Mounting locations of the vehicle identification number and of the nameplate V-1

0045_EN_FA043_V_04_00_00

2003-01 2/11

4 Mounting locations of the vehicle identification number and of

the nameplate:

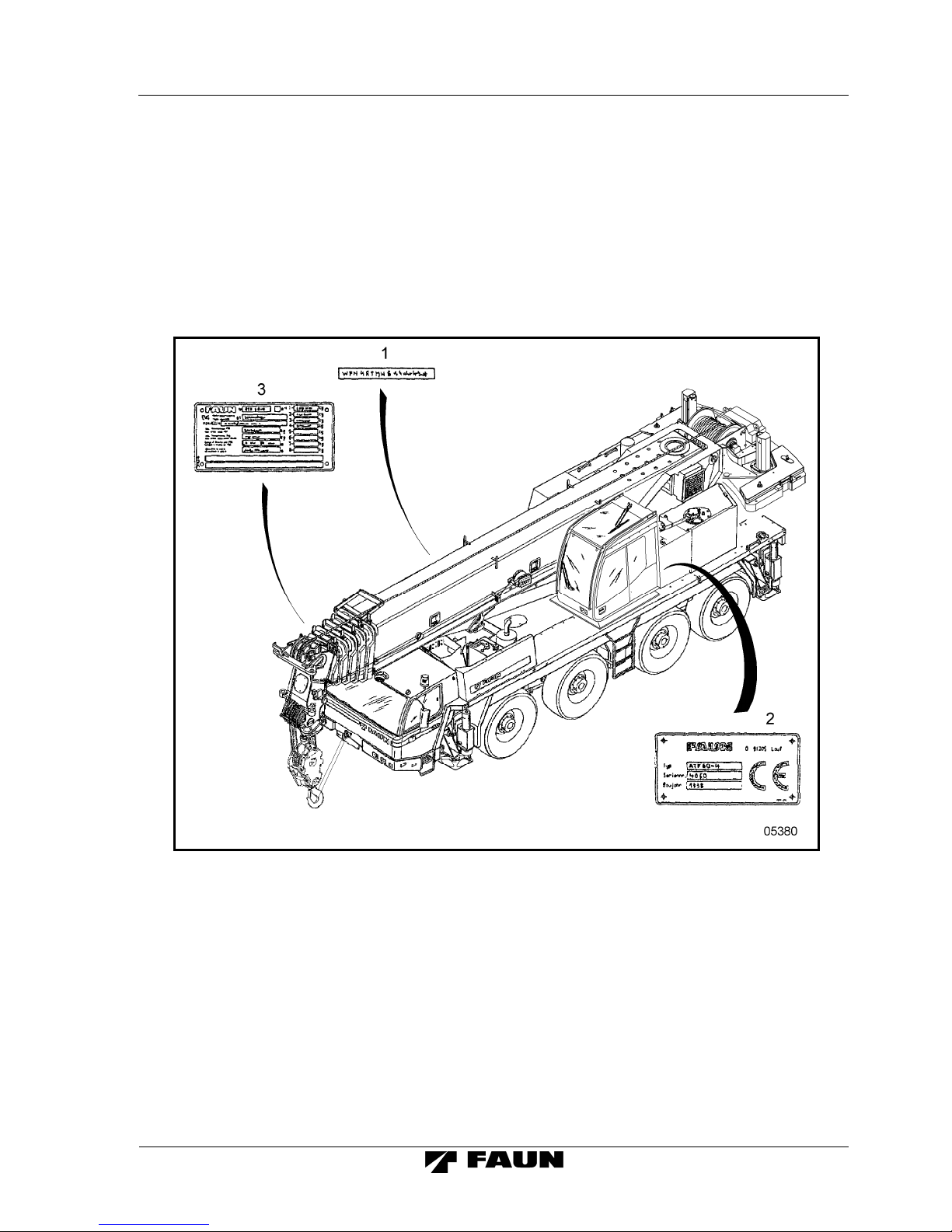

These plates are provided on the vehicle in the following locations:

The vehicle identification number (1) is stamped on the frame, on the right side of the vehicle, between the

1st and 2nd axles.

The nameplates bearing all the relevant vehicle data are located in the driver's cabin in the undercarriage (3)

to the right of the passenger's seat, next to the cab door, and on the rear outside of the superstructure cabin

(2).

1 = Vehicle identification number

2 = Nameplate, superstructure

3 = Nameplate, chassis