6. Operation

- Do not change the controller's function switch settings during the

operation; otherwise, it will cause injury.

- Do not approach the machine after instantaneous power failure

has been recovered.

Doing so may result in injury if the machine starts abruptly, it will

cause injury.

- Be sure to check that the power supply specifications are correct;

otherwise, it may caused controller failture.

- Be sure to provide an external emergency stop circuit so that

operation can be stopped with power supply terminated immediately.

- Be sure to conduct independent trial runs for the controller before

mounting the controller to the machine;

otherwise, it may cause injury.

- When an error occur, be sure to eliminate the cause, ensure

safety, and reset the error before restarting operation;

otherwise, it may cause injury.

7. Maintenance And Inspection

- Do not disassemble, remodel, or repair the unit;

otherwise, it will cause electric shock, fire, and unit malfunction.

- The capacitor of the power line deteriorates through prolonged use.

We recommended that the capacitor be replaced every five years

to prevent secondary damage.

8. Disposal

- Be sure to handle the controller as industrial waste while

disposing of it.

1. Handling Precautions

- Do not touch components inside of the controller;

otherwise, it will cause electric shock.

- Do not damage the cable by applying excessive load, placing

heavy objects on it, or clamping;

otherwise, it will cause electric shock or fire.

DANGER

- Turn the power supply OFF before wiring, transporting, and inspecting

the controller; otherwise, it may cause electric shock.

- Provide an external safety circuit so that the entire system

functions safely even when the controller is faulty.

- Connect the grounding terminal of the controller;

otherwise, it may case electric shock or malfunction.

- Do not use the controller in the following palces; water splashes,

the atmosphere of the corrosion, the atmosphere of the flammable

vapor, and the side of the combustibility.

Doing so may result in fire or the controller may become faulty.

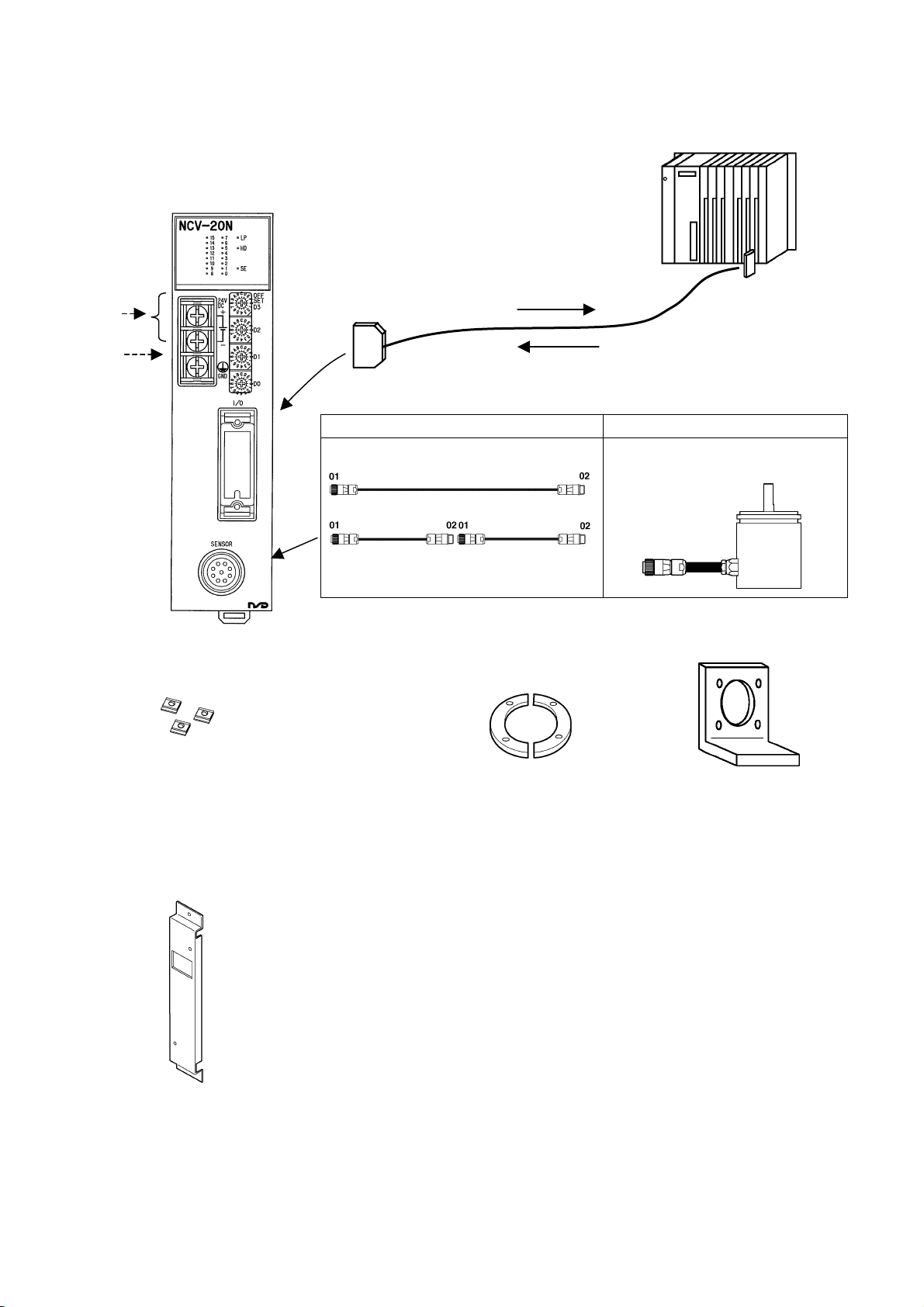

- Be sure to use the controller and the ABSOCODER sensor in the

environment designated by the general specifications in the manual.

Failure to do so may result in electric shock, fire, malfunction or unit

failure.

- Be sure to use the specified combination of the ABSOCODER

sensor, controller and sensor cable; otherwise, it may cause fire or

controller malfunction.

CAUTION

2. Storage

CAUTION

- Do not store the controller in a place exposed to water, or toxic

gas and liquid.

- Be sure to store the controller in designed temperature and humidity

range, and do not exposed to direct sunlight.

- Be sure to consult with NSD when the controller is stored for long

periods.

- Do not hold the cable or shaft of ABSOCODER sensor during

transport; otherwise, it will cause injury or controller malfunction.

CAUTION

3. Transport

Thank you very much for purchasing our product.

Before operating this product, be sure to carefully read this manual so that

you may fully understand the product, safety instructions and precautions.

- Please submit this manual to the operators actually involved in operation.

- Please keep this manual in a handy place.

Signal Words

Safety precautions in this guide are classified into DANGER and CAUTION.

Symbol Meaning

DANGER

Incorrect handling may cause a hazardous situation that

will result in moderate injury or physical damage.

Incorrect handling may cause a hazardous situation that

will result in death or serious injury.

Instructions accompanied by a symbol may also result in serious

damage or injury. Be sure to follow the all instructions accompanied by the symbol.

Graphic Symbols

Symbol Meaning

Indicates prohibited items.

Indicates items that must be performed to.

This product is not designed to be used under any situation affecting human

life. When you are considering to use this product for special purposes such as

medical equipment, aerospace equipment, nuclear power control systems,

traffic systems, and etc., please consult with NSD.

CAUTION

CAUTION

Application Limitation

4. Installation

- Do not step on the controller or place heavy objects on the controller;

otherwise, it will cause injury.

- Do not block the exhaust port or allow any foreign matter to enter

the controller; otherwise, it will cause fire or unit failure.

- Be sure to secure the controller and ABSOCODER sensor with the

provided brackets; otherwise, it may cause malfunction, injury, or

drop.

- Be sure to secure the specified distance between the main body

and the control panel or other equipments; otherwise, it may cause

malfunction.

5. Wiring

- Be sure to secure the terminal block firmly; otherwise, it may have

risk of fire.

- Be sure to mount the terminal cover provided with the controller,

before supplying the power, starting operation after the installation,

and wiring; otherwise, it may cause electric shock.

- Be sure to keep the sensor cable, control cable, and communication

cable at least 300 mm away from the main circuit and power line;

otherwise it may cause injury or malfunction.

- Be sure to connect all cables correctly; otherwise, it may cause injury

or controller malfunction.

- Be sure to firmly connect the external I/O connectors and sensor

connectors; otherwise, it may cause incorrect inputs and outputs or

injury.

CAUTION

CAUTION

(Please read this safety guide carefully before operation)

GENERAL SAFETY RULES

DANGER

CAUTION

CAUTION

CAUTION