NOVENCO ACP Series Instruction Manual

ACP-ACG Smoke

ACP-ACG SMOKE

INSTALLATION AND

MAINTENANCE

918816-0

English

1

918816-0

GB

MU 14424 1110

Novax Axial Flow Fans, Types ACP and ACG Smoke

Installation and Maintenance

1. Applications

2. Handling

2.1 Marking

2.2 Weight

2.3 Transport

3. Storage

4. Installation

4.1 Mounting

4.2 Before installation

4.3 Installation

4.4 Mounts

4.5 Duct connection

4.6 Wiring

5. Start-up

5.1 Before start-up

5.2 Motors with Y/Δstart

5.3 Start-up procedure

6. Maintenance

6.1 Safeguards before inspection

and maintenance

6.2 Fan housing

6.3 Impeller

6.4 Motor

6.5 Detaching the motor

6.6 Fitting the motor

6.7 Blade pitch adjustment

6.8 Fault finding

7. Testing functionality

and operational

readiness

7.1 Periodic inspection

8. Sound

9. EU declaration of

conformity

1. Applications

Novax fume fans, types ACP and ACG

Smoke, are compact, sturdy axial flow fans

suitable for meeting both everyday

ventilation requirements under normal

conditions and for extracting smoke/heat

in case of fire in all types of commercial and

industrial buildings.

Novax fume fans, types ACP and ACG

Smoke, are tested and approved, meeting

the requirements on fans for smoke

extraction in Class F300 (300°C for 60

minutes) in accordance with EN 12101-3.

2. Handling

2.1 Marking

ACP and ACG fume fans are provided with

nameplates stating Novenco's name and

address and details of fan type/size, e.g.

ACG Smoke 1000/380, number of blades,

year of manufacture, weight, serial

number/order number. The nameplate also

states maximum temperature and

operating time. If the fan has an approval

number, the nameplate states class/

category and the applicable test standard

(EN 12101-3). Finally, the nameplate states

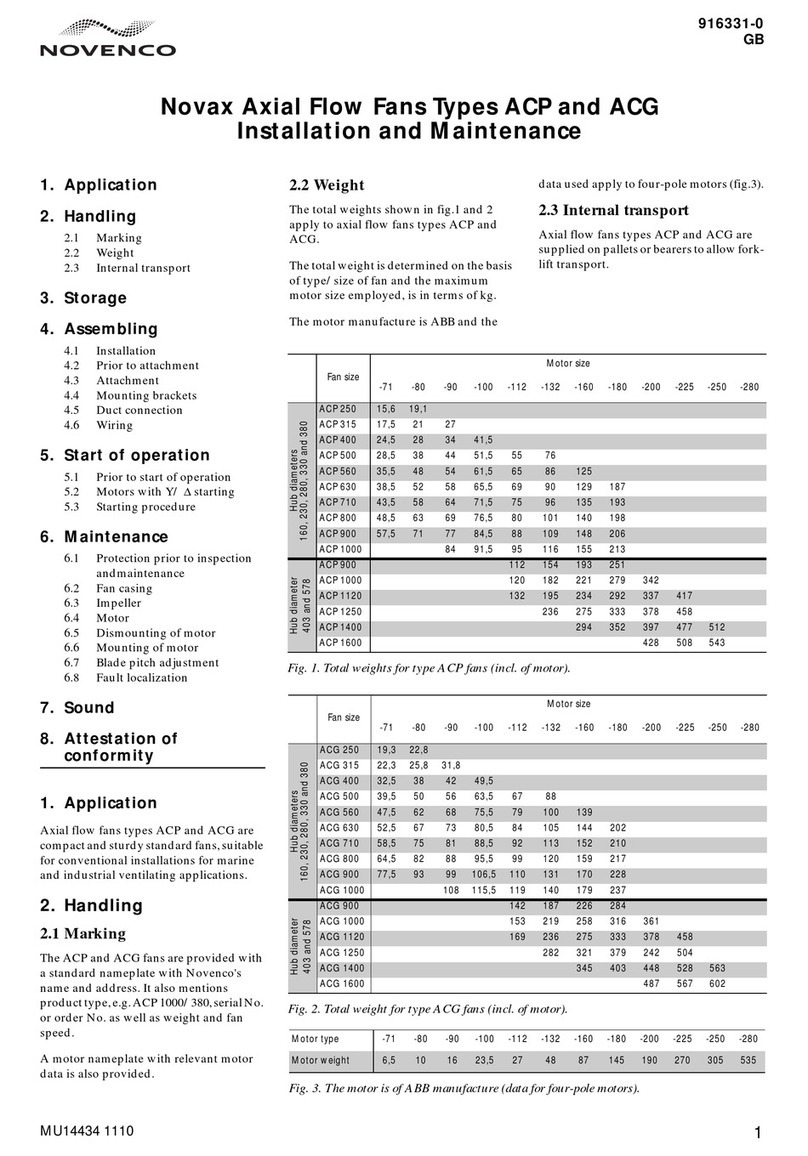

Fan size

Motor size

-90 -100 -112 -132 -160 -180 -200 -225 -250 -280

Hub diameter

160, 230, 280, 330 and 380

400 46 56

500 60 70 78 93

560 72 82 90 105 182

630 77 87 95 110 187 219

710 85 95 103 118 195 227

800 92 102 110 125 202 234

900 103 113 121 136 213 245

1000 112 122 130 145 222 254

Hub diameter

403

900 168 245

1000 179 256 288

1120 180 195 272 304

1250 272 242 319 351

1400 263 340 372

Hub diameter

578

900 192 269 301

1000 224 301 333 421

1120 226 241 318 350 438 523

1250 272 287 364 396 484 569 654

1400 388 420 508 593 678 828

1600 547 632 717 867

Fig. 2. Total weight of ACG Smoke fans incl. motor [kg]

Fan size

Motor size

-90 -100 -112 -132 -160 -180 -200 -225 -250 -280

Hub diameter

160, 230, 280, 330 and 380

400 38 48

500 48 58 66 81

560 58 68 76 91 168

630 62 72 80 95 172 204

710 68 78 86 101 178 210

800 73 83 91 106 183 215

900 81 91 99 114 191 223

1000 88 98 106 121 198 230

Hub diameter

403

900 138 215 162

1000 146 223 255

1120 143 158 235 267

1250 185 200 277 309

1400 217 294 326

Hub diameter

578

900 163 240 272

1000 185 262 294 382

1120 187 202 279 311 399 484

1250 226 241 318 350 438 523 608

1400 337 369 457 542 627 777

1600 488 573 658 808

Fig. 1. Total weight of ACP Smoke fans incl. motor [kg]

Fig. 3. Weight of motors for ACP and ACG Smoke [kg]

Motor size -90 -100 -112 -132 -160 -180 -200 -225 -250 -280

Weight 20 30 38 53 130 162 250 335 420 570

2

fan capacity with respect to pressure, air

quantity, output and maximum speed

(rpm).

A motor nameplate with relevant motor

data, including enclosure class, is also

provided.

2.2 Weight

The total weights shown in figs 1 and 2

apply to axial flow fans, types ACP and

ACG Smoke.

The total weight is determined by the type/

size of fan and the maximum size of the

motor used, and is given in kg.

Fig. 3 shows the weights of the various

motors. The motors are LOHER fire gas

motors and the data shown, which are

applicable for both ACP and ACG Smoke,

are the maximum weights for four-pole

motors.

2.3 Transport

During transport, care must be taken to

prevent water, e.g. rainwater, from entering

the motor or other sensitive components.

Novax fume fans, types ACP and ACG

Smoke, are supplied on pallets or skids

which allow fork-lift transport. The forks

must be positioned beneath the base. The

unit must be set down as slowly as possible

on a soft surface. Impacts, vibrations and

falls may lead to imbalance and

deformation or other damage to motor

bearings.

3. Storage

Novax fume fans can withstand outdoor

storage for up to one month providing the

packaging is intact. After removing the

packaging, fans must be stored in a

rainproof shelter.

If stored indoors, fans must be kept under

well-ventilated conditions with no risk of

condensation. Under such conditions,

storage duration may be extended to six

months.

The storage place must not be exposed to

vibrations, which may damage the motor

bearings. If stored for longer than three

months, the impeller should be turned

regularly by hand.

4. Installation

4.1 Mounting

Novax axial flow fans, types ACP and ACG

Smoke, are designed to operate in either

horizontal or vertical position (the

mounting position must be determined

before drain holes in the motor are drilled).

ACP Smoke has free inlet and non-ducted

outlet.

ACG Smoke has free inlet and ducted outlet

(outlet guide vane assembly).

4.2 Before installation

Before installation, ensure that the impeller

rotates freely in the fan housing, as far as

possible with equal distance between blade

tip and fan housing around the entire

circumference.

4.3 Installation

Fans must always be installed in such a way

as to prevent contact with rotating parts.

Free inlets and outlets must be guarded by

protective grilles. If ducts are connected,

these must be provided with protective

grilles on the side of the building.

The fan is provided with an arrow plate

denoting the direction of air flow through

the fan housing. During installation, ensure

that the fan is oriented so as to provide the

desired direction of air flow in the system.

The fan is best installed using special

mounts (available as optional extras, fig. 4),

but it may also be suspended by the

housing flanges or in special hangers.

Hangers must not impede the free intake

and discharge of air.

After securing the fan in position, check

that the impeller rotates freely in the

housing.

4.4 Mounts

Mounts for types ACP and ACG Smoke

consist of two mounting plates (fig. 4 pos.

01 and 02). Beneath these, two C-profiles

(pos. 03) must be fitted using bolts (pos. 05)

and nuts (pos. 04).

The distance between the ends of the C-

profiles and the mounting plates is

determined by the fan type/size and motor

size.

.

Mount the fan housing in the two flange

holes in the mounting plates and fit the

distance bush (fig. 5, pos. 07) by means of

joining elements (pos. 08 and 09) between

inlet cone and mounting plate (pos. 06).

ACP and ACG Smoke sizes 1250-1600 have

circular fan housing. The housing is

therefore installed using mount fittings (fig.

6 pos. 07A) and joining elements (fig. 6 pos.

08A and 09A).

The fittings must be attached to the back of

the mount and fan housing as shown in fig.

6.

To prevent vibrations spreading from the

fan to the surroundings, vibration dampers

may be fitted between fan and underlying

surface and flexible connectors may be

fitted to the ducts behind the fan (available

as optional extra).

Vibration dampers (fig. 5 pos. 10) should be

fitted on the C-profile ends using bolts (pos.

11).

Base plates (pos. 12) for attachment to the

foundation/floor should be fitted beneath

the rubber dampers.

The vibration frequency of the underlying

surface must differ at least 20% from the fan

speed.

If the motor is provided with condensation

drain holes, the fan must be oriented so that

the holes face downwards (are lowest).

It is of the utmost importance for the

Fig. 4. Mount for type ACP Smoke

Fig. 5. Mount for types ACP and ACG

Smoke 400-1120

Fig. 6. Mounts for types ACP and ACG

Smoke 1250-1600

3

performance and sound level of the axial

flow fan that the air flow is unimpeded and

free of eddies.

4.5 Duct connection

Novax ACG Smoke axial flow fans are

equipped with an outlet guide vane

assembly with core. This improves fan

efficiency and allows duct connection.

The duct on the outlet side of the fan must

be designed to ensure a smooth flow of air

without turbulence. Avoid, for instance,

sharp bends or flexible connectors in the

ducting immediately behind the fan.

ACP and ACG Smoke fans are prepared for

circular duct connections on the outlet side.

Flanges supplied as standard comply with

EUROVENT 1/2.

Systems with higher vibration levels or

more exacting performance requirements

must be provided with expansion joints

between the fan and duct, and the duct

must not be supported by the fan.

It is important to provide sufficient free

space for assembling and dismantling the

system and to facilitate cleaning and

maintenance.

4.6 Wiring

Important: Do not mount a frequency

converter on a fan intended

for smoke exhaust. The

electric installation must be

designed to bypass the

frequency converter and run

the fan at nominal speed in

the event of fire.

Electrical connections must be made by an

authorised electrician in accordance with

current legislation. Power is connected via

the motor terminal box as shown in the

wiring diagrams in the terminal box cover.

Three-phase motors are connected as

shown in the wiring diagrams in the

terminal box cover.

For the connection of single-phase motors,

see wiring diagrams for single-phase

variable motors.

Having wired the motor terminal box,

check that the direction of rotation of the

impeller complies with the arrow plate

fitted on the outside of the fan.

For reversible fans (alternating direction of

rotation) a time delay must be provided to

ensure that the impeller is stationary before

restarting.

5. Start-up

5.1 Before start-up

Before start-up, check that the fan and duct

connections are clean and free of tools and

other foreign matter.

Also ensure that the electrical connections

fulfil applicable requirements, that any

protective grilles on the fan inlet or outlet

sides are correctly fitted, and that the

direction of rotation of the impeller

complies with the arrow plate (check by

briefly starting the fan).

See fig. 7 pos. 01 and 02.

5.2 Motors with Y/Δstart

The relay must be set to the calculated time.

5.3 Start-up procedure

• Start the fan.

• Check that no abnormal sound occurs.

• Check that the vibration level is

normal. At operating speed, fan

vibration must not exceed 7 mm/s

rms* measured radially at two points

with 90° offset and at the free shaft end

of the motor. Otherwise, the fan must

be rebalanced.

When fixed in position, the fan must not be

operated if vibration levels exceed 11 mm/

s rms*.

When freely suspended or mounted on

vibration dampers, the fan must not be

operated if vibration levels exceed 18 mm/

s rms*.

* ISO 2954: Mechanical vibration of rotating

and reciprocating machinery –

Requirements for instruments for

measuring vibration severity.

After thirty minutes of operation, check

that the fan operates normally.

Important: The fan is designed for

continuous operation. The

following kinds of operation

may cause fatigue break in

the impeller and endanger

people.

- Operation with pulsating

counter pressure - called

pump mode

- Operation with repeated

starting and stopping

If in doubt Novenco should

be contacted to assess the

suitability of the fan.

6. Maintenance

6.1 Safeguards prior to

inspection and maintenance

Before inspecting or servicing the fan, it

must be switched off and disconnected

from the electrical system. Also ensure that

the fan cannot be restarted unintentionally.

6.2 Fan housing

As standard, the fan housing requires no

maintenance other than cleaning.

If the housing is painted, the surface should

be checked regularly and repaired where

necessary.

6.3 Impeller

The impeller (rotor unit) is supplied with

the blades factory adjusted to the pitch

corresponding to the desired operating

point (pressure and air flow) at the fan

speed in question. To ensure vibration-free

operation the impeller has been carefully

balanced in this position.

Vibration occurring during operation is

usually the result of dust or dirt

accumulating on the hub and blades, and

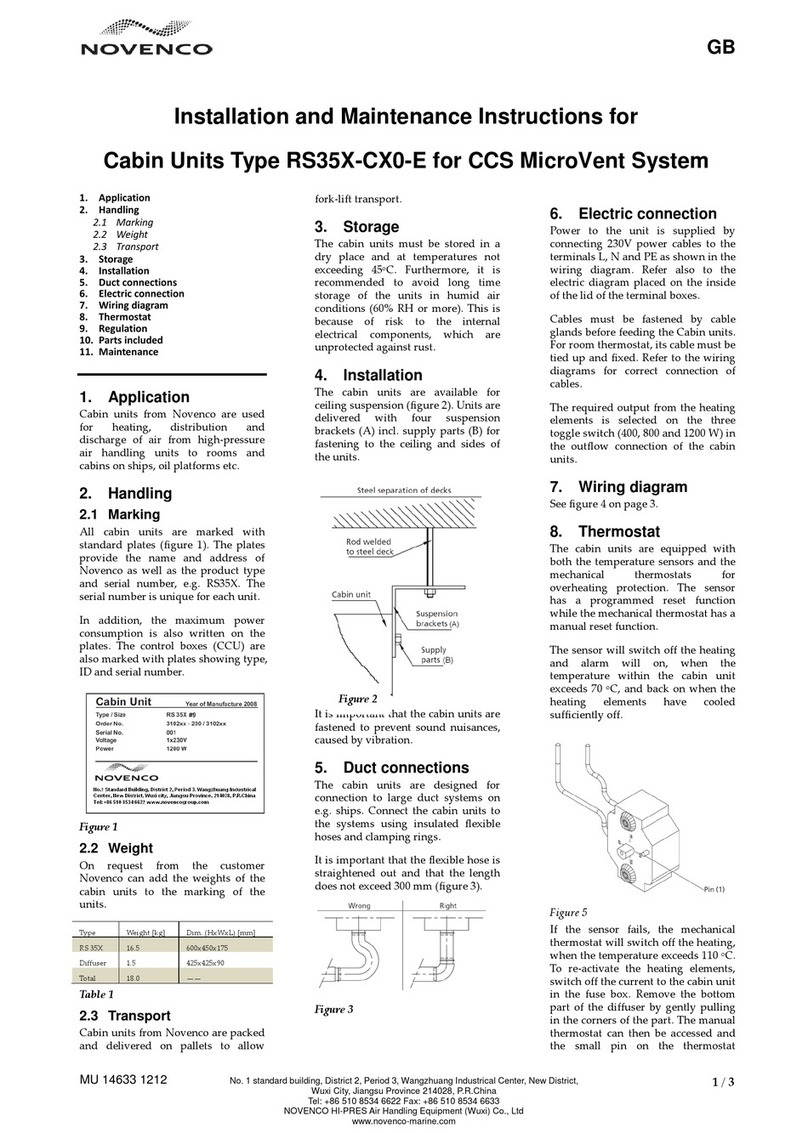

Fig. 7. Novax ACG Smoke

Fig. 8. Dismantling/assembling types ACG and ACP Smoke

1. Motor

2. Motor flange

3. Wire guard

4. Motor shell

5. S-washer

6. Set screw

7. Impeller

8. Centre disc

9. Centre screw

10. Set screw

11. Washer

12. Hub

13. Outlet guide vanes

14. Nut

4

Novenco A/S

Industrivej 22 Tel. 70 12 42 22

DK-4700 Naestved Fax 55 75 65 50

www.novencogroup.com [email protected]

will disappear after cleaning. Should this

not be the case, technical assistance should

be called in immediately as continued

vibration will shorten the service life of the

blades and motor bearings.

6.4 Motor

Normally, only the motor bearings require

maintenance. This should be performed as

described in the maintenance instructions

for electric motors.

6.5 Detaching the motor

Before detaching the motor, disconnect the

power supply and motor cable. Next,

detach any ducts and outlet guide vane (fig.

8 pos. 13, 10, 11, and 14) on the fan outlet

side.

Remove the impeller centre screw (pos. 09)

and centre disc (pos. 08).

Detach the impeller using a puller secured

in the two threaded puller holes in the hub

boss (pos. 12).

Loosen the screws in the motor shell (pos.

05 and 06). The motor (pos. 01) and motor

flange (pos. 02) can then be detached.

When dismantling the fan, be careful not to

expose individual parts to impacts or other

forces that might damage the motor

bearings or fan parts.

6.6 Fitting the motor

After servicing is complete the motor must

be refitted. Check that the motor flange (fig.

8 pos. 02) is correctly positioned and that

the motor shaft is concentrically positioned

in the fan housing before tightening the

bolts (pos. 06).

Refit the impeller (pos. 07) on the motor

shaft by means of a puller secured in the

threaded hole on the motor shaft. Tighten

the impeller hub against the motor shaft

collar. Check that blade clearance is equal

around the entire circumference of the

housing. If this is not the case, adjust the

motor position in the suspension system.

Now fit the centre screw (pos. 09) and centre

disc (pos. 08). It is recommended that lock

washers and lock nuts be replaced when

reassembling the fan. Finally, connect the

motor cable in the terminal box (pos. 01)

and any ducts and outlet guide vane (pos.

13).

To restart the fan, follow the procedure

described in section 5: Start-up.

6.7 Blade pitch adjustment

The blade pitch is factory adjusted using a

special tool (fixture) to provide the output

required by the customer/order on

delivery.

If a different output is required, it is possible

to alter blade pitch. This requires

knowledge of the motor load and the max.

permissible blade pitch in relation to the

motor rating (in case of blade pitch

increase).

Please contact Novenco before any such

adjustment of blade pitch. Special tools for

blade pitch adjustment and instructions for

impeller balancing are available from

Novenco.

A brochure describing the blade pitch tool

and its use is available on request.

6.8 Fault finding

Possible operating faults are described in

the following.

Insufficient output:

Blocked air supply on the inlet side:

• Damper closed

•Ductblocked

• Supply fan, if any, stopped

•Motordefective

• Motor cut out

• Incorrect direction of impeller rotation

Noise/vibration:

• Bearings in electric motor defective

• Impeller out of balance

• Impeller worn/damaged

• Bolts/components loose

• Impeller blades have different pitch

• Fan operating in "stall" mode – this

may damage the system and should be

remedied immediately, see

"Insufficient output".

7. Testing functionality

and operational

readiness

To maintain their fire approval, ACP and

ACG Smoke fans must be tested every three

months with respect to functionality and

operational readiness.

If ACP and ACG Smoke fans are also used

for ventilation purposes, such tests need

only be performed at six-month intervals

provided the fan is started at least once a

day by means of a time switch or carbon

monoxide sensor.

7.1 Periodic inspection

Novax fume fans must always be

maintained in proper operating condition.

To ensure satisfactory operation and long

service life, the fans should be inspected

every six months.

Such inspection should include the

following:

• Measurement of power consumption

• Measurement of fan housing vibration

• Control of fixation bolt torque and, if

necessary, readjustment

• Visual inspection of impeller, housing

and wiring

•Cleaning:

– Use compressed air to clean the

inside

– Use water to clean the outside

It is recommended that a log be kept of all

values and observations.

8. Sound

The sound generated by the fans depends

on installation and operating conditions,

and general data on sound generation is

therefore unavailable.

For further details, please refer to our

catalogue material or computer programs

designed to calculate specific sound

emissions.

9. EU declaration of

conformity

Novenco A/S

Industrivej 22

DK-4700 Naestved

hereby declares that ACP Smoke 400-1600

and ACG Smoke 400-1600 axial flow fans

have been manufactured in conformity

with Council Directive 2006/42/EC on the

approximation of the laws of the member

states relatingto machinery (the Machinery

Directive).

Directives

– EC Machinery Directive 2006/42/EC

– EMC Directive 2004/108/EC)

– Low Voltage Directive 2006/95/EC

Applied standards

EN ISO 12100-1: Safety of machinery -

Part 1

EN 12100-2: Safety of machinery -

Part 2

EN 13857: Safety of machinery -

Safety distances

EN 12101-3: Smoke and heat control

systems - Part 3, class 1

EN 60204-1: Safety of machinery -

Electrical equipment of

machines - Part 1:

General Requirements

It is a condition that Novenco installation

instructions have been followed.

Naestved, 1.11.2010

Steen Hansen

R&D manager

Novenco A/S

WWW.NOVENCO-BUILDING.COM

ACP-ACG Smoke

This manual suits for next models

1

Table of contents

Other NOVENCO Fan manuals

NOVENCO

NOVENCO NOVAX ACN-ACW-ARN Instruction Manual

NOVENCO

NOVENCO CNA Series Instruction Manual

NOVENCO

NOVENCO ZERAX AZL-AZN-AZW Instruction Manual

NOVENCO

NOVENCO AUO 290 Instruction Manual

NOVENCO

NOVENCO Novax Instruction Manual

NOVENCO

NOVENCO FALKINN ACN Instruction Manual

NOVENCO

NOVENCO Novax ACP Series Instruction Manual

NOVENCO

NOVENCO RS35x-CX0-E series User manual

Popular Fan manuals by other brands

Naterial

Naterial ANEMO ZN DC116 Assembly, Use, Maintenance Manual

S&P

S&P HR100V Homeowner's guide

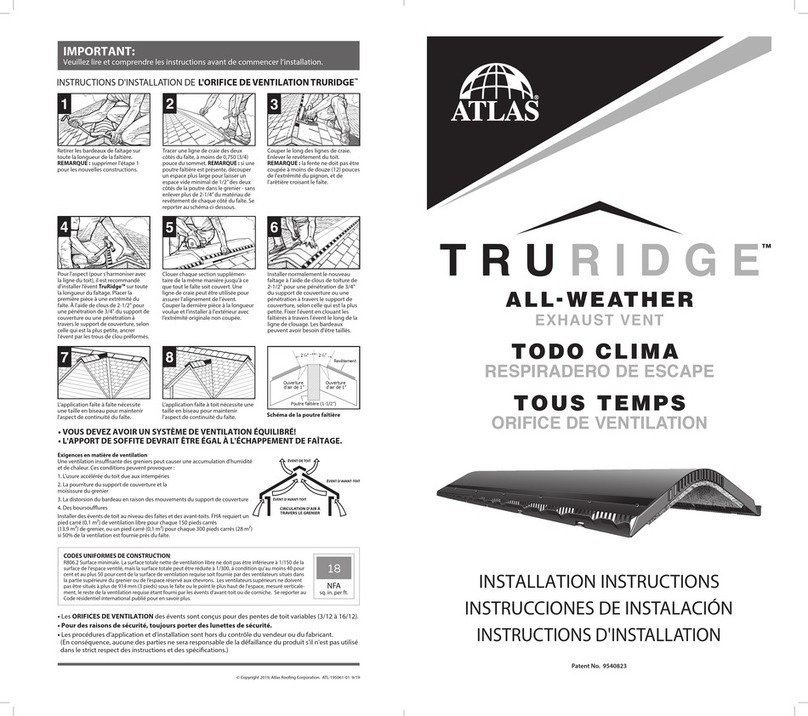

Atlas

Atlas Trueridge ALL- WEATHER installation instructions

Vetech

Vetech VENT-M30T3 instruction manual

Unold

Unold BREEZY SWING Instructions for use

Hunter

Hunter Contempo 59013 Owner's guide and installation manual