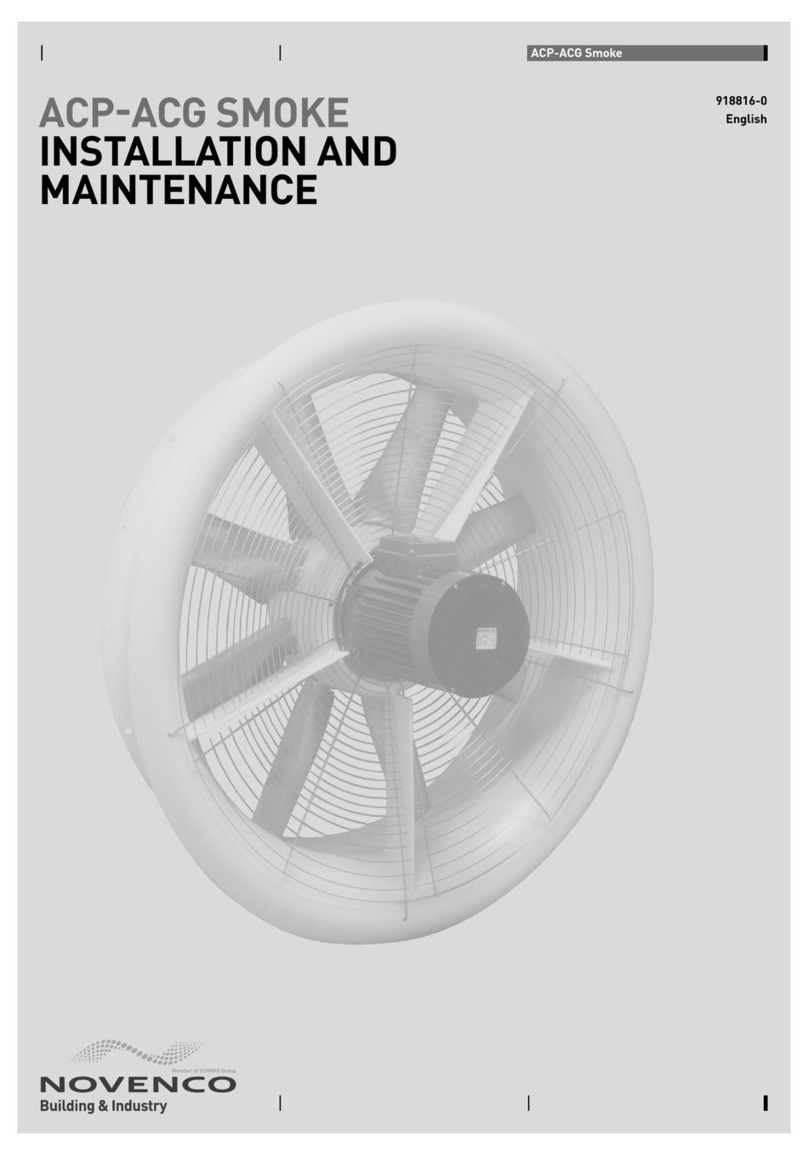

NOVENCO Novax ACP Series Instruction Manual

1

916331-0

GB

MU14434 1110

Novax Axial Flow Fans Types ACP and ACG

Installation and Maintenance

1. Application

2. Handling

2.1 Marking

2.2 Weight

2.3 Internal transport

3. Storage

4. Assembling

4.1 Installation

4.2 Prior to attachment

4.3 Attachment

4.4 Mounting brackets

4.5 Duct connection

4.6 Wiring

5. Start of operation

5.1 Prior to start of operation

5.2 Motors with Y/ Δstarting

5.3 Starting procedure

6. Maintenance

6.1 Protection prior to inspection

andmaintenance

6.2 Fan casing

6.3 Impeller

6.4 Motor

6.5 Dismounting of motor

6.6 Mounting of motor

6.7 Blade pitch adjustment

6.8 Fault localization

7. Sound

8. Attestation of

conformity

1. Application

Axial flow fans types ACP and ACG are

compactandsturdystandardfans,suitable

for conventional installations for marine

and industrial ventilating applications.

2. Handling

2.1 Marking

The ACP and ACG fans areprovided with

a standard nameplate with Novenco's

name and address. It also mentions

producttype,e.g.ACP1000/380,serialNo.

or order No. as well as weight and fan

speed.

A motor nameplate with relevant motor

data is also provided.

2.2 Weight

The total weights shown in fig.1 and 2

apply to axial flow fans types ACP and

ACG.

Thetotalweightisdetermined onthebasis

of type/size of fan and the maximum

motor size employed, is in terms of kg.

The motor manufacture is ABB and the

data used apply to four-pole motors (fig.3).

2.3 Internal transport

Axial flow fans types ACP and ACG are

suppliedon palletsorbearerstoallowfork-

lift transport.

Fig. 2. Total weight for type ACG fans (incl. of motor).

Fan size Motor size

-71 -80 -90 -100 -112 -132 -160 -180 -200 -225 -250 -280

Hub diameters

160, 230, 280, 330 and 380

ACG 250 19,3 22,8

ACG 315 22,3 25,8 31,8

ACG 400 32,5 38 42 49,5

ACG 500 39,5 50 56 63,5 67 88

ACG 560 47,5 62 68 75,5 79 100 139

ACG 630 52,5 67 73 80,5 84 105 144 202

ACG 710 58,5 75 81 88,5 92 113 152 210

ACG 800 64,5 82 88 95,5 99 120 159 217

ACG 900 77,5 93 99 106,5 110 131 170 228

ACG 1000 108 115,5 119 140 179 237

Hub diameter

403 and 578

ACG 900 142 187 226 284

ACG 1000 153 219 258 316 361

ACG 1120 169 236 275 333 378 458

ACG 1250 282 321 379 242 504

ACG 1400 345 403 448 528 563

ACG 1600 487 567 602

Fig. 1. Total weights for type ACP fans (incl. of motor).

Fan size Motor size

-71 -80 -90 -100 -112 -132 -160 -180 -200 -225 -250 -280

Hub diameters

160, 230, 280, 330 and 380

ACP 250 15,6 19,1

ACP 315 17,5 21 27

ACP 400 24,5 28 34 41,5

ACP 500 28,5 38 44 51,5 55 76

ACP 560 35,5 48 54 61,5 65 86 125

ACP 630 38,5 52 58 65,5 69 90 129 187

ACP 710 43,5 58 64 71,5 75 96 135 193

ACP 800 48,5 63 69 76,5 80 101 140 198

ACP 900 57,5 71 77 84,5 88 109 148 206

ACP 1000 84 91,5 95 116 155 213

Hub diameter

403 and 578

ACP 900 112 154 193 251

ACP 1000 120 182 221 279 342

ACP 1120 132 195 234 292 337 417

ACP 1250 236 275 333 378 458

ACP 1400 294 352 397 477 512

ACP 1600 428 508 543

Fig. 3. The motor is of ABB manufacture (data for four-pole motors).

Motor type -71 -80 -90 -100 -112 -132 -160 -180 -200 -225 -250 -280

Motor weight 6,5 10 16 23,5 27 48 87 145 190 270 305 535

2

3. Storage

Axial flow fans type ACP and ACG can

stand outdoor storage for one month

provided the packing is intact. Fans with

no packing must be stored in a sheltered

place.

If the fans are stored indoors under well-

ventilated conditions with no risk of

condensation the storage period may be

extended to six months.

The storage space must not be exposed to

vibrations likely to damage the motor

bearings. If the storage period exceeds

three months, it is recommended to turn

the impeller regularly by hand.

4. Assembling

4.1 Installation

Novaxaxialflow fanstypesACP andACG

are designed for operation in both

horizontal and vertical position. (Know-

ledge of installation position is required

before drilling of drain holes).

ACP is for free inlet and without

connection to duct on the pressure side.

ACGis forfreeinletandconnectiontoduct

on the pressure side. (Downstream guide

vane arrangement).

4.2 Prior to attachment

Prior to attachment make sure that the

impeller rotates freely in the fan casing,

wherever possible with equal distance

between blade tip and fan casing

throughout the circumference.

4.3 Attachment

The fan is provided with an arrow-plate

denoting the direction of air flow through

the fan casing. See during installation that

the fan is oriented so as to provide the

desired direction of air flow in the system.

The best way of installing the fan is using

mountingfeet(availableasoptionalextras,

fig. 4), but it may also be suspended in the

fan casing flanges or in special carriers.

The carriers must not hamper the free inlet

and outlet flow of the air.

When the fan has been finally secured

makesurethattheimpellerrotatesfreelyin

the casing.

.

4.4 Mounting feet

Mounting feet for types ACP and ACG

consist of two mounting plates (fig. 4items

01 and 02). Mount two c-profiles (item 03)

undertheseby meansofbolts(item05)and

nuts (item 04).

The distance between the end of the c-

profile and mounting plates is determined

by type/size and motor size.

Mount the fan casing in the two flange

holesofthemountingplatesandmountthe

distance bush (fig. 5, item 07) by means of

joiningelements (items 08and09)between

inlet cone and mounting plate (item 06).

The fan houses for ACP and ACG sizes

1250 – 1600 have circular fan casings.

Therefore, the fan casing is mounted with

fittings for mounting foot (fig. 6 item 07A)

and joining elements (fig. 6 items 08A and

09A).

Mount the fittings on the back of the

mounting foot and fan casing as shown on

fig. 6.

To prevent vibrations spreading from the

fan to the surroundings, anti-vibration

mountings may be inserted between fan

andsupportand flexibleconnectionsfitted

in the ducts after the fan (available as

optional extra).

Secure anti-vibration mountings (fig. 5

item 10) in the ends of the c-profile by

means of bolts (item 11).

Mount base plates (item 12) for attachment

inthefoundation/flooratthebottomofthe

rubber element.

The natural frequency of the support must

differ at least 20% from the fan speed.

If the motor is provided with drain holes

for condensed water the fan must be

oriented so that the holes turn downwards

(lowest point).

Generally,itisoftheutmostimportancefor

the performance and sound level of an

axial flow fan that the air flow is

unimpeded and free from eddies.

4.5 Duct connection

A downstream guide vane arrangement

with core is mounted on the Novax axial

flow fan with which the fan obtains a very

high efficiency and is used for connection

to duct.

The duct on the fan outlet side must be

designed to ensure smooth and

undisturbed flow of the air; avoid, for

instance, sharp duct bends immediately

after the fan.

ACP and ACG fans are prepared for

circularductconnectionson theoutletside.

Flanges supplied as standard comply with

EUROVENT 1/2.

Systems with a higher vibration level or

more exacting performance requirements

must be provided with expansion joints

between fan and duct, and ducts must not

be supported by the fan.

It is important to allow for free areas to

facilitate mounting and dismounting as

well as ordinary maintenance.

Fig. 4. Mounting foot for type ACP

Fig. 5. Mounting foot for types ACP and

ACG 250-1120

Fig. 6. Mounting foot for types ACP and

ACG 1250-1600

3

4.6 Wiring

Connectiontothemainsiseffecteddirectin

the motor terminal box.

Connect 3-phase motors as shown on the

diagrams in the terminal box lid.

Regarding 1-phase motors see diagrams

for 1-phase adjustable motors.

Having wired the motor terminal box,

check that the direction of rotation of the

impeller complies with the arrow-plate

fitted on the outside of the fan.

For reversible fans (alternating directions

ofrotation)atime delayarrangementmust

be provided to ensure that the impeller is

stationary before restarting.

Important: Only fans with steel hubs

may be run in reverse.

Reversible operation

increases risk of fan

stalling. If the fan stalls, the

service life is shortened.

5. Start of operation

5.1 Prior to start of operation

Priortostartofoperation checkthatthefan

and duct connections are clean and free

from tools and foreign substances.

Also ensure that the electric connections

meettheprescribedrequirements,thatany

wire guard fitted on the fan inlet or outlet

side is correctly mounted and that the

direction of rotation of the fan complies

with the arrow-plate (check by short-time

operation).

See fig. 7 items 01 and 02.

5.2 Motors with Y/Δstarting

Therelaymustbeset to thecalculatedtime.

5.3 Starting procedure

• Start the fan.

• Check that no abnormal noises occur.

• See that the vibration level is normal.

The vibration level at the fan

operating speed must not exceed 7

mm/s, rms*, measured radially at

two points, 90° offset and at the free

shaftendofthemotor. Otherwise, the

fan must be balanced.

Operation at a vibration level exceeding 11

mm/s, rms*, is not allowed in case of fixed

fan position.

Operation at a vibration level exceeding 18

mm/s, rms*, is not allowed in case of

position on feet or anti-vibration

mountings.

* ISO 2954, Requirements for instruments

for measuring vibration severity.

Afterthirtyminutesofoperationcheckthat

the fan operates normally.

Important: The fan is designed for

continuous operation. The

following kinds of

operation may cause

fatigue break in the

impeller and endanger

people.

- Operation in stall area

- Operation with pulsating

counter pressure - called

pump mode

- Operation with repeated

starting and stopping

IfindoubtNovencoshould

be contacted to assess the

suitability of the fan.

6. Maintenance

6.1 Protection prior to

inspection and maintenance

Whenthefanisoutofoperationforreasons

of inspection or repair/maintenance, the

electric system must be switched off and

protected so that the fan is not cut in

unintentionally.

6.2 Fan casing

The fan casing requires as standard no

maintenance other than ordinary cleaning.

If the fan casing is painted, the painted

surface should be checked regularly and

repaired where necessary.

6.3 Impeller

The impeller (rotor unit) is supplied from

the factory with the blades adjusted to the

pitch corresponding to the desired

operating point (pressure and air flow) at

the fan speed in question. To ensure

vibration-free operation the impeller has

been carefully balanced in this position.

Vibrationsoccurringduringoperationwill

normally be due to accumulations of dust

or dirt on hub and blades, and will

disappearaftercleaning.Shouldthisnotbe

the case, expert assistance should be called

in immediately, as continued vibrations

will shorten the life of the blades and the

motor bearings.

6.4 Motor

The motor normally only requires

maintenanceofthebearingsasindicatedin

the maintenance instructions for electric

motors.

6.5 Dismounting of motor

Prior to commencing the work, switch off

thecurrentanddisconnectthemotorcable.

Next, dismount any ducts and

downstream guide vane arrangement (fig.

8 items 13, 10, 11, and 14) on the fan outlet

side.

Removetheimpeller centrescrew(item09)

and centre disc (item 08).

Dismounttheimpellerbymeansofapuller

fastened in the two threaded holes of the

hub boss (item 12).

Detach the motor by loosening the screws

in the motor shell (items 05 and 06). Now

the motor (item 01) and motor flange (item

02) can be removed.

Fig. 7. Novax Type ACG

Fig. 8. Dismounting/mounting of types ACG and ACP

1. Motor

2. Motor flange

3. Wire guard

4. Motor shell

5. S-washer

6. Set screw

7. Impeller

8. Centre disc

9. Centre screw

10. Set screw

11. Washer

12. Hub

13. Outlet guide vanes

14. Nut

Novenco A/S

Industrivej 22 Tel. +45 70 12 42 22

DK-4700 Naestved Fax +45 55 75 65 50

www.novencogroup.com [email protected]

4

In dismounting and disassembling the fan

be careful not to expose the individual

parts to shocks etc. likely to damage the

motor bearings or other fan components.

6.6 Mounting of motor

Afterservicing remountthemotor; seethat

the motor flange (fig.8, item 02) is correctly

located and that the motor shaft is

concentrically placed in the fan casing

before tightening the bolts (item 06).

Mount the impeller (item 07) on the motor

shaft by means of a tool fastened in the

threaded hole of the motor shaft. Fix the

impellerhubto restagainstthe motor shaft

collar. Check that the blade clearan-

ce is the same throughout the

circumferenceofthecasing.Ifthisisnotthe

case, adjust the motor location in the

suspension arrangement.

Now mount the centre screw (item 09) and

centre disc (item 08). Replace lock washers

and lock nuts during fan assembly. Finally,

connectthemotorcable intheterminalbox

(item 01) and any ducts and downstream

guide vane arrangement (item 13).

To start the fan follow the procedure

described in section 5 (Start of operation).

6.7 Blade pitch adjustment

The blade pitch has been adjusted in the

factory with a special tool (fixture) to

deliver the performance required by the

customer/order on delivery.

If the fan performance is required to be

changed it is possible to change the blade

pitch. It requires knowledge of the motor

load and the max. permissible blade pitch

on the graph as related to the motor rating

(in case of blade pitch increase).

Contact Novenco before any such

adjustment of the blade pitch.

Novenco cansupplyspecialtoolsforblade

pitch adjustment and instructions for

impeller balancing.

The brochure "Blade-angle tool" is

available on request.

6.8 Fault localization

These are likely causes of breakdowns/

failures:

Deficiency in performance:

Blocked air supply to the fan inlet side:

– Damper closed

– Duct choked

– Supply fan, if any, stopped

– Motordefective

– Motorcutout

– Wrong direction of rotation of impeller.

Noise/vibrations:

– Bearings in electric motor defective

– Impeller out of balance

– Impeller worn/damaged

– Bolts/components loose

– Impeller blades have different pitch

angles

– Fan operates in the stalling area. May

result in break-down - repair failures,

see "Deficiency in performance".

7. Sound

The sound generation of the fans depends

on installation and operating conditions,

which means that no general data of the

sound generation can be given.

Reference is made to our catalogues or

computer programs for calculation of the

specific sound generation.

8. Attestation of

conformity

EU - Attestation of Conformity

Novenco A/S

Industrivej 22

DK-4700 Naestved

Hereby declares that axial flow fans types

ACP 250-1600 and ACG 250-1600 have

been manufactured in conformity with the

Council's directive 2006/42/EC regarding

mutual approximation of the machinery

laws (the Machinery Directive) of the

member states.

Directives

– EC Machinery Directive 2006/42/EC

– EMC Directive 2004/108/EC

– Low Voltage Directive 2006/42/EC

Applied standards

EN ISO 12100-1:Safety of machinery part 1

EN ISO 12100-2:Safety of machinery part 2

EN ISO 13857: Safety of machinery -

Safety distances

EN 60204-1: Safety of machinery -

Electrical equipment of

machines Part 1 :

General Requirements

ItisaconditionthatNovenco'sinstructions

for installation have been followed.

Naestved, 1. 11. 2010

Steen Hansen

R&D manager

Novenco A/S

This manual suits for next models

29

Other NOVENCO Fan manuals

NOVENCO

NOVENCO RS35x-CX0-E series User manual

NOVENCO

NOVENCO ACP Series Instruction Manual

NOVENCO

NOVENCO FALKINN ACN Instruction Manual

NOVENCO

NOVENCO Novax Instruction Manual

NOVENCO

NOVENCO NOVAX ACN-ACW-ARN Instruction Manual

NOVENCO

NOVENCO ZERAX AZL-AZN-AZW Instruction Manual

NOVENCO

NOVENCO AUO 290 Instruction Manual

NOVENCO

NOVENCO CNA Series Instruction Manual