1

PAGE

Repair Instructions No.176.11/96

PB 6S

Special Tools

Required

■

Adjustment tool for carbon brushes 9170 3022 60

■

Pulling-off device 9170 0314 440

Important!

■

Before beginning the maintenance work, perform an initial check with a high voltage test according

to VDE (see chapter Electrical and Mechanical Test Instructions).

■

Before all repair work, pull the power plug from the socket!

Disassembly

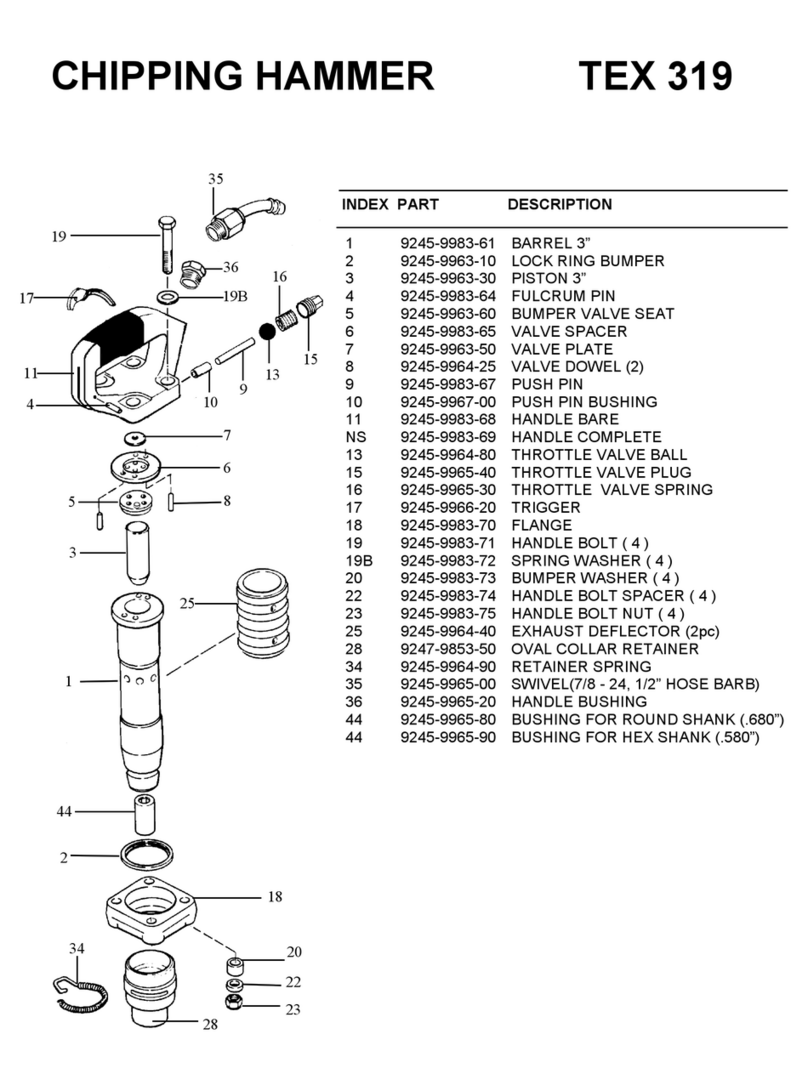

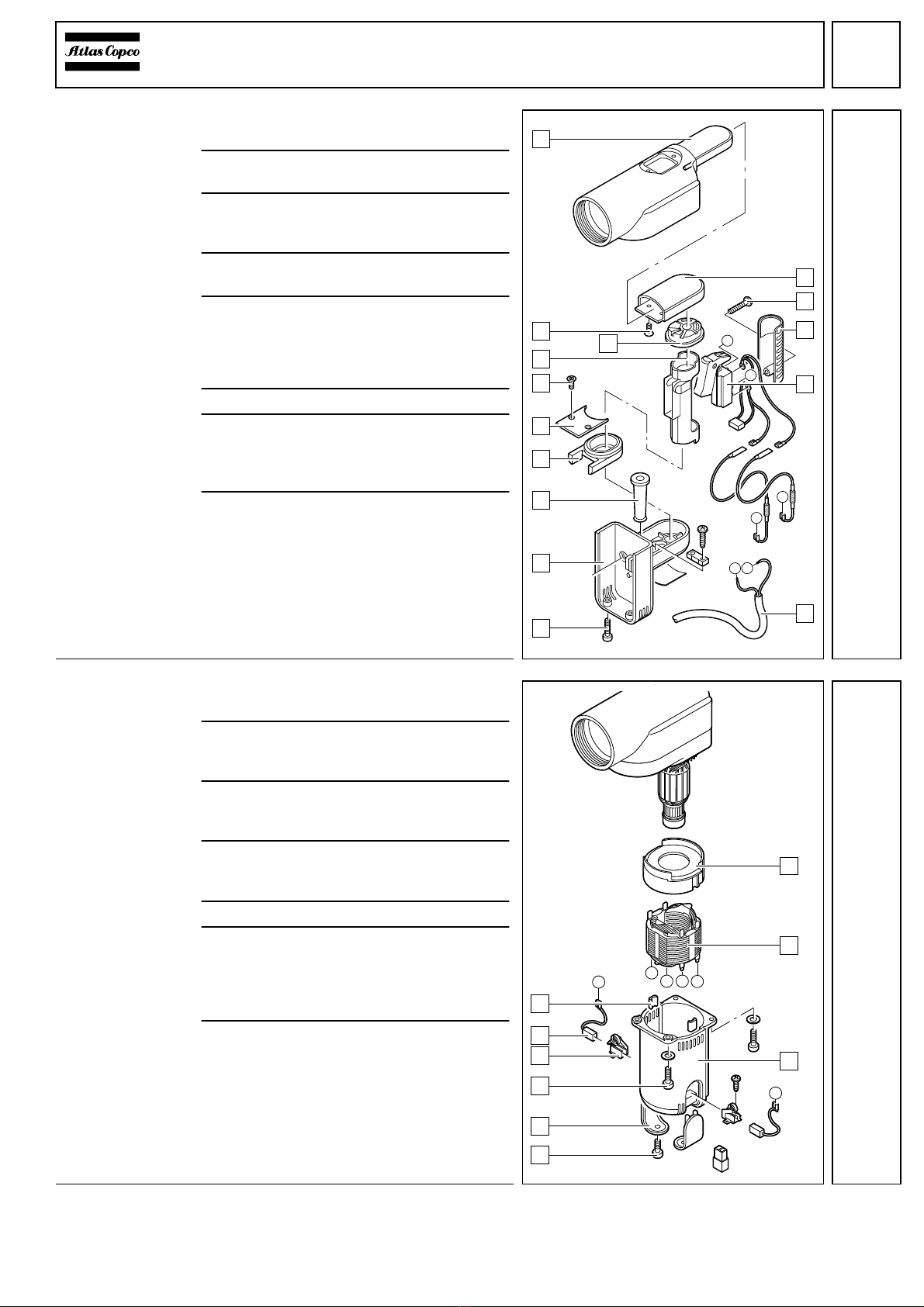

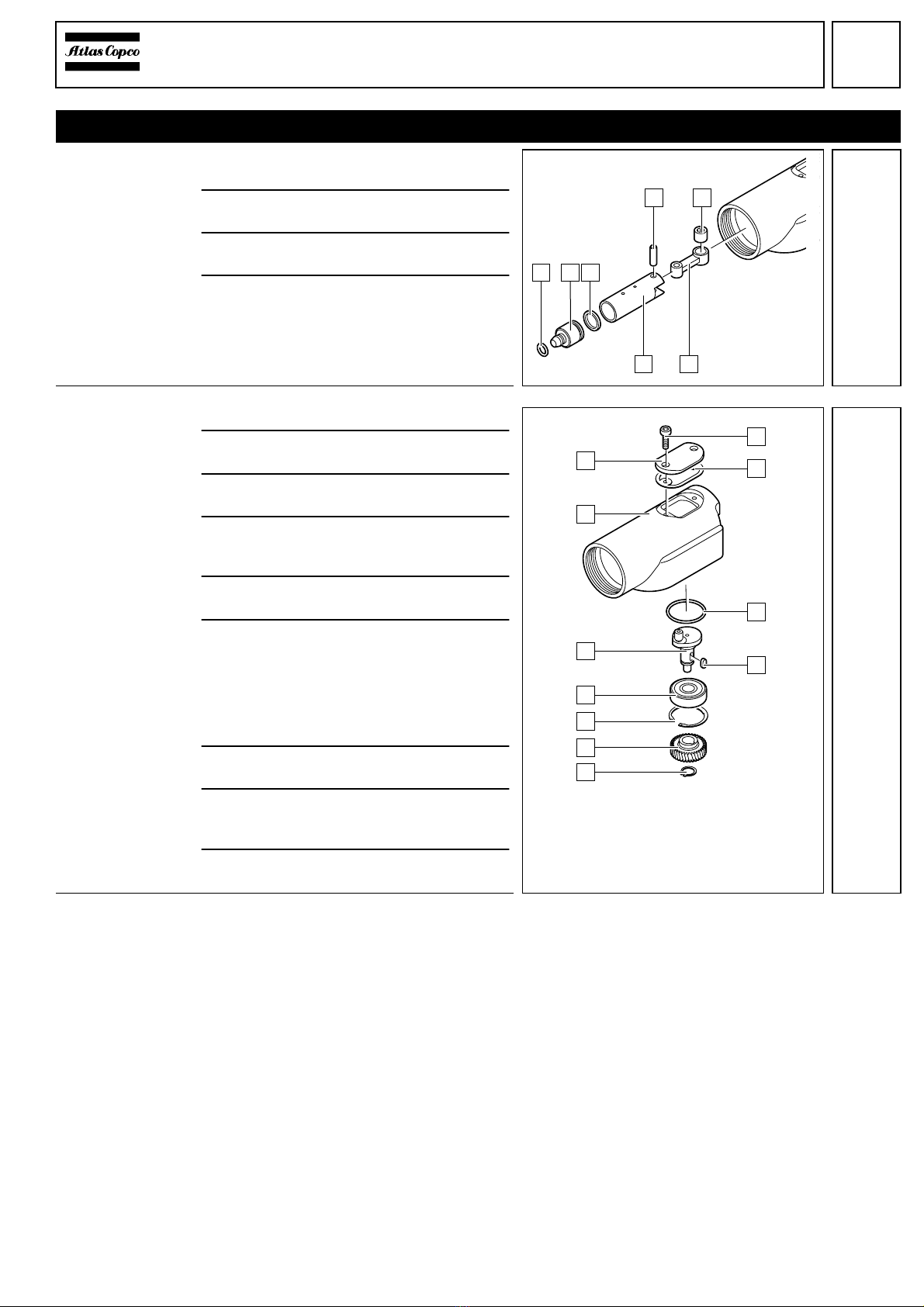

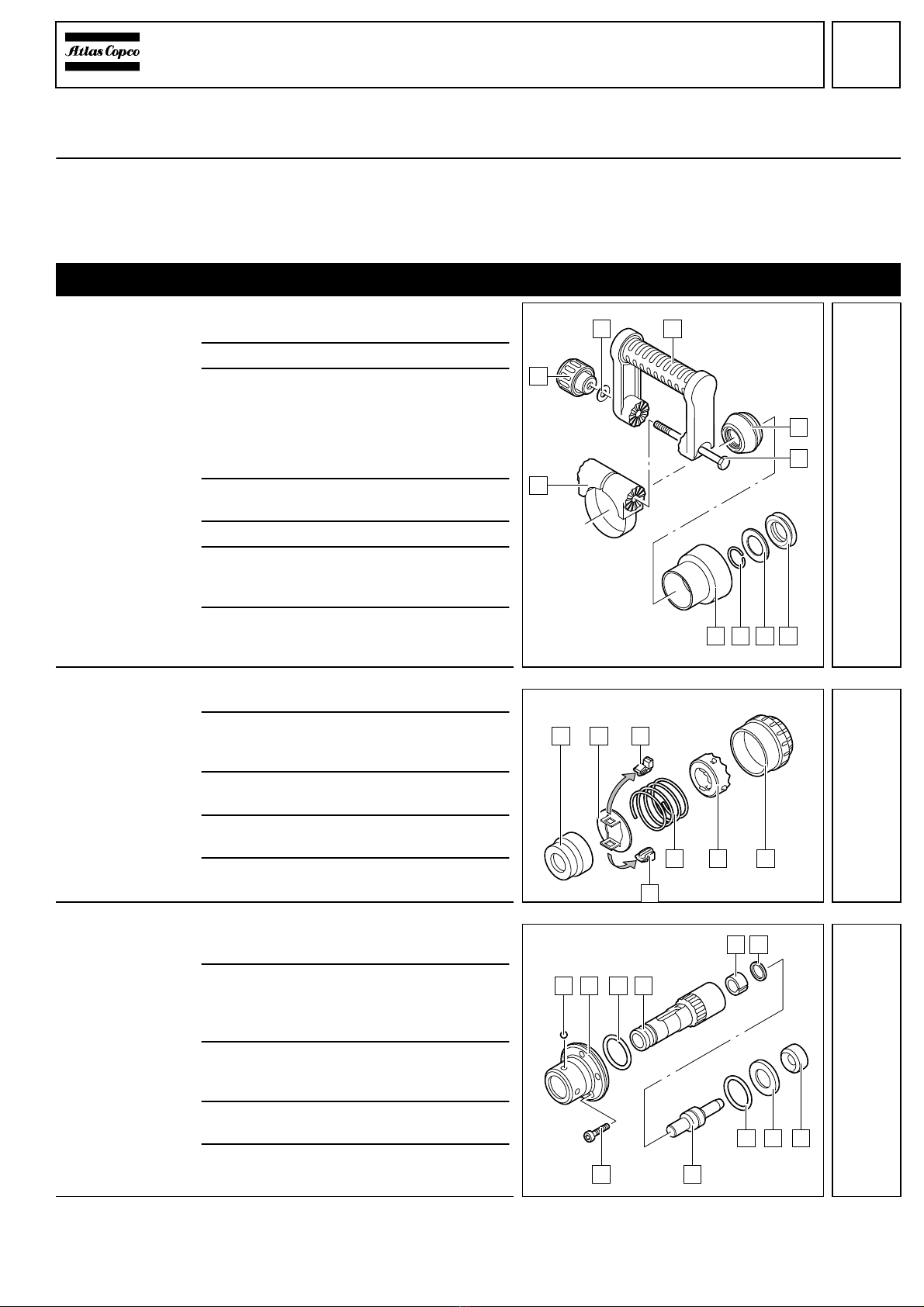

Removing the

auxiliary handle

1

Unscrewthenut(2)andremovethewash-

er (3).

2

Pull out the screw (6).

3

☞

Press the clamping ring (1) and re-

move the auxiliary handle (4). Release

the tension and remove the clamping

ring (1).

4

Push back the rubber sleeve (A) and lever

off the rubber bushing (5).

5

Remove the rubber sleeve (A).

6

Remove the locking ring (9) with aid of cut

special pliers. If necessary, use a screw-

driver for support.

7

Remove the damping element (8) and the

damper (7).

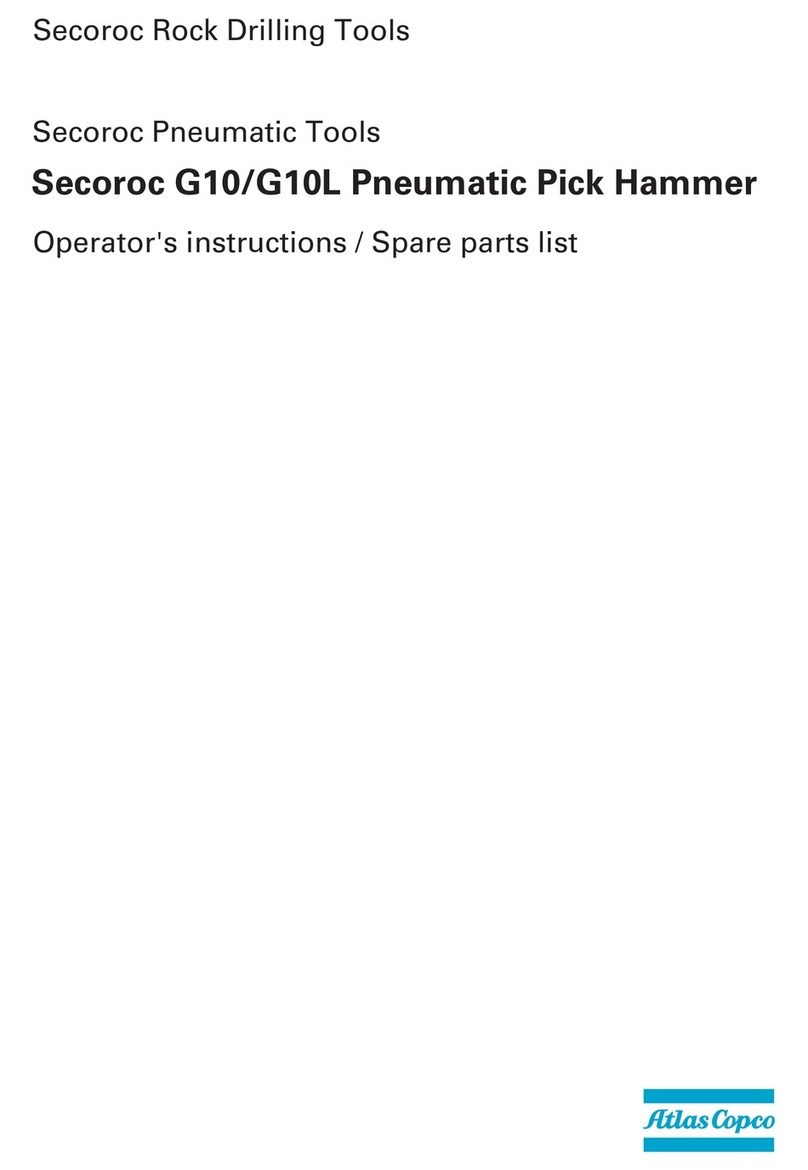

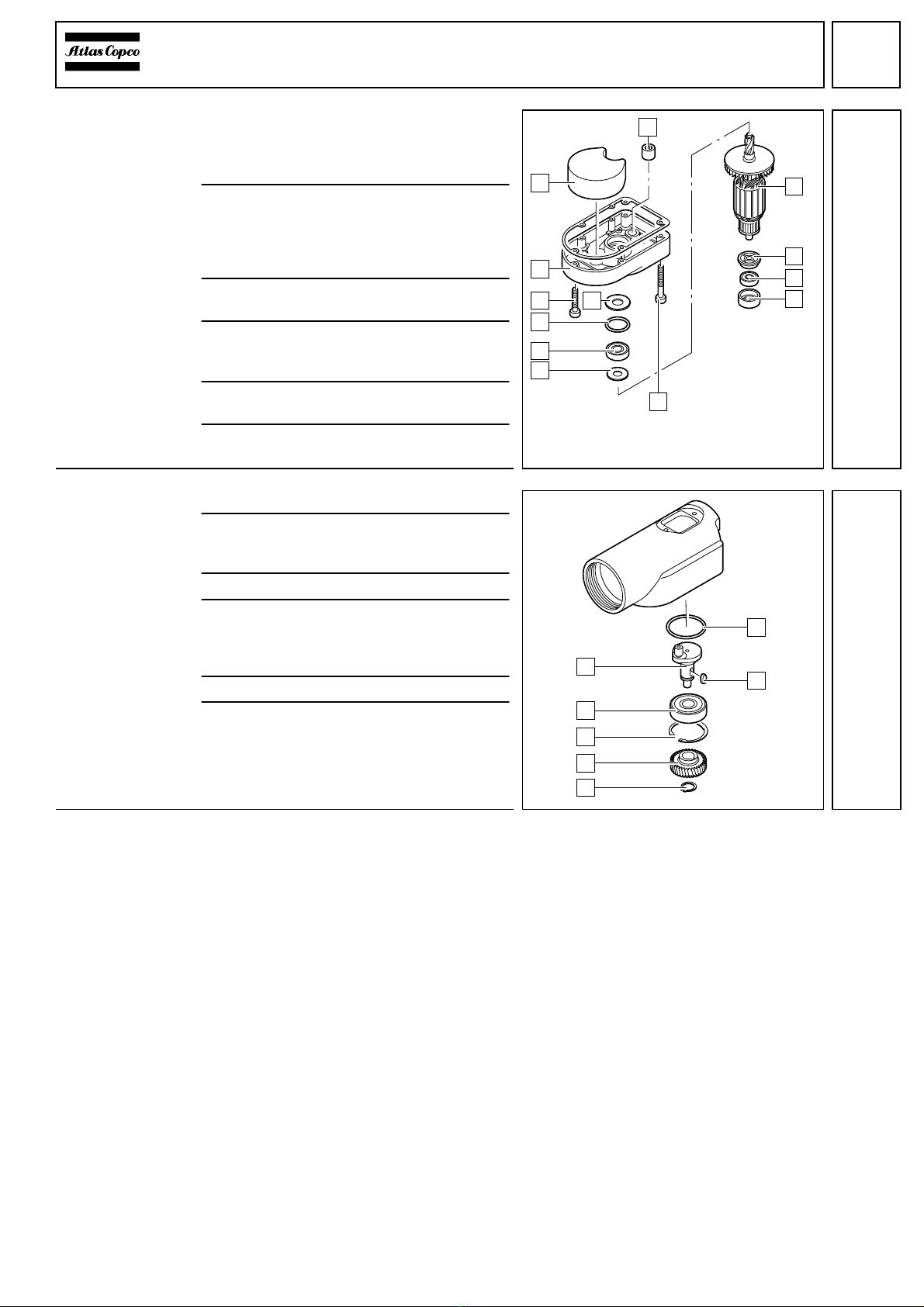

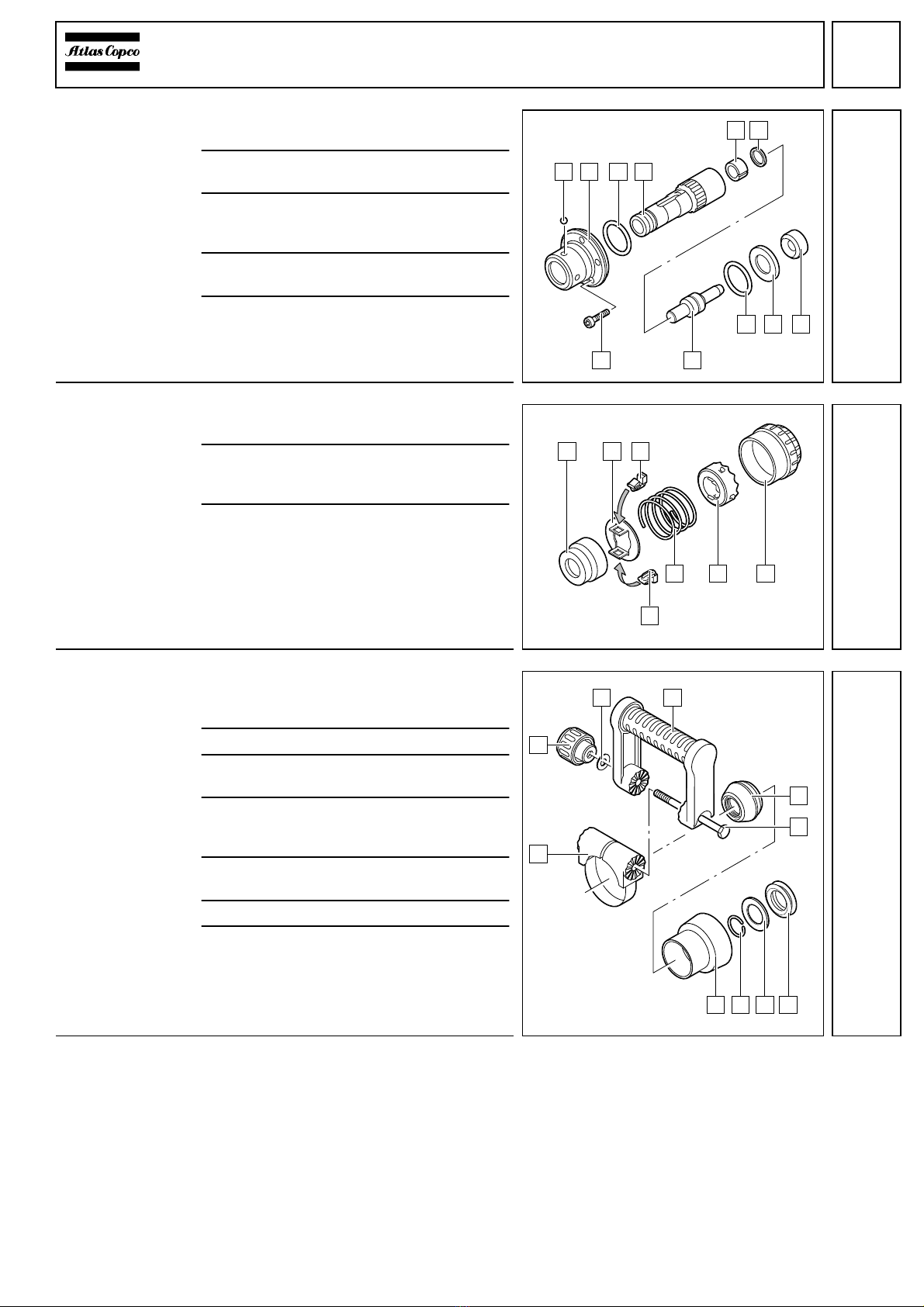

Disassembling

the ball holding

device

1

Remove the locking sleeve (1).

2

Depress the retaining plate (2) against re-

silience - the locking levers (3) are re-

leased. Remove the locking levers (3).

3

Release the retaining plate (2) and re-

move the pressure spring (6).

4

Remove the locking bolt (4) together with

the ball holding device (5).

5

Remove the ball holding device (5) from

the locking bolt (4).

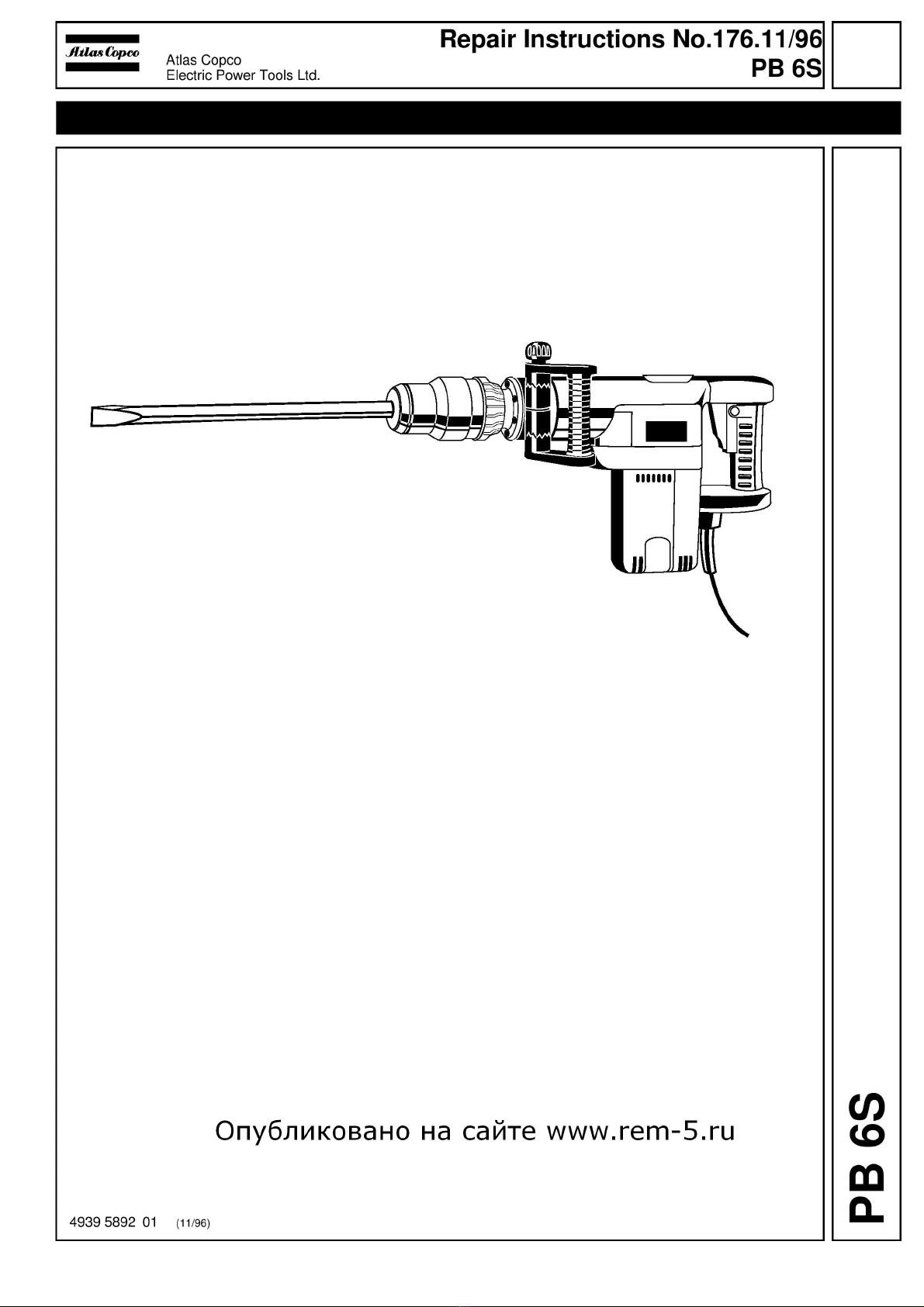

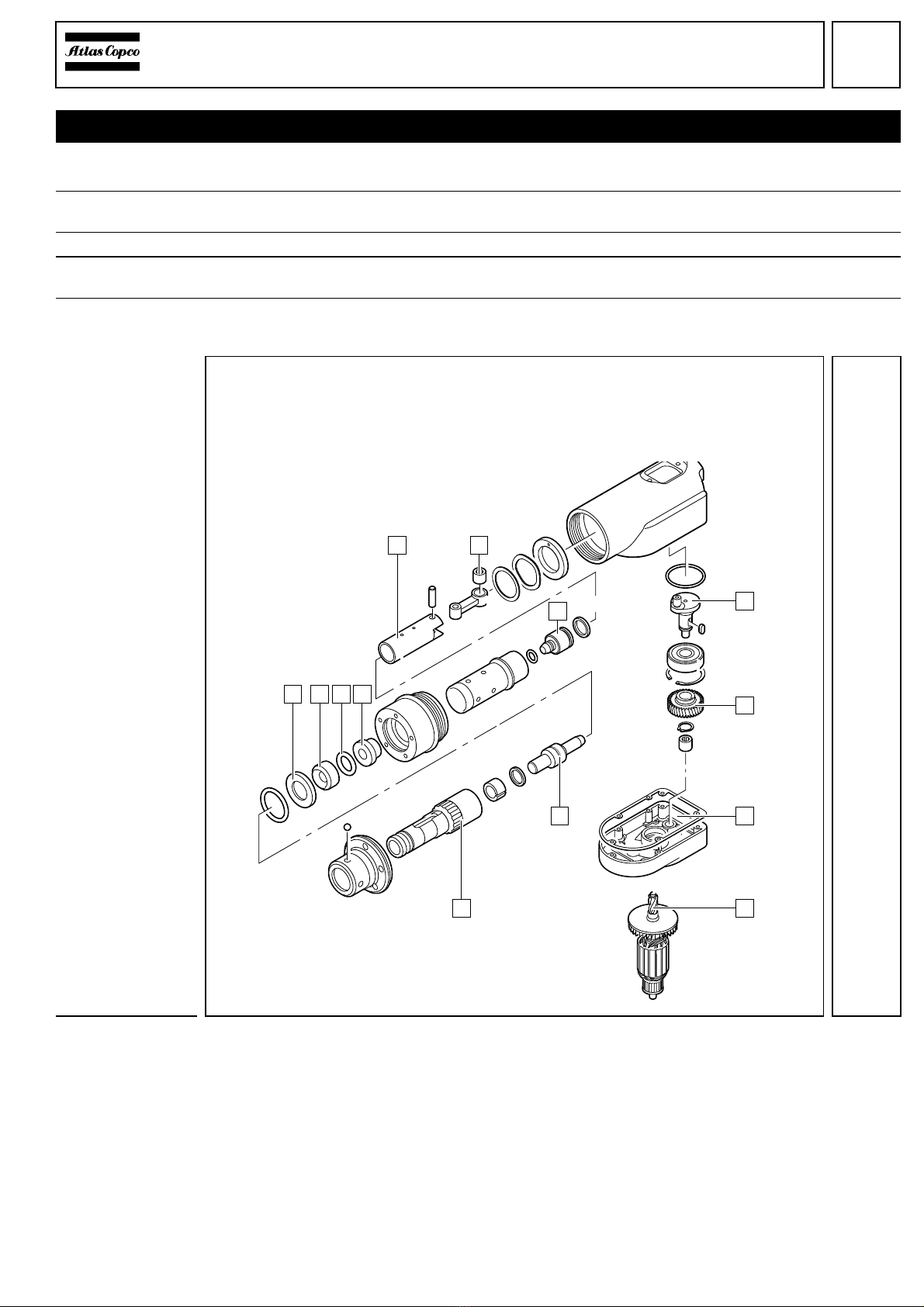

Disassembling

the tool

acceptance

1

Remove all four balls (1) with aid of a mag-

net.

2

Loosen the five screws (B) of the adapter

sleeve (2) and remove the adapter

sleeve (2) as well as the O-ring (3). If nec-

essary, hit it lightly with a plastic hammer.

3

Remove the tool acceptance (4) com-

pletely with the snap die (A), the

spacer (5) and the gasket (6).

4

Remove the snap die (A) from the tool ac-

ceptance (4).

5

Remove the O-ring (9), the spacer (8), as

well as the recoil ring (7).

1

2

8 7

6

4

5

A 9

3

1 2 3

456

1 2 4

5 6

789

AB

3

3