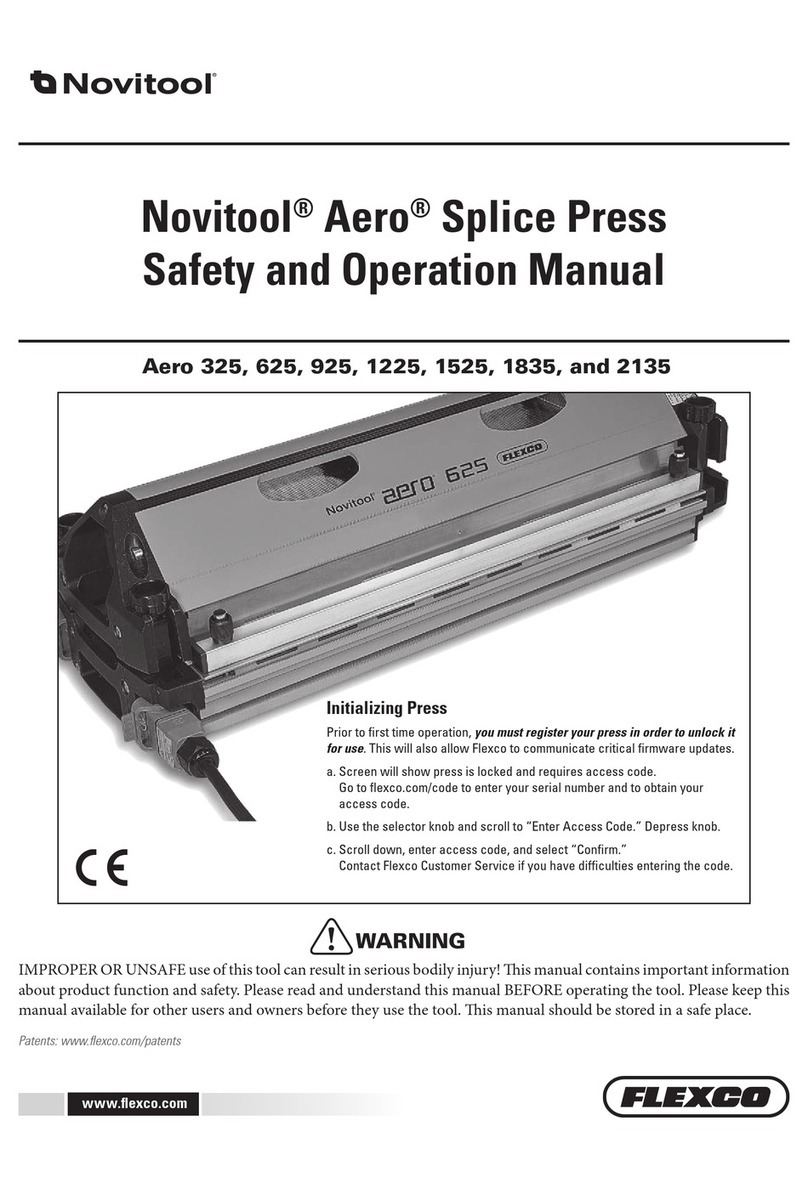

Novitool Aero 625 User manual

Novitool®Aero®Press

End Plate Removal Instructions

www.flexco.com

IMPROPER OR UNSAFE use of this tool can result in serious bodily injury! is manual contains important information

about product function and safety. Please read and understand this manual BEFORE operating the tool. Please keep this

manual available for other users and owners before they use the tool. is manual should be stored in a safe place.

WARNING

Patent number: US 9,090,022 B1 and other Patents Pending

www.flexco.com

—2—

Table of Contents

General Safety Rules...................................................................................... 3

End Plate Removal to Access Electrical Tray

Top Beam End Plate Removal to Access Electrical Tray ................. 5

Bottom Beam End Plate Removal to Access Electrical Tray........... 8

Electrical Tray Contents

Top Beam (Aero® 625 and 1525) Electrical Tray Contents ........... 10

Bottom Beam (Aero® 625 and 1525) Electrical Tray Contents..... 11

Reassembly of End Plate

Top Beam End Plate Reassembly...................................................... 12

Bottom Beam End Plate Reassembly ............................................... 15

Inspection Items .......................................................................................... 17

How to Clean the Platens ........................................................................... 17

Spare Parts List............................................................................................. 18

Technical Assistance ................................................................................... 18

Schematics.................................................................................................... 19

Ply 130™ply separator

—3—

Signal words:

“DANGER” indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury. is signal word is

limited to the most extreme situations.

“WARNING” indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

“CAUTION” indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury. It may also be used to

alert against unsafe practices.

Safety Symbol

is international safety symbol is used to

identify and call attention to specic

safety matters.

Safety Information

To avoid severe personal injury or property

damage, read carefully and understand the

following Safety Precautions.

!

General Safety Rules – Save These Instructions

Ensure machine, power cable and power source

are not positioned in standing water or exposed

to wetconditions.

Do not connect machine to power or operate

machine if machine is wet. Machine intended

for non-condensing/non-icing conditions.

NEVER leave power cord plugged into wall

while detached from unit as this could lead to

a serious electrical danger if it comes in contact

with uids, such as water.

Service shall only be performed by

a qualied electrician. Power shall

be removed before service. Follow

Lock-Out Tag-Out procedures.

Observe proper maintenance procedures. Do

not modify electrical circuit.

1. WORK AREA

!DANGER

High Voltage!

Do not operate power tools in explosive

atmospheres, such as in the presence of ammable

liquids, gases, or dust. Power tools create sparks

which may ignite the dust or fumes.

!CAUTION

Keep your work area clean and well lit.

2. ELECTRICAL SAFETY

!DANGER

e Aero® is a single insulated machine and

needs a multiple wire grounded power cord and

grounded power supply system. Do not modify

electrical cables provided.

Never alter or remove safety devices.

Never operate press with an extension cord.

!WARNING

Operating press on incorrect voltage can cause

serious damage and potential hazards. Available

Aero® power cords:

• 110 volt; single phase

• 230 volt; single phase

• 230 volt; three phase

• 400 volt; three phase + neutral

• 400 volt; three phase

• 460 volt; three phase

Do not use outdoors. is machine is designed

for indoor use only. e press must be

transported in transport case when outdoors.

Inspect machine before each use. Ensure

machine and power cable are not damaged.

Machine shall not be operated with damaged

controllers, power cords, or other mechanical

components.

Ply 130™ply separator

www.flexco.com

—4—

!CAUTION

Only operate Aero® with machine positioned on

a level, rm surface.

NEVER use a machine which is defective or

operating abnormally. If machine appears to

be operating unusually, making strange noises,

or otherwise appears defective, stop using it

immediately and arrange for repairs.

Do not use machine if switch does not turn

it on or o. Any machine that cannot be

controlled with a switch is dangerous and must

be repaired.

Check for misalignment or binding of moving

parts, breakage of parts, and any other

condition that may aect machine operation. If

damaged, have machine serviced before using.

In order to maintain air ow, do not cover the

air inlets on top, at ends and on sides where air

ows through.

Maintain machine in clean condition. Remove

any oils, greases, or food product from outside

and inside machine.

Avoid dropping or severe handling of machine

at all times, including during movement in

transport case.

If the electrical supply cord is damaged, it must

be replaced by a special cord available from the

manufacturer or it’s service agent.

3. PERSONAL SAFETY

!WARNING

Use safety equipment. Always wear eye

protection, gloves, non-skid safety shoes, and

adhere to other safety standards of the facility

where operating the press.

Stay alert, watch what you are doing, and use

common sense when operating a machine. Do

not use machine while tired or under inuence

of drugs, alcohol, or medication. A moment of

inattention while operating machines may result

in serious personal injury.

Do not wear loose clothing or jewelry. Keep

your hair, clothing, and gloves away from

moving parts. Loose clothes, jewelry, or long

hair can be caught in moving parts.

When moving in transport case, ensure casters

are unlocked and case is latched securely.

Abide by all instructions and warning labels.

is equipment is not to be used by children

or persons with reduced physical, sensory or

mental capabilities, or lack of experience and

knowledge of the equipment.

4. USE AND CARE

!WARNING

Read and understand Aero® operations manual

before using machine.

Do not store solvents in Aero® transport case.

General Safety Rules

!CAUTION

e Aero has been optimized for process speed,

portability, and ease of use. A resulting aect

of the designed portability is that the structure

will deect as internal air pressure is increasing

during splice process. e length of press will

determine how much deection will occur at

any specic pressure. Beam extrusions were

designed with strength to return to their normal

state when pressure is relieved; deection will

not be permanent.

—5—

A

A1

Aero®Press End Plate Removal and Reassembly

Tools to Service Press

• 2 mm hex key

• 6 mm hex key

• 7 mm crescent wrench

• Aero® splice press instruction manual

A2 End Plate Removal to Access Electrical Tray

Both top and bottom press beams contain an electrical tray with all electrical and pneumatic

components. Prior to accessing electrical trays unplug all power cables (power switch alone is not

sucient). Procedure to remove electrical trays are as follows:

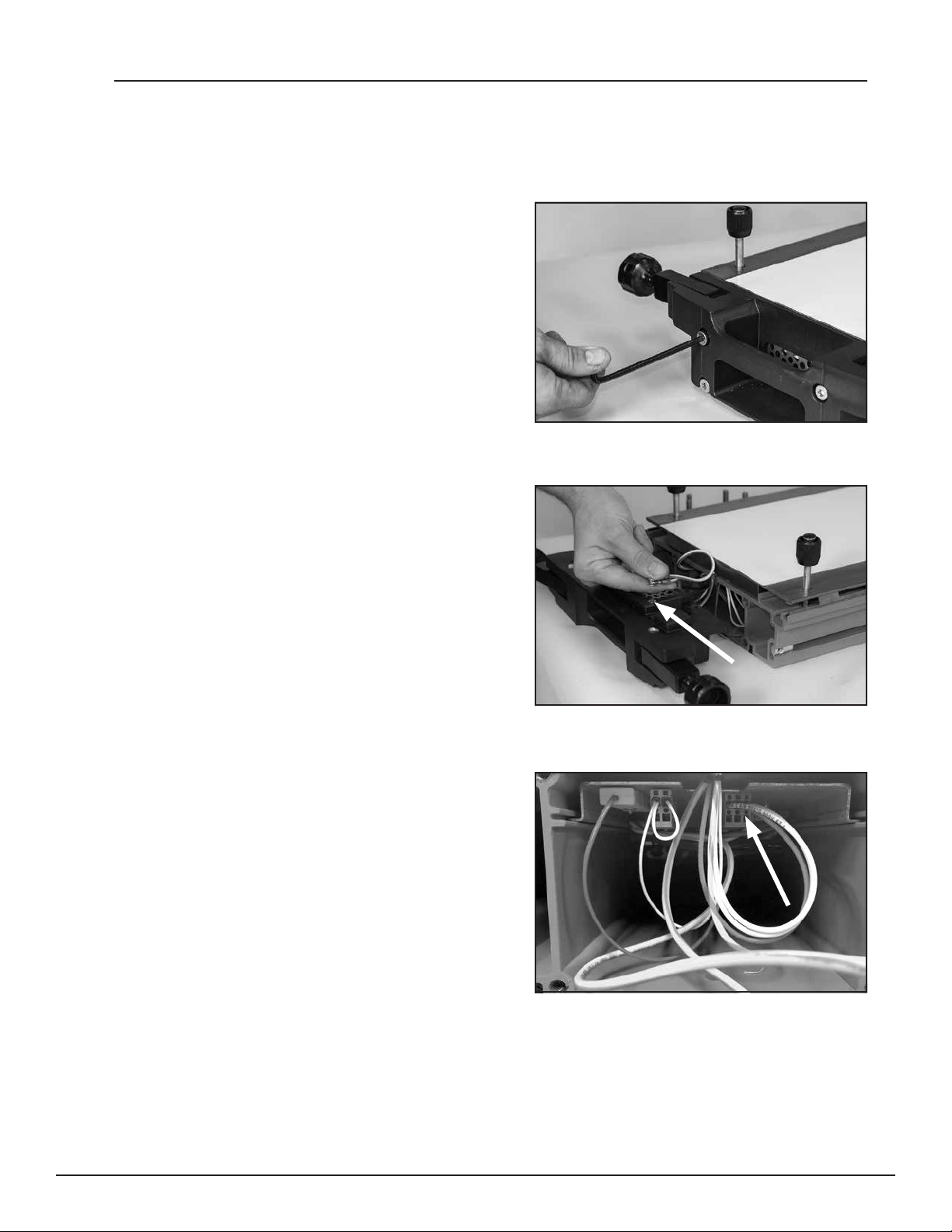

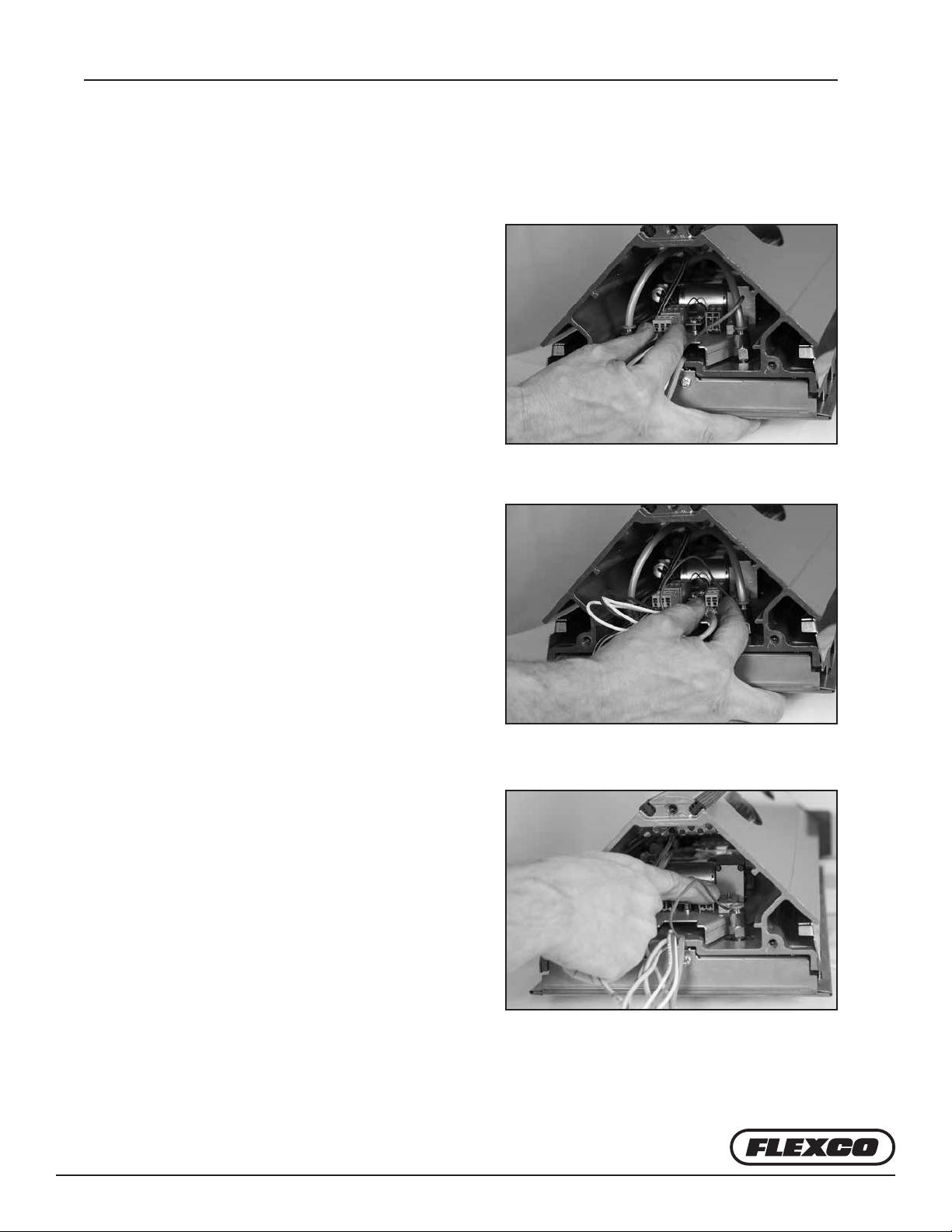

ÜTop Beam End Plate

Removal To Access

Electrical Tray:

1. Locate rear top end plate (end without display

screen). Using 6 mm hex key, unscrew 3 bolts

located on rear top end plate.

Pull away from extrusion.

2. Disconnect ground wires from end plate.

Remove end plate.

Ply 130™ply separator

www.flexco.com

—6—

Top End Plate Removal

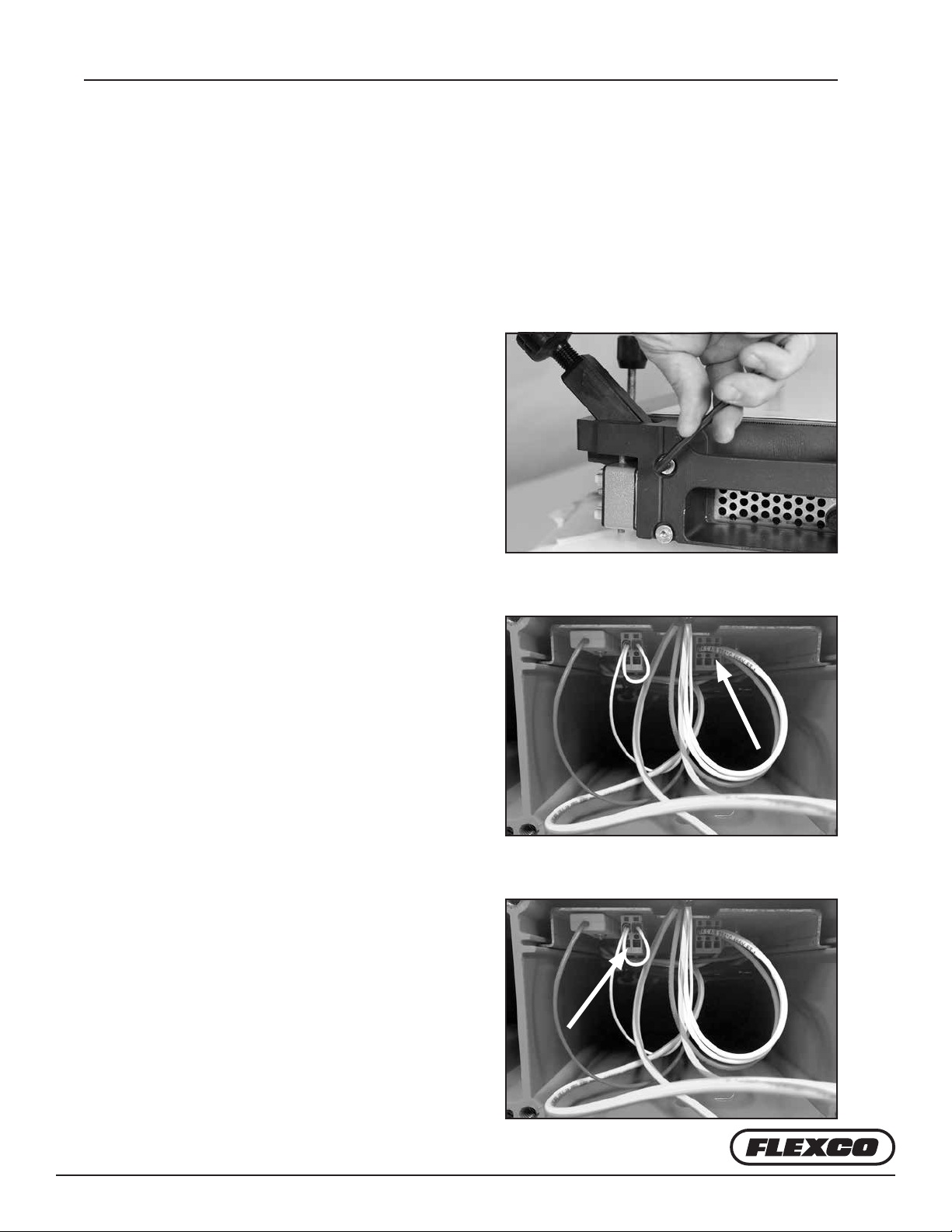

3. Disconnect by pulling three connectors straight out inside top beam of press.

NOTE: pull on connectors not wires themselves:

A. Heater connector (gray): 2 white wires

and 1 red wire

B. ermal fuse connector (gray): whitewire

C. ermocouple connector (yellow):

2 mm hex key may be used to

assist in removal

Ply 130™ply separator

—7—

Top End Plate Removal

4. Disconnect the 2 pneumatic connections.

Hold down blue ring of connector and pull

hose out.

5. Using 6 mm hex key, unscrew 3 screws located

on front end plate.

Ensure wires are free to move and not tangled. en gently pull top end plate to slide electrical tray

out of beam.

Ply 130™ply separator

www.flexco.com

—8—

Bottom End Plate Removal

ÜBottom Beam End Plate Removal to Access Electrical Tray:

1. Locate rear end plate (end without electrical

connectors). Using a 6 mm hex key, unscrew 4

screws located on rear bottom end plate.

Pull away from extrusion.

2. Disconnect ground wires from end plate.

Remove end plate.

3. Disconnect by pulling three connectors

straight out inside top beam of press.

NOTE: pull on connectors not wires

themselves:

A. Heater connector (gray): 2 white wires

and 1 red wire

Ply 130™ply separator

—9—

Bottom End Plate Removal

B. ermal fuse connector (gray): whitewire

C. ermocouple connector (yellow): 2 mm

hex key may be used to assist in removal

4. Using 6 mm hex key unscrew 4 screws located

on front end plate.

Ensure wires are free to move and not tangled. en gently pull top end plate to slide electrical tray

out of beam.

Ply 130™ply separator

www.flexco.com

—10—

Electrical Tray Contents

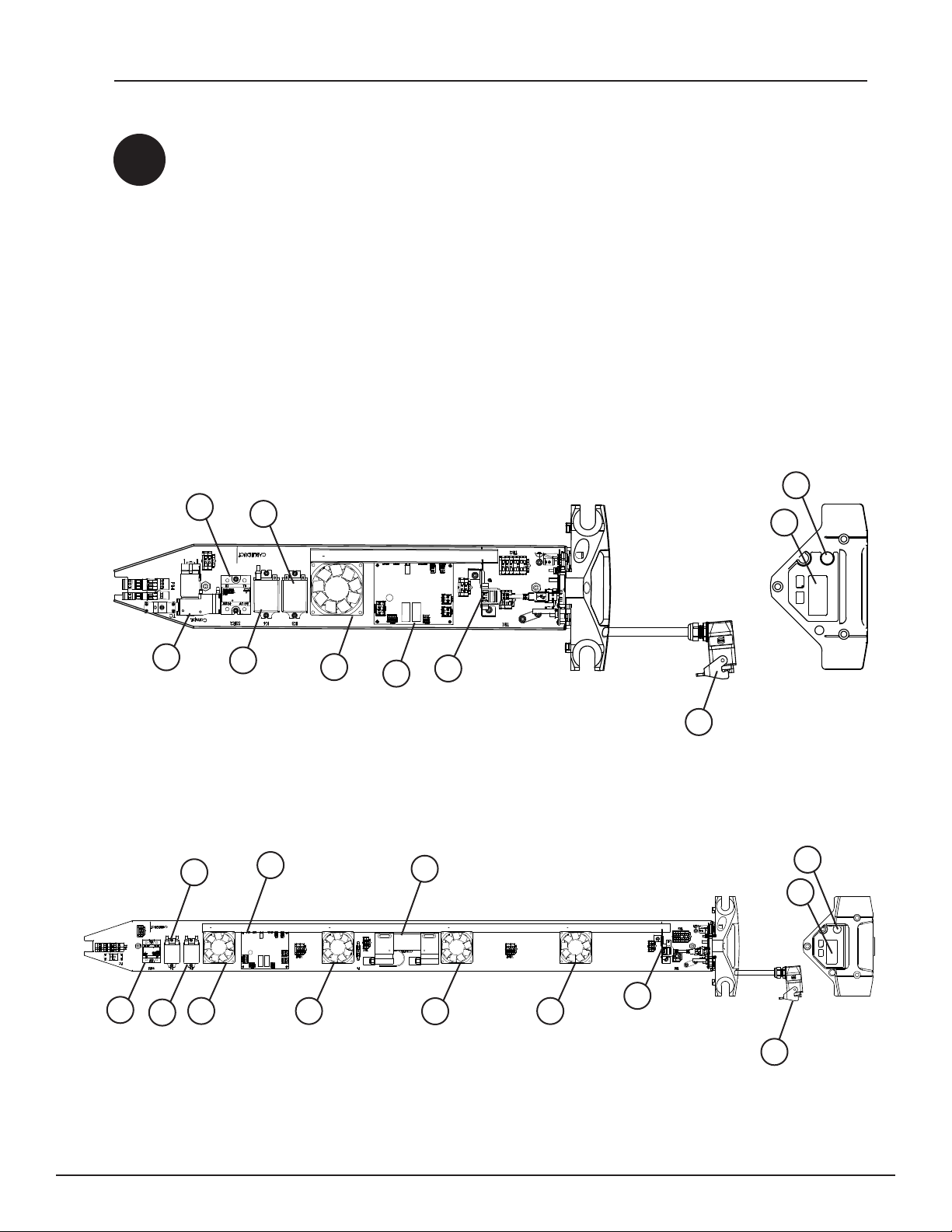

A3 Electrical Tray Contents

Top Beam Electrical Tray Contents:

A. Umbilical cable

B. Main controller with display and

control knob

C. Press release valve

D. USB connector

E. Cooling fans

F. Compressor

G. ermal fuse relay

H. Power control PCB

I. Solid state relay

J. S/P relay

F

IG

JEHD

A

B

C

Aero® 625 Top Beam Electrical Tray

Aero® 1525 Top Beam Electrical Tray

I

J

A

B

C

G

H

E

F

EED

E

Ply 130™ply separator

—11—

Electrical Tray Contents

Bottom Beam Electrical Tray Contents:

A. Power connection

B. Umbilical cable connection

C. Cooling fans

D. 24VDC power supply

E. ermal fuse relay

F. Power controller PCB

G. Solid state relay

H. S/P relay

I. Buzzer

J. Fuses

Aero® 625 Bottom Beam Electrical Tray

H

G

C

FDC

IEJ

B

A

Aero® 1525 Bottom Beam Electrical Tray

H

GF

I

E

C C

D

CC

J

A

B

C

Ply 130™ply separator

www.flexco.com

—12—

A4 Reassembly of End Plates

ÜTop Beam End Plate Reassembly:

1. Gently slide electrical tray into beam ensuring wires are free to move and not tangled

and that there is no binding. e tray should slide in with no resistance and the end

plate should t ush to the extrusion. If there is resistance, check to make sure wires

are not catching.

2. Using 6 mm hex key, screw 3 screws located

on front of end plate starting with the two

lower screws and nalizing with the top screw.

3. At rear of press re-connect the 2 pneumatic

connections. Press hose into quick connect

tting.

Top End Plate Reassembly

Ply 130™ply separator

—13—

4. Reconnect three connectors inside top beam of press:

A. Heater connector (gray): 2 white wires

and 1 red wire

B. ermal fuse connector (gray): white wire

C. ermocouple connector (yellow): brown

wire. Match prongs to same size slot

(typically + and - up).

Top End Plate Reassembly

Ply 130™ply separator

www.flexco.com

—14—

5. Reconnect ground wires to end

plate ensuring wires are oriented

to t within the extrusion prole.

Position head plate ush with the

extrusion. Place wires within slot

at end of extrusion to ensure that

the wires aren’t pinched between

the beam and the head plate. If

there is resistance a wire may be

pinched and must be adjusted.

6. Using 6 mm hex key, screw

the rear top end plate starting

with the two lower screws and

nalizing with the top screw.

Top End Plate Reassembly

Ply 130™ply separator

—15—

ÜBottom Beam End Plate Reassembly:

1. Gently slide electrical tray into beam ensuring wires are free to move and not tangled

and that there is no binding. e tray should slide in with no resistance and the

end plate should t ush to the extrusion. If there is resistance, check to make sure

wires are not catching. Check the bottom of the press to ensure that the air intake

perforated plate is not showing.

2. Using 6 mm hex key, screw 4 screws located

on front of end plate.

3. Reconnect three connectors inside bottom

beam of press:

A. Heater connector (gray): 2 white wires

and 1 red wire

B. ermal fuse connector (gray): white wire

Bottom End Plate Reassembly

Ply 130™ply separator

www.flexco.com

—16—

C. ermocouple connector

(yellow): brown wire

4. Reconnect ground wires to

end plate ensuring wires are

oriented to t within the

extrusion prole.

Position head plate ush with

the extrusion. Place wires

within slot at end of extrusion

to ensure that the wires aren’t

pinched between the beam

and the head plate. If there

is resistance a wire may be

pinched and must be adjusted.

5. Using 6 mm hex key, screw 4

screws located on rear bottom

end plate.

Bottom End Plate Reassembly

—17—

B

B1

Inspection Items

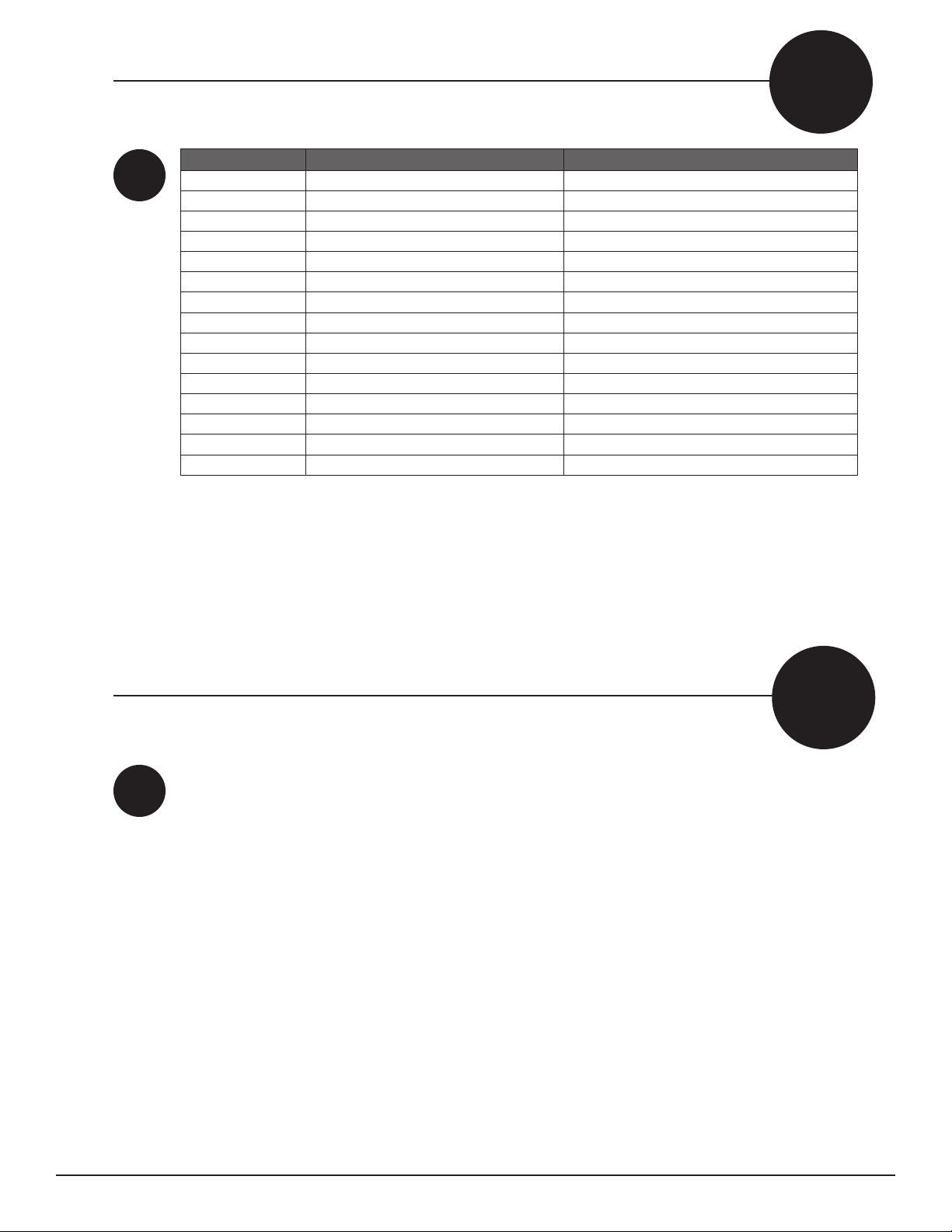

Inspection Task Every Cycle Every 100 Cycles Every 1000 Cycles

Inspect press connector bolt condition and replace if condition is

degraded. X

Inspect platen condition and clean (G2) or replace as needed. X

Inspect extrusion and head plates for any signs of fatigue. X

Inspect power connector pins for signs of arcing or wear. X

To clean the top and bottom platens, place an all-purpose cleaner on a clean cloth and wipe platens.

For area requiring further cleaning use a nylon abrasive pad.

C

C1

How to Clean the Platens

www.flexco.com

—18—

Item Code Ordering Number Description

08650 AERO-COMPRESSOR-SMALL Compressor 625-1225

08645 AERO-COMPRESSOR-LARGE Compressor 1525-2135

09249 SPRING-BAFFLE-AERO-G3-625 Spring baffle for 625

09250 SPRING-BAFFLE-AERO-G3-925 Spring baffle for 925

09251 SPRING-BAFFLE-AERO-G3-1225 Spring baffle for 1225

09252 SPRING-BAFFLE-AERO-G3-1525 Spring baffle for 1525

09253 SPRING-BAFFLE-AERO-G3-1835 Spring baffle for 1835

09254 SPRING-BAFFLE-AERO-G3-2135 Spring baffle for 2135

08604 AMIGO-FRICTION-TAPE-33X25 Tape for clamp bars

09262 BOLT-CLAMP-TOGGLE-AERO-G3 Press connector bolt

09342 T/C-SUBASSY-AERO-G3 Thermocouple

09343 FUSE-ASSY-THERMAL-AERO-G3 Thermofuse

09351 FUSE-ASSY-CERAM-FL-0326020.MSP Main power fuse 625-1225

09374 CARTRIDGE-FUSE-F-20A-RS-3375256 Main power fuse 1525-2135

08700 AERO-FUSE-CERAMIC-4A Power supply fuse/Large compressor fuse 1525-2135

Contact Flexco’s Customer Service if other parts are required: www.exco.com.

D

D1

Spare Parts List

Contact Flexco’s Customer Service if technical assistance or repair is needed: www.exco.com

E

E1

Technical Assistance

—19—

F

Schematics

Lower RS485-A

Upper RS485-A

Upper RS485-B

Lower RS485-B

V-

V-

V+

V-

Main Controller

WH

GN

BN

WH

GN

BN

07-1C

07-1C

07-1C

USB USB

RD 0,50mm²

WH 0,50mm²

06-3C

06-3C

3x 0.25mm²

3x 0.25mm²

USB Cable

06-8C

06-7C

06-7C

FLEXCO

20

15

20

15

Schematics Main Controller 625, 925, 1225, 1525, 1835, 2135

Ply 130™ply separator

www.flexco.com

—20—

Schematics Lower Press 625

Schematics

A1+

A2-

L1

T1

A1

A2

A3

A4

A3

A4

GND

1 3

5

1 23 4

5 6

Power controller Heat

05-D5

05-D5

K 1

Thermal fuse

Thermal overload relay

SSR power on/off

Serial / parrallel contact

Heating 1

24 Vdc power

1 2 3

GND

05-1A

05-1A

05-1A

B1

WH 0.50mm²

K 2

A

B

A

B

VT 2.5mm²

BU 2.5mm²

RD 0.75mm²

RD 0.50mm²

RD 0.75mm²

WH 0.75mm²

WH 0.50mm²

OG 0.50mm²

F4 20Amp

F3 20Amp

F2 20Amp

F1 20Amp

F5 4.0Amp

TB 1

BN 2.5mm²

BK 1.5mm²

BK 2.5mm²

OG 2.5mm²

GY 2.5mm²

BK 2.5mm²

BK 2.5mm²

2.5mm²

2.5mm²

2.5mm²

1.5mm²

2.5mm²

S1

05-5D05-5D

YE 1.5mm²

RD 0.75mm²

WH 0.50mm²

BU 2.5mm²

VT 2.5mm²

1

J1

P1

WH 0.75

24 Vdc

-

+

-

+

WH 0.75mm²

P8

P10

TB3

P2

SSR1

TF1

YE

BN

BK

GY

OG

WHBU 2.5mm²

DKBU 2.5mm²

DKBU 2.5mm²

DKBU 2.5mm²

GNYE 2.5 mm²

GNYE 2.5 mm²

Ground pin 1

Pin connections Omron

2 From C (DPDT)

B

A

6

5

3 4

2

1

E-Tray bottom

Ground pin 2

Bottom Headplate

backside

GNYE 2.5 mm²

LWB

supply

Splice plate

2

2

1

2

3

4

5

77

6

8

9

19

11

10

21

31

40

41

42

05-1A

05-1A

05-1A

05-1A

43

44

33

32

+

42

9

34

34

L

N

110 -240 Vac

1a

2a

10

8

18

17

16

17

18

16

15

15

13

14

13

14

45

35

12

45

35

11

10

BK 1.5mm²

OG 2.5mm²

GY 2.5mm²

7

6

24

NDR-120-24

10

2

2

36 46

19

20

21

22

20 20

21

GNYE 1.5 mm²

Q1032

B2

B1

+24Vdc

0 Vdc

+24Vdc

0 Vdc

04/1A

04/1A

04-2E

+24Vdc

WH 0.75mm²

RD 0.75mm² RD 0.75mm²

WH 0.75mm²

0 Vdc WH 0.75mm²

J1

P2

K

A

B

+

-

Thermo couple 1 Type K

Omron relay K2

Power controller heater SSR1

B5

B4

B3

WH

GN

BN

B2

B3

B4

B5

B6

WH

GY

GN

YE

BN

Buzzer

WH 0,5mm²

YE 0,5mm²

cable 6x 0,25mm²

cable 3x 0,25mm²

YE

BN

OG 0,5mm²

WH 0,5mm²

TB 4

P1

J1

VT 0,5mm²

WH 0,5mm²

V-

Input 0

Input 1

Input 2

Input 3

V-

RS485-B

RS485-A

Thermo couple +

Thermo couple -

Heater SSR +

Heater SSR -

S/P relay +

S/P relay -

Output 1

V-

Output 2

V-

V-

NC

V+

Power Controller

RD 0.75mm²

BK 0,25mm²

BK 0,25mm²

RD 0,25mm²

RD 0,25mm²

Fan M1

Fan M2

04-2E

04-2E

04-2E

44

43

33

32

44

33

-

+

45

35

46

36

39

49

23

23

23

23

23

24

24

24

Other manuals for Aero 625

1

This manual suits for next models

4

Table of contents

Other Novitool Power Tools manuals

Popular Power Tools manuals by other brands

Cleco

Cleco 20PTHD Series installation manual

Sieg

Sieg X2.7 instruction manual

Jefferson Professional Tools & Equipment

Jefferson Professional Tools & Equipment JEFPDB0750-12S user manual

MBW

MBW GP12 Operator's safety and service manual

Scheppacha

Scheppacha HP800 Original instruction manual

Parkside

Parkside PHKSA 18-Li B2 Operation manual