Location - Installation Notes

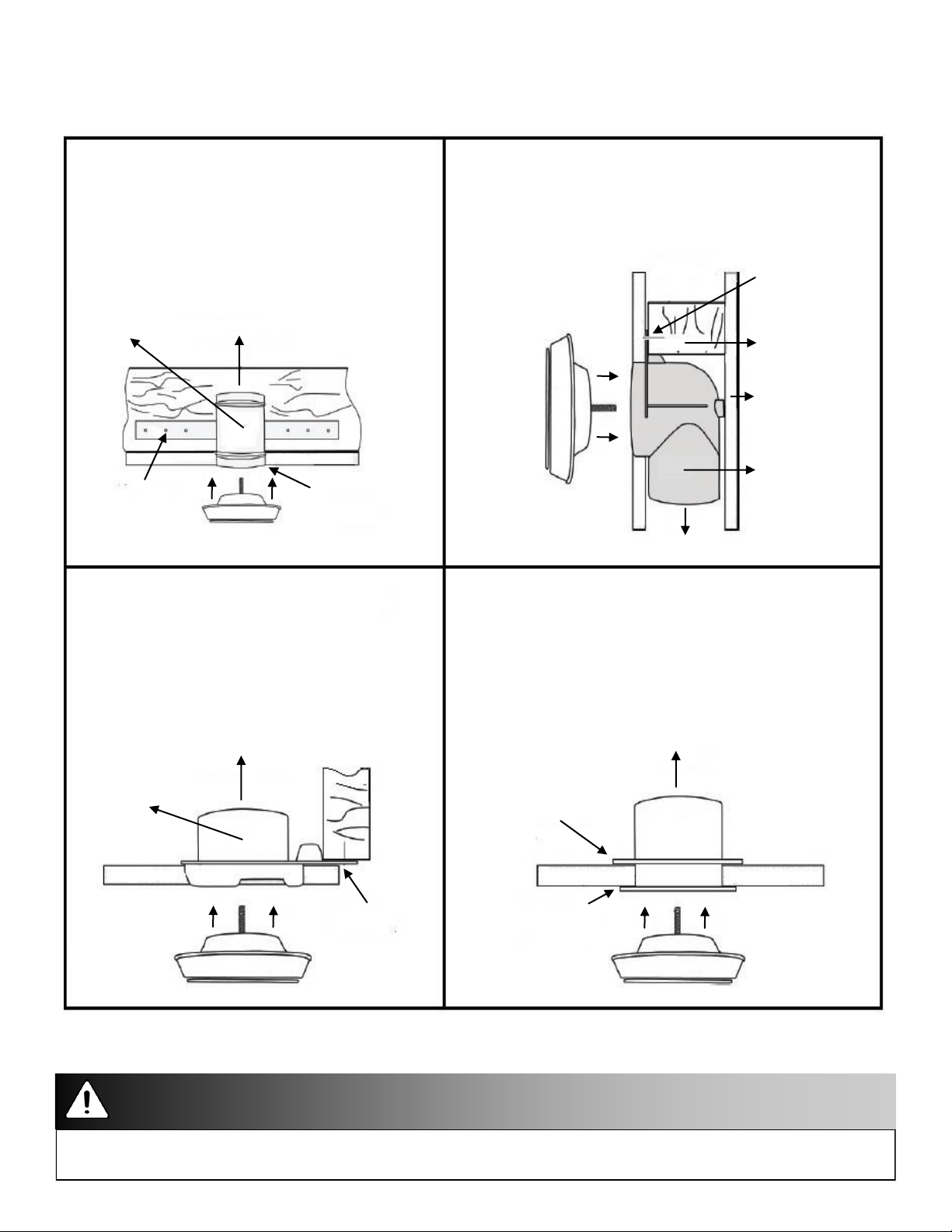

Install the unit in a heated space that provides clearance for service access. A typical location is in

either a mechanical room or an area close to the outside wall within close proximity to where the

weatherhoods are mounted. If a basement area is inconvenient or non-existent, install the unit in a

utility room or laundry room.

Attic installations are not recommended due to

The complexity of work to install

Freezing conditions in the attic

Difficulty of access for servicing and cleaning

If attic installation is necessary the unit must be situated in a conditioned space.

Leave sufficient clearance at the front of the access door for servicing the air filters and core. The

recommended clearance is a minimum of 25 in (635 mm) for opening and closing the door. Airia

provides four straps for hanging the unit from the basement floor joists.

2

Table of Contents

Location ...................................................................................................................................... 2

Pre-Installation Notes ................................................................................................................... 3

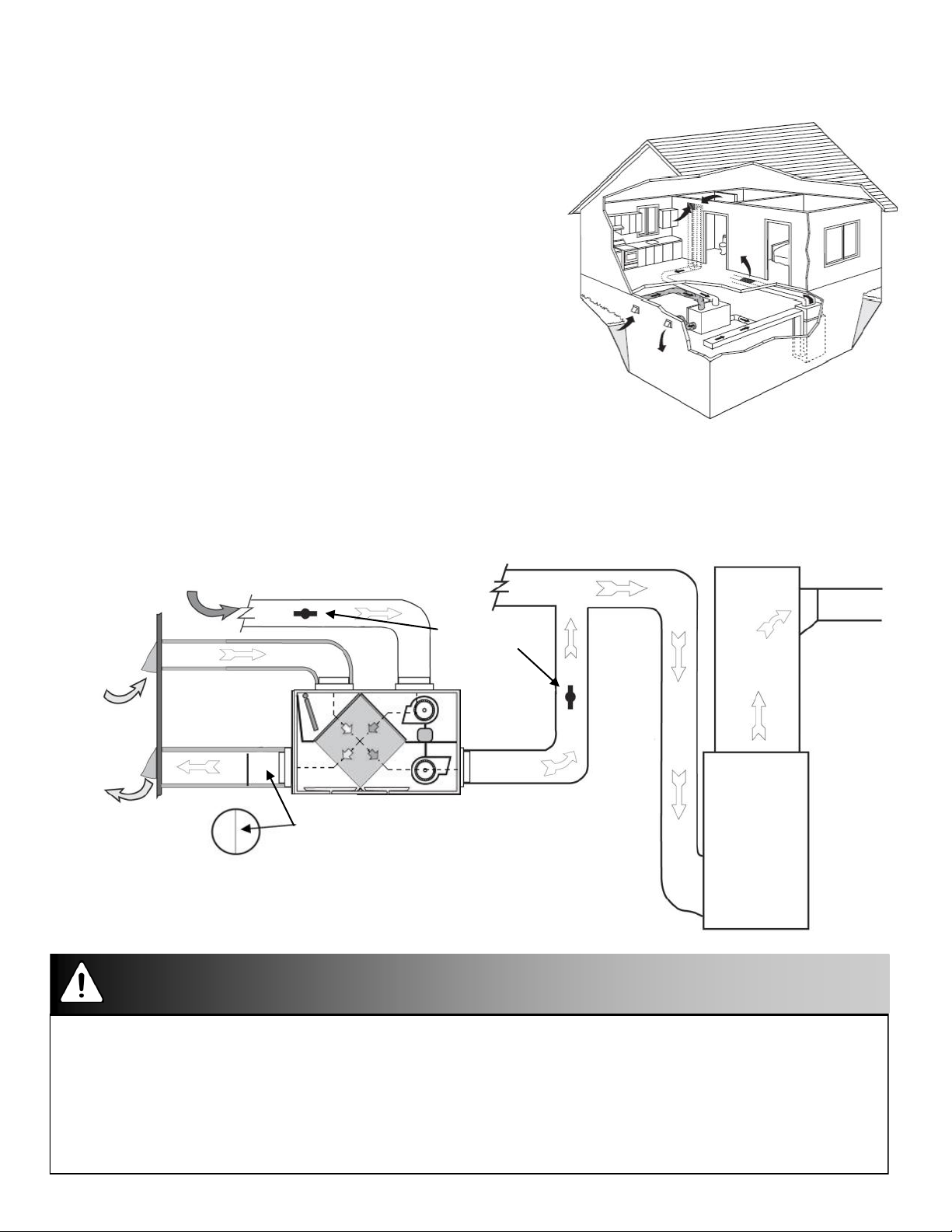

Simplified Installation (Return/Return Method) ................................................................................ 4

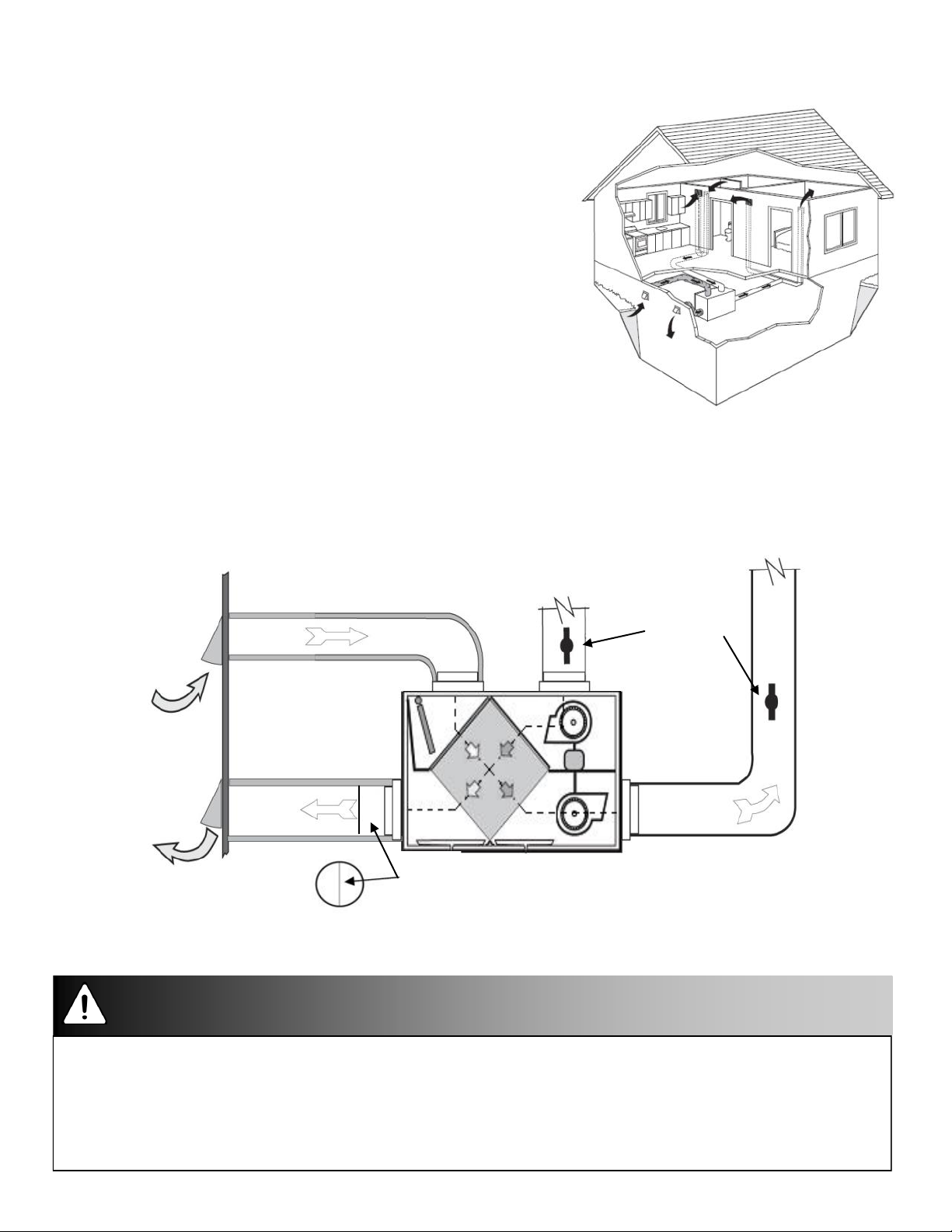

Partially Dedicated System ............................................................................................................ 5

Fully Dedicated System ................................................................................................................. 6

Hanging Straps ............................................................................................................................ 7

Drain Connection ......................................................................................................................... 8

Grilles ......................................................................................................................................... 9

Grille Fittings .............................................................................................................................. 10

Airflow Weatherhood and Weatherhood Requirements ................................................................... 11

Dual Hood .................................................................................................................................. 12

Main Control Installation .............................................................................................................. 13

Mechanical Timers Installation ...................................................................................................... 14

Installation and Operation 20/40/60 Minute Timers: 99-DET01 ........................................................ 17

Installer Selectable High Speed Settings ....................................................................................... 16

Dimensional Model Drawings - AIR135-ES Model ............................................................................ 17

Balancing the Airflows ................................................................................................................. 18

Determining the CFM ................................................................................................................... 19

Balancing Collar Instructions ........................................................................................................ 19

Balancing the Airflows with a Pitot Tube ....................................................................................... 20

Balancing the Airflow Using the Door Ports ................................................................................... 21

Airflow Reference Chart - AIR135-ES ............................................................................................. 22

Troubleshooting .......................................................................................................................... 24

Installation and Operation of Wireless 20/40/60 Minute Timers: 99-DET02....................... ................. 15

Installation and Pairing of Repeaters: 99-RX02.............................................................. .................. 16