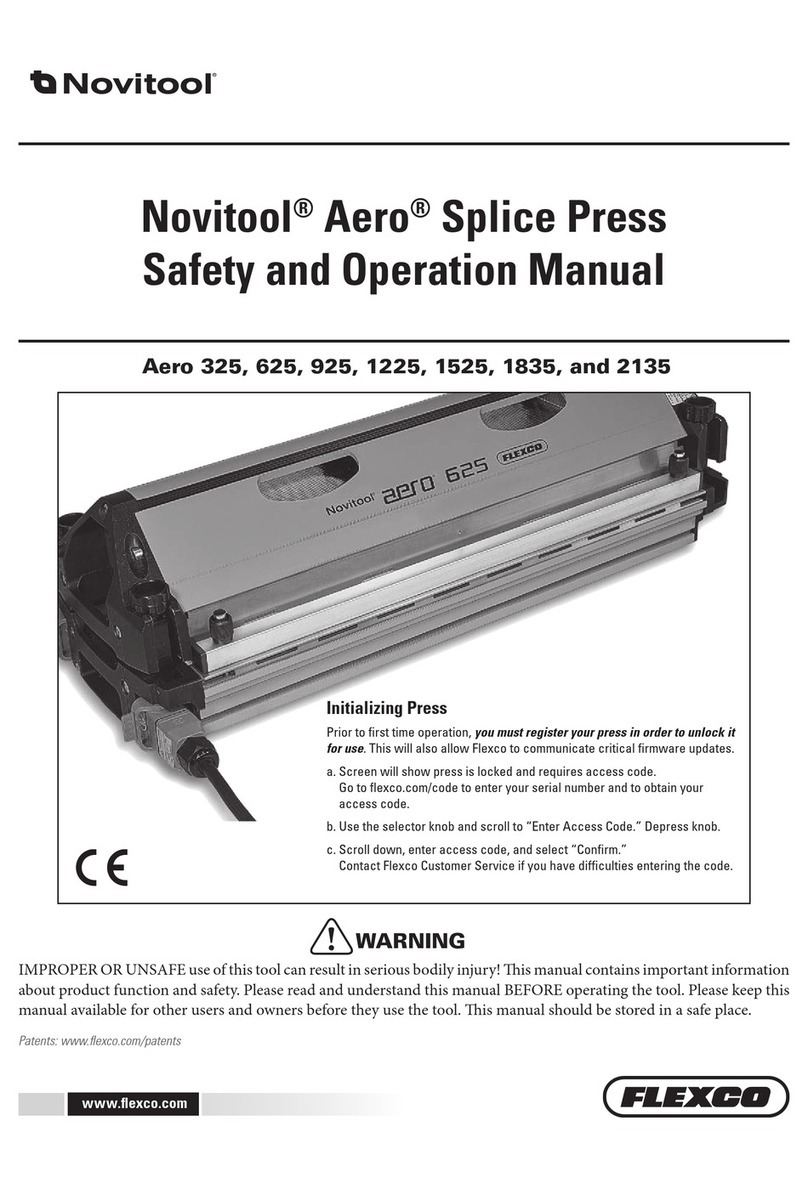

Novitool Aero 08080 Guide

Aero® Press Stand

Safety and Operation Manual

www.flexco.com

www.flexco.com

Splicing Press Efficiency in the Fabrication Workshop

IMPROPER OR UNSAFE use of this tool can result in serious bodily injury! is manual contains important information

about product function and safety. Please read and understand this manual BEFORE operating the tool. Please keep this

manual available for other users and owners before they use the tool. is manual should be stored in a safe place.

WARNING

www.flexco.com

—2—

Table of Contents

Main Components Aero® Press Stand ........................................................3

Description..................................................................................................... 4

Specications.................................................................................................. 4

General Safety Rules......................................................................................5

Aero Stand™ Assembly..................................................................................7

Installing Aero® Press into Aero Press Stand ...........................................15

Operation of the Aero® Press Stand ..........................................................17

Removing the Aero® Press from the Aero Stand .....................................18

Warranty .......................................................................................................19

Disclaimer e Aero Press Stand has been tested successfully with the Aero 900,

Aero 1200, and Aero 1500 models. It is intended for use only with Aero splicing

presses manufactured by Flexco and only in these three specic models.

—3—

Main Components Aero® Press Stand

No. Item No. Description Qty No. Item No. Description Qty

1 08309 AERO STAND COLUMN ASSEMBLY 1 7.5 G1726 HEX NUT M12 × 1.75 ZN 2

2 08307 AERO STAND TOP BEAM ASSEMBLY 1 7.6 G2027 HFBOLT M12 × 100 ZN 2

3 08313 AERO STAND BASE 1 7.7 G2037 SCREW SHCS M6 × 30 ZN 2

4 08312 AERO STAND CRADLE 1 7.8 G2036 SCREW SHCS M8 × 35 ZN 3

5 08326 LIFTING INTERFACE 1 7.9 G2039 NUT NYLOK FLNG M6 ZN 2

6 Q1786 AERO STAND CROSS SUPPORT 1 7.10 G2040 SPACER 6 MM × 16 MM ZN 2

7.1 Q1753 LEVELING FOOT 4 7.11 G2038 NUT NYLOK FLNG M8 ZN 3

7.2 G2041 PIN DETENT 9.5 MM × 60 MM ZN 2 7.12 G2050 SCREW HEX FLG M10 × 20 ZN 1

7.3 G1991 M8 × 1.25 × 20 HHCS FLNG ZN 12 7.13 08320 AERO STAND LOCATING POST 1

7.4 G2026 SCREW HEX FLG M8 × 30 ZN 4

2

1

6

3

4

5

7.7

7.4

7.3

7.6

7.1

7.5

7.2

7.10

7.11

7.13

7.12

7.9

7.8

www.flexco.com

—4—

Specifications

Description

With the Aero® Press Stand, you are in possession of a

quality Novitool® product from Flexco. e carefully

developed and built machine gives you the option of

the highest quality conveyor belting fabrication. With

the Aero Stand, you can now easily position the Aero

900, 1200, or 1500 press for fabrication convenience

and time savings.

e stand is manufactured from heavy gauge sheet

metal to assure stability for continuous press use.

e design allows for the Aero presses to be loaded

quickly and conveniently. e lower beam of the

Aero is xed into the stationary cradle of the press

stand. e upper beam is connected into the press

using cable interface. One person can operate it

easily, where movement of the upper half of the press

is assisted with counterweights.

Two Aero stand models are available. One stand

includes an umbilical cable that allows raising of the

upper beam without electrically disconnecting the

two press beams.

Aero Stand Ordering Information

Item Number 08080 08114

Description AERO-STAND-CW AERO-STAND-CW-UMCABLE

Dimensions (Assembled) 1399 × 1116 × 1854 mm

(55” × 44” × 73”)

1399 × 1116 × 1854 mm

(55” × 44” × 73”)

Dimensions (Working) 1583-1883 × 1116 × 1854 mm

(62-74” × 44” × 73”)

1583-1883 × 1116 × 1854 mm

(62-74” × 44” × 73”)

Shipping Weight 139 kg (306 lbs) 141 kg (311 lbs)

Feature NA Umbilical Cable Extension

e Identication plate of the Aero Press Stand is located on the inside of the column assembly door.

Tools Required for Assembly of the Aero Stand

• 13, 15, and 19 mm wrenches

• Adjustable wrench

• 5 and 6 mm Hex wrenches

—5—

Signal words:

“DANGER” indicates an imminently

hazardous situation which, if not avoided, will

result in death or serious injury. is signal

word is limited to the most extreme situations.

“WARNING” indicates a potentially

hazardous situation which, if not avoided,

could result in death or serious injury.

“CAUTION” indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury. It may also be used

to alert against unsafe practices.

Safety Symbol

!

is international safety symbol is used to

identify and call attention to specic

safety matters.

Safety Information

To Avoid Severe Personal Injury or Property

Damage, read carefully and understand the

following Safety Precautions.

1. WORK AREA

!CAUTION

Keep your work area clean and well lit.

Cluttered benches and dark areas invite

accidents.

2. PERSONAL SAFETY

!CAUTION

Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety shoes,

hardhat, or hearing protection must be used

for appropriate conditions.

Never alter or remove safety devices.

!WARNING

Stay alert, watch what you are doing and use

common sense when operating a tool. Do not

use tool while tired or under the inuence of

drugs, alcohol, or medication. A moment of

inattention while operating tools may result in

serious personal injury.

Dress properly. Do not wear loose clothing

or jewelry. Contain long hair. Keep your hair,

clothing, and gloves away from moving parts.

Loose clothes, jewelry, or long hair can be

caught in moving parts.

3. TOOL USE AND CARE

!CAUTION

Check for misalignment or binding of moving

parts, breakage of parts, and any other condition

that may aect the tool’s operation. If damaged,

have the tool serviced before using. Poorly

maintained tools cause many accidents.

General Safety Rules –Save These Instructions–

www.flexco.com

—6—

5. AERO STAND SAFETY

!DANGER

Read and understand the Aero Press operations

manual before using the press in the Aero Stand.

!CAUTION

Avoid pinch points during the assembly and in

operation. Exercise caution when moving weights

or liing and positioning ofcomponents.

Exercise care to avoid unbalanced component

conditions during assembly.

Do not cut or kink the liing cables during

handling, assembly, or operation of the

AeroStand.

!WARNING

Two persons are required for assembly of the Aero

Stand. Portions of the process are dicult for one

person to perform without risk of injury.

Ensure that Aero Press is secure in stand prior

tooperation.

Do not move the press stand to a dierent

location while the press is installed.

Do not exceed weight capacity of the Aero Stand

cradle. e Aero Stand design is for use only with

Aero presses 900, 1200, and 1500.

Ensure that the weight pins are installed securely

in the proper position before operating the stand.

Ensure that vertical column door is closed and

latched during operation of the stand.

Avoid raising/lowering of the upper beam with

excessive speed.

General Safety Rules -Save These Instructions-

4. SERVICE AND MAINTENANCE

!CAUTION

When servicing a tool, use only original

replacement parts. Use of unauthorized parts or

failure to follow Maintenance Instructions, may

create a risk of injury.

Do not wipe plastic parts with solvent. Solvents

such as gasoline, thinner, benzene, carbon

tetrachloride, and alcohol may damage and

crack plastic parts. Do not wipe them with

such solvents. Wipe plastic parts with a so

cloth lightly dampened with soapy water and

drythoroughly.

!WARNING

Only qualied repair personnel must perform

tool service. Service or maintenance performed

by unqualied personnel could result in a risk

ofinjury.

NEVER use a tool, which is defective or

operating abnormally. If the tool appears to be

operating unusually, making strange noises,

or otherwise appears defective, stop using it

immediately and arrange for repairs

Maintain tools with care. Keep machine parts

clean. Properly serviced tools are less likely to

bind or clutter material and are easier to control.

—7—

www.flexco.com

Aero Stand Assembly

A

With column assembly laying on the oor, open door and remove packing

material. Install pins in weight mechanism to Aero 1500 location. Slide all

three weights to the top and fasten into place with the toggle clamp. Ensure

that latch is secured to the weights.

Using six M8 × 20 mm screws (item # 7.3) assemble base (item # 3) to

column assembly (item # 1). Note: Install all screws intially loose, tightening

aer all are installed.

A1

A2

www.flexco.com

—8—

B1

B1

Aero Stand Assembly

A4

Ensure jam nuts are positioned onto the threaded shas of the leveling feet

(as shown) before installation. Install two leveling feet (item # 7.1) into Aero

Stand base (item # 3). Ensure leveling feet are fully engaged through mounts.

Ensure jam nuts are positioned onto the threaded shas of the leveling

feet (as shown) before installation. Install two leveling feet (item # 7.1)

into cross support assembly (item # 6). Ensure leveling feet are fully

engaged through the mounts.

A3

—9—

Aero Stand Assembly

A6

Using two M12 × 100 mm bolts (item # 7.6) and two M12 nuts (item # 7.5)

assemble cross support assembly (item # 6) into column assembly (item # 1).

With the weight latch engaged, manually support the weights (position A),

remove the pins and lower the weights, taking care to avoid pinch points.

Support the remaining (Aero 900) weight (Position A), disengage the

weight latch and lower the Aero 900 weight. Avoid pinch points within the

weight path!

A5

A

www.flexco.com

—10—

Aero Stand Assembly

A8

A7

Using six M8 × 20 mm screws (item # 7.3) assemble cradle (item # 4)

to column assembly (item # 1) Note: Install all screws intially loose,

tightening aer all are installed.

Raise the Aero 900 weight and engage the weight latch. Raise the Aero 1200

and 1500 weights and secure them in the uppermost position with the pins.

Avoid pinch points within the weight path!

—11—

Aero Stand Assembly

A10

Install locating post (item # 7.13) into cradle (item # 4) using one M10 ×

20mm screw (item # 7.12), inserted from below. Position A for Aero 1200

and 1500. Position B for the Aero 900. Post is keyed for proper orientation.

Using four M8 × 30 mm screw (item # 7.4), install top beam assembly

(item # 2) to column assembly (item # 1). Note: Install all screws initially

loose, tightening aer all are installed.

A9

A

B

www.flexco.com

—12—

Aero Stand Assembly

A11 Cut the plastic ties that are holding the three cables looped and hanging

from the top beam assembly. Inside the column assembly, ensure that the

weights are secured with the weight latch.

Follow the cables from the pulley located in the top beam from the back

side of the Aero Stand assembly for proper positioning. Fix the cables to

the weight system using the provided quick link clevises.

e cable that runs through the center groove of the pulley should be

fastened to the center clevis, the cable in the le groove in the le clevis,

and the right groove to the right clevis. Take care not to cut, kink, or twist

cables. Aer the cables are installed, ensure that the quick link nuts are

secured to close the link.

Cut zip ties that are fastened to the three cables in the top beam assembly,

allowing them to hang freely.

—13—

Aero Stand Assembly

A13

With longer extension (A) towards the column assembly, install liing

interface (item #5) to the three cables hanging from the top beam

assembly using three M8 × 35 mm screws (item # 7.8) and three M8 nuts

(item # 7.11).

With Aero Stand 08114, use two M6 × 30 mm screws (item # 7.7), two

M6 nuts (item # 7.9), and two 6 mm spacers (item # 7.10) to secure the

umbilical cable extension (item # 08319) into the liing interface, with

non-latch connector extending from end B.

A12

A

B

www.flexco.com

—14—

Aero Stand Assembly

With the Aero Stand located for operation, rotate the leveling feet as

necessary to be sure that the stand is level. Assure that the leveling feet

shas remains fully engaged through the frame. Tighten all leveling feet

jam nuts to the frame.

A14

—15—

B

B1

B2

Installing the Aero Press into the

Aero Press Stand

Place the lower beam of the Aero Press in the support cradle, with the

locating post extending up through press handle opposite the control end.

Avoid pinch point where locating post interfaces with the press.

Load the upper beam of the Aero Press onto the lower beam. Use the detent

pins (item #7.2) to connect the liing interface to the top of the Aero Press

upper beam. Ensure the press is centered under the liing cables.

!

www.flexco.com

—16—

Installing the Aero Press into the Aero Press Stand

B3

B4

If using umbilical cable extension, secure the upper beam connectors to the

top of the Aero Press with Velcro fastening strip.

With an Aero 900 or 1200 loaded into the stand, ensure weight latch is

engaged and support counterweights (position A) labeled AERO 1500 and

1200. Remove the pins from the Aero 1500 counterweight and install them

into the counterweight corresponding with the Aero Press in the stand.

Ensure both weight pins are completely engaged. Avoid pinch points within

the weight path!

A

—17—

Operation of the Aero Press Stand

C

C1

With the Aero Press upper and lower beams disconnected from each

other, manually raise and lower the upper beam as needed for your

splicing process.

www.flexco.com

—18—

D1

D

• Push down on the locating post latch, simultaneously liing the lower

beam of the Aero Press from the Aero Stand cradle. Avoid pinch points!

• Turn o the electrical power supply to the Aero Press

• Disconnect power and umbilical cables

• Open the vertical column door and use the latch to lock the active

weights in the uppermost position

• If an umbilical cable extension is integrated into the interface, detach the

cable end that is fastened to the upper beam with Velcro

• With the weights locked in the uppermost position, remove detent pins

connecting the liing interface to the upper beam of the Aero Press

• Unfasten the upper press beam from the lower beam and remove from

the stand

Removing the Aero Press from the Aero Stand

—19—

Warranty

Warranty provided is limited to defects in materials and workmanship.

e warranty has a maturity of one year from the date of delivery. In this period, the

necessary parts will be made available free of charge. Any further warranty claims,

damages, or consequential damages are excluded.

e above warranty shall apply exclusively and only under the following conditions:

• An expert according to the conditions and standards of the competent

authorities must install the appliance.

• Any warranty claims are forfeited when performing repairs, modications or

adaptations, and/or assembling unapproved components without the prior

consent of Flexco. In addition, any warranty claims are forfeited when installed

by way of deviation from the national and local regulations.

• Claims during the warranty period provide no extension of the warrantyperiod.

E

E1

Unit 7 Kingsmark Freeway • Oakenshaw • Bradford, BD12 7HW • United Kingdom

Tel: +44-1274-600-942 • Fax: +44-1274-673-644 • Email: sales@exco.co.uk

Visit www.flexco.com for other Flexco locations and products.

©2012 Flexible Steel Lacing Company. 12-13. For reorder: X3154

This manual suits for next models

1

Table of contents

Other Novitool Power Tools manuals

Popular Power Tools manuals by other brands

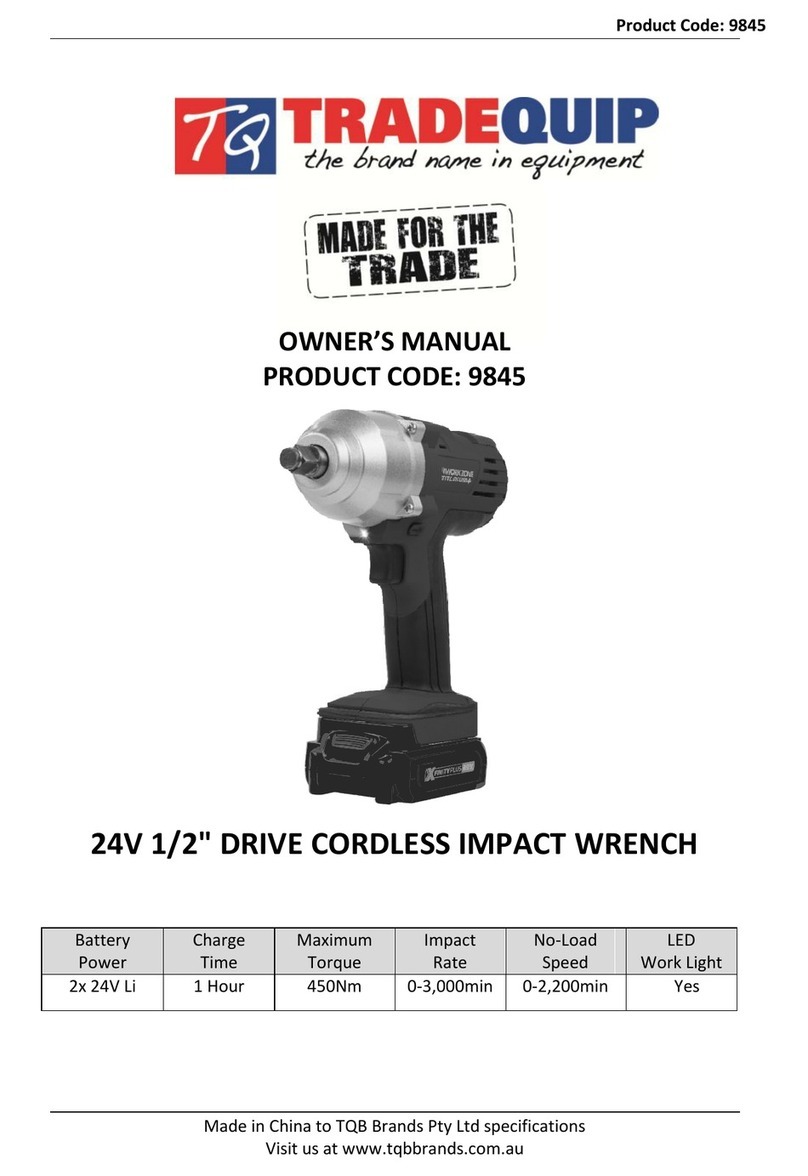

TradeQuip

TradeQuip 9845 owner's manual

Parkside

Parkside PGKGA 40-Li B2 Translation of the original instructions

Powerfix Profi

Powerfix Profi PFRS 1.5 A1 operating instructions

Bosch

Bosch GOP 30-28 Professional Original instructions

Land Pride

Land Pride BB3578 Operator's manual

Hilti

Hilti TE 40 operating instructions