SAFETY........................................................................................................................................2

FORWARD ...................................................................................................................................4

COMPACTOR/DRIVER APPLICATIONS.....................................................................................4

MAINTENANCE............................................................................................................................5

STANDARD PRACTICES.................................................................................................5

CARRIER COMPATIBILITY .........................................................................................................6

SPECIFICATIONS........................................................................................................................7

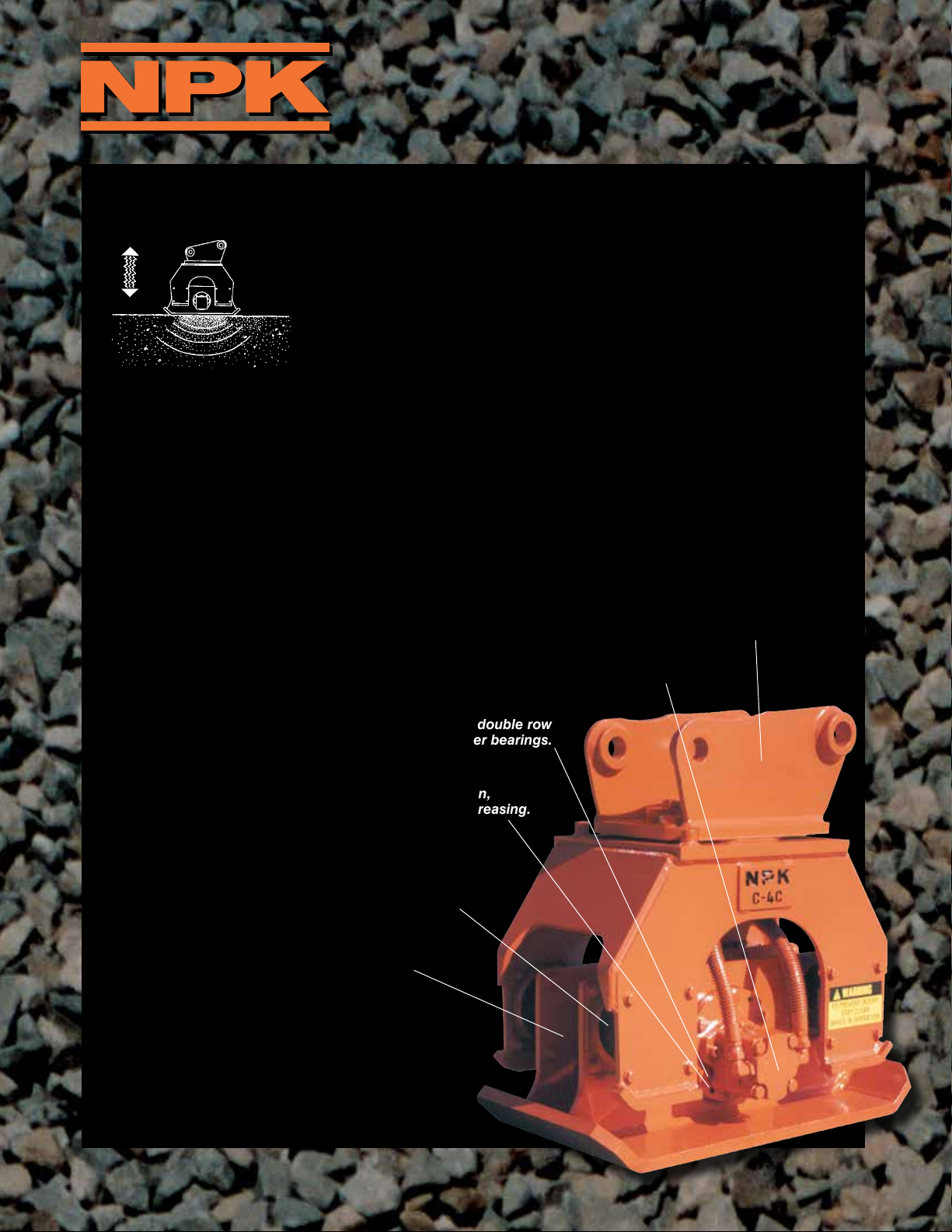

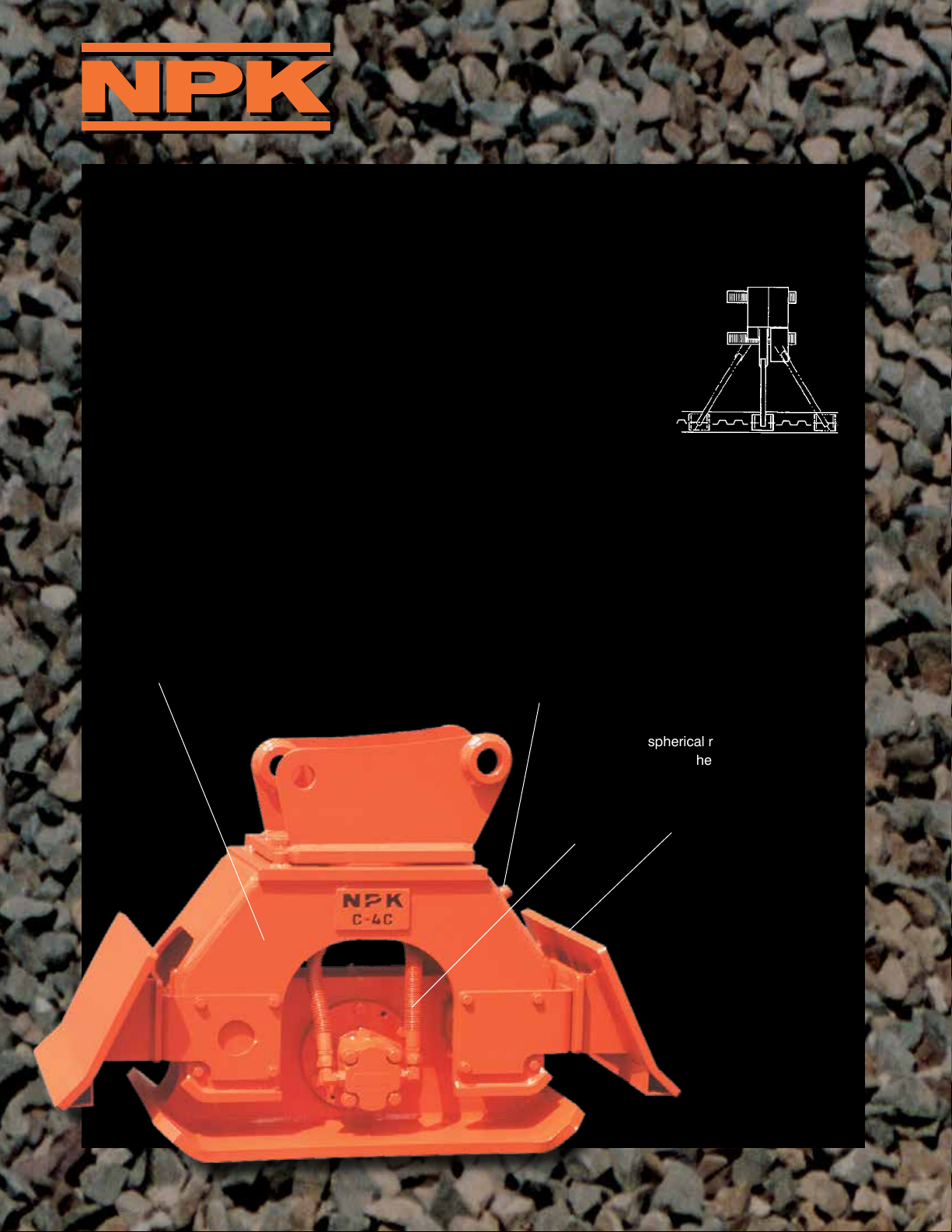

COMPACTOR/DRIVER STRUCTURE.......................................................................................10

C2D THROUGH C12C COMPACTOR/DRIVERS...........................................................10

COMPACTOR/DRIVER SERIAL NUMBER LOCATION ............................................................14

UNDERSTANDING COMPACTION ...........................................................................................15

COMPACTION FORCES............................................................................................................16

SOIL MATERIAL.........................................................................................................................17

SOIL DENSITY TESTING...........................................................................................................19

LABORATORY TESTS ...................................................................................................19

FIELD TESTS..................................................................................................................21

FIELD TEST REPORT....................................................................................................23

CLASSIFICATION OF COMPACTION EQUIPMENT.................................................................24

COMPACTION METHODS AND EQUIPMENT SELECTION ....................................................25

COMPACTOR MODEL SIZE vs PERFORMANCE ....................................................................25

PRODUCTIVITY .........................................................................................................................26

HYDRAULIC INSTALLATION.....................................................................................................27

BACKHOE/EXCAVATOR COMPACTOR LINES............................................................27

SHUT-OFF VALVES .......................................................................................................27

COMPACTOR CONTROL VALVE..................................................................................28

RETURN OIL...................................................................................................................28

PREVENTION OF CONTAMINATION............................................................................29

CHANGING THE FILTER ELEMENT AND HYDRAULIC OIL .........................................29

HYDRAULIC QUICK DISCONNECTS ............................................................................30

BACKFILL ATTACHMENT .........................................................................................................33

BEFORE OPERATION...............................................................................................................34

DECIDE IF SWIVEL LOCK FEATURE WILL BE USED ..................................................34

BEFORE OPERATION...............................................................................................................35

LUBRICATION................................................................................................................35

MAINTENANCE AND INSPECTION..........................................................................................36

DAILY MAINTENANCE...................................................................................................36

LUBRICANT TERMS AND DEFINITIONS..................................................................................37

OPERATION...............................................................................................................................39

SOIL COMPACTION.......................................................................................................40

LEAVE IT RUNNING.......................................................................................................41

COMPACTION AROUND PIPE ......................................................................................41

NARROW TRENCH COMPACTION...............................................................................42

SHEET/PILE DRIVING AND EXTRACTING ...................................................................43

SHEET/PILE AND POST/PIPE ADAPTERS...................................................................43

SWIVEL FEATURE.........................................................................................................44

STORAGE OF THE COMPACTOR/DRIVER .............................................................................45

WARRANTY REGISTRATION FOR NEW UNITS......................................................................46

WARRANTY STATEMENTS ......................................................................................................47

NOTES AND RECORDS............................................................................................................49