Novex EI8600 User manual

USER GUIDE

For Research Use Only. Not for use in diagnostic procedures.

PowerEase®500 Power Supply

A programmable power supply for electrophoresis

Catalog Numbers EI8600, EI8700, and EI8675

Document Part Number A12162

Publication Number MAN0000738

Revision 9.0

Table of Contents

Warning...................................................................................................................................................................4

Kit Contents............................................................................................................................................................5

Product Specifications...........................................................................................................................................6

Front and Rear View of PowerEase®500............................................................................................................7

Introduction..........................................................................................................................................................10

Description of PowerEase®500 ..........................................................................................................................10

Methods ....................................................................................................................... 12

Getting Started .....................................................................................................................................................12

Operational Modes ..............................................................................................................................................13

Using PowerEase®500.........................................................................................................................................14

Printing..................................................................................................................................................................21

Custom Methods..................................................................................................................................................22

Troubleshooting...................................................................................................................................................24

Appendix...................................................................................................................... 25

Instrument Symbols and Safety.........................................................................................................................25

Consignes De Securite.........................................................................................................................................26

Sicherheits Anweisungen ...................................................................................................................................27

Run Conditions for Gels .....................................................................................................................................28

Repair, Maintenance, and Cleaning ..................................................................................................................29

Background Information on Voltage, Current, and Resistance.....................................................................31

Accessory Products..............................................................................................................................................32

Technical Support ................................................................................................................................................33

3

Warning

Federal

Communications

Commission

Advisory

This equipment has been tested and found to compl

y

with the limits for a Class

A digital device, pursuant to part 15 of the FCC rules. These limits are designed

to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at their expense.

Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

4

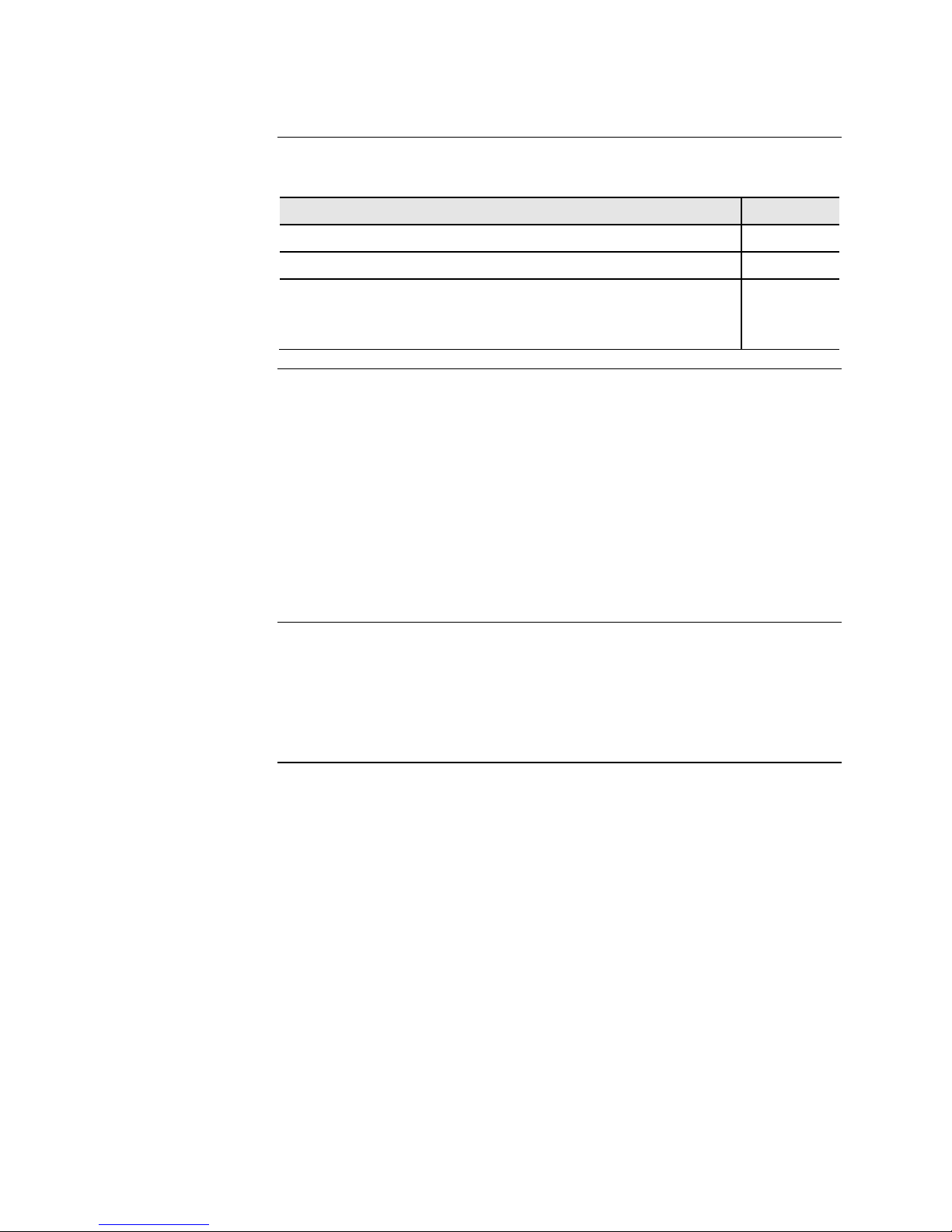

Kit Contents

Types of Kits This manual is supplied with the followin

g

kits:

Kit Catalog No.

PowerEase®500 Power Supply (100/120 Vac 50/60 Hz) EI8600

PowerEase®500 Power Supply (220/240 Vac 50/60 Hz) EI8700

PowerEase®500 Pre-Cast Gel System

includes PowerEase®500, Temperature Monitoring Probe,

XCell

SureLock

™Mini-Cell and XCell II™Blot Module

EI8675

Kit Components PowerEase®500 Power Suppl

y

contains:

PowerEase®500 Power Supply 1 each

Instruction Manual 1 each

Extra Fuses 2 each

Power Cord (U.S., Canada, Europe, Taiwan and Japan) 1 each

Warranty Card 1 each

Temperature Probe (Optional) 1 each

See page 6for specifications and detailed description of PowerEase®500 Power

Supply.

Note To ensure safe, reliable operation, alwa

y

s operate the PowerEase®500 Power

Supply in accordance with the manufacturer’s instructions. Always wear

protective gloves and safety glasses when working in a laboratory environment.

See safety information on pages 25–27.

Warranty information is provided on page 33.

5

Product Specifications

Specifications Input Powe

r

100–120 VAC: 100–120V, 50/60 Hz, 1.2 A at maximum load

Fuse: One 1A/250V/AGC fast blow fuse

220–240 VAC: 220–240VAC, 50/60 Hz, 0.5 A at maximum load

Fuses: Two 1A/250V/5 × 20 mm fast blow fuses

Output Range 1–500 V (minimum step size 1 V)

1–500 mA (minimum step size 1 mA)

0.1–50 W (minimum step size 0.1 W)

Automatic crossover on reaching set limits.

Accuracy Voltage: ± 2% or ± 2 volts

Current: ± 2% or ± 2 mA

Wattage ± 2% or ± 0.2 watt

Drift < 1% in 8 hours after 30 minute warm-up

with constant supply voltage

Circuit Protection Open Circuit; Short Circuit; Thermal Protection

Over Voltage, Current, Wattage

Safety Load Detection

Thermal Shutoff (with optional temperature probe)

Isolated Floating Ground

Memory Control Non-volatile, up to 24 hours

Custom Methods Stored to RAM

Computer Interface RS232C

Display LCD, view area 114 x 64 mm

240 × 128 dots

Dimensions 16.5 cm (w) × 18 cm (h) × 20.5 cm (d)

Weight 2.9 kg (6.4 lbs)

Operating Ambient temperature 4–30°C, ≤80% relative

Environmental humidity, altitude < 2000 meters, indoor use only,

Conditions pollution degree 2

6

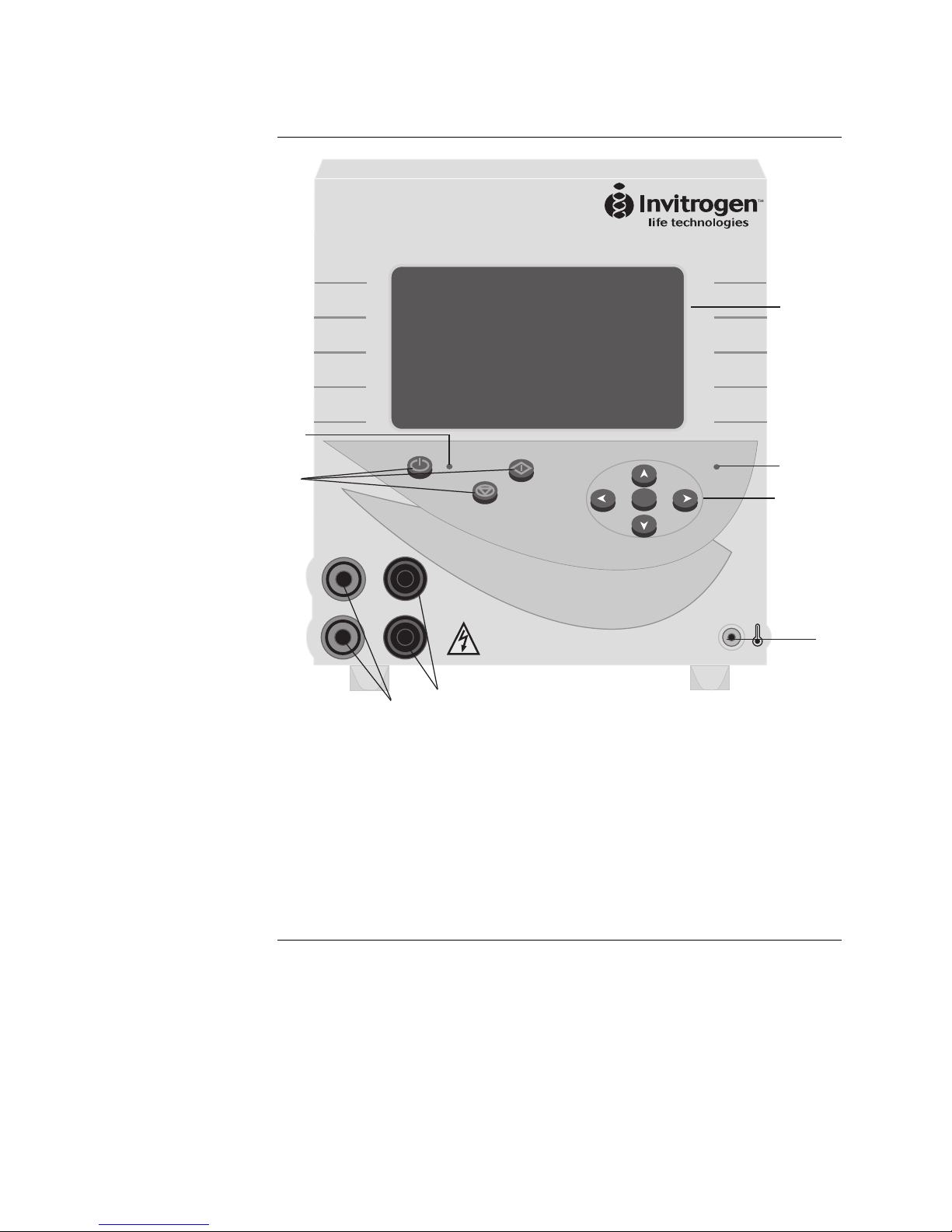

Front and Rear View of PowerEase®500

Front View of

PowerEase®500

+

TEMP

P

o

w

e

r

E

a

s

e

5

0

0

SELECT

S

T

O

P

S

T

A

R

T

POWER HIGH VOLTAGE

1

7

4

3

5

2

6

8

1. LCD Screen

2. Power Output Jacks, Positive (Red)

3. Power Output Jacks, Negative (Black)

4. Temperature Probe Jack

5. Functional Keys (Power, Start, Stop)

6. Directional Keys (Up, Down, Left, Right)

7. High Voltage LED

8. Power LED

Continued on next page

7

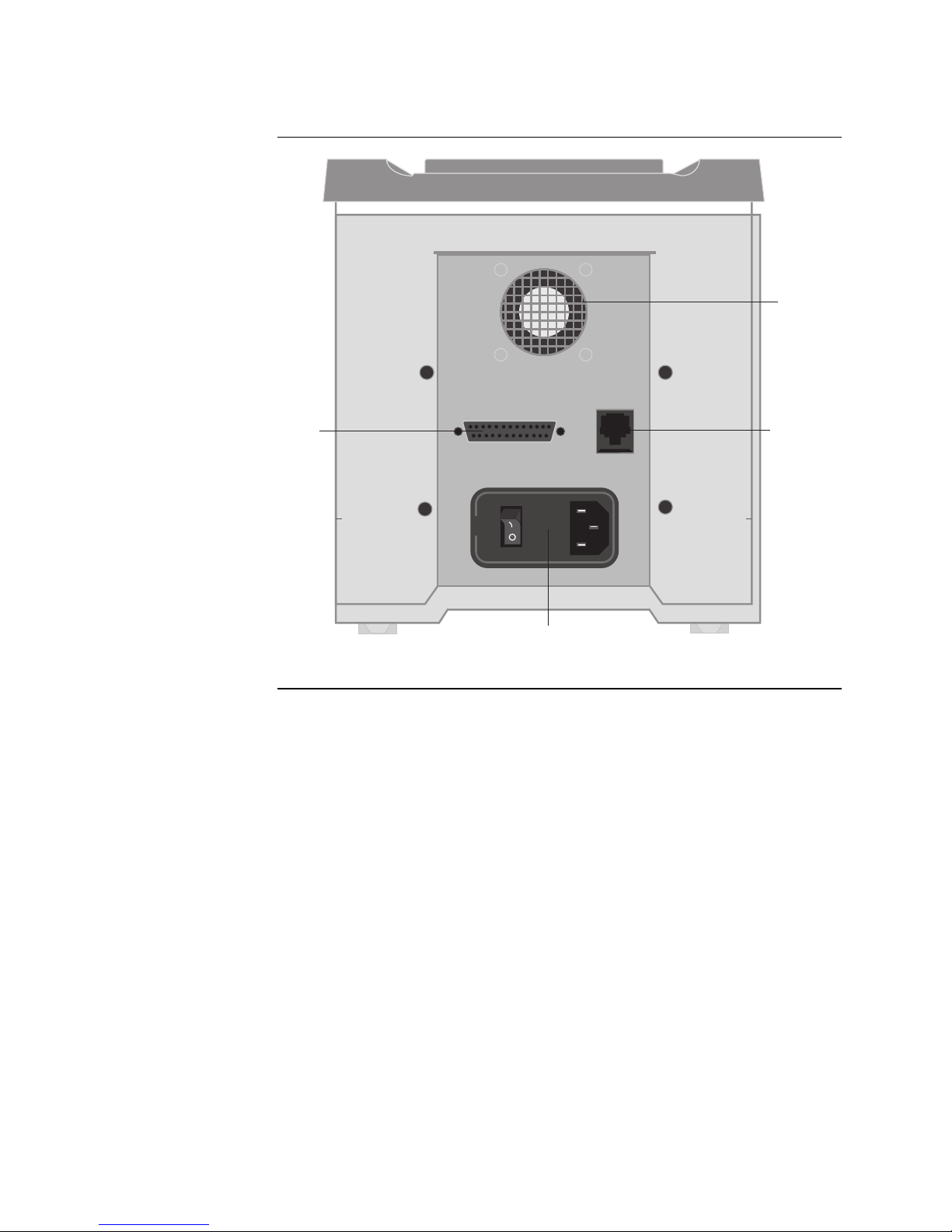

Front and Rear View of PowerEase®500, Continued

Rear View of

PowerEase®500

PRI TER

RS232

Fan

RS232C

Communi-

cation

Port

Printer

Port

Power Entry Module

with On/Off

main power switch

Continued on next page

8

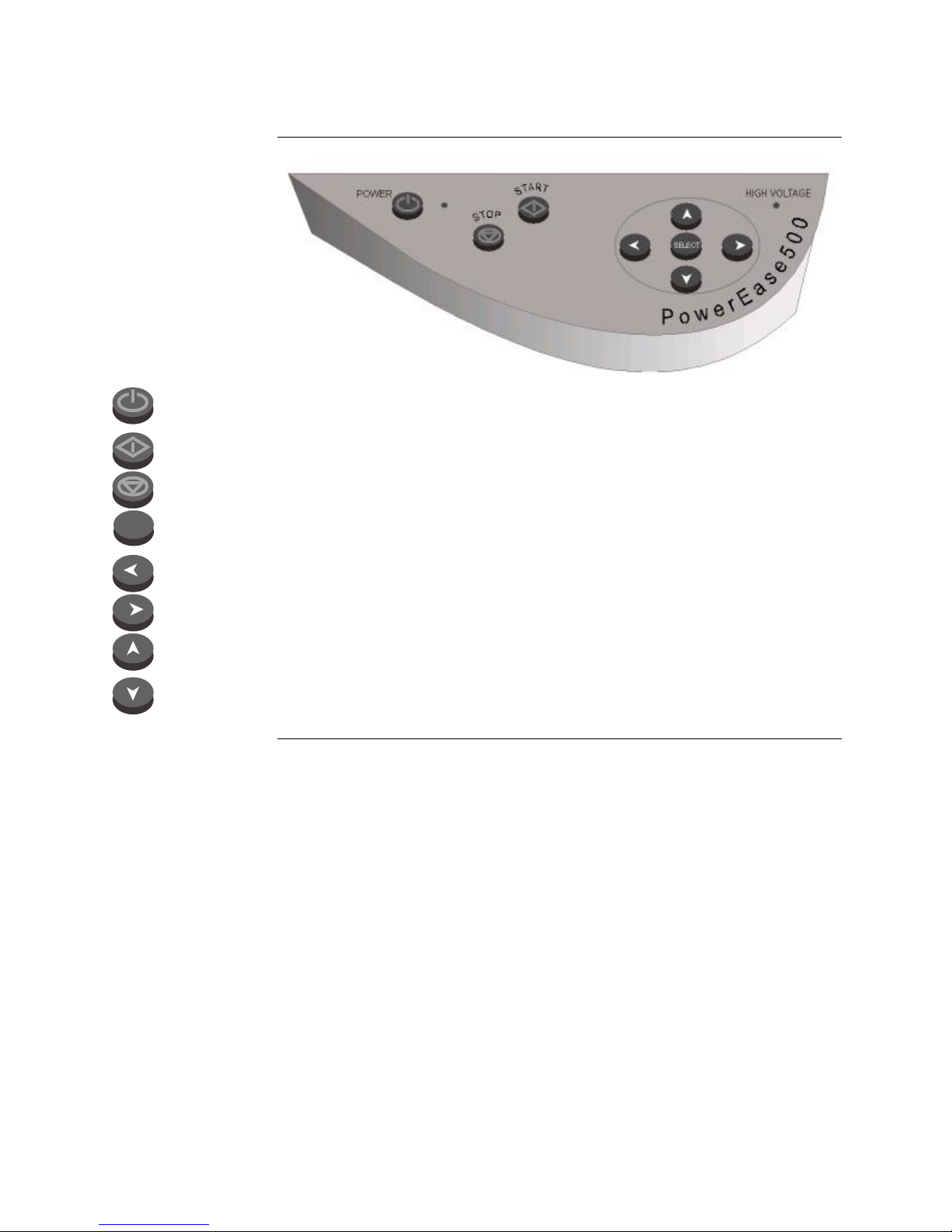

Front and Rear View of PowerEase®500, Continued

Key Pad

Power button secondary On/Off switch for the high voltage components, fan, and LCD

screen.

Start button used to start a selected method program.

Stop button used to end the selected method and to backup to a previous screen.

SELECT

Select button used to select a menu choice and to move forward to the next applicable

screen.

Left directional button for moving left around the menu.

Right directional button for moving right around the menu.

Up directional button for moving up around the menu and to adjust numerical and

character values (higher).

Down direction button for moving down around the menu and to adjust numerical and

character values (lower).

9

Introduction

Description of PowerEase®500

Product

Description

The PowerEase®500 Power Suppl

y

is a microprocessor-controlled power suppl

y

for electrophoresis of pre-cast and hand-poured mini-gels. The power supply is

designed to simplify electrophoresis by combining high performance and

programming flexibility with ease of use when running mini-gel and blotting

applications.

The PowerEase®500 Power Supply is designed around the single gel concept:

you need to think only about the electrical parameters and limits for a single gel.

This manual describes the setup and operation of PowerEase®500 Power Supply

including important information on safety and maintaining the unit.

Features of

PowerEase®500

The important features of PowerEase®500 Power Suppl

y

are:

•Large LCD display allows electrical parameters to be displayed in either

graphical or numerical formats

•Eight pre-programmed methods for running and blotting Novex®pre-cast

mini-gels

•Four custom methods for running your custom applications

•Simple three step operating procedure to start running or blotting Novex®

pre-cast gels

•Microprocessor control provides highly accurate electrical outputs resulting

in exceptional blotting capability

•Parallel port for printing experimental results to most printers

•Optional Temperature Probe to continuously monitor the buffer temperature

and shut the unit down in the event of overheating

•Two sets of output jacks allows electrophoresis of multiple mini-cell units in

constant voltage, current, or watts

Continued on next page

10

Description of PowerEase®500, Continued

Flowchart The followin

g

flowchart describes the various screens displa

y

ed on the

PowerEase®500 Power Supply and the keypad buttons (Start, Stop or Select)

used to navigate through the screens.

Start/Select

Start

Select

Power ON

Start-Up Screen

Gel Method Screen

Gel Quantity Screen

Method Run Large Display

Stop

Select

Method dit Screen Method Run Large Display Previous Screen

StopStart

Previous Screen

Select, once Select, twice

Select Method Run/ dit Screen

Method Run Graphic Display

Select, onceSelect, twice

Method Run Large Display

Method Run Graphic Display

11

Methods

Getting Started

Installing

PowerEase®500

1. Place the PowerEase®500 Power Suppl

y

on a level bench. Keep the area

around the power supply clear to ensure proper ventilation of the unit.

2. Position the unit properly such that the On-Off switch and the power cord

attachment module located on the rear of the unit are easily accessible.

3. Check the label located near the power entry module to ensure that the unit

is of the proper local voltage. Attach the power cord to the power entry

module. Use only properly grounded AC outlets.

Installing an

Optional Printer

The PowerEase®500 Power Suppl

y

has a DB25 parallel connector located on the

rear of the unit. This allows the PowerEase®500 Power Supply to print a report

of your electrophoresis results in ASCII format to most commonly available

printers.

Use the following steps to install a printer:

1. Using a parallel printer cable, connect the male DB25 end of the printer cable

into the port marked “Printer” located on the rear of the PowerEase®500

Power Supply.

2. Connect the opposite end of the cable into the appropriate connector on the

printer. Refer the user manual of your printer for instructions on connecting

the cable to the printer.

RS232 Port The RS232 Port is desi

g

ned to be connected to a computer durin

g

dia

g

nostics

and/or servicing by qualified field service engineers only.

Installing an

Optional

Temperature

Probe

If

y

ou have ordered the Temperature Monitorin

g

Probe, use the followin

g

instructions to install the probe:

1. Unpack the Temperature Monitoring Probe and inspect for any possible

damage to the wire or connector which may have occurred during shipping.

2. Plug the connector end of the Temperature Monitoring Probe into the port

located at the front lower right corner of the PowerEase®500 Power Supply

marked “TEMP”.

3. Place the opposite end of the Temperature Monitoring Probe with the blue-

colored bead into an electrophoresis cell buffer chamber to display

temperature on the LCD screen of the PowerEase®500 Power Supply. You

can bent the wire, but avoid crimping or pinching the wire. Temperature will

be displayed at all times even when the PowerEase®500 Power Supply is

stopped.

12

Operational Modes

Introduction The PowerEase®500 Power Suppl

y

is capable of operatin

g

at limitin

g

volta

g

e,

limiting current, and limiting power. We recommend operating the PowerEase®

500 Power Supply at limiting voltage for most applications. See below for more

details.

Voltage Limiting

The recommended settin

g

for operatin

g

the PowerEase®500 Power Suppl

y

is

voltage limited. For most electrophoresis methods, resistance increases

throughout the run. Using voltage limiting provides the following advantages:

•Current and watts decrease throughout the run, providing a natural safety

margin.

•The same voltage setting can be used regardless of the number or thickness

of gels being electrophoresed.

Current Limiting Discontinuous buffer s

y

stems and, to a lesser extent continuous s

y

stems,

increase resistance during the run. If you use the current limiting setting on the

PowerEase®500 Power Supply, the voltage will increase as resistance increases

to satisfy Ohm’s law (V=IR, see page 21). If no voltage limit is set and a local

fault condition occurs, such as a poor connection, very high local resistance

may cause the voltage to increase to a maximum of the power supply. This will

lead to local overheating and damage to the electrophoresis cell or create unsafe

conditions.

When running under constant current conditions, set a voltage limit on the

power supply at or slightly above the maximum expected voltage.

Wattage Limiting If power is constant, volta

g

e will increase and current will decrease durin

g

a

run, but the total amount of heat generated by the system will remain constant

throughout the run. However, locally high resistance can cause a high

proportion of the total heat to be generated over a small distance. This can

damage the electrophoresis cell and/or gel(s).

If operating at wattage limiting, set the voltage limiting to slightly above the

maximum expected for the run.

13

Using PowerEase®500

Introduction You can operate the PowerEase®500 Power Suppl

y

immediatel

y

after

installation using three simple steps (see below). For programming custom

settings, see page 22.

Starting

PowerEase®500

1. Plu

g

the power cord of the PowerEase®500 Power Suppl

y

into an available

electrical outlet rated at the appropriate electrical values for the power

supply.

2. Turn on the main power switch located on the rear of the PowerEase®500

Power Supply (see page 8for rear view of PowerEase®500 Power Supply).

Always leave this switch in the ON position to keep the back-up battery fully

charged.

3. Press the Power button located on the keypad (see page x for a figure of the

keypad). This Power button is a secondary power button and does not

actually shut the instrument down, but shuts down the high voltage, fan,

and LCD screen. When powered back up, the LCD screen will revert to the

same screen as when the secondary power was shut off.

4. A Start-Up screen appears (see page 15).

To avoid condensation, the main power switch located on the rear of the unit

should be left on between use during operation in a cold room or in high

humidity environments.

Operating

PowerEase®500

A simple operatin

g

procedure of the PowerEase®500 Power Suppl

y

is provided

below. For more details on the different screens and custom methods, see

pages 14–23.

1. Turn on the PowerEase®500 Power Supply.

2. Press Select once the Start-Up screen appears.

3. Select your gel type from the Gel Method screen.

4. Choose the number of gels to be electrophoresed from the Gel Quantity

screen.

5. Press the Start button to begin electrophoresis.

Note: To reset the PowerEase®500 Power Supply, press the Stop button.

Note The maximum number of Novex®mini-

g

els that can be electrophoresed at the

same time using PowerEase®500 Power Supply and the XCell SureLock™Mini-

Cell is listed in the following table:

Gel Type Number of Gels

Novex®Tris-Glycine Gels 10 gels

NuPAGE®Novex®Tris-Acetate Gel 6 gels

NuPAGE®Novex®Bis-Tris Gels 2 gels

Novex®Tricine Gels 4 gels

Novex®TBE-Urea gels 10 gels

Continued on next page

14

Using PowerEase®500, Continued

Start-Up Screen The Start-Up screen is the first screen to appear after pressin

g

the Power

b

utton

on the keypad.

Press the Select button to advance to the Gel Method screen.

Note: After first use, the last screen previously in use will appear after shutting

the power off and back on again.

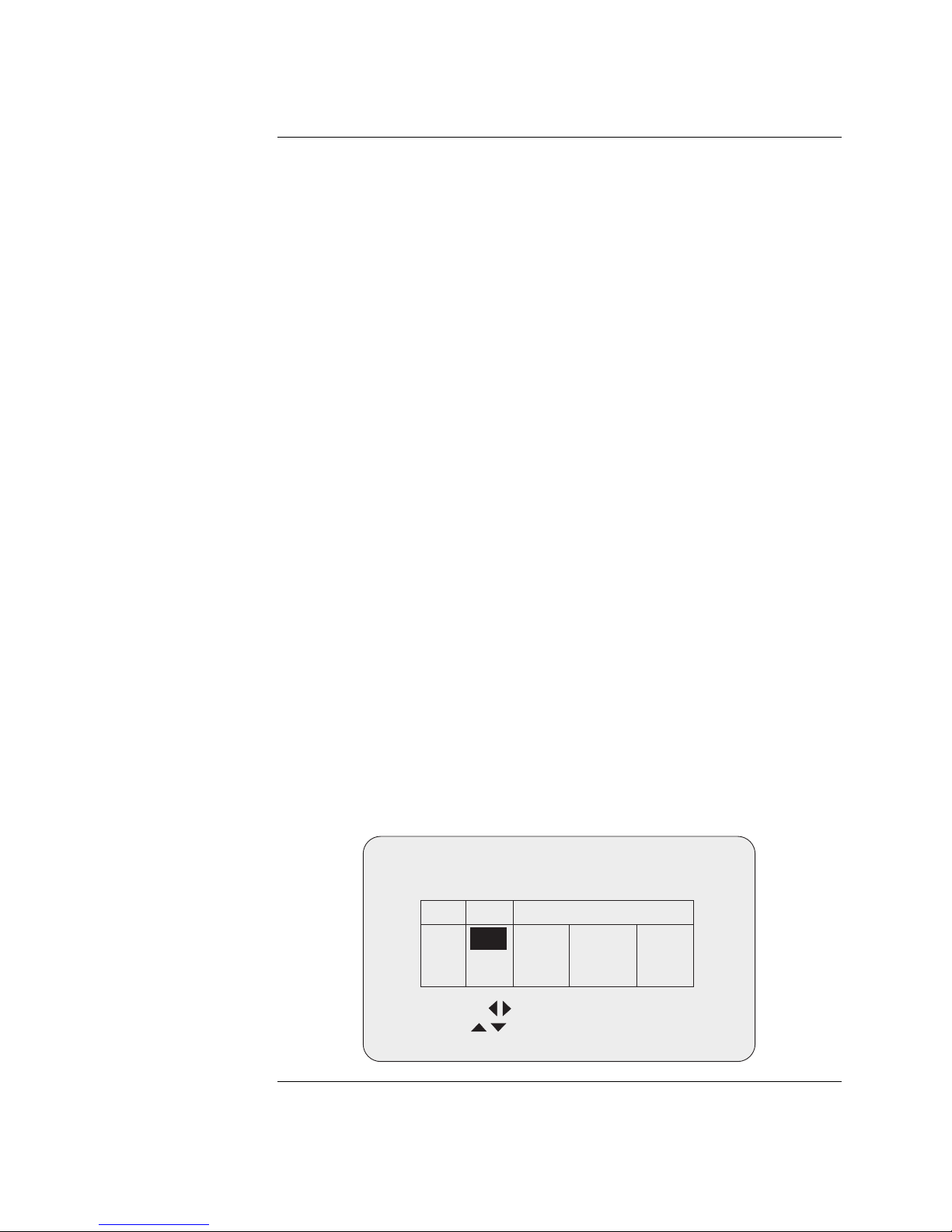

Gel Method

Screen

The Gel Method screen (see fi

g

ure below) allows

y

ou to select from a choice of

eight pre-programmed methods for Novex®mini-gels or four user-defined

methods.

1. Use the directional arrow buttons to navigate through the menu.

2. Press the Select button to choose the method. You will advance to the Gel

Quantity screen (see next page) if a pre-programmed method is chosen, or to

the Custom Method Option screen (see page 22) if a user defined method is

selected.

Note: The pre-programmed method durations are set to the shortest run time per

gel type, or buffer level and buffer strength to prevent over-running a gel.

Different percentage gels within a single gel type can cause a gel to take longer to

run. Additional time can be added to the pre-programmed method before,

during, and after a run (see page 20).

TBE Gel

Tris-Gly Gel

User-Custom3

User-Custom1

Western Blot

IEF Gel

uPAGE Blot

uPAGE Gel

TBE-Urea Gel

Tricine Gel

User-Custom2

User-Custom4

SELECT to continue

and moves cursor

Continued on next page

15

Using PowerEase®500, Continued

Gel Quantity

Screen

The Gel Quantit

y

screen (see the followin

g

fi

g

ure) allows

y

ou to scale the pre-

programmed method’s current and power values by the number of gels that are

to be run.

1. Use the Up and Down arrows on the keypad to increase or decrease the

number of gels from 1 to the maximum allowable quantity of gels which can

be run for the specified method.

2. Press the Start button to begin the electrophoresis. The Method Run Large

Display screen will be displayed.

3. If you need to edit any electrophoresis parameters, press the Select button to

advance to the Method Edit screen (see page 19).

The Stop button returns you to the Gel Method screen (or the Custom Method

Options screen if a custom method is in use).

If the number of gels selected causes the current to be scaled such that the

PowerEase®500 Power Supply maximum power limit of 50 watts is exceeded, an

error message “Power Limit Reached” will be displayed. Similarly, if the current

exceeds 500 mA, an error message “Current Limit Reached” will be displayed.

Change the number of gels appropriately to continue electrophoresis.

Note: Avoid changing the number of gels during the run, unless gels are

removed during the run. If you would prefer to see the total output parameters,

leave the gel number at “1” before starting.

Tris-Glycine Gel

umber of

Gels to be run:

START begins; SELECT edits

adjust number of gels

2

Continued on next page

16

Using PowerEase®500, Continued

Method Run Large

Display

The Method Run Lar

g

e Displa

y

screen (see the followin

g

fi

g

ure) is displa

y

ed

after the Start button is pressed from the Gel Quantity screen or the Method

Edit screen. This screen displays the status of the method during a run in an

easy to read format. The screen displays:

•Selected Method

•Status (running or paused)

•Number of Gels

•Run Condition (Limiting Parameters)

•Actual Voltage and Current (large display)

•Step Time Remaining

•Present Step Number

•Actual Wattage (small display)

•Detected Temperature (if installed)

Pressing the Select button once takes you to the Method Run Graphic Display

screen (see page 18) and to the Method Run/Edit screen (see page 19) if pressed

twice.

The Stop button pauses the run if pressed once, stops the method if the method

is already in the paused state and takes you to the Method Edit screen.

To resume, press the Start button.

Tris-Glycine Gel

Voltage is constant

RU I G

SELECT views; STOP pauses

Time

Temp:

Power:

Step:

Left: 0:07

24oC

2W

1

125V

30mA

Gels

2

Continued on next page

17

Using PowerEase®500, Continued

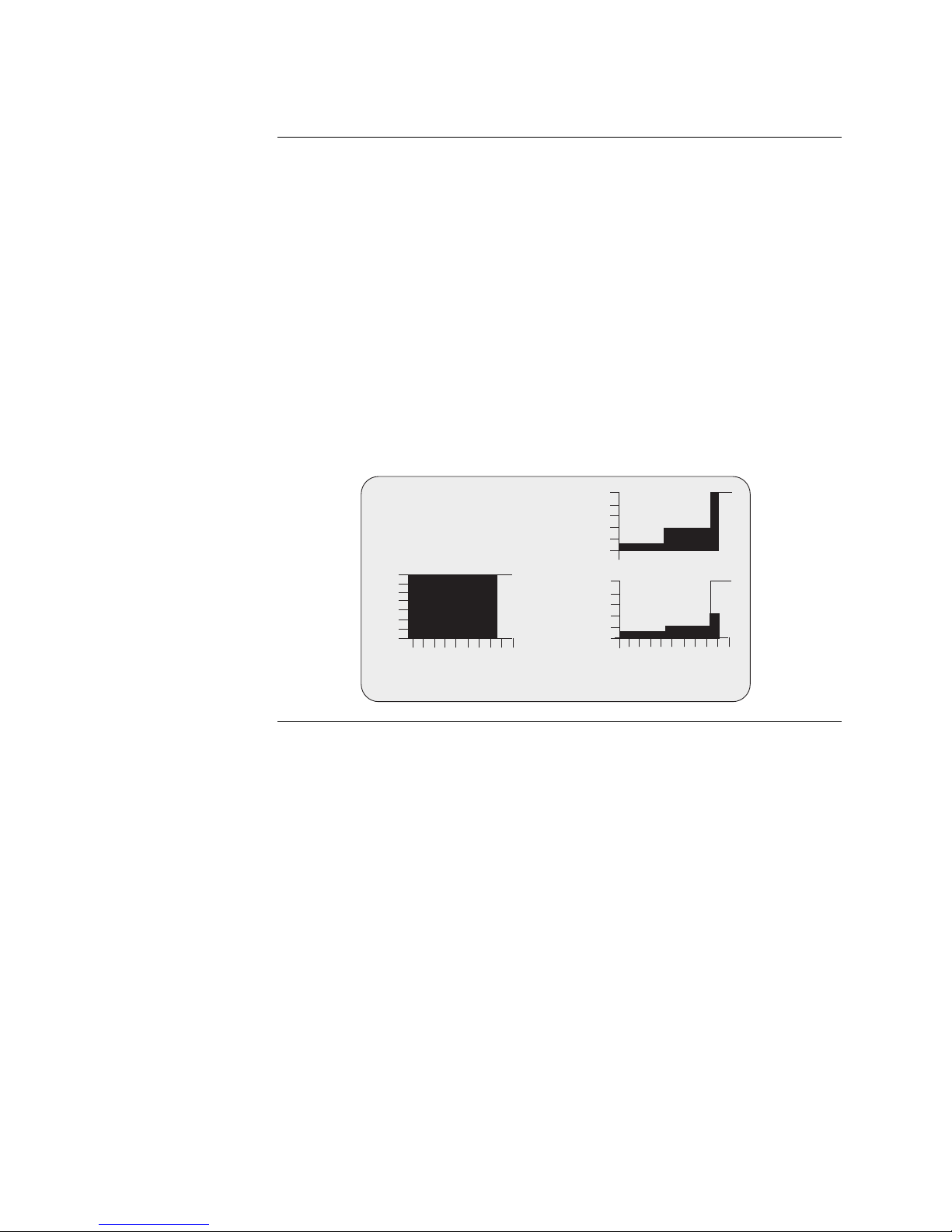

Method Run

Graphic Display

The Method Run Graphic Displa

y

screen (see the followin

g

fi

g

ure) is

displayed after the Select button is pressed from the Method Run Large

Display screen. This screen displays the status of the method during a run in a

graphical format. The screen displays:

•Selected Method

•Status (running or paused)

•Present Run Time

•Voltage, Current, and Wattage (applied during the run)

•Run Condition (Limiting Parameter)

The Select button takes you to the Method Run/Edit screen (see page 19).

The Stop button pauses the run if pressed once, stops the method if pressed

twice and takes you to the Method Edit screen.

To resume, press the Start button.

IEF Gel

500V

RU I G

SELECT views; STOP pauses

6mA

2:07

2W

c

u

r

r

e

n

t

v

o

l

t

s

p

o

w

e

r

Continued on next page

18

Using PowerEase®500, Continued

Method Edit

Screen

The Method Edit screen (see the followin

g

fi

g

ure) is displa

y

ed after the Select

button is pressed from the Gel Quantity screen. The Method Edit screen allows

you to edit the following method parameters:

•Step Duration

The maximum step duration is 24 hours. If the duration is set to zero, the

step will be deleted and all following steps will be moved up. If you set an

empty step to non-zero, the voltage, current, and wattage settings from the

previous line will be copied.

•Step Voltage Limit

•Step Current Limit

•Step Power Limit

•Load Check State

The Load Check state is either ON or OFF, and determines whether or not

the PowerEase®500 Power Supply unit will detect ‘No Load’ conditions. The

default value for Load Check is ON and is the recommended state.

•Gel Quantity

The gel quantity limit determines the maximum voltage, current, and

wattage for the step. Values must be in the range of 1–500 volts, 1–500 mA,

and 0.1–50 watts for one gel (the values for current and watts will be reduced

if multiple gels are selected).

If you have changed a pre-programmed method, the method will always run as

edited until you cycle back to the Gel Method screen. At this point the pre-

programmed method will revert to the default parameters.

To edit the parameters on this screen:

1. Press the Left or Right arrow buttons to move the cursor between different

fields. As the cursor moves from field to field, a status message on LCD

display is updated to show the affected parameters if changes are made.

2. Use the Up and Down buttons to adjust field values.

3. Press the Start button to begin the run and change the display to the monitor

state. The Stop button takes you to the Gel Quantity screen (see page 16).

Tris-Glycine Gel

START begins; STOP for prior

moves cursor

adjusts run time

Load Check: ON

24

o

C

Step Time Limits

125V 100 mA 18.0W

1

2

3

1:30

Continued on next page

19

Using PowerEase®500, Continued

Method Run/Edit

Screen

The Method Run/Edit screen (see the followin

g

fi

g

ure) is displa

y

ed after the

Select button is pressed from the Method Run Large Display screen or the

Method Run Graphic Display screen. This screen displays the status of the

method during a run and allows you to edit parameters during the run for the

current step displayed on this screen.

The screen displays:

•Selected Method

•Status (running or paused)

•Number of Gels

•Total Time Elapsed

•Run Condition (limiting parameter or error condition if detected)

•Detected Temperature (if probe is installed)

•Present Step Number

•Present Parameter Set Points

•Step Time Elapsed

•Actual Voltage, Current and Wattage

Make the appropriate change using the directional arrow keys and press the

Start button.

The Select button takes you to the Method Run Large Display if pressed once,

and to the graphic display if pressed twice.

The Stop button pauses the run if pressed once and stops the method if the

method is already paused.

20

This manual suits for next models

5

Table of contents