NOVENCO FALKINN ACN Instruction Manual

1

Installation and Maintenance

Novax Smoke Exhaust Fan Type ACN Smoke

1. Application

2. Handling

2.1 Marking

2.2 Weight

2.3 Transport

3. Storage

4. Installation

4.1 Prior to attachment

4.2 Attachment

4.3 Mounting brackets

4.4 Duct connection

4.5 Electric connection

5. Start of operation

5.1 Prior to start of operation

5.2 Motors with Y/Δstarting

5.3 Starting procedure

6. Maintenance

6.1 Protection prior to inspection and

maintenance

6.2 Fan casing

6.3 Impeller

6.4 Motor

6.5 Dismounting of motor

6.6 Mounting of motor

6.7 Blade pitch adjustment

6.8 Fault localization

7. Test of operability and

operating condition

7.1 Periodic inspection

8. Sound

9. Attestation of conformity

1. Application

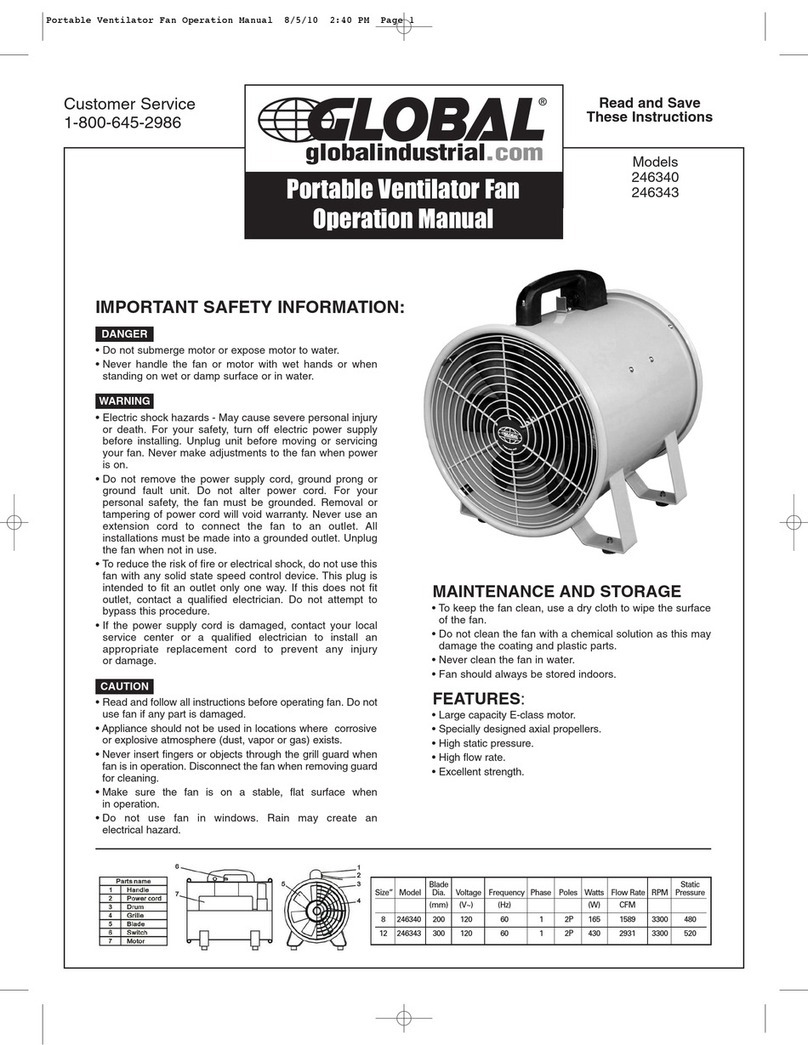

Novax smoke exhaust fans type ACN-

smoke are sturdy axial flow fans de-

signed for both the daily ventilation re-

quirements under normal conditions

and smoke/heat exhaustion in the event

of a fire in all kinds of commercial and in-

dustrial buildings.

Novax smoke exhaust fans type ACN-

smoke are tested and approved to meet

the requirements of fans for smoke ex-

haustion class F300 (300°C for 60 min-

utes) and F400 (400°C for 120 minutes)

according to standard: EN 12101-3.

2. Handling

2.1 Marking

The ACN smoke exhaust fan is provided

with a standard nameplate with Noven-

co's name and address.

It also mentions type/size e. g. ACN

1000/380, number of blades, year of pro-

duction, weight, serial number/order

number (production number). Further-

more, it mentions maximum tempera-

ture and working period in minutes and

if the fan is supplied with approval

number, class/category are also men-

tioned as well as test standard applied

(EN 12101-3). Fan pressure, air quantity,

output and maximum speed per minute.

The fan is also provided with a motor

nameplate with relevant motor data in-

cluding insulation class of the motor.

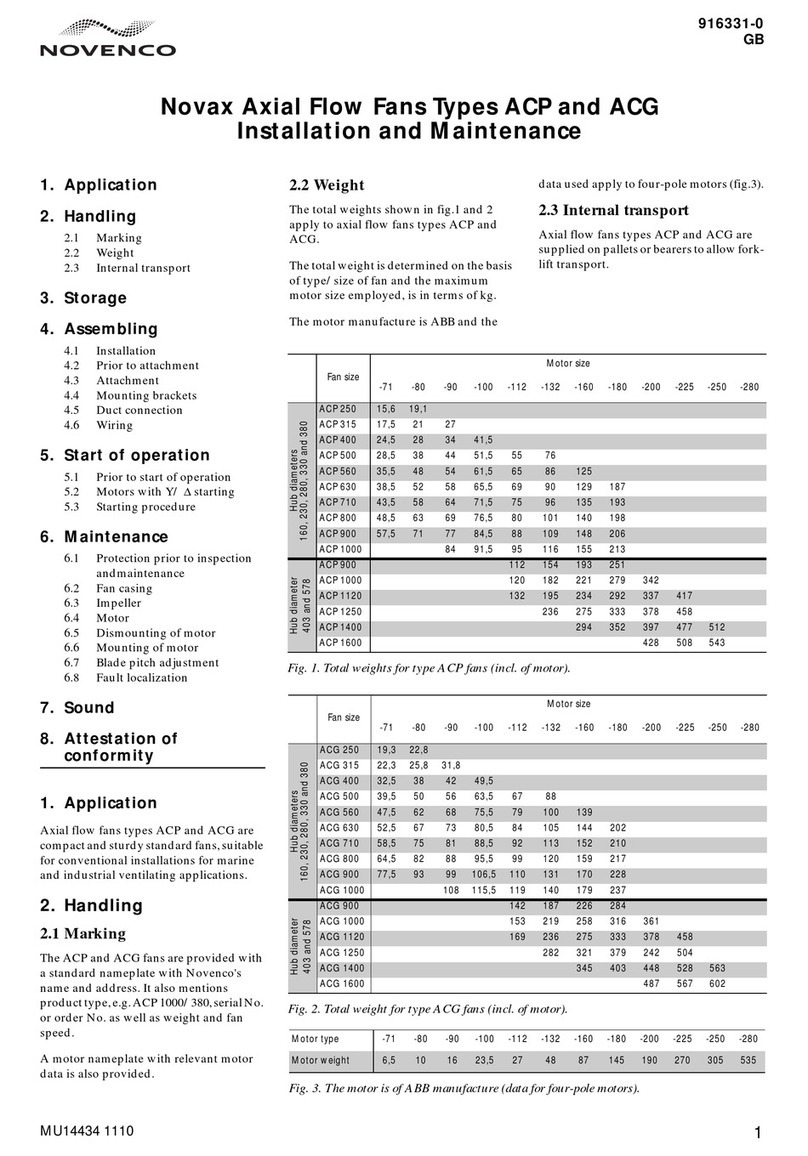

2.2 Weight

The total weights shown in table 1 apply

to axial flow fan type ACN-smoke. The

total weight is determinedon the basis of

type/size of fan and maximum motor

size employed and is in terms of kg.

2.3 Transport

When transporting the fans take care

that no water (e. g. rainwater) gets into

the motor or other sensitive components.

Novax smoke exhaust fans type ACN-

smoke are delivered on pallets or bearers

to allow fork-lift transport.

The forks of the fork-lift truck must lift

underneath the frame. Set down the fan

as slowly as possible and on a soft foun-

dation. Vibrations, shocks, and fall may

result in imbalance and deformation and

may damage the motor bearings.

MU 14347 0610

918149-0

GB

Table 1. Example of total weights (Fan incl. motor, LOHER 4-pole) [kg]

Type ACN-smoke

Fan size

Motor size

-90 -100 -112 -132 -160 -180 -200 -225 -250 -280

Hub diameters

160, 230, 280, 330 and 380

400 47 57

500 62728095

560 75 85 93 108 185

630 80 90 98 113 190 222

710 93 103 111 126 203 235

800 102 112 120 135 212 244

900 118 128 136 151 228 260

1000 154 164 172 187 264 296

Hub diameters

403

900 170 247

1000 207 284 316

1120 205 220 297 329

1250 222 237 314 346

1400 255 332 364

Hub diameters

578

900 206 283 315

1000 245 322 354 442

1120 257 272 349 381 469 554

1250 307 322 399 431 519 604 689

1400 459 491 579 664 749 899

1600 616 701 786 936

Motor type -90 -100 -112 -132 -160 -180 -200 -225 -250 -280

Motor Weight (kg) 20 30 38 53 130 162 250 335 420 570

2

3. Storage

Novax smoke exhaust fans type ACN-

smoke can stand outdoor storage for 1

month provided the packing is intact.

Fans with no packing must be stored in

a sheltered place.

If the fans are stored indoors under well-

ventilated conditions with no risk of con-

densation the storage period may be ex-

tended to 6 months. The storage place

must not be exposed to vibrations likely

to damage the motor bearings.

If the storage period exceeds 3 months, it

is recommended to turn the impeller re-

gularly by hand.

4. Installation

4.1 Prior to attachment

Prior to attachment make sure that the

impeller rotates freely in the fan casing,

wherever possible with equal distance

between blade tip and fan casing throug-

hout the circumference.

4.2 Attachment

Fans must always be installed so that the

rotating partscannot be touched. The fan

must be provided with a wire guard on

the inlet and outlet sides. If ducts are con-

nected, they should be provided with

wire guards on the inlet side.

The fan is provided with an arrow-plate

denoting the direction of air flow

through the fan casing. See during instal-

lation that the fan is oriented so as to pro-

vide the desired direction of air flow in

the system.

The best way of installing the fan is using

mounting feet (available as optional ex-

tras), but it may also be suspended in the

fan casing flanges or in special carriers.

The carriers must not hamper the free in-

let and outlet of air.

When the fan has been finally secured

make sure that the impeller rotates freely

in the casing.

If the motor is provided with drain holes

for condensed water the fan must be ori-

ented so that the holes turn downwards

(lowest point).

Generally, it is of the utmost importance

for the performance and sound level of

an axial flow fan that the air flow is un-

impeded and free from eddies.

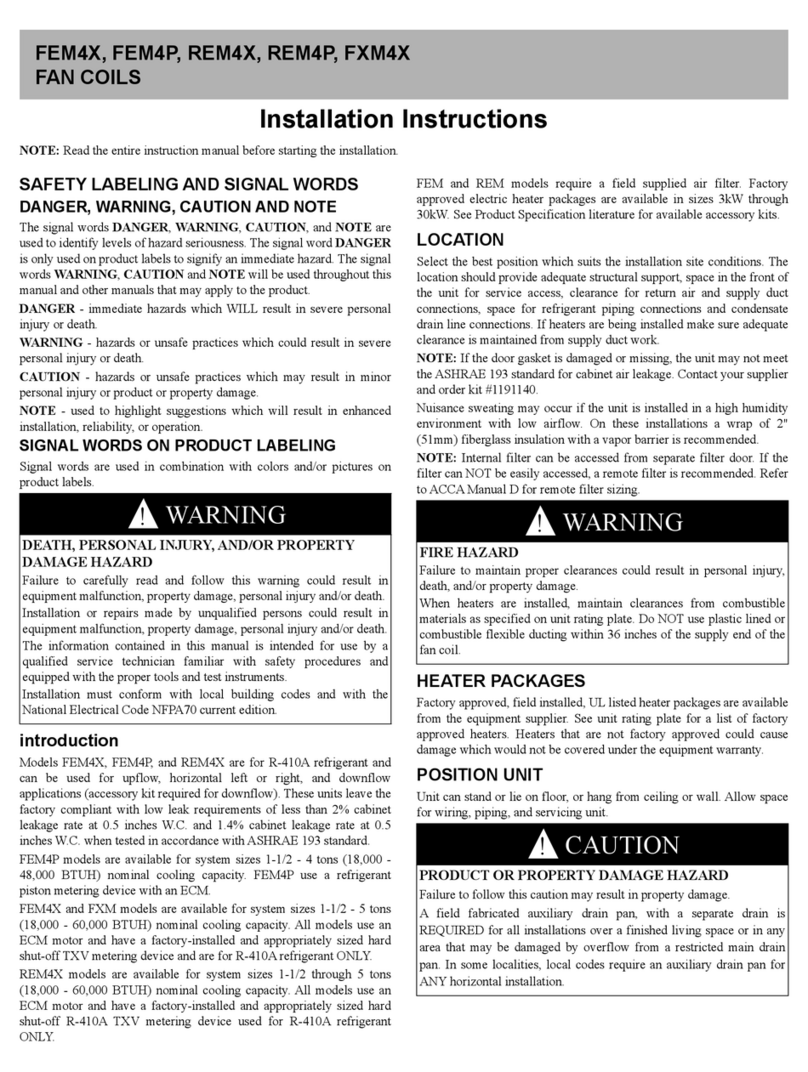

4.3 Mounting feet

Mounting feet for type ACN-smoke con-

sist of two mounting plates (see fig.

1item 01).

Mount two stiffeners (item 02) between

these by means of joining elements (item

03). Stiffeners are only available from fan

size 630 mm inclusive.

To prevent vibrations spreading from the

fan to the surroundings, anti-vibration

mountings may be inserted between fan

and support and flexible connections fit-

ted in the ducts before and after the fan

(available as optional extras).

Secure anti-vibration mountings (fig. 2

ite m 0 6) in the mou nting fe e t by means o f

bolts (item 05).

Mount base plates (item 07) for attach-

ment in the foundation/floor at the bot-

tom of the rubber element.

The natural frequency of the support

must differ at least 20% from the fan

speed.

The anti-vibration mountings serve to

ensure that the natural frequency of the

system does not exceed 10 Hz and that

the damping is at least 80% at 1500 r.p.m.

Figure 1. Mounting foot for type ACN

Figure 2. ACN with mounting foot and antivibration mountings

3

4.4 Duct connection

In order to achieve the capacities stated

on the performance curves the fans must

be provided with ducts as shown in fig.

3 and fig. 4.

The duct or inlet cone on the fan inlet si-

de must be designed to ensure smooth

and undisturbed flow of the air;

ACN-smoke fans are prepared for circu-

lar duct connection on both inlet and out-

let sides.

Flanges supplied as standard

for type ACN comply with EUROVENT

1/2.

Systems with higher vibration level or

more exacting performance require-

ments must be provided with expansion

joints between fan and duct, and ducts

must not be supported by the fan.

It is important to allow for free areas to

facilitate mounting and dismounting as

well as ordinary maintenance.

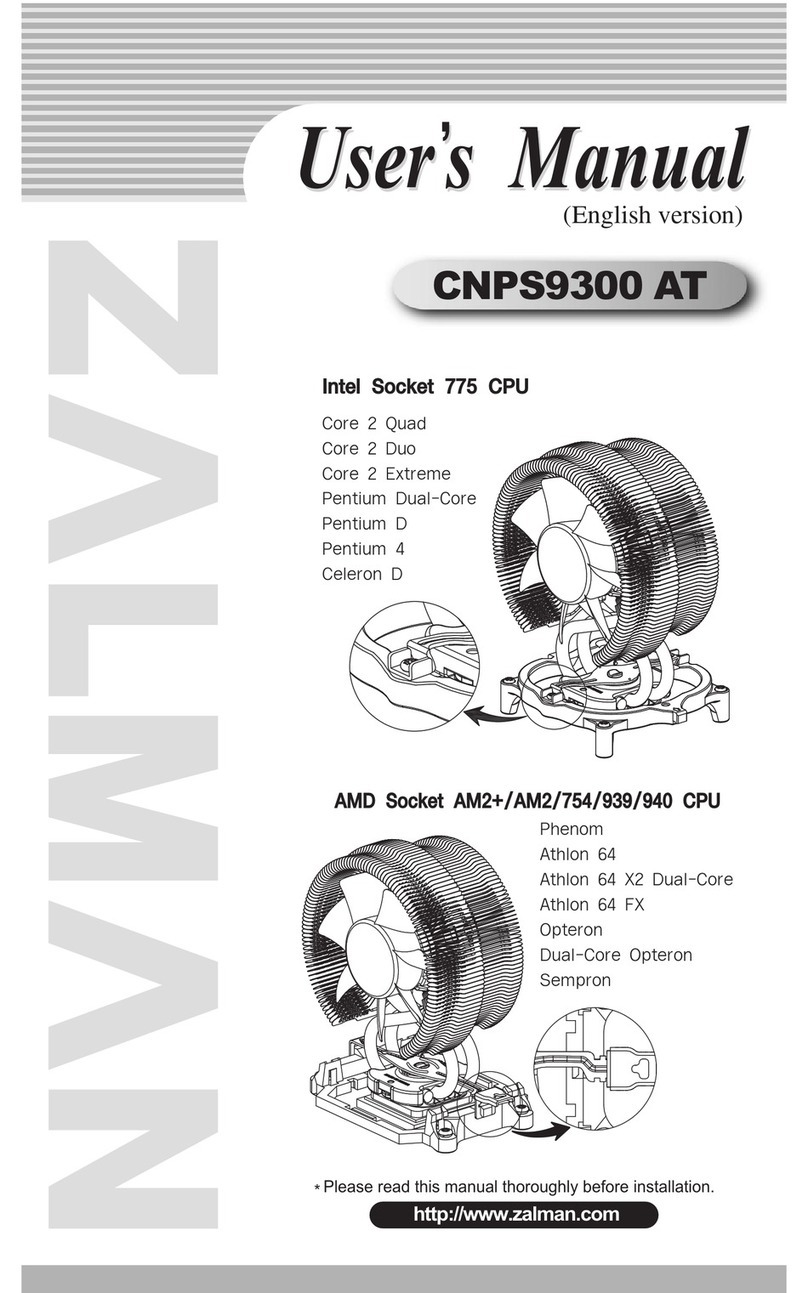

4.5 Electric connection

Connection to the mains is made accord-

ing to current legislation and by author-

ized personnel.

Connection to the mains is effected direct

in the motor terminal box or in the termi-

nal box mounted on the outside of the

fan casing (see fig. 6). Connection is

made according to connection diagram

on the inside of the terminal box cover.

Having wired the motor terminal box,

check that the direction of rotation of the

impeller complies with the arrow-plate

fitted on the outside of the fan.

5. Start of operation

5.1 Prior to start of operation

Approval (prior to start of operation).

After installation of the axial flow fans

their correct installation, operation and

interaction must be established through

an approval test.

The person responsible for the operation

of the system must take the initiative for

this test.

The approval test must be confirmed by

the person responsible for the operation

of the system and the documentation

must be kept and produced whenever

asked for.

Prior to start of operation check that the

fan and duct connections are clean and

free from tools and foreign substances.

Also check that the electric connections

meet the prescribed requirements, that

any wire guard fitted on the fan inlet or

outlet side is correctly mounted and that

the direction of rotation of the fan com-

plies with the arrow-plate (check by

short-time operation).

5.2 Motors with Y/Δstarting

The relay must be set to the calculated ti-

me.

5.3 Starting procedure

•Startthefan

• Check that no abnormal noises occur.

• See that the vibration level is normal.

The vibration level at the fan operat-

ing speed must not exceed 7 mm/s

rms, measured radially at 2 points, 90º

offset and at the free shaft end of the

motor. Otherwise, the fan must be bal-

anced. Operation at a higher vibration

level exceeding 11 mm/ s rms* is not

allowed in case of fixed fan position.

Operation at a higher vibration level

exceeding 18 mm/s rms* is not al-

lowed in case of position on feet or an-

ti-vibration mountings.

• After 30 minutes of operation check

that the fan operates normally.

* ISO 2954, Requirements for instru-

ments for measuring vibration sever-

ity.

6. Maintenance

6.1 Protection prior to inspection

and maintenance

When the fan is out of operation for rea-

sons of inspection or repair/maintenan-

ce, the electric system must be switched

off and protected so that the fan is not cut

in unintentionally.

6.2 Fan casing

The fan casing requires no maintenance

other than ordinary cleaning.

If the fan casing is painted, the painted

surface should be checked regularly and

repaired where necessary.

Figure 3. Installation in duct system

Figure 4. Inlet cone for connection to duct

4

6.3 Impeller

From the factory the impeller is supplied

with the blades adjusted to the pitch cor-

responding to the desired operating

point (pressure and air flow) at the fan

speed in question. To ensure vibration

free operation the impeller has been

carefully balanced in this position.

Vibrations occurring during operation

will normally be due to accumulations of

dust or dirt on the hub and blades, and

will disappear after cleaning. Should this

not be the case, expert assistance should

be called in immediately, as continued

vibrations will shorten the life of the mo-

tor bearings.

6.4 Motor

The motor normally only requires main-

tenance of the bearings as indicated in

the maintenance instructions for electric

motors.

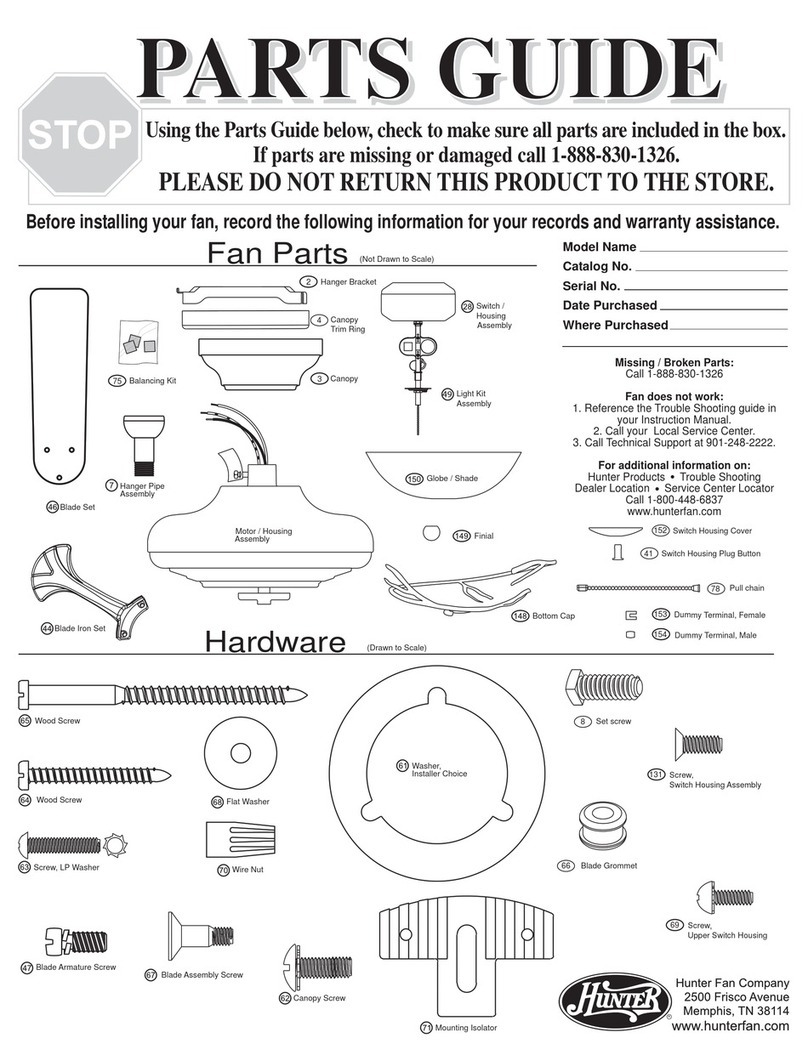

6.5 Dismounting of motor for

types

ACN-smoke (see fig. 5)

Prior to commencing the work, switch

off the current and disconnect the motor

cable. Next, dismount any ducts on the

fan inlet and outlet sides. Remove the

impeller centre screw (see item 01), cen-

tre disc (see item 02) and hub cover (see

item 03).

Dismount the impeller by means of a

puller fastened in the 2 threaded holes of

the hub boss/threaded holes for puller

(see item 05).

Detach the motor by loosening the

screws in the motor shell (see item 06).

Now the motor (see item 11) and motor

flange (see item 10) can be removed.

In dismounting and disassembling the

fan be careful not to expose the individu-

al parts to shocks etc. likely to damage

the motor bearings or other fan compo-

nents.

6.6 Mounting of motor for types

ACN-smoke (see fig. 5)

After servicing remount the motor, take

care that the motor flange (item 10) is cor-

rectly located and that the motor shaft is

concentrically placed in the fan casing

before tightening the bolts (item 06).

Mount the impeller (item 04) on the mo-

tor shaft by means of a tool fastened in

the threaded hole of the motor shaft.

Fix the impeller hub to rest against the

motor shaft collar.

Check that the blade clearance of the im-

peller is the same throughout the circum-

ference of the casing. If that is not the

case, adjust the motor location in the sus-

pension arrangement.

Now mount centre screw (item 01), cen-

tre disc (item 02), and hub cover (item

03). Replace lock washers/lock nuts dur-

ing fan assembly. Finally connect motor

cable (item 13) in terminal box (item 12)

and ducts, if any.

To start the fan follow the procedure de-

scribed in section 5. Start of operation.

6.7 Blade pitch adjustment

The blade pitch has been adjusted in the

factory with a special tool (mounting fix-

ture) to deliver the performance required

by the customer/order on delivery.

If the fan performance is required to be

changed it is possible to change the blade

pitch. It requires knowledge of the motor

load and the max. permissible blade

pitch on the graph as related to the motor

rating (in case of blade pitch increase).

Contact Novenco before any such ad-

justment of the blade pitch. Novenco can

supply special tools for blade pitch ad-

justment and instructions for impeller

balancing. The brochure “Blade Angle

Tool” is available on request.

Figure 5. Dismounting/mounting of axial flow fan

5

6.8 Fault localization

These are likely causes of breakdowns/

failures:

Deficiency in performance:

•Blocked air supply to the fan inlet side:

– Damper closed

– Duct choked

– Supply fan, if any, stopped

– Motor defective

– Motor disconnected

• Wrong direction of rotation of impel-

ler

Noise/vibrations:

• Bearings in electric motor defective

• Impeller out of balance

• Impeller worn/damaged

• Bolts/components loose

• Impeller blades have different pitch

angles

• Fan operates in the stalling area. May

result in breakdown. Repair failures,

see “Deficiency in performance”.

7. Test of operability and

operating condition

ACN-smoke approved for smoke con-

trol must be tested four times a year as to

operability and operating condition.

If smoke exhaust fans type ACN-smoke

are used for standard ventilation as well,

a test every six months is sufficient if the

regular starts of the fans ensure at least

one start a day - as a result of connection

to a time switch or carbon monoxide

alarm.

7.1 Periodic inspection

Novax smoke exhaust fans must always

be kept in operational and perfect condi-

tion by the user. The fans should be in-

spected twice a year to ensure a satisfac-

tory function and long life.

The inspection must include:

• Measuring of power consumption

•Measuringofvibrations on fan casing

• Check of torque for fixing bolts and –

correction of it, if necessary.

• Visual inspection of impeller, fan cas-

ing, and connection to the electricity

supply

•Cleaning:

– inside with pressure air

– outside with water

It is recommended to enter all values and

observations in a log.

8. Sound

The sound generation of the fans de-

pends on installation and operating con-

ditions, which means that no general da-

ta of the sound generation can be given.

Reference is made to our catalogues or

computer programs for calculation of

the specific sound generation.

9. Attestation of conform-

ity

EU – Attestation of Conformity

The Machinery Directive 2006/42/EC,

part 2, A

Novenco A/S

Industrivej 22

DK-4700 Naestved

Hereby declares that axial flow fans type

ACN-smoke 400-1600 have been manu-

factured in conformity with the Coun-

cil's directives

2006/42/EC regarding mutual approxi-

mation of the machinery laws (the Ma-

chinery Directive) of the member states.

Applied standards:

EN ISO 12100-1: Safety of machinery

part 1

EN ISO 12100-2: Safety of machinery

part 2

EN ISO 13857: Safety of machinery -

Safety distances

EN 12101-3: Smoke and heat control

systems - Part 3, class 1

EN 60204-1: Safety of machinery -

Electrical equipment of

machines Part 1:

General Requirements

It is a condition that Novenco's instruc-

tions for installation have been followed.

Naestved, 01.06.2010

Steen Hansen

R&D Manager

Novenco A/S

Figure 6. Electric connection through fan casing to external terminal box

External terminal boxExternal terminal box

Electric cable/Electric cable/

Flexible metallic conduitFlexible metallic conduit

MetalMetal

cable glandcable gland

(relief)(relief)

NutNut

Novenco A/S

Industrivej 22 Tel. (+45) 70 12 42 22

DK-4700 Naestved Fax (+45) 55 75 65 50

Denmark www.novencogroup.com

Table of contents

Other NOVENCO Fan manuals

NOVENCO

NOVENCO Novax ACP Series Instruction Manual

NOVENCO

NOVENCO AUO 290 Instruction Manual

NOVENCO

NOVENCO ACP Series Instruction Manual

NOVENCO

NOVENCO NOVAX ACN-ACW-ARN Instruction Manual

NOVENCO

NOVENCO CNA Series Instruction Manual

NOVENCO

NOVENCO Novax Instruction Manual

NOVENCO

NOVENCO ZERAX AZL-AZN-AZW Instruction Manual

NOVENCO

NOVENCO RS35x-CX0-E series User manual

Popular Fan manuals by other brands

Hunter

Hunter 21978 Parts guide

Termozeta

Termozeta BASSOTTO XL instruction manual

Progress Lighting

Progress Lighting AirPro P250102 installation manual

Luma

Luma Comfort MF26B owner's manual

KDK

KDK K14X5 Operating and installation instructions

Vent-Axia

Vent-Axia Lineair LINEAIR100 B Installation and wiring instructions