- 5 -

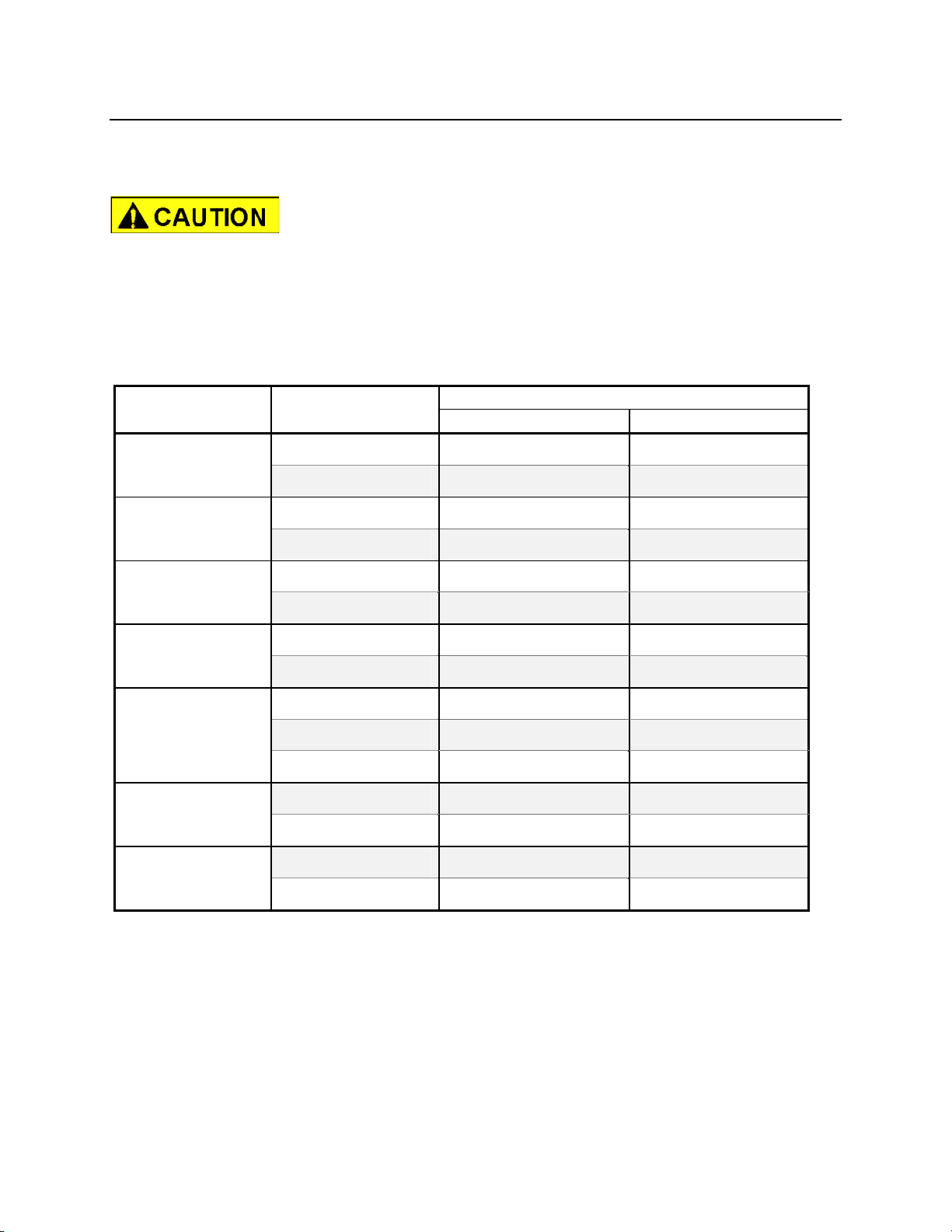

CARRIER MACHINE COMPATIBILITY

These carrier weight ranges are intended as a guideline only. Other factors, such as

stick length, counterweights, undercarriage, etc., must be taken into consideration.

Mounting a HAMMER that is too heavy for the carrier machine

can be dangerous and damage the machine. Verify carrier

stability with hammer before transport or operation.

Mounting a HAMMER that is too small for the carrier machine can damage the

HAMMER, cause tool breakage and void Warranties. Please consult NPK Engineering

for specific detailed information.

CARRIER WEIGHT lbs. (kg)

HAMMER MOUNTING RECOMMENDED RANGE

MODEL STYLE (lb) (kg)

E200 Excavator 2,200 - 4,400 1,000 - 2,000

Skid Steer 2,400 - 3,500 1,100 - 1,600

E201 Excavator 2,800 - 5,500 1,300 - 2,500

Skid Steer 3,000 - 5,500 1,350 - 2,500

E202 Excavator 5,400 - 9,000 2,450 - 4,100

Skid Steer 5,000 - 7,500 2,300 - 3,400

E203 Excavator 6,600 - 12,000 3,000 - 5,500

Skid Steer 6,000 –9,000 2,700 - 4,100

E204 Excavator 8,800 - 15,000 4,000 - 7,000

Skid Steer 8,000 - 14,000 3,600 - 6,400

Backhoe 9,000 - 15,000 4,100 – 7,000

E205 Excavator 13,000 - 22,000 6,000 - 10,000

Backhoe 13,000 - 20,000 6,000 - 9,000

E207 Excavator 22,000 - 31,000 10,000 - 14,000

Backhoe 20,000 - 25,000 9,000 - 11,500

*Specifications subject to change without notice.