NOVENCO Novax Instruction Manual

MU 14309 0410 1

918768-0

GB

Installation and maintenance

for Novax fan type ACL

1. Application

2. Handling

2.1 Marking

2.2 Weight

2.3 Transport

3. Storage

4. Installation

4.1 Preparation

4.2 Installing the fan

4.3 Installing the acoustic diffuser (op-

tional)

4.4 Duct connection (alternative)

4.5 Electrical connection

5. Start-up

5.1 Before start-up

5.2 Motors with Δ/Y starter

5.3 Start-up procedure

6. Maintenance

6.1 Safeguards prior to inspection and

maintenance

6.2 Fan housing

6.3 Impeller

6.4 Motor

6.5 Detaching the motor

6.6 Fitting the motor

6.7 Blade adjustment

6.8 Fault finding

7. Testing functionality and

operational readiness

7.1 Periodic inspection

8. Sound

9. Declaration of conformity

1. Application

Novax ACL fans are compact, sturdy ax-

ial flow fans. They are designed for re-

placing existing fans for energy-saving

reasons. The fans are capable of meeting

everyday ventilation requirements un-

der normal conditions in all types of

commercial and industrial buildings.

Please read the relevant sections of these

instructions carefully before installing

the product or performing any mainte-

nance.

2. Handling

2.1 Marking

ACL fans are equipped with nameplate,

stating Novenco’s name and address

and providing information on product

type, e.g. ACL 710/380, serial or order

number, and fan speed.

A motor nameplate with relevant motor

data, including insulation class, is also

provided.

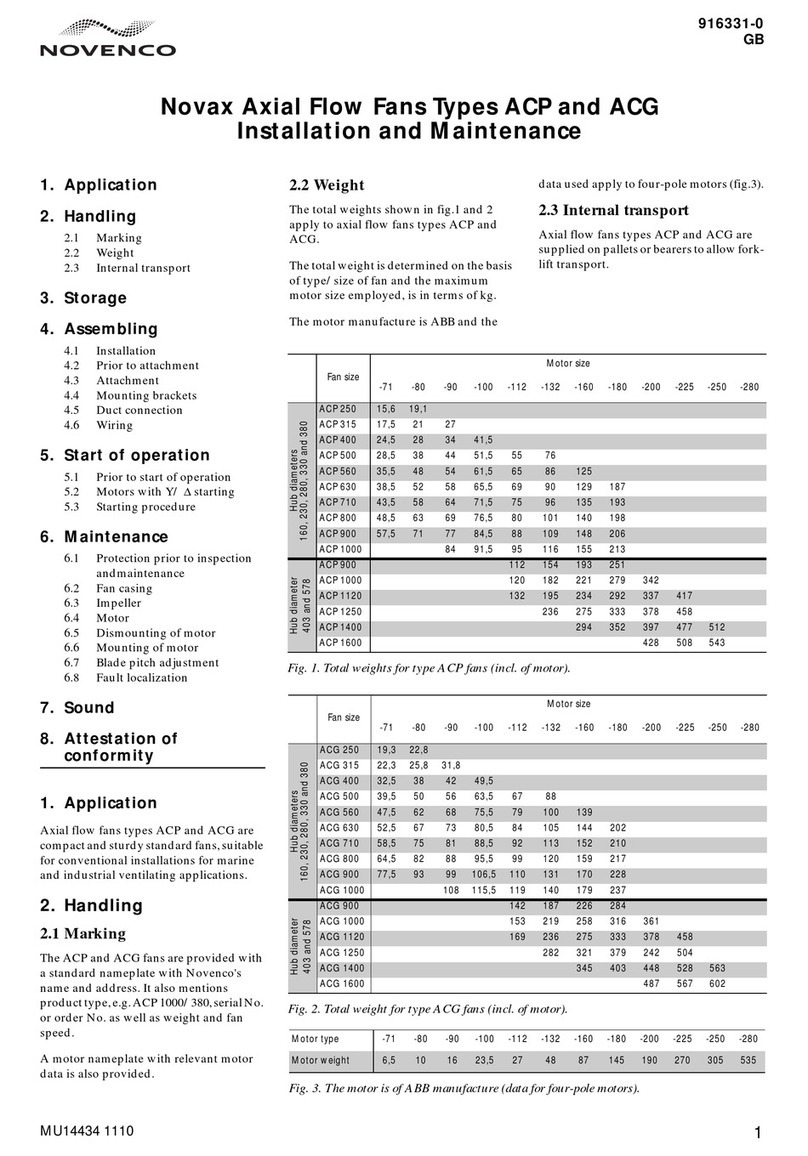

2.2 Weight

The total weights of ACL axial flow fans

are shown in table 1.

2.3 Transport

During transport, care must be taken to

prevent water (e.g. rainwater) from en-

tering the motor or other sensitive com-

ponents.

Novax ACL fans are supplied on pallets

or skids, enabling fork-lift transport. The

forks must be positioned beneath the

base. The unit must be set down as slow-

ly as possible on a soft surface. Impacts,

vibrations and falls may cause imbal-

ance and deformation or damage to mo-

tor bearings.

3. Storage

Novax fans can withstand outdoor stor-

age for up to one month providing the

packaging is intact. After removing the

packaging, fans must be stored in a rain-

proof shelter.

If stored indoors under well-ventilated

conditions with no risk of condensation,

storage duration may be extended to six

months.

The storage place must not be exposed to

vibrations, which may damage the mo-

tor bearings. If stored for longer than

three months, the impeller should be

turned regularly by hand.

4. Installation

Before installing the ACL fan in the ven-

tilation system, a suitable location must

be identified and prepared. This will in-

clude removing the existing fan and clos-

ing off any holes capable of allowing

false air to be sucked into the system.

Note that it is of the utmost importance

for the performance and sound level of

the axial flow fan that the air flow is un-

impeded and free of eddies.

The required direction of air flow must

also be taken into consideration when

deciding location. The fan is provided

with an arrow plate denoting the direc-

tion of air flow through the housing. The

housing can only face one way.

Sizes

Motor size

-80 -90 -100 -112 -132 -160 -180

Hub diameter

230, 330 and 380

400 65 72 79

500 82 89 96 104 130

560 87 94 100 109 135 170

630 97 104 110 119 145 180

710 107 114 120 129 155 190

800 119 126 132 141 167 202

900 131 138 144 163 179 214 261

Motor type -80 -90 -100 -112 -132 -160 -180

Motor weight 11 18 25 34 59 94 141

Table 1. Total fan weights (incl. motor) and weights of motors alone [kg]

2

It is important to provide sufficient free

space for assembling and dismantling

the system and to facilitate cleaning and

maintenance.

4.1 Preparation

Measure out and mark the hole to be cut

for the fan on the panel itself.

If existing duct height necessitates stand-

ing the fan on a raised base or support,

this should be prepared first.

Then measure the height from the base to

the centre of the fan and mark this posi-

tion on the panel. Drill a hole through the

panel at the centre point.

Mark the circumference of the hole on

both sides of the panel using, for exam-

ple, a cord and felt-tip pen as a drawing

compass.

Check the measurements and markings

before cutting the hole.

Cut the hole through the panel and any

insulating material. Smooth any rough

edges.

Fit and secure edging strip.

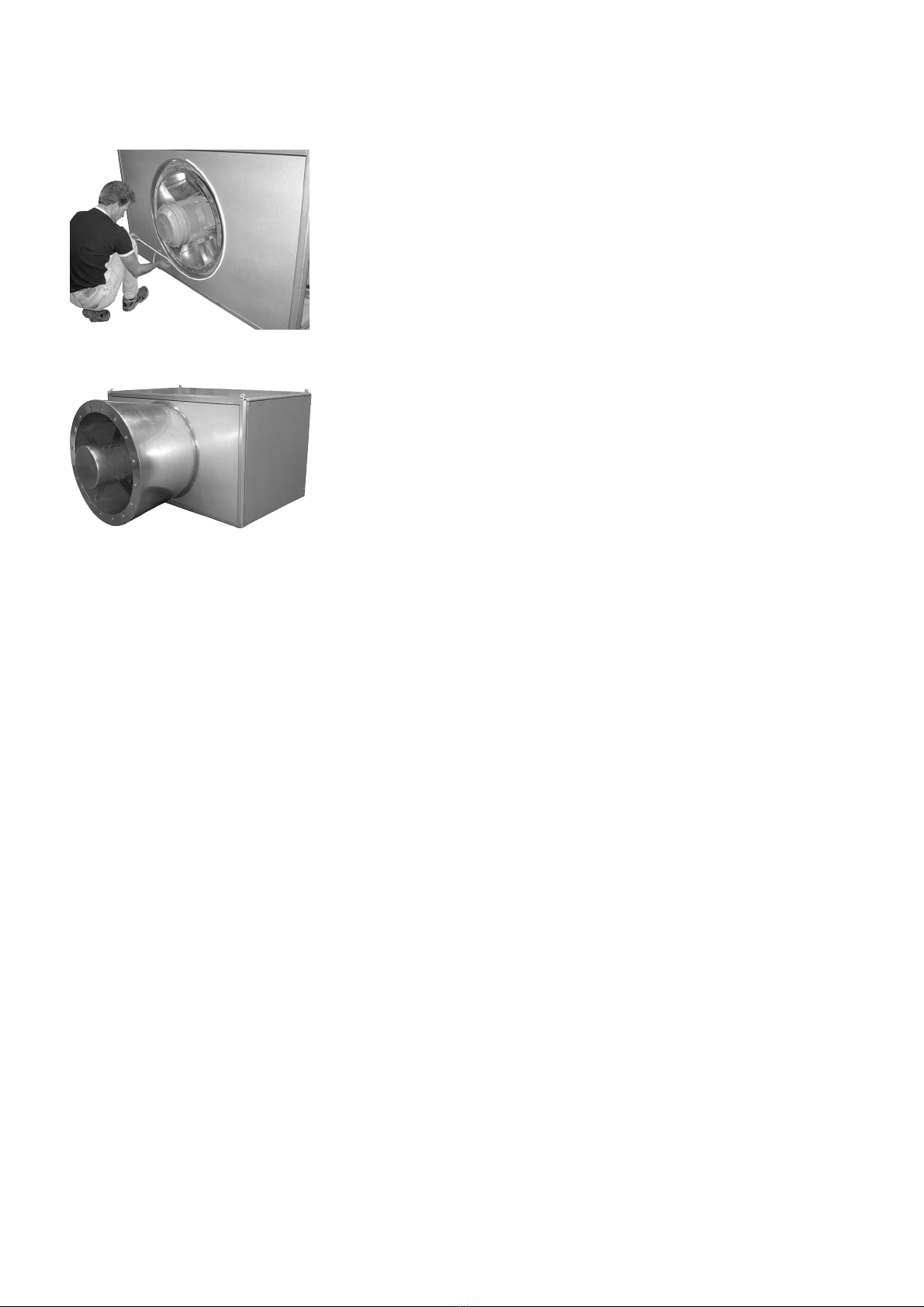

4.2 Installing the fan

ACL fans are supplied ready to install,

with factory-fitted mount, guides, cross

supports, protective grille and end plate.

Loosely position accompanying rails on

base where fan is to stand.

Then place fan on rails and push into po-

sition against stops on rails so that fan is

aligned with hole cut in panel beside

stops. Note that rails are held securely in

place by fan after it has been positioned

on them.

Push fan along cross supports towards

panel until end plate and panel are in

close contact.

Horizontally centre fan in relation to

hole in panel.

Screw mount securely to cross supports.

Check position of fan in relation to hole

in panel and adjust if necessary. Check

that end plate is in close contact with

panel.

Secure fan in position with screws

through guides and rails and through

rails and base.

Before tightening screws, adjust rails to

ensure they are parallel with panel.

Firmly tighten screws holding guides

and rails in place.

Screw rod holders to panel. Secure fan by

fitting rod to panel across end plate

above fan housing.

Tu rn impell e r b y h a nd to chec k t h a t i t can

freely rotate in fan housing. Check also

that clearance between impeller blade

tips and fan housing is equal all the way

round.

4.3 Installing the acoustic dif-

fuser (optional)

Fit sealing strip to outside panel surface

around circumference of hole. See

figure 3.

Centre diffuser opposite fan.

Attach diffuser to panel using self-cut-

ting screws.

Adjust inner core of diffuser to provide

1-1.5 cm clearance between core and fan

motor.

Sizes Centre height Diameter

Hub diameter

230, 330 and 380

400 403 535

500 403 635

560 413 695

630 503 775

710 503 855

800 603 945

900 753 1065

Table 2. ACL fan dimensions [mm]

Figure 1. Measurements for cutting hole in panel

Figure 2. Installing the fan

h

r

Rod

End plate

Guide

Cross support

Rail

Mount

Panel

3

4.4 Duct connection (alterna-

tive)

ACL fans are prepared for circular duct

connections on the outlet side.

The duct may need to be adapted prior to

connection, e.g. the outlet side may need

to be shortened to make room for the dif-

fuser.

If the existing duct has a different diam-

eter than the diffuser, an adapter must be

fitted.

Systems with high vibration levels or ex-

acting performance requirements must

be provided with expansion joints be-

tween the fan and duct. The fan should

not be used to support the duct.

4.5 Electrical connection

Electrical connection must be made by

an authorised electrician in accordance

with current legislation. Power should

be connected direct to the frequency con-

verter. See figure 6. Connections should

be made in accordance with frequency

converter wiring diagrams. Note that the

fan cable is screened. It must be connect-

ed in such a way that the screen remains

unbroken.

If an external frequency converter is to be

used, its interference filter must meet

current requirements and regulations.

After connecting the fan, check that the

direction of impeller rotation complies

with the arrow plate on the fan housing.

Alternatively, the fan can be installed

without frequency converter. In such sit-

uations, the fan should be connected via

a terminal box or plug socket. Note! A

switch must be installed in the immedi-

ate vicinity of the fan.

5. Start-up

5.1 Before start-up

Before start-up, check that the fan has

been installed correctly. The section in

which the fan is installed and the adjoin-

ing duct should be checked and cleaned

of dirt, foreign matter and tools before

the fan is started.

Also ensure that the electrical connec-

tions fulfil applicable requirements, that

any protective grilles on the fan outlet

side are correctly fitted, and that the di-

rection of impeller rotation complies

with the arrow plate (check by briefly

starting the fan).

5.2 Motors with Δ/Y starter

The relay must be set to the calculated

time.

5.3 Start-up procedure

Staring the fan

1Start the fan

2Check that no abnormal sound oc-

curs.

3Check that the vibration level is nor-

mal. At operating speed, fanvibration

must not exceed 7 mm/s rms meas-

ured radially at two points with 90°

offset and at the free shaft end of the

motor. Otherwise, the fan must be re-

balanced.

Operation at vibration levels higher

than 18 mm/s rms is inadvisable if vi-

bration dampers have been used. See

ISO 2954 – Requirements for instru-

ments for measuring vibration severity.

4After thirty minutes of operation,

check that the fan operates normally.

6. Maintenance

6.1 Safeguards prior to inspec-

tion and maintenance

Before inspecting or servicing the fan, it

must be switched off and disconnected

from the electrical system. Safeguards

must be taken to prevent the fan from re-

starting unintentionally.

6.2 Fan housing

As standard, the fan housing requires no

maintenance other than cleaning.

If the housing is painted, the surface

should be checked regularly and re-

paired where necessary.

6.3 Impeller

The impeller (rotor unit) is supplied with

blade pitch factory adjusted to the re-

quired operating conditions (pressure

and air flow) and actual fan speed. To en-

sure vibration-free operation, the impel-

ler has been carefully balanced in this po-

sition.

Vibration during operation is usually

caused by dust or dirt accumulating on

the hub and blades, and can normally be

corrected by cleaning. Should this not be

the case, technical assistance should be

called in immediately as continued vi-

bration will shorten the service life of the

blades and motor bearings.

6.4 Motor

Normally, only the motor bearings re-

quire maintenance. This should be per-

formed as described in the maintenance

instructions for electric motors.

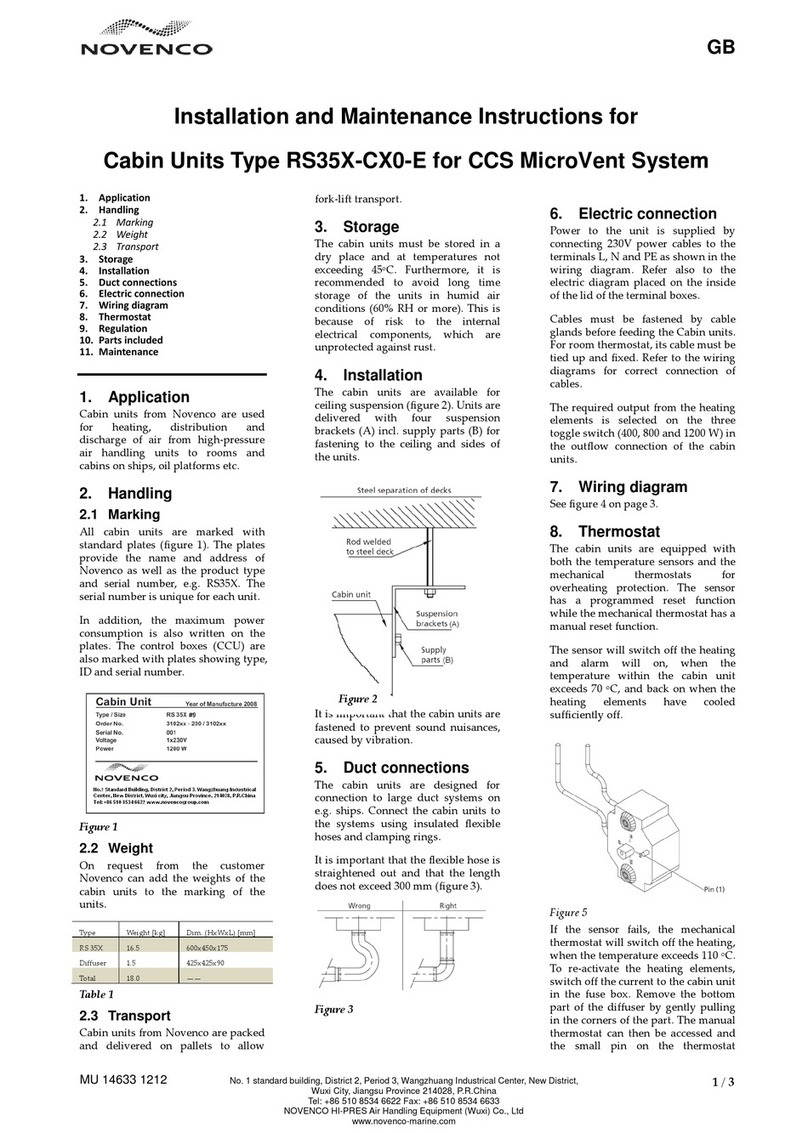

6.5 Detaching the motor

Before detaching the motor, disconnect

the power supply to the fan.

Remove rod from top of end plate. Loos-

en mount from cross supports and pull

fan housing away from panel until mo-

tor is free of panel opening.

Now loosen mount from rails on base.

Remove entire assembly (fan housing

plus mount) from rails and lay aside on

an even surface.

Remove motor cable (pos. 12) from mo-

tor.

Remove impeller centre screw (pos. 01),

centre disc (pos. 02) and hub cover (pos.

Figure 3. Fitting the sealing strip

Figure 4. Fully installed diffuser

4

03).

Remove impeller using puller secured in

the two threaded puller holes in the hub

boss (pos. 05).

Loosen bolts in motor shell (pos. 06). Mo-

tor (pos. 11) and motor flange (pos. 10)

can then be removed.

When dismantling the fan, be careful not

to expose individual parts to impacts or

other forces that might damage the mo-

tor bearings or other fan parts.

6.6 Fitting the motor

After servicing is complete the motor

must be refitted. Check that the motor

flange (pos. 10) is correctly positioned

and that the motor shaft is concentrically

positioned in the fan housing before

tightening the bolts (pos. 06).

Refit impeller (pos. 04) on motor shaft

using puller secured in threaded hole on

motor shaft. Tighten impeller hub

against motor shaft collar.

Check that blade tip clearance is equal

around the entire circumference of the

housing. If this is not the case, adjust mo-

tor position in suspension system.

Then refit hub cover (pos. 03), centre disc

(pos. 02) and centre screw (pos. 01). It is

recommended that lock washers and

lo c k nut s be repla c ed w h e n rea s s em b li n g

the fan. Finally, reconnect motor cable

(pos. 12) to motor.

The fan must then be reinstalled against

the panel as previously described in sec-

tion 4. Installation.

To restart the fan, follow the procedure

described in section 5. Start-up.

6.7 Blade adjustment

The blade pitch is factory adjusted using

a special tool (fixture) to provide the out-

put required by the customer/order on

delivery.

If a different output is required, it is pos-

sible to alter blade pitch. This requires

knowledge of the motor load and the

max. permissible blade pitch in relation

to the motor rating (in case of blade pitch

increase).

Please contact Novenco before any such

adjustment of blade pitch. Special tools

for blade pitch adjustment and instruc-

tions for impeller balancing are available

from Novenco.

A brochure describing the blade pitch

tool and its use is available on request.

6.8 Fault finding

Possible operating faults are described in

the following.

Insufficient output

• Blocked air supply on inlet side

–Damperclosed

– Duct blocked

– Supply fan (if any) stopped

– Motor defective

– Motor cut out

• Incorrect direction of impeller rota-

tion

Noise/vibration

• Bearings in electric motor defective

• Impeller out of balance

• Impeller worn/damaged

• Bolts/components loose

• Impeller blades have different pitch

• Fan operating in "stall" mode. This

may damage the system and should

be remedied immediately, see "Insuf-

ficient output”.

Sizes Min. Average

Hub diameter

230, 330 and 380

400 0.6 1.2

500 0.5 1.4

560 0.6 1.5

630 0.6 1.7

710 0.7 2.0

800 0.8 2.2

900 0.9 2.5

Table 3. Blade tip clearance [mm]

Figure 5. Exploded drawing of ACL fan

01: Centre screw

02: Centre disc

03: Hub cover

04: Impeller

05: Hub boss

06: Screw for motor shell

07: Washer for motor shell

08: Motor shell

09: Fan housing

10: Motor flange

11: Motor

12: Motor cable

13: Metal lead-through

5

Novenco

Industrivej 22 Tel. +45 7012 4222

DK-4700 Naestved Fax +45 5575 6550

Denmark www.novencogroup.com

7. Testing functionality

and operational readi-

ness

ACL fans should be tested every six

months with respect to functionality and

operational readiness provided the fan is

started at least once a day by means of a

time switch.

7.1 Periodic inspection

ACL fans must always be maintained in

proper operating condition. To ensure

satisfactory operation and long service

life, the fans should be inspected every

six months.

Inspection should include:

• Measurement of power consumption.

• Measurement of fan housing vibra-

tion.

• Control of fixation bolt torque and, if

necessary, readjustment.

• Visual inspection of fan housing, im-

peller and electrical connection.

• Cleaning

– with compressed air inside

– with water outside

It is recommended that a log be kept of

all values and observations.

8. Sound

The sound generated by the fans de-

pends on installation and operating con-

ditions, and general data on sound emis-

sion is therefore unavailable.

For further details, please refer to our

catalogue material or computer pro-

grams designed to calculate specific

sound emissions.

9. Declaration of con-

formity

In accordance with the European Ma-

chinery Directive 2006/42/EC, Annex II

A.

Manufacturer:Novenco A/S

Address: Industrivej 22

DK-4700 Naestved

We hereby declare that axial flow fans,

type ACL 400-900,

afulfil the requirements contained in

the following Directives on the condi-

tion that the product is installed in ac-

cordance with the installation instruc-

tions. If the product has been altered

in any way, the declaration no longer

applies.

Directives

–EC Machinery Directive 2006/42/

EC

–EMC Directive 2004/108/EC

–LVD 2006/95/EC

bhave been manufactured in accord-

ance with the following harmonised

standards.

Applied standards

–EN ISO 12100-1:

Safety of machinery – Part 1

–EN ISO 12100-2 + 12100-2/A1:

Safety of machinery – Part 2

–EN ISO 13857:

Safety of machinery – Safety dis-

tances

–EN 60204-1:

Safety of machinery – Electrical

equipment of machines – Part 1:

General Requirements

On the provisothat Novenco installation

instructions have been followed.

Naestved, 1.4.2010

Steen Hansen

R&D manager

Novenco A/S

Figure 6. Electrical connection through fan housing

Electric cableElectric cable

Metal lead-throughMetal lead-through

(relief)(relief)

NutNut

Table of contents

Other NOVENCO Fan manuals

NOVENCO

NOVENCO RS35x-CX0-E series User manual

NOVENCO

NOVENCO Novax ACP Series Instruction Manual

NOVENCO

NOVENCO FALKINN ACN Instruction Manual

NOVENCO

NOVENCO NOVAX ACN-ACW-ARN Instruction Manual

NOVENCO

NOVENCO CNA Series Instruction Manual

NOVENCO

NOVENCO AUO 290 Instruction Manual

NOVENCO

NOVENCO ACP Series Instruction Manual

NOVENCO

NOVENCO ZERAX AZL-AZN-AZW Instruction Manual

Popular Fan manuals by other brands

Caframo

Caframo Ecofan BelAir operating instructions

Black & Decker

Black & Decker BXFD52002GB Original instructions

Perel

Perel TV76501 user manual

Savoy House

Savoy House Circulaire owner's manual

Honeywell

Honeywell HT-900 Series TURBO FORCE owner's manual

Monte Carlo Fan Company

Monte Carlo Fan Company 5WF52XXD-L Series owner's manual