual PIN numbers. The required parameter can

be selected from the numeric keypad, the four-digit PIN entered.

Clock Adjust.

To access the clock adjust mode; Hit button ‘1’ on the numeric

keypad. This is covered in the Operator’s Handbook.

The same editing procedure applies to all parameters.

Should you need to change the PIN number for any entry, this can

be done by hitting button ‘D’ once you have reached the edit mode

for that particular parameter. This will allow a new four digit PIN to

be entered and saved. Like all PIN numbers, if you forget what you

have set, you’re bugg***d!

Shift Period and Lease Period.

These parameters relate to Daily activation periods (Shift) and

Global activation period (Lease). If a driver is to be restricted to say

a twelve hour period each day then the start and end times for the

“shift” can be entered here. During the inactive period he will not

be able to ply For Hire, and the meter is effectively locked.

The Lease Period provides a means to disable the meter should,

for example, the driver be leasing the cab (or the equipment) and

he fail to pay at the required time. The owner (or leaser) can set

the start and end time and date so that the meter will lock at ex-

piry.

Registration Number.

This provides a means to enter the vehicle identification number,

as may be required in some countries, for inclusion on printed re-

ceipts

Setup: Cab number, GST.

This provides a means to enter the cab number and the compa-

nies GST number. Follow the same procedures for all settings,

some provide two parameters under the one selection.

Configuration.

Roughly; consists of 3 sets of two digits:

First digit pair: Options and connections.

Second pair: Interface protocol and port vectors.

Third digit pair: Number of decimal places, Baud rates, GPS vector.

Connections

For most installations the single 8 way loom supplied is adequate

to allow connections to be made in the engine compartment or

under the dashboard. The loom is colour coded as per diagram

overleaf.

Should the installation require connections to data plugs, GPS

swipe-reader etc. then additional cables may be required (remove

the meter module from the case to plug these in).

Ideally, power and ground connections should be taken directly

from the vehicle’s battery terminals.

Note:

1 Although the meter is protected by internal overload

devices, the lamp circuit should be protected by an external

fuse (orange wire) at the battery connection (3 Amp). Where

regulations allow, meter power (brown wire) should also be

taken through a fuse. It’s a good idea to ensure these fuses

are removed until all connections have been made, to avoid

damage in the event of accidental shorting of the wires.

2 The lamp drive circuits are controlled by conventional +12v

switching, switching +12v power to the light(s). These are

however solid-state switches and can be easily damaged by

overload conditions. If the aux outputs have other purposes

than tariff lights ensure the circuit is not likely to exceed 3

amps, or if it is required to switch other vehicle circuits, it is

recommended that external relays (with spike suppression

diodes) be used in order to protect the meter circuit board

from damage.

3 Where a receipt printer is to be used, Lamp o/p #3 should

be configured as “Hired” lamp drive, ie selected for all

operating tariffs. This is connected internally to power the

receipt printer. An optional loom is available with an inline

printer connector should this be considered easier.

Once all required connections are made the meter module can be

fitted into the case and the main connector plugged in (note this

is polarised such that it has a correct and an incorrect way round.

Don’t force the connector in,! You could have it back to front!

Calibration and

Configuration.

Press button ‘D’ for the

Data screen then

button ‘A’, “Menu”.

Provided a valid

“Installation key” is in

place the meter will

respond by displaying

“Calibration screen” rather than display the menu.

First, use the function to count the speedo pulses over a measured

distance, (eg a measured kilometre).

To count Speedo pulses hit the button ‘B’, (Start), this resets the “New

count” to zero, every pulse received from the speedo system will now

be counted and displayed. Drive the vehicle for a short distance in

order to confirm correct operation and satisfactory pick-up of speedo

pulses. Note that alternate pushes of the button ‘B’ freeze, and restart

the counting of pulses. Now drive over the measured kilometre,

starting the count at the beginning and freezing the count as you cross

the 1,000 metre mark (or 1mile for imperial) on the road.

With the exact calibration displayed, hit the button ‘D’ (save) in order

to store this number in memory. “Cal. Saved” briefly appears on the

display, as the meter switches Off.

Before storing the new calibration figure it is possible to make fine

adjustments if required, using buttons ‘A’ and ‘C’ to increment and

decrement the displayed figure.

Check operation, remove the key, then replace the sealing screw and

collar, make sure that the holes in the screw will allow the wire seal to

pass neatly across the sealing tab.

The Calibration Registration number is advanced each time the meter

is recalibrated.

Confirm the correct number is saved by viewing it in the “Data Mode”.

Testing.

For the sake of these instructions the four Operate buttons are re-

ferred to as button ‘A’, ‘B’, ‘C’, and ‘D’.

With the meter screen blank, the meter is said to be “Off”.

Switch the meter through it’s modes, to check operation is OK.

If the meter is configured for a modem, connection will be verified (or

not) in the For Hire screen by the appropriate symbol, or the banner

“No Modem” as the meter searches for it.

If a receipt printer is connected, it can be tested by printing the

“Running Totals”. (button ‘D’ in the Global Totals Mode).

If a GPS receiver is connected the ‘+’ symbol will show once a “Good

fix” has been established.

With the meter “Speedo signal pulse wire” connected to the vehicle’s

speedo system it should be possible to verify that distance pulses are

being received by the meter when the vehicle is traveling. This is done

in the “Calibration Mode” and requires the use of a special purpose

device called an “Installation key” to unlock the calibration mode.

To prevent unauthorised alterations to the calibration figure, this func-

tion can ONLY be accessed if the Installation key is in place, this MUST

be fitted to the 4-pin connector under the sealing collar. Ensure you

get it the correct way round with the arrow pointing to the right.

Popular Automobile Accessories manuals by other brands

Concourse

Concourse SMART WHEELS quick start guide

Mont Blanc

Mont Blanc FK188 Fitting instructions

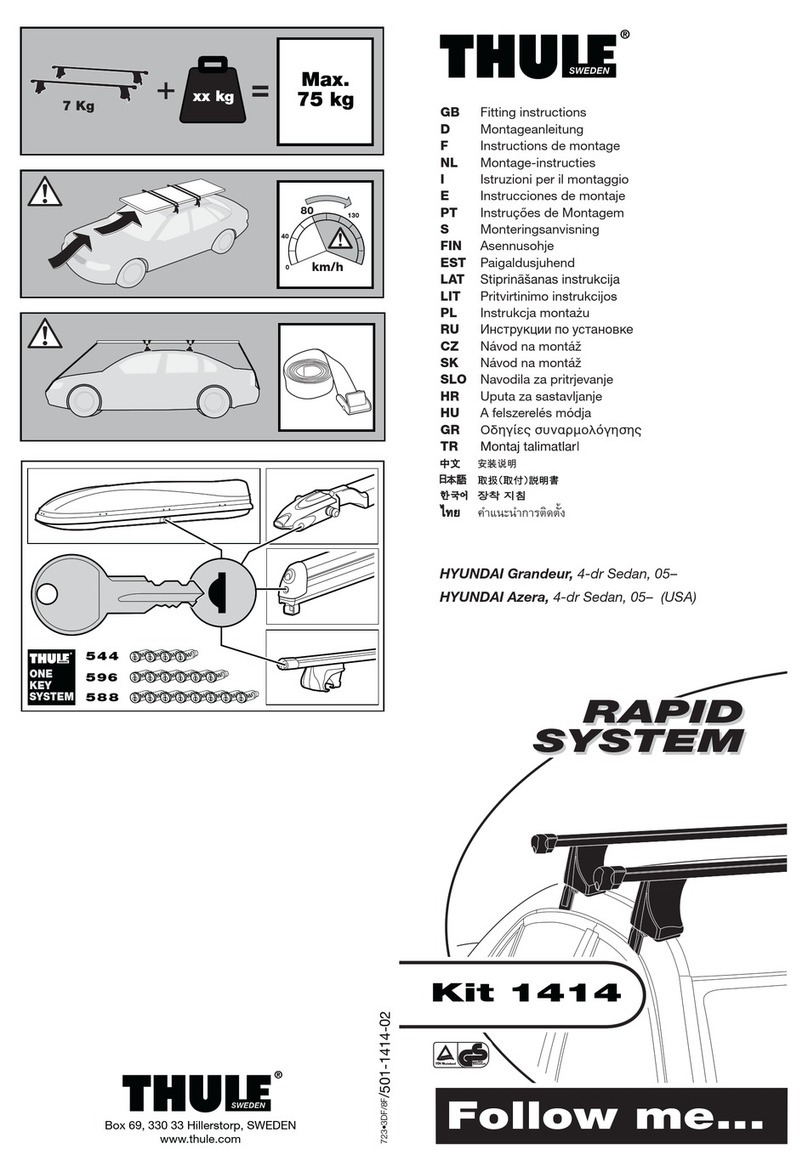

Thule

Thule 1200 Fitting instructions

Ferno

Ferno iNSLINE Fastening System user manual

Horizon Fuel Cell Technologies

Horizon Fuel Cell Technologies H-500 user manual

Nokia

Nokia CK-300 User and installation guide

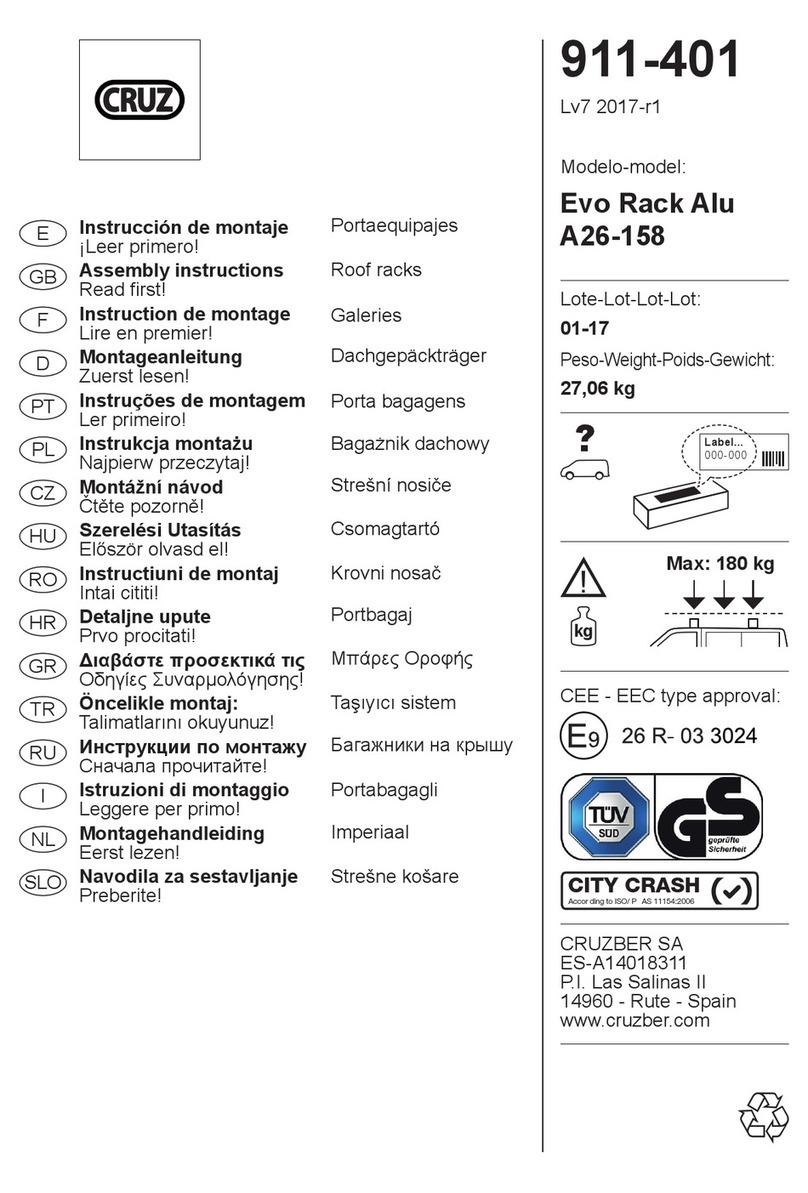

Cruz

Cruz Evo Rack Alu A26-158 Assembly instructions

GMC

GMC AUX-GM2 Quick start installation guide

1st Call Lockouts

1st Call Lockouts TouchClone version 1.5 User's manualer's manual

Stag

Stag 400 DPI installation guide

Carbine

Carbine 44cr Quick reference install guide

ANATEL

ANATEL S57L0 operation instruction